Quick Connect Rotation Stage with Crossed-Roller Bearings

- Continuous 360° Manual Rotation with ±5° Fine Adjustment

- Vernier Scale Provides 5 arcmin Resolution

- Low Axial Wobble and High Load Capacity

- Integrated 3" Dovetails for Quick-Connect Construction

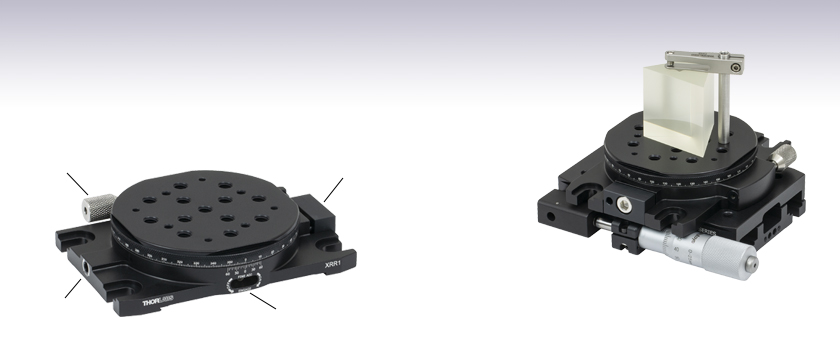

Rotation

Locking Screw

Fine Adjuster

Engagement Screw

Fine Adjuster

Dovetail

Locking Screw

XRR1

Rotation Stage

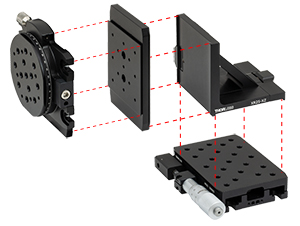

Application Idea

The XRR1 Rotation Stage is directly compatible with our XR25 and XR50 Series Translation Stages. Here it is shown mounted on an XR25P stage with a dispersing prism and PM5 Clamping Arm.

Please Wait

| Specifications | ||

|---|---|---|

| Item # | XRR1(/M) | |

| Coarse Rotation Range | 360°, Continuous | |

| Fine Adjustment Range | ±5° | |

| Fine Adjustment Resolution (Nominal) |

5.78 mrad/rev (0.331°/rev) | |

| Axial Wobble | <500 µrad (0.028°) | |

| Horizontal Load Capacity |

Overall: 50 lbs (22.7 kg) Fine Adjustment: 15 lbs (6.80 kg) |

|

| Vertical Torque Capacitya | 9 lb-in (1.02 N·m) | |

| Platform Size | Ø3.19" (Ø81.0 mm) | |

| Platform Mounting Holes |

1/4"-20 (M6 x 1.0) (13 Places) 8-32 (M4 x 0.7) (4 Places) 6-32 (M4 x 0.7) (4 Places) |

|

| Mounted Platform Height |

On Breadboard: 0.91" (23.0 mm)b Dovetail Stacked: 0.83" (21.1 mm) |

|

| Base Dimensions | 4.33" x 3.58" (110.0 mm x 91.0 mm) | |

| Base Mounting Features | 3" Quick Connect Dovetails | |

| Mounting Slot for 1/4"-20 (M6 x 1.0) Cap Screws (4 Places) |

||

Features

- 360° of Continuous Coarse Rotation and ±5° Fine Adjustment

- Vernier Scale Provides 5 arcmin Resolution

- Radial Crossed-Roller Bearing for High Load Capacity and Low Axial Wobble

- Circumference is Laser Engraved at 1° Increments

- Tapped Holes for Standard Optomechanics and Clamping Arms

- Quickly Connect Stages and Accessories Using 3" Dovetails

- See the Quick-Connect Stages Tab for Complete Line of Components

Thorlabs' XRR1(/M) Rotation Stage provides 360° of continuous manual rotation and features a side-mounted screw for fine adjustment. It also incorporates a radial crossed-roller bearing for high load capacity and low axial wobble. This dedicated, zero-clearance bearing mechanism also provides an axial constraint for the rotating world, resulting in superior stiffness compared to other bearing types. The top and bottom plates are machined from cast tool and jig aluminum for minimal internal stress and improved stability. The rotating world features an array of mounting holes and 3" male dovetails for compatibility with our XR25 or XR50 translation stages or the accessories sold below. We also offer the XRNR1 Compact Rotation Stage with 2" male dovetails.

When the fine adjustment is disengaged, the stage can be smoothly and continuously rotated by hand through a full 360°, measured by the 1° graduation marks on the side of the mount. When the fine adjustment is engaged, the fine adjuster screw provides ±5° of fine adjustment, measured with 5 arcmin resolution by the vernier scale. The end of the adjuster screw incorporates a 5/64" (2.0 mm) hex allowing it to be actuated in space-constrained environments. The adjuster knob can also be removed using a hex key, as illustrated in the video on our kinematic mirror mounts page. The rotating platform is lockable using the 5/64" (2.0 mm) hex screw on the end of the base. The top plate of each stage is tapped with an array of mounting holes. The base can be attached to an optical table or breadboard using the four 1/4" (M6) counterbored clearance slots.

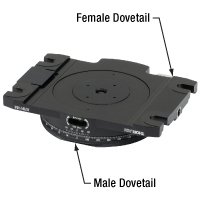

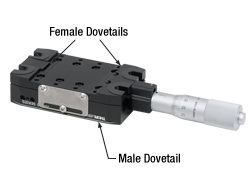

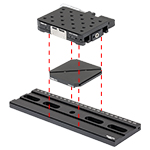

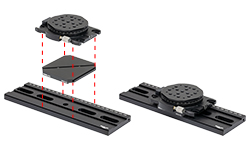

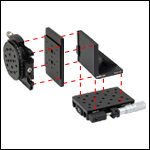

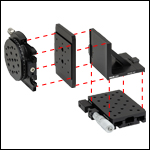

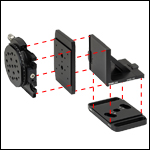

Each stage features 3" mating female dovetails on the bottom plate and male dovetails on the top plate (as shown in the image below) that allow for quick construction of multi-axis systems using no additional hardware. Refer to the photos in the vertical assembly kits section below to see how multi-axis systems can be quickly constructed using this novel design. The 3" dovetails on our XRR1(/M) rotation stage are directly compatible with the dovetails on our XR25 or XR50 series translation stages. Additional functionality is provided by a complete line of accessories that include multi-axis assembly kits, rail carriers, baseplates, and stage positioners. An adapter plate for mounting compact 25 mm stages with integrated 2" dovetails is also available. For more information about a specific accessory, please see the Quick-Connect Stages tab.

Click to Enlarge

The 3" female dovetails on the bottom of the stage mate with the male dovetails on another stage to form multi-axis configurations. The left female dovetail is on a retractable clamping arm, allowing stages to be dropped into place.

The XRR1(/M) Rotation Stage provides 360° of coarse rotation

and ±5° of fine rotation. Each stage features 3" dovetails on the top and bottom plate that allow for quick construction of multi-axis systems. The top stage can be locked at any location along the dovetail, allowing for coarse positioning. The base of the stage also has counterbores for mounting directly to optical breadboards.

Click to Enlarge

Figure 1: An example of how to read a vernier scale. The red arrow indicates what is known as the pointer. Since the tick mark labeled 10 on the vernier scale aligns with one of the tick marks on the main scale, this vernier scale is reading 75.60 (in whatever units the tool measures).

Reading a Vernier Scale

Vernier scales are typically used to add precision to standard, evenly divided scales (such as the scale on Thorlabs' rotation mounts). A vernier scale has found common use in many precision measurement tools, the most common being calipers and micrometers. The direct vernier scale uses two scales side-by-side: the main scale and the vernier scale. The vernier scale has a slightly smaller spacing between its tick marks (10% smaller than the main). Hence, the lines on the main scale will not line up with all the lines on the vernier scale. Only one line from the vernier scale will match well with one line of the main scale, and that is the trick to reading a vernier scale.

Figures 1 through 3 show a vernier scale system for three different situations. In each case, the scale on the left is the main scale, while the small scale on the right is the vernier scale. When reading a vernier scale, the main scale is used for the gross number, and the vernier scale gives the precision value. In this manner, a standard ruler or micrometer can become a precision tool.

The 0 on the vernier scale is the "pointer" (marked by a red arrow in Figs. 1 - 3) and will indicate the main scale reading. In Figure 1 we see the pointer is lined up directly with the 75.6 line. Notice that the only other vernier scale tick mark that lines up well with the main scale is 10. Since the vernier 0 lines up with the main scale’s 75.6, the reading from Figure 1 is 75.60 (in whatever units the tool measures in).

That is essentially all there is to reading a vernier scale. It's a very straightforward way of increasing the precision of a measurement tool. To expound, let’s look at Figure 2. Here we see that the pointer is no longer aligned with a scale line, instead it is slightly above 75.6, but below 75.7; thus the gross measurement is 75.6. The first vernier line that coincides with a main scale line is the 5, shown with a blue arrow. The vernier scale gives the final digit of precision; since the 5 is aligned to the main scale, the precision measurement for Figure 2 is 75.65.

Since the vernier scale is 10% smaller than the main scale, moving 1/10 of the main scale will align the next vernier marking. This asks the obvious question: what if the measurement is within the 1/10 precision of the vernier scale? Figure 3 shows just this. Again, the pointer line is in between 75.6 and 75.7, yielding the gross measurement of 75.6. If we look closely, we see that the vernier 7 (marked with a blue arrow) is very closely aligned to the main scale, giving a precision measurement of 75.67. However, the vernier 7 is very slightly above the main scale mark, and we can see that the vernier 8 (directly above 7) is slightly below its corresponding main scale mark. Hence, the scale on Figure 3 could be read as 75.673 ± 0.002. A reading error of about 0.002 would be appropriate for this tool.

As we've seen here, vernier scales add precision to a standard scale measurement. While it takes a bit of getting used to, with a little practice, reading these scales is fairly straightforward. All vernier scales, direct or retrograde, are read in the same fashion.

Click to Enlarge

Figure 2: An Example of a vernier scale. The red arrow indicates the pointer and the blue arrow indicates the vernier line that matches the main scale. This scale reads 75.65.

Click to Enlarge

Figure 3: An Example of a vernier scale. The red arrow indicates the pointer and the blue arrow indicates the vernier line that matches the main scale. This scale reads 75.67, but can be accurately read as 75.673 ± 0.002.

| Posted Comments: | |

user

(posted 2020-09-26 13:23:29.417) Dear Sir/Madam,

Is Your rotation stage XRR1/M compatible with the XR25N/M (Translation Stage Positioner) and XR25N1/M (Translation Stage Return Positioner)?

Best Regards llamb

(posted 2020-09-29 08:10:04.0) Thank you for contacting Thorlabs. While these three products can certainly be mounted together onto our XR25DR- series dovetail rails for positioning, the XRR1/M stage's contact points for either the XR25N/M positioner or the XR25N1/M return positioner are not ideal. You'll either be contacting the curved side around the stage's fine adjuster screw, or otherwise contacting the bore on the other side of the stage for the fine adjustment clutch screw, so you would lose access to engaging/disengaging the fine adjustment screw. |

Rotation Mount and Stage Selection Guide

Thorlabs offers a wide variety of manual and motorized rotation mounts and stages. Rotation mounts are designed with an inner bore to mount a Ø1/2", Ø1", or Ø2" optic, while rotation stages are designed with mounting taps to attach a variety of components or systems. Motorized options are powered by a DC Servo motor, 2 phase stepper motor, piezo inertia motor, or an Elliptec™ resonant piezo motor. Each offers 360° of continuous rotation.

Manual Rotation Mounts

| Rotation Mounts for Ø1/2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | MRM05(/M) | RSP05(/M) | CRM05 | PRM05(/M)a | SRM05 | KS05RS | CT104 |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Features | Mini Series | Standard | External SM1 (1.035"-40) Threads |

Micrometer | 16 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Compatible with 30 mm Cage Translation Stages and 1/4" Translation Stagesb |

| Additional Details | |||||||

| Rotation Mounts for Ø1" Optics | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | RSP1(/M) | LRM1 | RSP1D(/M) | DLM1(/M) | CLR1(/M) | RSP1X15(/M) | RSP1X225(/M) | PRM1(/M)a |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

|

| Features | Standard | External SM1 (1.035"-40) Threads |

Adjustable Zero | Two Independently Rotating Carriages | Rotates Optic Within Fixed Lens Tube System |

Continuous 360° Rotation or 15° Increments |

Continuous 360° Rotation or 22.5° Increments |

Micrometer |

| Additional Details | ||||||||

| Rotation Mounts for Ø1" Optics | ||||||

|---|---|---|---|---|---|---|

| Item # | LM1-A & LM1-B(/M) |

CRM1T(/M) | CRM1LT(/M) | CRM1PT(/M) | KS1RS | K6XS |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Optic Carriage Rotates Within Mounting Ring | 30 mm Cage-Compatiblea | 30 mm Cage-Compatible for Thick Opticsa |

30 mm Cage-Compatible with Micrometera |

±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mounta |

| Additional Details | ||||||

| Rotation Mounts for Ø2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | RSP2(/M) | RSP2D(/M) | PRM2(/M) | LM2-A & LM2-B(/M) |

LCRM2(/M) | KS2RS | K6X2 |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Features | Standard | Adjustable Zero |

Micrometer | Optic Carriage Rotates Within Mounting Ring | 60 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mount |

| Additional Details | |||||||

Manual Rotation Stages

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | RP005(/M) | PR005(/M) | MSRP01(/M) | RP01(/M) | RP03(/M) | QRP02(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Standard | Two Hard Stops | ||||

| Additional Details | ||||||

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | XRNR1(/M) | XRR1(/M) | PR01(/M) | CR1(/M) | XYR1(/M) | OCT-XYR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Fine Rotation Adjuster and 2" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and 3" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and SM1-Threaded Central Aperture |

Fine Pitch Worm Gear | Rotation and 1/2" Linear XY Translation | |

| Additional Details | ||||||

Motorized Rotation Mounts and Stages

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | DDR25(/M) | PDR1C(/M) | PDR1(/M) | PDR1V(/M) | PDXR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM05 Lens Tubes, 16 mm Cage System, & 30 mm Cage System |

Compatible with 16 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

Vacuum-Compatible; Also Compatible with SM05 Lens Tubes & 30 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | K10CR1(/M) | PRM1Z8(/M)a | DDR100(/M) | ELL14 | HDR50(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM1 Lens Tubes & 30 mm Cage System | Compatible with SM1 Lens Tubes, 16 mm Cage System, 30 mm Cage System |

Compatible with SM1 Lens Tubes, Open Frame Design for OEM Applications |

Compatible with SM2 Lens Tubes |

|

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Tapped Platforms | ||

|---|---|---|

| Item # | PRMTZ8(/M)a | ELL18(/M)b |

| Click Photo to Enlarge |

|

|

| Features | Tapped Mounting Platform for Mounting Prisms or Other Optics | Tapped Mounting Platform, Open Frame Design for OEM Applications |

| Additional Details | ||

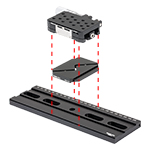

Build Multi-Axis Configurations

Click for Details

Z-axis assembly kits allow stages to be mounted in vertical orientations.

Quick-Connect Dovetails

Click to Enlarge

The female dovetails on the bottom of one stage mate with the male dovetails on another.

XR & XRN Dovetail Stages and Accessories

Our XR series manual stages feature quick-connect dovetails that allow for the construction of multi-axis systems without the need for additional hardware. The common dovetail feature with a single locking clamp makes it quick and simple to swap parts in and out while preserving excellent orthogonality.

Our selection of products with a quick-connect dovetail includes:

- Linear Translation Stages:

- Stackable 1-Axis Stages

- Pre-Assembled 2- and 3-Axis Configurations

- Rotational Stages:

- 360° Flat Rotation

- Tip/Tilt Goniometers

- Adapters:

- Z-Axis Assembly Kits

- Parallel and Perpendicular Mounting between 2" and 3" Dovetails

- Rail Accessories:

- Stationary Mounting Platforms

- Rail Component Positioners

- Base Plates and Rails

Most items are available in compact (2" dovetail) and full-size (3" dovetail) varieties. Adapters are available to interface between the two sizes. See the tables below for all available options.

| Linear Translation Stages | |||||

|---|---|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

|

|

| Items | Compact 25 mm Stages | Compact 9 mm Vertical Stage | Full-Size 25 mm Stages | Full-Size 50 mm Stages | 14 mm Vertical Stage |

| Motion | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | Z (Vertical) |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |||

| Additional Features | |||||

| Rotation and Goniometric Stages | |||

|---|---|---|---|

| Click Photo to Enlarge |  |

|

|

| Items | Compact Rotation Stage | Compact Goniometric Stages | Full-Size Rotation Stage |

| Motion | 360° Rotation | ±8° Tip/Tilt About Fixed Point Above Stage | 360° Rotation |

| Quick-Connect Dovetail | 2" Dovetail | 3" Dovetail | |

| Additional Features | |||

| Stage Adapters | ||

|---|---|---|

| Z-Axis Assembly Kits |  |

|

| Compact Z-Axis Assembly Kits, 2" Dovetails |

Full-Size Z-Axis Assembly Kits, 3" Dovetails |

|

| Parallel Mounting Adapters |

|

|

| Parallel Mounting Adapter, Male 2" Dovetail to Female 3" Dovetail |

Parallel Mounting Adapter, Male 3" Dovetail to Female 3" Dovetail |

|

| Perpendicular Mounting Adapter |

|

|

| Perpendicular Mounting Adapter Male 2" Dovetail to Female 3" Dovetail | ||

| Dovetail Accessories | ||

|---|---|---|

| Mounting Platforms |  |

|

| 2" Mounting Platforms | 3" Mounting Platforms | |

| Rail Positioners |  |

|

| 2" Rail Positioners | 3" Rail Positioners | |

| Dovetail Bases | |||

|---|---|---|---|

| Base Plates |  |

|

|

| 2" Dovetail Base Plate | 3" Dovetail Base Plate with Rotational Adjustment | ||

| Rails / Extended Bases |

|

|

|

| 2" Dovetail Rails | 3" Dovetail Rails | ||

Click for Details

XRR1/M Rotating World Features

Click for Details

XRR1 Rotating World Features

- Coarse Manual Rotation and ±5° Fine Adjustment

- Rotation Locking Screw with 5/64" (2.0 mm) Hex

- Four Holes for Breadboard Mounting with 1/4"-20 (M6 x 1.0) Screws

- Directly Compatible with XR25 and XR50 Series Translation Stages Using 3" Mating Dovetail

- Dovetail Clamp Screw has a Maximum Torque of 15 in•lbs

- XRN-A1 Adapter (Sold Separately) Enables Compatibility with XRN25 Series Compact Translation Stages

The XRR1(/M) Rotation Stage provides 360° of continuous manual rotation and features a side-mounted fine adjuster screw which rotates the platform 5.78 mrad (0.331°) per revolution. The top plate of each stage is tapped with an array of mounting holes as illustrated in the diagrams on the right.

This stage and our other stages with integrated 3" mating dovetails can be easily stacked and secured to one another. The stages are secured by a single dovetail locking mechanism with a 3/16" (5 mm) hex. The mating dovetail also allows this stage to be used with the variety of accessories below.

- Kits Consist of Angle Bracket and Mounting Plate

- Support Vertical Mounting Configurations

- Compatible with 3" Mating Dovetail Stages

- Dovetail Clamp Screw has a Max Torque of 15 in•lbs

The XR25-XZ(/M) and XR25-YZ(/M) Assembly Kits enable vertical mounting of an XRR1(/M) Rotation Stage. These assembly kits can be directly mounted onto a baseplate or onto our XR25 or XR50 Series Translation Stages. When used to mount the rotation stage vertically on a linear translation stage, the XR25-XZ kit positions the surface of the rotation stage parallel to the direction of linear motion, while the XR25-YZ kit would orient the rotation stage platform perpendicular to the direction of motion, as illustrated in the photos to the right.

Each kit includes an angle bracket and a mounting plate. The female dovetails on the rotation stage attach to one side of the mounting plate. The mounting plate's other side is then mated to an arm of the angle bracket. The other arm of the angle bracket is attached to the baseplate or translation stage.

- XRN-A1 Adapter Enables Perpendicular Mounting of 2" Dovetail Components onto 3" Dovetail Components

- XR25-A2 Adapter Enables Parallel Mounting of 3" Dovetail Components

- Adapters Add 0.275" (7.0 mm) to the Overall Stacked Height of Components

These adapters provide additional mounting options for our quick-connect, crossed-roller bearing stages. The XRN-A1 adapter enables perpendicular mounting of components with a female 2" dovetail to components with a male 3" dovetail, as illustrated in the photo to the right. The XR25-A2 adapter enables parallel mounting of two components with 3" dovetails. The second photo below illustrates a parallel mounting configuration with a smaller footprint.

To assemble, first loosen the dovetail locking screw on the end of the top stage or accessory. Position the adapter on the bottom stage or baseplate, as illustrated in the photos below, then align the top component on the adapter. Lastly, tighten the dovetail locking screw (maximum torque: 15 in•lbs) on the end of the top component until the entire assembly is secure. Please note that the deep-set screws in the sides of the adapter are not user adjustable.

Click to Enlarge

XRR1 Stage Mounted onto XR25DR Baseplate Using XR25-A2 Adapter

| Mounting Adapter Compatibility | |||

|---|---|---|---|

| Item # | Orientation | Top Component | Bottom Component |

| XRN-A1 | Perpendicular | XRN25 Series XRNR1 Stages |

XR25 Series XR50 Stages XRR1 Stages XRV1(/M) Stage |

| XR25-A2 | Parallel | XR25 Series XR50 Stages XRR1 Stages |

XR25 Series XR50 Stages XRR1 Stages |

Click to Enlarge

Stages can mounted vertically using a vertical assembly kit and the XR25-B1 baseplate.

Click for Details

The radial slots and counterbored center hole allow the base plate to be rotated with respect to the table's hole matrix. The two slots and orthogonal mounting dovetails provide 360° adjustment.

- Allows for Coarse Rotational or Translational Alignment of Stages with Table Hole Matrix

- Orthogonal Male Dovetails for Two Stage Mounting Orientations

- Compatible with 3" Mating Dovetail Stages

The XR25-B1(/M) Baseplate provides an additional table mounting option for our XRR1(/M) rotation stage. The baseplate features two orthogonal male dovetails that allow for two mounting orientations of the stage. A center Ø1/4" (M6) counterbored hole and two radial counterbored slots allow for coarse angular adjustment with respect to the table's 1/4"-20 (M6) hole matrix. For situations where the stage is oriented with the table's hole matrix, two 2.2" (55.9 mm) long 1/4" (M6) counterbored slots on the edge of the baseplate allow for coarse translation adjustment along the hole matrix before the base is secured to the table.

Vertical Stage Configuration

For situations where a vertically mounted rotation stage is needed, either the XR25-XZ or the XR25-YZ angle bracket (sold above) can be secured directly to the baseplate. This configuration is illustrated in the photo to the right and described in more detail in the Vertical Stage Assembly Kits section above.

Click for Details

Mechanical Drawings

- Provide Clamping Force for Our Platform Mounts

- Threaded Hole on Top and Threaded Stud on Bottom of Post

- 6-32 Threads on PM3 and PM4

- 8-32 Threads on PM5

- M4 x 0.7 Threads on All Metric Versions

- Maximum Optic Heights from 0.97" to 1.65" (24.6 mm to 41.8 mm)

- Extension Posts Available to Increase Max Optic Height

- PM3SP(/M) with PM3(/M): Hold Optics up to 2.21" (56.1 mm) Tall

- PM4SP(/M) with PM4(/M): Hold Optics up to 3.61" (91.7 mm) Tall

Click to Enlarge

Clamping Arm Extension Posts with Metric Indicator Groove

Thorlabs' Clamping Arms provide clamping force to secure optics to our kinematic platform mounts, stages, and V-clamps. The PM3(/M) accommodates optics up to 0.97" tall and features a 0.69" center-to-center distance between the post and the nylon-tipped setscrew that holds the optic. The PM4(/M) accommodates optics up to 1.61" and features a 1.16" center-to-center distance between the post and the nylon-tipped setscrew. The maximum optic height of the PM3(/M) or PM4(/M) Clamping Arms can be extended using our PM3SP(/M) or PM4SP(/M) Extension Posts, respectively. These extension posts are identical to the posts included in each complete clamping arm. Each clamping arm features 6-32 (M4 x 0.7) threads. The PM3 and PM4 can be mounted in 8-32 tapped holes by using the AS6E8E thread adapter, which features internal 6-32 threads and external 8-32 threads. This thread adapter has an outer diameter of 0.24", which is the same as the PM4SP extension post and the post included with the PM4 clamping arm. This allows the clamping arm to be adjusted across the seam between either post and the adapter. The smaller diameters of the included post for the PM3 clamping arm and the PM3SP extension post cause the thread adapter to act as a stop for the clamping arm.

The PM5(/M) clamping arm is made entirely from heat-treated stainless steel, which helps maintain stability in fluctuating temperatures and provides vacuum compatibility. This clamping arm is recommended for use with the POLARIS-K1M4(/M), but it can be used with any platform mount or stage that has one or more 8-32 (M4 x 0.7) tapped holes. The PM5(/M) can hold optics up to 1.65" tall, and the distance from the post center to the contact point that holds the optic is 0.90".

Each clamping arm is attached to its post using a flexure mechanism that locks with a 5/64" (2.0 mm) balldriver or hex key. The setscrew on top of the clamping arm also accepts a 5/64" (2.0 mm) balldriver or hex key in order to clamp down on the optic. The post includes a through hole which can be leveraged for added torque when tightening down the post. Please see the diagram above for additional information.

Products Home

Products Home

Zoom

Zoom

Rotation Stage with Crossed-Roller Bearings

Rotation Stage with Crossed-Roller Bearings