Compact Quick Connect Component Positioners for 2" Rails and Stages

- Fine Adjustment of Platforms Along the Rail Axis

- Positioner Provides Up to 0.40" (10.2 mm) of Translation

- Return Positioner Travels Up to 0.17" (4.3 mm)

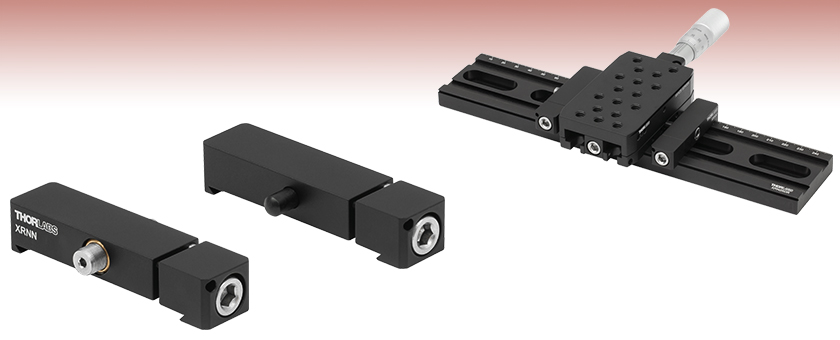

XRNN

Positioner

XRNN1

Return Positioner

Application Idea

Fine Tuning the Position of a Translation Stage

Please Wait

Click to Enlarge

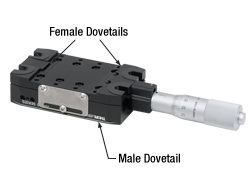

Click to EnlargeFigure 1.1 XRNN Positioner

Click to Enlarge

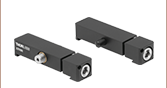

Click to EnlargeFigure 1.2 XRNN1 Return Positioner

Features

- Clamps Directly to 2" XRN Mating Dovetails

- See the Quick-Connect Stages Tab for Complete Line of Compatible Components

- Included Dovetail Clamp Screw has a Maximum Torque of 15 in•lbs

- Fine Positioning of Stages and Carriers Along a 2" Dovetail Rail

- XRNN(/M) Positioner:

- 1/4"-80 Adjuster Screw Provides 0.013" (320 µm) of Translation per Revolution

- Translation Range of 0.40" (10.2 mm)

- XRNN1(/M) Return Positioner:

- Spring Loaded Plunger with Travel Range of 0.17" (4.3 mm)

- Use with XRNN(/M) Positioner for Bidirectional Adjustment

The XRNN(/M) Translation Stage Positioner and XRNN1(/M) Translation Stage Return Positioner are designed to aid in fine alignment of stages or carriers mounted on a 2" dovetail rail. Each positioner includes a 2" mating dovetail that can be locked to a 2" dovetail rail using a clamping mechanism (3/16" [5.0 mm] hex), providing quick and convenient placement along the rail.

The XRNN(/M) incorporates an F25SS100 1/4"-80 adjuster screw to provide smaller, smoother movement than coarse translation by hand. The screw allows for 0.4" (10.2 mm) of travel before the interior of the bushing is exposed; longer adjuster screws can be installed if desired.

The XRNN1(/M) translation stage return positioner is comprised of a spring-loaded plunger integrated into a 2" mating dovetail clamp. The plunger can travel a maximum range of 0.17" (4.3 mm), and the compression spring tension can also be adjusted with a 5/32" (4.0 mm) hex driver. When used in conjunction, the XRNN(/M) positioner and XRNN1(/M) return positioner provide precision alignment along the axis of a rail. When a carrier or stage is placed between the translation stage positioners, actuating the adjustment screw pushes it toward the XRNN1(/M) return positioner, compressing the spring loaded plunger. Retracting the adjustment screw on the XRNN(/M) positioner causes the spring-loaded plunger on the XRNN1(/M) return positioner to expand, which keeps the carrier or stage in contact with the actuating screw of the XRNN(/M) positioner.

To use, place and lock the positioners along the rail so that they are both in contact with the stage or carrier. Loosen the clamp holding the stage or carriage to the rail, then turn the adjuster screw with a 5/64" (2.0 mm) balldriver to push the platform until the desired amount of translation is achieved.

For our complete selection of 2" dovetail components, see the Quick-Connect Stages tab.

| Posted Comments: | |

| No Comments Posted |

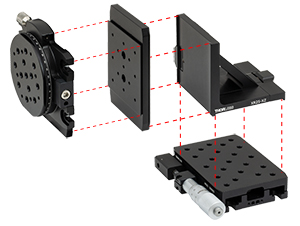

Build Multi-Axis Configurations

Click for Details

Figure 107B Z-axis assembly kits allow stages to be mounted in vertical orientations.

Quick-Connect Dovetails

Click to Enlarge

Figure 107A The female dovetails on the bottom of one stage mate with the male dovetails on another.

XR & XRN Dovetail Stages and Accessories

Our XR series manual stages feature quick-connect dovetails that allow for the construction of multi-axis systems without the need for additional hardware. The common dovetail feature with a single locking clamp makes it quick and simple to swap parts in and out while preserving excellent orthogonality.

Our selection of products with a quick-connect dovetail includes:

- Linear Translation Stages:

- Stackable 1-Axis Stages

- Pre-Assembled 2- and 3-Axis Configurations

- Rotational Stages:

- 360° Flat Rotation

- Tip/Tilt Goniometers

- Adapters:

- Z-Axis Assembly Kits

- Parallel and Perpendicular Mounting between 2" and 3" Dovetails

- Rail Accessories:

- Stationary Mounting Platforms

- Rail Component Positioners

- Base Plates and Rails

Most items are available in compact (2" dovetail) and full-size (3" dovetail) varieties. Adapters are available to interface between the two sizes. See the tables below for all available options.

| Linear Translation Stages | |||||

|---|---|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

|

|

| Items | Compact 25 mm Stages (Modular Motorized Also Available) |

Compact 9 mm Vertical Stage | Full-Size 25 mm Stages (Modular Motorized Also Available) |

Full-Size 50 mm Stages | 14 mm Vertical Stage |

| Motion | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |||

| Additional Features | |||||

| Rotation and Goniometric Stages | |||

|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

| Items | Compact Rotation Stage | Compact Goniometric Stages | Full-Size Rotation Stage |

| Motion | 360° Rotation | ±8° Tip/Tilt About Fixed Point Above Stage | 360° Rotation |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |

| Additional Features | |||

| Stage Adapters | ||

|---|---|---|

| Z-Axis Assembly Kits |  |

|

| Compact Z-Axis Assembly Kits, 2" Dovetails |

Full-Size Z-Axis Assembly Kits, 3" Dovetails |

|

| Parallel Mounting Adapters |

|

|

| Parallel Mounting Adapter, Male 2" Dovetail to Female 3" Dovetail |

Parallel Mounting Adapter, Male 3" Dovetail to Female 3" Dovetail |

|

| Perpendicular Mounting Adapter |

|

|

| Perpendicular Mounting Adapter Male 2" Dovetail to Female 3" Dovetail | ||

| Dovetail Accessories | ||

|---|---|---|

| Mounting Platforms |  |

|

| 2" Mounting Platforms | 3" Mounting Platforms | |

| Rail Positioners |  |

|

| 2" Rail Positioners | 3" Rail Positioners | |

| Dovetail Bases | |||

|---|---|---|---|

| Base Plates |  |

|

|

| 2" Dovetail Base Plate | 3" Dovetail Base Plate with Rotational Adjustment | ||

| Rails / Extended Bases |

|

|

|

| 2" Dovetail Rails | 3" Dovetail Rails | ||

Products Home

Products Home

2" Rail Platform Positioners

2" Rail Platform Positioners