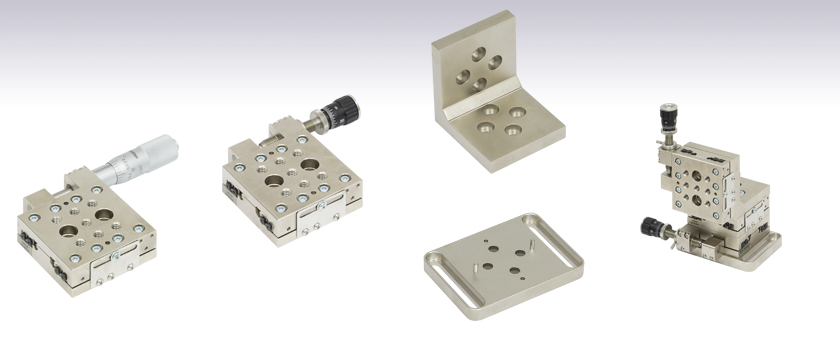

Linear Translation Stages: 1" (25 mm) Travel, Manual, Crossed-Roller Bearings

- Micrometer or Differential Drive Options

- Crossed-Roller Bearings for High Load Capacity

- Solid, All-Steel Construction

LNR25M

Micrometer Drive Stage

LNR25D

Differential Drive Stage

LNR25P2

Angle Bracket

LNR25P1

Base Plate

Three LNR25D Stages Mounted

in an XYZ Configuration

Please Wait

| TravelMax™ Specificationsa | ||

|---|---|---|

| Travel | 25 mm (1") | |

| Minimum Step Size | 1, 10, or 25 µmb | |

| Barrel Diameter | Ø3/8" (Ø9.5 mm) | |

| Horizontal Load Capacity | 20 kg (44 lbs) | |

| Vertical Load Capacity | 8 kg (17.6 lbs) | |

| Runout Over Full Range | ±1.5 µm (±0.000059") | |

| Bearings | Crossed Roller | |

| Body Construction | All Steel | |

| Weight (Including Drives) | LNR25D: 0.57 kg (1.26 lbs) LNR25M: 0.61 kg (1.34 lbs) |

|

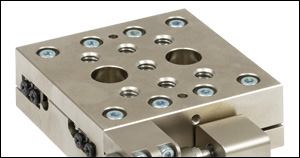

Click to Enlarge

Rear View of Three LNR25D Stages Mounted in an XYZ Configuration

Click to Enlarge

Top Plate of LNR25 Series Stages Features Tapped 1/4"-20 (M6) Mounting Holes

Features

- 1" (25 mm) Travel

- Available with Differential or Micrometer Drive

- Rugged, Thermally Matched, All-Steel Construction

- Right- or Left-Handed, XYZ Configurable

- Extremely Durable and Long Lasting

The LNR25 series of stages offer excellent stability and high load capacity, making them ideal solutions for all translation applications. Their rigid, all-steel construction and heavy-duty crossed-roller bearings provide uniform performance over the entire range of motion. The LNR25M is fitted with the imperial 150-811ST micrometer, which provides 1" of travel, 0.025" of translation per revolution, and 0.001" graduations. Its metric counterpart, the LNR25M/M, is fitted with the 150-801ST micrometer, which provides 25 mm of travel, 0.5 mm of translation per revolution, and 0.01 mm graduations.

For applications that require increased resolution, consider the LNR25D, fitted with the DM12 differential actuator. The coarse adjustment uses a 0.5 mm pitch thread that provides 0.013" (318 µm) of translation per revolution with a range of 1'' (25 mm). The coarse adjustment can be locked using a thumbscrew located on the mounting collar. The differential adjustment, which features a scale with 0.5 μm graduations, provides 0.001" (25 μm) of translation per revolution over a 0.01'' (250 μm) range.

Designed with the highest quality linear rails available, the performance is further enhanced by using thermally matched materials that ensure stable, smooth performance. A locking screw located on the opposite side from the actuator optionally holds the moving stage in place. In addition to the manual actuator options here, a stepper motor translation stage (LNR25ZFS) is also available. The LNR25 series of stages is also compatible with our slim ZST225B Stepper Motor Actuator. We also offer barrel adapters for select screw adjusters, making them compatible with the stages below.

Click to Enlarge

LNR25P1 Base Plate

Click to Enlarge

LNR25P2 Angle Bracket

| TravelMax Crossed-Roller Bearing Stages Selection Guide |

|---|

| 1" (25 mm) Travel |

| 2" (50.8 mm) Travel |

Wide Range of Mounting Options

The TravelMax™ was designed with flexibility and functionality in mind. The top surface of the LNR25 stage, shown to the right, is equipped with an array of seven 1/4"-20 (M6) tapped holes to maximize the mounting options for moving components. Two through holes in the top platform give access to two 1/4-20" (M6) counterbored holes that allow the stage to be bolted directly to the work surface. The position of the actuator mounting blocks is easily reconfigured to allow left-hand or right-hand use.

The LNR25P1 base plate, shown to the left, provides additional mounting options and provides extra clearance between the stage and the work surface. Counterbored clearance holes match up to the tapped holes in the base of the stage, permitting mounting in two orthogonal orientations. This plate is compatible with both the imperial and metric versions of the LNR25ZFS(/M) stage. The plate measures 65.3 mm x 90.5 mm x 10 mm (2.57" x 3.56" x 0.39") [L x W x H], ships with two dowel pins, and includes four alignment holes to ensure mounting orthogonality.

Multiple LNR25ZFS series stages can be bolted together in XY, XZ, YZ, or XYZ configurations for applications where movement is required in more than one axis. The LNR25P2 angle bracket, shown to the left, provides the vertical mounting necessary for movement in the Z direction. Again, this bracket is compatible with both the imperial and metric versions of the LNR25ZFS(/M) stage. The plate is shipped with four dowel pins and includes four alignment holes on each face to ensure orthogonality when mounting stages.

| TravelMax™ Specifications | ||

|---|---|---|

| Travel | 25 mm (1.0") | |

| Horizontal Load Capacity | 20 kg (44 lbs) | |

| Vertical Load Capacity | 8 kg (17.6 lbs) | |

| Runout Over Full Range | ±1.5 µm (±0.000059") | |

| Bearings | Crossed Roller | |

| Body Construction | All Steel | |

| Weight (Including Drives) | LNR25D: 0.57 kg (1.26 lbs) LNR25M: 0.61 kg (1.34 lbs) |

|

| DM12 Differential Drive Specifications [Included with LNR25D(/M)] |

|

|---|---|

| Coarse Travel | 25 mm (1.0") |

| Coarse Distance per Rev | 0.5 mm |

| Fine Travel | 250 µm |

| Fine Distance per Rev | 25 µm |

| Fine Graduation | 0.5 µm |

| Weight | 46.1 g (1.6 oz) |

| Micrometer Specifications | ||

|---|---|---|

| Item # | 150-811ST (Included with LNR25M) |

150-801ST (Included with LNR25M/M) |

| Travel | 0 - 1.000" | 0 - 25.00 mm |

| Graduation | 0.001" per Division | 10 µm per Division |

| Distance per Rev | 0.025" | 0.5 mm |

| Scale Surface | Hard-Chrome Plating | |

| Weight | 89.5 g (3.15 oz) | |

| Posted Comments: | |

Andrey Revyakin

(posted 2023-05-02 09:56:45.933) Would it be possible to upload left-handed versions of the stage in CAD formats as well? Thanks! do'neill

(posted 2023-05-02 09:32:47.0) Response From Daniel at Thorlabs. Thank you for your feedback. I will pass on your suggestion and in the meantime I will reach out to you directly to discuss your application. Georgy Onishchukov

(posted 2020-08-12 06:47:42.577) The stage is mounted horizontally, load of about few kg is mounted just outside the upper stage plate. By about 15 mm travel from zero position the pitch deviation is still too strong for our application.

A solution might be a better (tighter) alignment of the V-grooves. Unfortunately no information about the procedure in the manual. Could you provide us with it? cwright

(posted 2020-08-17 04:58:53.0) Response from Charles at Thorlabs: Hello Georgy and thank you for contacting us. Our technical support team will reach out to you about your application. sharrell

(posted 2012-02-29 16:24:00.0) A Response from Sean at Thorlabs: Thank you for your feedback. I apologize that we do not specify a consistent set of specifications across our two product lines. I've spoken with the product engineers, and we will endeavor to test both sets of stages under the same conditions in the near future. We don't have your email address, but if you'd like us to contact you with a status update, please write us at techsupport@thorlabs.com. user

(posted 2012-02-29 03:38:23.0) You do a good job listing the specs of the cheaper aluminum stages but on these expensive steel stages so many of the specs are missing. I get the feeling they might not be as good as the aluminum stages even with the roller bearings. Why should I spend more for a stage which might be inferrior to the aluminum stages. I see the angular deviation is 244 urad which is not that good for the price. The alum stage had 250 urad for much less. Do you see my point? bdada

(posted 2011-09-20 17:53:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. We have already contacted you with this information. karthick

(posted 2011-09-11 03:38:13.0) Please send me the solidworks file of LNR25D stage.

I have solidworks 2010 and it says that i cant open as its a future verison.

Thanks

karthick jjurado

(posted 2011-06-29 09:39:00.0) Response from Javier at Thorlabs to acable: Thank you very much for your feedback. We will add a photo of the LNR25P2 mounting plate which shows the 8 alignment pin holes (4 on each axis) shortly. acable

(posted 2011-06-28 15:40:29.0) The base plate appears to have alignment pins, but there is no indication that the angle bracket has similar alignment features. Please carify how the stage can be bulit up into a 3 axis system ensuring the orthogonality of the 3 axis. Customer Email: acable@thorlabs.com bdada

(posted 2011-04-08 12:33:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. Below is our measured angular deviation data:

Pitch: 53 µrad

Yaw: 244 µrad

We will work on updating our website with this information. Please contact TechSupport@thorlabs.com if you have further questions. user

(posted 2011-04-07 13:52:49.0) What is the angular deviation of these stages? jjurado

(posted 2011-03-11 10:36:00.0) Response from Javier at Thorlabs to patrick.parkinson: Thank you for submitting your inquiry. We can certainly offer the LNR25 stage without the micrometer or differential drive. Keep in mind that this stage is compatible with the ZST25B motorized actuator, which includes a 3/8" diameter barrel, whereas the regular ZST25 is 1/4"-80 threaded. I will contact you directly for processing a formal quotation. patrick.parkinson

(posted 2011-03-11 06:52:46.0) Is it possible to purchase this stage with no drive? I already have some ZST 25 type motorised translation stages, I would like to use these with the LNR25 translation stage (as long as it is compatible). Thanks. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

Products Home

Products Home

Crossed Roller Bearing Mechanism, Steel Body

Crossed Roller Bearing Mechanism, Steel Body