1" (25.0 mm) Travel Vertical Translation Stage

MVS1

1" Travel Vertical Stage

Application Ideas

- 1" (25.0 mm) Vertical Travel with Micrometer

- Crossed-Roller Bearings for High Load Capacity and Straightness

- Interchangeable Top Platform with 8-32 (M4) and 1/4"-20 (M6) Taps

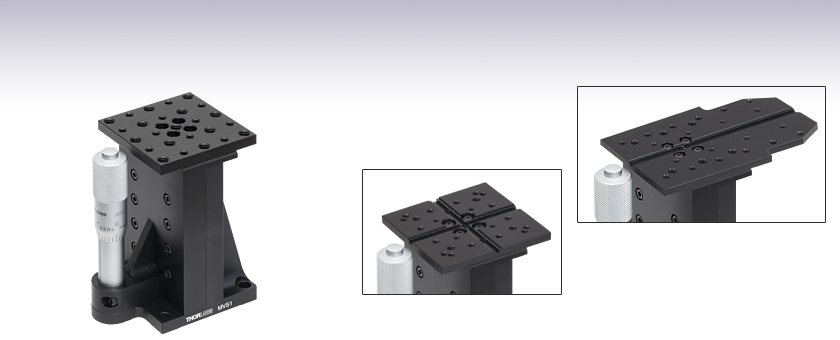

MVS1 Stage with

MMP1 Grooved Top Plate

MVS1 Stage with

AMA003 Extended Grooved Top Plate

Please Wait

| Item # | MVS1 | MVS1/Ma |

|---|---|---|

| Travel Range | 1" | 25.0 mm |

| Working Height Range | 3.92" to 4.92" | 99.5 mm to 124.5 mm |

| Micrometer Graduations, per Division | 0.001" | 10 µm |

| Adjustment per Micrometer Revolution | 0.025" | 0.5 mm |

| Load Capacity (Within Plate Area) | 2 kg (4.4 lbs) | |

| Load Capacity when Stage is Inverted (Within Plate Area) |

0.75 kg (1.65 lbs) | |

| Backlash | <1 µm | |

| Linearityb | 100% | |

| Straightness | ±5.0 µm | |

| Parallelism of Top and Bottom Plates | 140 µm Over Area of Plates | |

| Spring Preload at 0 mm Travel | 13 N | |

| Spring Preload at 13 mm Travel | 27 N | |

| Weight | 0.65 kg (1.43 lbs) | |

| Construction | Black-Anodized Aluminum | |

| Vertical Manual Stages Selection Guide |

|---|

| 1/2" (13 mm) Travel |

| 1" (25 mm) Travel |

| 4" (101.6 mm) or 10" (254 mm) Travel |

Features

- 1" (25.0 mm) of Vertical Travel

- Micrometer Adjuster for Fine Positioning

- Array of 1/4"-20 (M6) and 8-32 (M4) Mounting Holes

- Grooved and Extended Top Plates for Our Keyway Accessories for Nanopositioning Stages are Available

- Black-Anodized Aluminum Construction

The MVS1(/M) Vertical Translation Stage provides 1" (25.0 mm) of height adjustment and a working height range of 3.92" to 4.92" (99.5 mm to 124.5 mm). The top mounting plate has an array of thirteen 1/4"-20 (M6 x 1.0) and twelve 8-32 (M4 x 0.7) tapped holes. The stage is constructed from black-anodized aluminum and includes crossed roller bearings for uniform performance over the entire range of motion.

If required, the user can replace the top plate with our MMP1(/M) grooved top plate, allowing the stage to be used with our range of keyway accessories for nanopositioning stages. Three extended top platforms with a similar grooved keyway are also available for use in applications that require extra reach beyond the edge of the vertical stage.

The stage is shipped complete with a fine-adjustment micrometer drive with a 0.001" (10 µm) graduated scale. It delivers 0.025" (0.5 mm) of height adjustment per revolution, making the stage ideal for aligning a wide range of optical components. For motorized vertical translation, the included micrometer can be replaced with one of our 1" (25 mm) ZST, ZFS, or Z9 actuators.

| Posted Comments: | |

Andrey Kuznetsov

(posted 2024-03-26 15:22:21.087) Your MVS1 STEP model is made of sheets instead of solid bodies, please reupload a proper model! cstroud

(posted 2024-04-04 10:36:29.0) Thanks for reaching out. Sorry there was an error in this Solidworks file. Our engineers are looking into this model and will update it shortly. I will reach out to you directly to discuss this further. Adrian Bahani

(posted 2021-11-01 14:13:07.697) Your CAD model is blank cwright

(posted 2021-11-02 07:08:16.0) Response from Charles at Thorlabs: Thank you for your feedback. We are looking into having a suitable file uploaded as soon as we can. I will reach out to you with a file you can use in the mean time. Craig Bidwell

(posted 2021-10-07 14:55:04.48) The Solidworks file appears to be empty. cwright

(posted 2021-10-08 07:26:48.0) Response from Charles at Thorlabs: Thank you for you feedback. We will look into getting this fixed as soon as possible. In the mean time the Step file appears to be in good order and can be loaded into solidworks. Alex genson

(posted 2021-06-15 17:29:10.167) is where new version ? jcater

(posted 2021-06-16 09:40:06.0) Response from Jack at Thorlabs: Thank you for your feedback. The MVS005(/M) and MVS010(/M) are being superseded and replaced by the MVS05(/M) and MVS1(/M) respectively and will be released and on the website soon. Lutz Huwel

(posted 2020-08-13 21:52:27.737) Can you please let me know if the MVS010 vertical translation stage is compatible with your motorized actuator? If so: (1) which one do you recommend if I want to achieve vertical positioning precision of about 10 to 20 micrometer? (2) Is the MVS010 load capacity of 2 kg changed when using it with a motorized actuator?

Regards,

Lutz Huwel DJayasuriya

(posted 2020-08-28 05:42:45.0) Thank you for your inquiry. The micrometer drive is held in the stage by two M3 x 8 socket screws which can easily be unscrewed to fit a new drive. The majority of our drives which hold a 3/8" barrel, however the ZSF25B would be the most suitable with the MVS010 design. The ZFS should be able to handle the load capacity of the MVS010. Due to the actuator not being designed for this stage the precision positioning spec would change, theoretically it should fir within your range. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

- 1" (25.0 mm) of Vertical Travel

- Array of 1/4"-20 (M6) and 8-32 (M4) Tapped Mounting Holes

The MVS1(/M) Vertical Translation Stage provides 1" (25.0 mm) of height adjustment, an array of 1/4"-20 (M6 x 1.0) and 8-32 (M4 x 0.7) tapped holes, and a load capacity of 2 kg (4.4 lbs). The top plate is attached using four M3 x 0.5-threaded screws with 2.5 mm (3/32") hex heads. It can be replaced with one of the top plates and platforms offered below.

- Array of 1/4"-20 (M6) and 8-32 (M4) Tapped Mounting Holes

- Replacement Top Plate for the MVS1(/M) Vertical Stage

- Allows One to Switch Between an Imperial and Metric Mounting Surface on Our Stages

The RB13P1(/M) Mounting Plate is the same as the top plate that is included with the MVS1(/M) vertical stage. It has an array of thirteen 1/4"-20 (M6) and twelve 8-32 (M4) tapped holes. For more details, please see the mechanical drawings of the imperial and metric top plates included in the table above and to the right.

The MMP1(/M) grooved top plate allows the MVS1(/M) stage to be used with our range of keyway accessories for nanopositioning stages (such as the HCS030 Optic Mount shown to the right). The top plate is easily changed by removing four attachment screws with a 2.5 mm (3/32") hex key or balldriver.

Our range of keyway accessories includes mounts to hold and manipulate optical fibers, laser diodes, gradient-index lenses, spherical lenses, and other commonly used optical components. Accessories are mounted to the top platform using a tongue-in-groove system and are retained with cleats and cap screws. When the height of the MVS1(/M) stage is set to 112.5 mm (4.43"), it is compatible with our 6-axis NanoMax stages. The plate includes sixteen 6-32 (M3) tapped holes for cleats and other hardware, as well as four 4-40 (M2) taps and nine 8-32 (M4) taps. For more details, please see the mechanical drawings of the imperial and metric top plates included in the table above.

- Extend the Mounting Surface of the MVS1(/M) Stage

- Array of 8-32 (M4), 6-32 (M3), and 4-40 (M2) Tapped Holes

- Three Mounting Surface Length Options:

- 88 mm (3.46")

- 95 mm (3.74")

- 105 mm (4.13")

- Groove for Keyway Accessories for Nanopositioning Stages

These extended platforms are designed to be replacements for the top plate of the MVS1(/M) vertical stage. The extended mounting surface contains of array of 8-32 (M4), 6-32 (M3), and 4-40 (M2) tapped holes, which are convenient for attaching components or accessories that need to reach into smaller spaces. Three sizes are available, offering platform lengths of 88.0 mm (3.46"), 95.0 mm (3.74"), or 105 mm (4.13"). Two AMA010 (AMA010/M) accessory mounting cleats are included with the purchase of each platform. These platforms can also be used with our Multi-Axis Flexure Stages.

Products Home

Products Home

Zoom

Zoom

Crossed Roller Bearing Vertical Stage

Crossed Roller Bearing Vertical Stage