Linear Translation Stages: 50.8 mm (2") Travel, Manual, Crossed-Roller Bearings

- Simple Micrometer or Differential Drive

- Solid All-Steel Construction

- Crossed-Roller Bearing Design

for High Load Capacity - Motorized Actuators Available

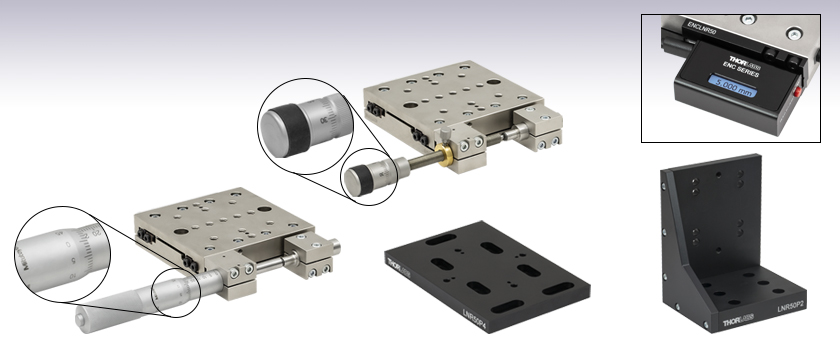

LNR50DD

Differential Drive Stage

LNR50P4

Base Plate

LNR50M

Micrometer Drive Stage

LNR50P2

Right-Angle Bracket

ENCLNR50

Stage Position Encoder

Attached to LNR50DD Stage

(Each Sold Separately)

Please Wait

| Key Specsa | |

|---|---|

| Travel | 50.8 mm (2") |

| Bearings | Crossed Roller |

| Horizontal Load Capacity | 30 kg (66 lbs) |

| Vertical Load Capacity | 4 kg (8.8 lbs) |

| Weight (Without Drives) | 1.8 kg (3.96 lbs) |

| Runout Over Full Range | ±5 µm |

| Top Plate Dimensions | 100.0 mm x 100.0 mm (3.94" x 3.94") |

| Stage Height | 25.0 mm (0.98") |

| Body Construction | All Steel |

Features

- Rugged, Thermally Matched All-Steel Construction

- Heavy-Duty Crossed-Roller Bearings

- Right- or Left-Handed XYZ Configurable

- Multiple Drive Options

- LNR50M(/M) Stage with Micrometer Drive

- LNR50D(/M) Stage with Differential Drive

- Refer to Other Drives Tab for Additional Options

- Extremely Long Life

TravelMax™ series stages are equipped with actuator side clamps that are removable, thereby allowing a variety of manual, piezo extenders, or motorized actuators to be fitted. The stages featured here are shipped preconfigured with either a micrometer drive (Item # LNR50M) or a differential drive (Item # LNR50DD). Pre-configured motorized stages are also available. Alternatively, the stage can be purchased without drives; please contact Tech Sales for a quote. Please refer to the Other Drives tab for details of other compatible actuators such as motor or piezo drives.

Click to Enlarge

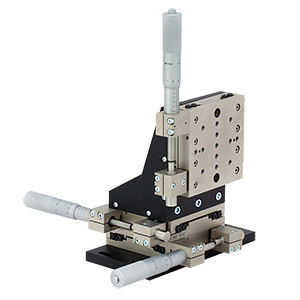

XYZ Configuration Using Three LNR50M Stages with

LNR50P4 Base Plate and LNR50P2 Right-Angle Bracket

| TravelMax™ Crossed-Roller Bearing Stages Selection Guide | |

|---|---|

| Manual | 25 mm (1") Travel |

| 50.8 mm (2") Travel | |

| Motorized | 25 mm (0.98") Travel |

| 50 mm (1.97") Travel | |

These stages offer stability, long travel, and high load capacity as well as flexible drive options, making them an ideal solution for all translation applications. Designed with the highest quality linear rails available, the performance is further enhanced by utilizing thermally matched materials that ensure stability, even in less-than-ideal conditions. The rigidity of the all-steel construction, along with the heavy-duty crossed-roller bearings, provides uniform performance over the entire 50.8 mm (2") range of motion.

Actuator Options

Two drive options are available depending on application requirements. The standard micrometer supplied with the LNR50M stage provides a 50.8 mm (2") range with a thread pitch of 0.1 mm. The Vernier scale provides graduations every 10 µm. The LNR50DD stage is equipped with a differential drive. The coarse adjustment provides 0.5 mm per revolution while the fine adjustment provides 50 μm per revolution. The fine adjuster on the differential drive has graduations every 1 µm.

For applications requiring fine positioning, the removable static pin that provides a stop for the stage's actuator can be replaced by a piezo drive. Combining the standard manual actuator with a piezo drive allows for both long travel and fine adjustment. Both open-loop and closed-loop piezo drives are available with 20 µm to 100 µm of travel and resolution as low as 5 nm.

Encoder Option

The ENCLNR50 Optical Encoder can be mounted to the LNR50 series translation stages and provides positional information in either inches or millimeters to a resolution of 1.0 µm and an accuracy of 10.0 µm.

Wide Range of Mounting Options

TravelMax™ stages were designed with flexibility and functionality in mind. The top and bottom surfaces of the LNR series of stages are equipped with a wide array of 1/4"-20 (M6 x 1.0) tapped holes to maximize the mounting flexibility of components. Two counterbored clearance holes are present in the moving world to allow the stage to be bolted easily to the work surface in either a left- or right-handed configuration.

The LNR50P2 Right-Angle Bracket allows the LNR50 stage to be mounted vertically. When combined with the LNR50P4 Base Plate, it can be used to build an XZ, YZ, or XYZ configuration. The LNR50P4 Base Plate provides additional mounting options and provides extra clearance between the stage and the work surface (e.g., when fitting motor drives).

| Item # | LNR50DD(/M) | LNR50M(/M) |

|---|---|---|

| Adjuster Type | Differential Adjusters | Micrometer |

| Travel | 50.8 mm (2") | |

| Screw Pitch | Coarse: 0.5 mm Fine: 50 µm |

0.1 mm |

| Locking Mechanism | Collet Style | N/A |

| Vernier Graduations | N/A | 10 µm |

| Bearings | Crossed Roller | |

| Horizontal Load Capacity | 30 kg (66 lbs) | |

| Vertical Load Capacity | 4 kg (8.8 lbs) | |

| Weight (Without Drives) | 1.8 kg (3.96 lbs) | |

| Runouta Over Full Range | ±5 µm | |

| Pitch Angular Deviation | 0.03° | |

| Yaw Angular Deviation | 0.015° | |

| Body Construction | All Steel | |

| Stage Fitmenta | Actuator Type | Item # | Travel Range | Description |

|---|---|---|---|---|

| Primary Actuators |

Manual Differential Drive |

DRV8 | 50.8 mm (2.00") |

The DRV8 Differential Drive is incorporated into the LNR50DD(/M) stage and provides 2.0" (50.8 mm) of coarse adjustment (500 µm per rev) and 300 µm of fine adjustment (50 µm per rev). The large diameter knob has graduations every 1.0 µm and allows precise, ultra-smooth control over the entire range of motion. |

Stepper Motor Drives |

DRV225 | 25.0 mm (0.98") |

The DRV225 and DRV250 Stepper Motors offer 25 mm (0.98") or 50 mm (1.97") of travel, respectively. When used with one of our BSC201, BSC202, or BSC203 Stepper Motor Controllers, a resolution better than 50 nm can be achieved. The hybrid stepper motor has a rotor that consists of 50 individual magnetic teeth, which is ideally suited for micro-stepping applications. With 409 600 microsteps per revolution, micro-stepping also ensures smooth low-speed motion with low vibrational noise. Each stepper motor drive is equipped with a trapezoidal screw thread for more efficient high-load operation than is available from a standard threading. | |

| DRV250 | 50.0 mm (1.97") |

|||

| Secondary Piezo Actuators |

Open-Loop Piezo Actuators |

PAS005 | 20 µm | Our PAS Series Piezo Actuators provide adjustment lengths of 20 µm or 40 µm at a resolution of 20 nm and 40 nm, respectively. The drive voltage is 0 - 75 V. Thorlabs supplies a number of suitable piezo controllers such as our KPZ101 K-Cube™ piezo driver. Alternate drivers with a BNC connector can be used with the MDC40211 SMC-to-BNC adapter. The actuator is shipped with a flat tip as shown, but can accept any of our PAA Series actuator tips. |

| PAS009 | 40 µm | |||

Closed-Loop Piezo Actuator |

PAZ009 | 40 µm | The PAZ009 Closed-Loop Piezo Actuator has a travel range of 40 µm at a resolution of 10 nm. The drive voltage for this actuator is 0 - 75 V. Feedback connection is provided via a 7 pin LEMO connector that can be used in conjunction with our APT series of motion controllers, such as our BPC301 benchtop piezo driver. Alternate drivers with a BNC connector can be used with the MDC40211 or T4292 SMC-to-BNC adapters. The actuator is shipped with a flat tip as shown, but can accept any of our PAA Series actuator tips. |

| Posted Comments: | |

| No Comments Posted |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

- Available with Micrometer or Differential Drive (See Other Drives Tab for Alternatives)

- 100.0 mm x 100.0 mm (3.94" x 3.94") Top Plate with Thirteen 1/4"-20 (M6 x 1.0) Threaded Holes and Two 1/4" (M6) Counterbores

- EN8 (AISI 1040) Steel Body

LNR50 series stages offer stability, long travel, and high load capacity as well as flexible drive options, making them an ideal solution for all translation applications. Two drive options are available depending on application requirements. The standard micrometer supplied with the LNR50M provides a 50.8 mm (2") range with a thread pitch of 0.1 mm. The Vernier scale provides graduations every 10 µm. The LNR50DD is equipped with a differential drive. The coarse adjustment provides 0.5 mm per revolution while the fine adjustment provides 50 μm per revolution. The fine adjuster scale on the differential drive has graduations every 1 µm.

Two stages can be configured for XY applications without additional adapters, while XYZ configurations require three stages and an LNR50P2(/M) bracket, available below. As illustrated in the photo to the right, a NanoMax 6-Axis Stage can mounted on top of an LNR50 series stage using the AMA562(/M) Adapter Plate.

| ENCLNR50 Encoder Kit Specifications | |

|---|---|

| On-Axis Accuracy | 10.0 µm (Typ.) |

| Repeatability | 2.0 µm (Typ.) |

| Resolution | 1.0 µm |

| Power/Data Cable (Included) | 1 m USB Cable, Type A to Micro-B |

| Power Supply (Sold Separately) | DS5 |

- Optical Position Encoder Mounts to LNR50 Series Stages

- Local Manual Control and Position Readout via Onboard Display

- Remote Control via USB and Kinesis Software

- Includes 1 m USB Cable (DS5 Power Supply Sold Separately)

The ENCLNR50 Stage Position Encoder is designed for our LNR50 series translation stages and provides positional information in either inches or millimeters to a resolution of 1.0 µm and an accuracy of 10.0 µm. The module is comprised of the optical encoder scale bracket that attaches directly to the stage and the position reader assembly which is then attached to the bracket, as illustrated in the animation below. The module is powered via a USB micro-B connection. A 1 m long USB type A to micro-B cable is included in the kit, but the DS5 power supply is sold separately. In addition to power, the USB connection also enables the encoder module to display the stage position and control the unit via our Kinesis software. We also offer the ENCXR50 position encoder for XR50 series stages, and ENCXR25 position encoder for the XR25 series stages.

The encoder must be installed on the same side of the stage where the lock plate is initially installed, on the side opposite the adjustment knob, as shown in the photo to the right. The lock plate must first be removed before mounting the encoder.

Click to Enlarge

Closeup of the ENCLNR50 Encoder Installed on the LNR50DD Stage

Click to Enlarge

XYZ Configuration Using Three LNR50M Stages with

LNR50P4 Base Plate and LNR50P2 Right-Angle Bracket

- Mount an LNR50 Series Translation Stage in the Vertical Plane

- Dowel Pin Holes to Ensure Orthogonality (6 Dowel Pins Included)

- Dimensions (L x W x H): 108.0 mm x 88.0 mm x 133.5 mm (4.25" x 3.46" x 5.26")

The LNR50P2(/M) Right-Angle Bracket allows an LNR50 series stage to be mounted vertically. When combined with the LNR50P4 Base Plate, it can be used to build an XZ, YZ, or XYZ configuration.

The base of the bracket contains six counterbored holes for 1/4"-20 (M6 x 1.0) cap screws, allowing it to be attached to the top of an LNR50 series stage or directly to an optical table. The vertical side has two 1/4"-20 (M6 x 1.0) tapped holes and eight Ø0.28" (7.0 mm) through holes.

The XYZ assembly shown to the right was constructed using the LNR50P2 Right-Angle Bracket, LNR50P4 Base Plate, and three LNR50M translation stages. Dowel pins are included with the base plate and right-angle bracket to assist in alignment of the stage.

- Provides Additional Clearance Between the Stage and the Work Surface

- Dowel Pin Holes to Ensure Orthogonality (2 Dowel Pins Included)

- Made from Aluminum Alloy

The LNR50P4 base plate provides additional mounting options and provides extra clearance between the stage and the work surface (e.g., when fitting motor drives). Tapped holes match up to the two counterbored clearance holes mentioned above, and four slotted holes allow the LNR50P2 angle bracket to be attached directly. The base plate measures 100.0 mm x 145.0 mm x 12.0 mm (3.94" x 5.71" x 0.47").

Products Home

Products Home

Zoom

Zoom

Crossed Roller Bearing Mechanism

Crossed Roller Bearing Mechanism