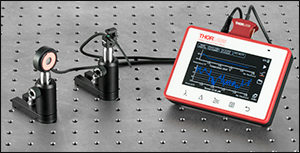

Handheld Optical Power and Energy Meter Console with Multi-Touch Technology

- Projected Capacitive Touchscreen with Color Display

- Over 35 Compatible Optical Power and Energy Sensors

- Supports Spectral Calibration and Attenuation Correction

- Inputs for Temperature and Humidity Sensors

PM400

Touchscreen Power

and Energy Meter Console

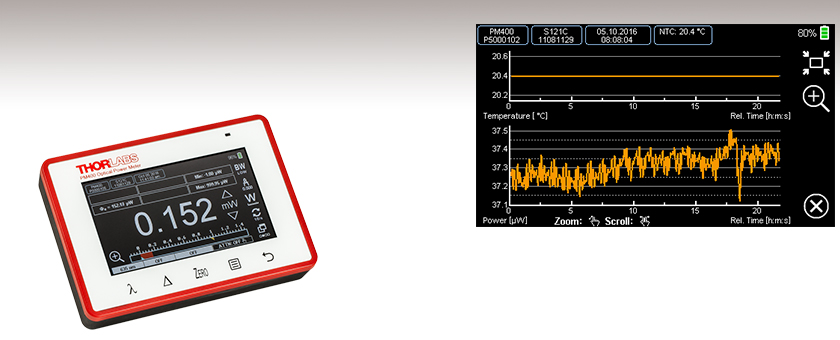

The PM400 allows power or energy measurements and temperature data to be recorded, saved, and analyzed at a later time. The graphs can be zoomed and scrolled using multi-touch gestures.

Please Wait

| PM400 Power Meter Consolea | |

|---|---|

| Compatible Sensors | Photodiode Power, Thermal Power, Thermal Position & Power, and Pyroelectric Energyb |

| Optical Power Rangec | 100 pW to 200 W |

| Optical Energy Rangec | 10 µJ to 15 J |

| Max Repetition Ratec | 3 kHz |

| Available Sensor Wavelength Rangec | 185 nm - 25 μm |

| Display Refresh Rate | 10 Hz (Numerical) 25 Hz (Analog Simulation) |

| Bandwidthc | DC - 100 kHz |

| Power Meter Selection Guide |

|---|

| Sensors |

| Photodiode Power Sensors |

| Thermal Power Sensors |

| Thermal Position & Power Sensors |

| Pyroelectric Energy Sensors |

| Power Meter Consoles and Interfaces |

| Digital Handheld Console |

| Analog Handheld Console |

| Touchscreen Handheld Console |

| Dual-Channel Benchtop Console |

| USB Interfaces with External Readout |

| Complete Power Meters |

| Power Meter Bundles |

| Wireless Power Meters with Sensors |

| Compact USB Power Meters |

| Field Power Meters for Terminated Fibers |

Features

- Compact Digital Power Meter Console

- For CW and Pulsed Source Detection

- Inputs for Temperature and Humidity Sensors

- Save and Apply User-Provided Spectral Calibration and Attenuation Correction Files

- Touchscreen Display with Multi-Touch Technology

- USB 2.0 Interface for Remote Control, Data Transfer, and Charging

- Long-Life Internal Li-Polymer Battery

- Up to 10 Hours of Battery-Powered Operation between Charging

- Compatible with TSP-TH Temperature Probe

- Sensor Upgrade and Recalibration Services Available

- Optical Power Monitor PC Software Available (See Software Tab for Details)

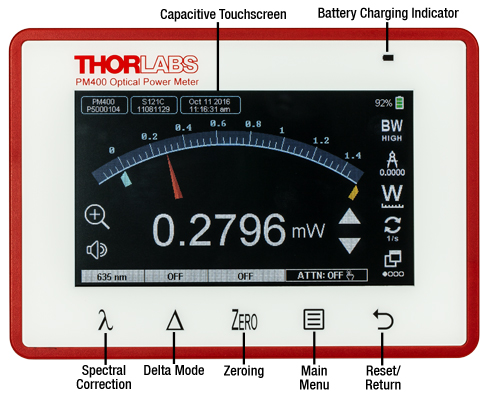

The PM400 console is designed to be used with Thorlabs' power, position & power, and energy sensors to measure the optical power of laser light, other monochromatic, or near monochromatic light sources or the energy of pulsed light sources. The projected capacitive touchscreen uses multi-touch technology, allowing data displays to be zoomed and scrolled with hand gestures. Capacitive touch buttons on the front of the unit enable fast access to set the source wavelength or spectrum, a delta mode that shows the change in power from a user-selected set point, the zeroing function, and device main menu. The touchscreen is sensitive enough that it can be operated while wearing latex, nitrile, or cotton gloves. The screen is also backlit and can be dimmed to 1% of the maximum brightness.

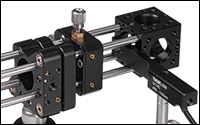

Click to Enlarge

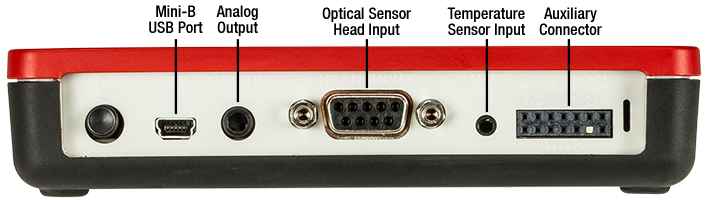

Figure 1.1 The PM400 features a variety of input ports for compatible optical sensors and temperature sensors, as well as a 14-pin auxiliary input for custom applications.

In the simplest operating mode, power and energy measurements can be viewed with a simulated analog needle or numerical display. Alternatively, data can be logged over time and saved to the device's internal memory. A graph display allows the user to examine and analyze the results with multi-touch enabled zoom and scrolling features, while a statistics display allows the user to program and analyze a sequence of measurements. In addition to pre-programming source wavelengths or spectra for calibrating their measurements, users can also enter and save up to twelve attenuation values or data files to correct for effects that external devices (such as filters or beamsplitters) may have on the power measurement. Measured data, calibration information, and attenuation curves can all be saved to the unit's internal 4 GB flash memory. The user can modify and copy the files saved to internal memory by connecting the unit to a PC via the USB port.

The PM400 console is compatible with more than 35 photodiode, integrating sphere, fiber, thermal, and pyroelectric sensors designed for use from the UV to the Mid-IR, available below. The Sensor Selection tab offers a comparison of the operating wavelengths and power or energy ranges for each sensor. Thorlabs' compatible C-series sensors can be hot-swapped when used with the PM400 console. The sensor connector contains the sensor information, including NIST-traceable responsivity curves, sensor types, and model numbers, which the PM400 uses to produce calibrated power measurements. These details can be shown on the sensor information display screen of the PM400. Alternatively, the console can be connected to compatible third-party and custom sensors via either the female DB9 connector or the 14-pin auxiliary input (see the Specs and Pin Diagrams tab for sensor compatibility information).

An external humidity sensor or combined humidity/temperature sensor unit can be connected via the 14-pin auxiliary input (see the Pin Diagrams tab). This input also provides access to the four programmable I/O ports for controlling shutters, interlock devices, laser warning lights, and other common lab devices. Alternatively, a 2.5 mm stereo (3P) jack accepts the TSP-TH thermistor temperature probe, as shown in Figure G1.1.

A 3.5 mm mono audio (2P) jack provides a 0 to 2 V analog signal that corresponds to the ratio of the measured value to the full scale value; a BNC adapter for this jack is included so that the output can be easily viewed using an oscilloscope or other device.

Data can also be recorded via the USB PC connection and optical power monitor software. This software is capable of handling up to eight consoles simultaneously. The features of the PC control software are highlighted in the Software tab.

As the PM400 uses a projected capacitive touchscreen, the outer surface is glass that can be easily cleaned with any common screen cleaning fluid.

To view the full range of Thorlabs' power and energy meter consoles, please refer to the Console Selection tab.

Sensor Upgrade Service

Thorlabs' current line of C-Series sensors and power meter consoles are not compatible with old power meter consoles and sensor heads, respectively. We offer a sensor upgrade service if you want to use your existing sensors with a new power meter console. Note: upgraded sensors will be incompatible with old power meter consoles and new sensors converted to work with older consoles will not be compatible with the PM400. Please contact our Tech Support team for details.

Recalibration Services

Recalibration services are available for our power sensors, energy sensors, and consoles. We recommend that your Thorlabs sensor and console be recalibrated as a pair; however, each may be recalibrated individually. All of the sensors on this page come with a manufacturer calibration by default, but we also offer an ISO 17025 accredited calibration for some items. For more information on calibration options, please see the Recalibration tab or the calibration sections at the bottom of this page. Recalibration of a thermal position sensor can be requested by contacting Tech Support.

| Table 2.1 Specifications | |

|---|---|

| Compatible Detectors | Thorlabs' C-Series Photodiode, Thermal Power, Thermal Position & Power, and Pyroelectric Sensors (Except Item # ES408C) Photodiodes up to 5 mA, Thermopiles up to 1 V, and Pyroelectric Detectors up to 100 V See Table 2.2 for Additional Details |

| Display | |

| Type | 4.3" TFT, WQVGA, 400 x 272 Pixels, 16 Bit Color |

| Viewing Area | 95 mm x 54 mm |

| Update Rate (Max) | 10 Hz Numerical, 25 Hz Analog Simulation |

| Format | Numerical, Bar Graph, Trend Graph, Statistics, and Simulated Analog Needle |

| Backlight | LED, Adjustable |

| Features | Projected Capacitive Touchscreen and Buttons, Support Stand, Rubberized Outside, 2 x M3 Threaded Inserts for Mounting on Back Side |

| Analog Output | |

| Connector | 3.5 mm Mono Audio (2P) Jack, Adapter to BNC Included |

| Signal | Amplified Input Signal - Not Corrected |

| Voltage Range | 0 to 2 V |

| Accuracy | ±3% |

| Bandwidth | Up to 100 kHz, Dependent on Sensor and Settings |

| Auxiliary Input/Output | |

| Connector | 2 x 7 Pins, 0.1" Socket, Top Side |

| Function | 4 x GPIO 2 x 10 bit ADC for External Temperature, Relative Humidity Sensor +3.3 V, +/- 2.5 V (100 mA Max) |

| Temperature Sensor Internal to C-Series Optical Sensora | |

| Temperature Sensor Type | Thermistor |

| Temperature Measurement Range | -10 °C to 80 °C |

| External Temperature Sensor | |

| Supported Temperature Sensor | Thermistor NTC 0.1 - 100 kΩ, B-Value 1000 - 9999 K |

| Temperature Measurement Range | -10 °C to 80 °C (with TSP-TH) |

| Connector | 2.5 mm Stereo Audio (3P) Jack |

| Sound | |

| Type | Internal Speaker |

| Function | Laser Tuning Support, Console Function Support |

| Memory | |

| Type | NAND Flash |

| Size | 4 GB |

| Interfaces | |

| Type | USB 2.0 |

| Connector | Mini-B USB |

| Power Management | |

| Battery | LiPo 3.7 V 2600 mAh |

| Charger | Built In; Charging Current: 0.5 / 1 A |

| Power Connector | Mini USB |

| General | |

| Operating Temperature Rangeb | 0 to 40 °C |

| Storage Temperature Range | -40 to 70 °C |

| Dimensions | 136 mm x 96 mm x 29 mm |

| Weight | 0.35 kg |

| Table 2.2 Sensor Compatibility | |||

|---|---|---|---|

| Sensor Type | Photodiode Power Sensors | Thermal Power Sensors Thermal Position & Power Sensors |

Pyroelectric Energy Sensorsa |

| Input Type | Current | Voltage | Voltage |

| Connector (on PM400) | Female DB9 | ||

| Units | W, dBm, W/cm², A | W, dBm, W/cm², V | J, J/cm², W, W/cm², V |

| Measurement Ranges | 6 Decades; 50 nA, 500 nA, 5 µA, 50 µA, 500 µA, 5 mA Ranges Selectable in W (Sensor Dependent) |

9 Ranges: 2, 4, 10, 20, 40, 100, 200, 400, 1000 mV Ranges Selectable in W (Sensor Dependent) |

4 Ranges: 200 mV, 2V, 20 V, 100 V Ranges Selectable in J (Sensor Dependent) |

| Display Resolution | 1 pA / Responsivity Value (A/W) | 1 μV / Responsivity Value (V/W) | 100 μV / Responsivity Value (V/J) |

| AD Converter | 16 bit | ||

| Accuracy | ±0.2% Full Scale (5 μA - 5 mA) ±0.5% Full Scale (50 nA) |

±0.5% Full Scale (10 mV - 1 V) ±1% Full Scale (2 mV) |

±0.5% Full Scale |

| Bandwidth | DC - 100 kHz, Dependent on Sensor and Settings | N/A | |

| Trigger Threshold | N/A | N/A | 3% - 90% Full Scale |

| Time Constant Correction Range |

N/A | 1 s - 30 s | N/A |

| Repetition Rate (Max) | N/A | N/A | 3 kHz |

| Wavelength Correction | nm, A/W (Sensor Dependent) | nm, V/W (Sensor Dependent) | nm, V/J (Sensor Dependent) |

| Beam Area Setting | Diameter 1/e² or Rectangular XY | ||

Video Insight: Optical Power Meter Parameter Setup

To obtain the most accurate power readings a power meter should be configured specifically for the light incident on the power sensor. Video 3.1 demonstrates how to set three important optical power meter parameters: the center wavelength of the light, the maximum optical power the sensor will measure, and the zero offset resulting from the detection of ambient light.

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

Click to Enlarge

Figure 3.2 The Front Panel of the Touchscreen Power Meter

Touchscreen Power Meter Front Panel

Thorlabs' PM400 Power Meter features a front panel with several key elements, as shown in Figure 3.2. The projected capacitive touchscreen and buttons are sensitive enough to allow smooth operation even when the user wears cotton, latex, or nitrile gloves, but durable enough to be cleaned with standard screen cleaning solvents.

- Capacitive Touchscreen: The capacitive touchscreen allows the user to control the console functions with finger taps and swipes. Features include numerical displays of power and energy measurements, logging of long-term measurements, settings for a calibration wavelength or a preset attenuation value, and temperature monitoring. The user can switch measurement views by swiping one finger over the screen to the left or right, or by tapping the window icon in the lower right corner of the screen. More details on the measurement options are provided below.

- Spectral Correction Button: This button opens a screen where the user can quickly select or save up to 12 measurement wavelengths. The PM400 will use this wavelength setting in conjunction with the calibration data recorded in the connector of Thorlabs' power and energy sensors in order to provide a calibrated optical power or energy reading. The selected wavelength is displayed above the button.

- Delta Mode: In delta mode, the power meter will display the power or energy relative to a user selected setpoint. Pressing this button saves the current power or energy reading as the reference value, and subsequent measurements will be displayed as the difference between the actual value and the reference. The reference value is displayed above this button when Delta Mode is active.

- Zeroing: Quickly set the current power or energy value as the zero point for subsequent measurements. The measured power or energy when the console is zeroed will be displayed above the Zero button.

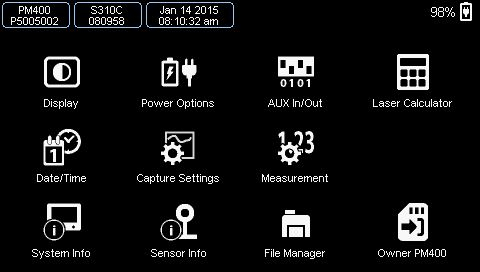

- Main Menu: This button provides quick access to the main menu. From here, the user can access a submenu to set the parameters for long-term power measurements, device settings, the file manager, sensor info, and the laser calculator. Details are provided below.

Additional Features

In addition to allowing users to select different measurement modes and settings, the PM400 incorporates other features to allow users to customize the interface.

- Language Settings: English, French, German, and Chinese can be selected.

- Display Brightness and Contrast: The power meter screen is backlit and can be dimmed to 1% of the maximum brightness. In addition, the user can choose whether to have the display show white text on a black background, or black text on a white background.

- Laser Tuning Sound: The power meter plays an audible tone to aid in identifying when peak power is achieved while tuning a laser. The console will beep repeatedly, with the frequency of the beep increasing as the measured power increases.

- Programmable I/O Ports: The PM400 features four programmable I/O ports for controlling shutters, interlocks, laser warning lights, etc.

The Touchscreen Display

The screenshots below provide an overview of some of the measurement views, measurement settings, functions, and calculators accessible through the touchscreen display.

Figure 3.3 Numerical Display

Figure 3.3 Numerical Display| Subpanel Display Options | |||

|---|---|---|---|

| Photodiode Power Sensors | Thermal Power Sensors | Thermal Position & Power Sensors | Pyroelectric Energy Sensors |

| Current (IDET) | Voltage (VDET) | Voltage (VDET) | Voltage (VDET) |

| Power (Φe) | Power (Φe) | Power (Φe) | Energy (WDET) |

| Power in dBm (Φe) | Power in dBm (Φe) | Power in dBm (Φe) | N/A |

| Max | Max | Max | Max |

| Min | Min | Min | Min |

| Ratio (Max/Min) | Ratio (Max/Min) | Ratio (Max/Min) | Ratio (Max/Min) |

| Sensor Temperaturea | Sensor Temperaturea | Sensor Temperaturea | N/A |

| Frequency | Frequency | Frequency | Frequency |

| External NTC Temperature | External NTC Temperature | External NTC Temperature | External NTC Temperature |

| Irradiance (Ee) | Irradiance (Ee) | Irradiance (Ee) | Fluence (He) |

| N/A | N/A | XY Position | N/A |

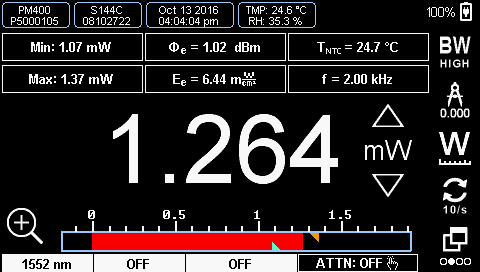

The numerical display shows a digital measurement of the power or energy with a bar graph along the bottom. The orange and blue triangles on the bar graph show the min and max values detected during the measurement. To reset the min and max values, press the reset button on the front panel. The six rectangular subpanels immediately above the power or energy measurement are configurable displays, allowing the user to select which parameters to view. The Subpanel Display Options table provides a summary of available settings for each style of detector.

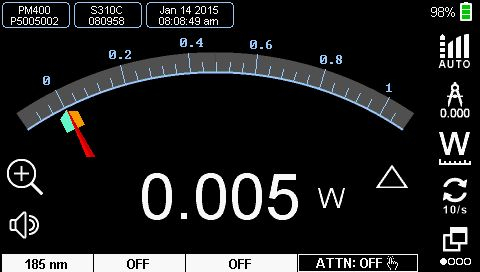

Figure 3.4 Simulated Analog Needle

Figure 3.4 Simulated Analog Needle

Measurements can be viewed with a simulated analog needle. The orange and blue marks are indicators for the max and min measured power, and the scale can be zoomed by a factor of 10. Icons down the side of the screen allow the user to set the bandwidth, adjust the resolution of the digital value at the bottom of the display, change units, adjust the display update rate or change screens.

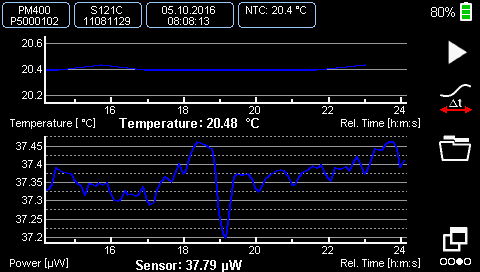

Figure 3.5 Graph View

Figure 3.5 Graph View

In the graph view, the user can monitor the optical power or energy of a source as it changes over time. A second, optional display can be added that shows the readout from a connected temperature sensor (the upper graph in Figure 3.5). Icons on the side of the window allow the user to start and stop the measurement, scroll through the data, and open the folder where the measurement is saved.

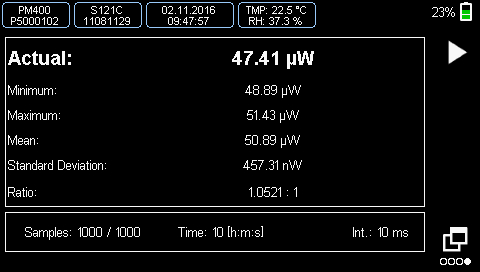

Figure 3.6 Statistics Display

Figure 3.6 Statistics Display

In the statistics display, the user can start a sequential measurement. The sample rate and duration can be adjusted from the Capture Settings screen, accessible from the main menu. The bottom bar of the display shows the number of measurements taken, total elapsed time since the measurements were started, and the measurement interval. The main part of the display shows statistics for the accumulated measurements, including the minimum, maximum, mean, and standard deviation.

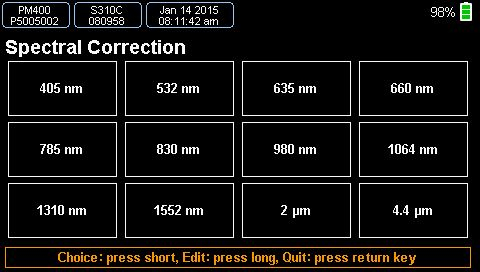

Figure 3.7 Spectral Correction

Figure 3.7 Spectral CorrectionThis mode can be entered by pressing the λ symbol on the front panel. The unit can store up to 12 preset spectral correction entries, editable by the user. In their simplest form, these entries can consist of a single user-entered wavelength that will be used in conjunction with the NIST-traceable calibration data from a Thorlabs' sensor to produce a calibrated power measurement. Alternatively, each entry can be a .csv file with the source spectrum that has been uploaded and saved. When a spectral correction entry is selected, the entry name will be displayed in the field above the spectral correction button.

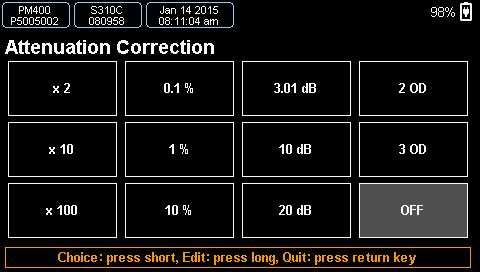

Figure 3.8 Attenuation Correction

Figure 3.8 Attenuation Correction

External devices within a setup, such as a filter or beamsplitter, may be needed to attenuate the signal being measured. The attenuation correction function allows the PM400 to display a power reading that accounts for these sources of attenuation. Attenuation values can be assigned as a multiplier (e.g. x2), in percent, in dB, or in OD (optical density). Alternatively, complete filter transmission curves can be uploaded and saved. Up to 12 different attenuation settings can be programmed and stored.

Figure 3.9 Main Menu

Figure 3.9 Main Menu

The PM400 main menu allows access to device features including the screen brightness, the menus to set the parameters for power, energy, and temperature measurements, a screen for calculating laser pulse characteristics, and a unit converter.

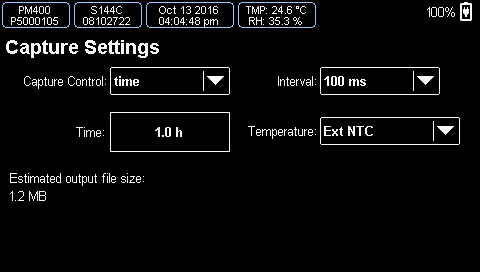

Figure 3.10 Capture Settings

Figure 3.10 Capture Settings

This screen allows the user to set the parameters for taking data. User-selectable settings include manual or automatic data acquisition, the exposure time, the number of samples, and the capture interval. It also allows the temperature logging parameters to be set. Once all of the settings are selected, this screen will return an estimated file size so that the user can ensure there is enough free memory on the device. In the case of manual operation (the user manually starts and stops the measurement), the estimated output file size will be the rate at which memory is used up as the data is collected.

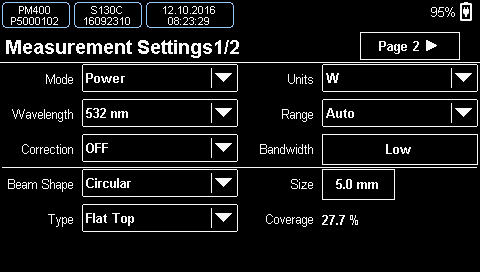

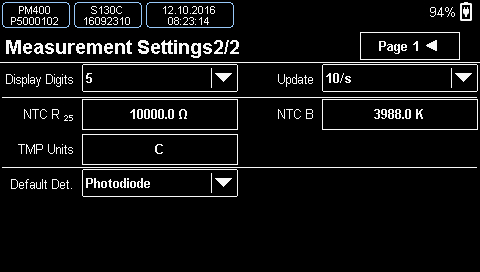

Figure 3.11 Sensor Measurement Settings

Figure 3.11 Sensor Measurement Settings

This screen allows the user to view sensor-dependent content, adjust common settings such as wavelength, attenuation, mode, etc., and enter beam parameters.

Figure 3.12 Temperature Sensor Settings

Figure 3.12 Temperature Sensor Settings

If an external temperature sensor is hooked up to the PM400, the user can adjust the parameters here.

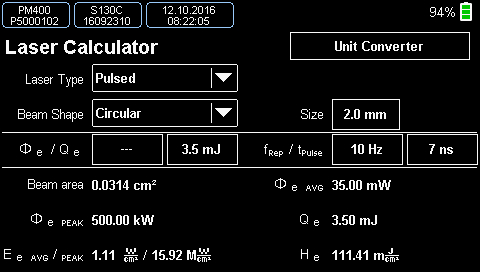

Figure 3.13 Laser Calculator and Unit Converter

Figure 3.13 Laser Calculator and Unit Converter

The PM400 has several calculators. The laser calculator screen allows the user to calculate laser beam parameters based on available inputs. A unit converter provides quick conversions between Watts and dBm or between wavelength, frequency, wavenumbers, and photon energy.

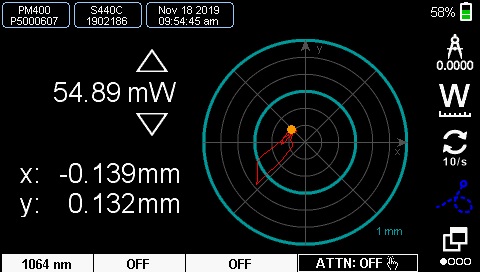

Figure 3.14 Position Trace Display (Thermal Position Sensors Only)

Figure 3.14 Position Trace Display (Thermal Position Sensors Only)

When used with the S440C or S442C thermal position sensors, the PM400 console can display a trace of the beam's position within a Ø1 mm circle or Ø6 mm circle on the sensor surface. The total beam power is also monitored in this mode.

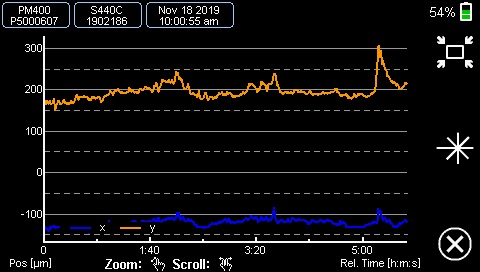

Figure 3.15 Position Graph Display (Thermal Position Sensors Only)

Figure 3.15 Position Graph Display (Thermal Position Sensors Only)Similar to the graph display in Figure 3.5, the console can display a graph of the beam's X and Y coordinates over time when used with the S440C or S442C sensors. The user can toggle between this plot and a plot of the the beam's total power over time.

The PM400 Console is capable of supporting any of Thorlabs' C-Series sensor heads (except the ES408C Pyroelectric Energy Sensor) as well as some third-party and custom detectors. The main connections are shown in Figure 4.1, and the pin diagrams are provided to aid in determining sensor compatibility. Compatible sensor specifications are provided on the Specs tab.

Figure 4.1 Top View of the PM400 Console

Optical Sensor Head Input

9-Pin Female D-Sub

| Pin | Connection |

|---|---|

| 1 | +5 V (100 mA Max Current from this Pin) |

| 2 | DO NOT USEa |

| 3 | AGND (Analog Ground): Photodiode Ground (Anode), Thermal and Pyroelectric Sensor Ground |

| 4 | Photodiode Cathode |

| 5 | Pyroelectric Sensor + |

| 6 | DGND (Digital Ground) |

| 7 | Present: Connect this Pin via a 1 kΩ to 10 kΩ Resistor to Pin 3 (AGND) to Enable a Custom Sensor |

| 8 | Thermal Sensor + |

| 9 | Not Connected |

Auxiliary Connector

14-Pin Dual-In-Line Socket, 0.1" (2.54 mm) Pitch

| Pin | Connection |

|---|---|

| 1 | Ground |

| 2 | +3.3 VDC, 0.1 A |

| 3 | Do Not Use (No Function) |

| 4 | ADC Current In (Humidity Sensor) |

| 5 | Temp / Humidity Detection Module |

| 6 | ADC Current In (Temperature Sensor) |

| 7 | GPIO 02 |

| 8 | GPIO 01 |

| 9 | GPIO 03 |

| 10 | GPIO 04 |

| 11 | Ground |

| 12 | + 2.5 VDC, 0.05 A |

| 13 | Ground |

| 14 | -2.5 VDC, 0.05 A |

Mini-B USB 2.0 Port

For Remote Control with a Mini-USB Device and Charging

Analog Output

0 to 2 V,

3.5 mm Mono Audio (2P) Jack

Temperature Sensor Input

2.5 mm Stereo Audio (2P) Jack

for NTC

Click to Enlarge

Figure 5.1 The PM400 is shipped in an eco-friendly package.

Included Components

- Power Meter Console with Multi-Touch Technology

- BNC to 3.5 mm Mono Audio Adapter for Analog Output

- USB Cable, Type A to Mini B

- Operating Manual

- Certificate of Calibration

Compatible Power Meters

- Consoles:

- PM100A Analog Power and Energy Meter Console

- PM200 Legacy Touch Screen Power and Energy Meter Console

- PM100D Digital Power and Energy Meter Console

- PM400 Capacitive Touchscreen Power and Energy Meter Console

- PM5020 Dual-Channel Benchtop Optical Power and Energy Meter Console (Version 4.0 or Later)

- Complete Power Meters:

- PM160, PM160T, and PM160T-HP Wireless Handheld Power Meters with Bluetooth® Technology

- PM16 Series Compact USB Power Meters

- PM60 and PM61 Fiber Optic Power Meter Series (Version 6.0 or Later)

- Interfaces:

- PM101 Series Power Meter Interfaces with External Readout (Version 2.0 or Later)

- PM102 Series Power Meter Interfaces with External Readout (Version 2.1 or Later)

- PM103 Series Power Meter Interfaces with External Readout (Version 3.0 or Later)

- PM100USB USB Interface Digital Power and Energy Meter

Other Compatible Devices

- ERM2xx Series Extinction Ratio Meters

- SPCNT Single Photon Counting Device

- TSP01 USB Temperature and Humidity Data Logger

- TSP-TH Additional Temperature Probe

- WM202 Wavelength Meter

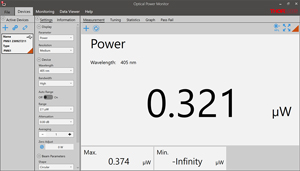

Optical Power Monitor

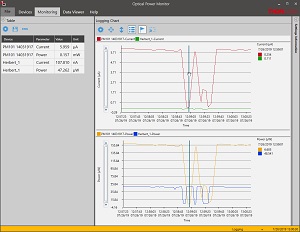

The Optical Power Monitor GUI software features readout from up to eight power meters or other compatible devices, or remote wireless operation.

For details on specific software features, please see the user manual.

Users interested in the legacy Power Meter Software can find it by visiting the software page.

The PM101 Series Power Meters are only compatible with version 2.0 or later. The PM102 Series Power Meters are only compatible with version 2.1 or later. The PM103 Series Power and Energy Meters are only compatible with version 3.0 or later. The PM5020 Console is only compatible with version 4.0 or later. The PM60 and PM61 Power Meter Series are only compatible with version 6.0 or later.

Optical Power Monitor GUI Software for Touchscreen, Handheld, and USB-Interface Power Meters

Features

- Operate up to Eight Devices Simultaneously

- Record and Analyze Measurements in Real Time

- Intuitive Analog Display and Graphing Modes

- Configurable Long-Term Data Logging

- Also Supports Position Measurements with Thermal Position & Power Sensors

- Compatible with USB and Bluetooth® Connections

The Optical Power Monitor (OPM) software GUI enables seamless control of up to eight compatible devices that are connected via USB, RS232, or Bluetooth® wireless technologya. The latest software, firmware, drivers, and utilities for these power meters can be downloaded here.

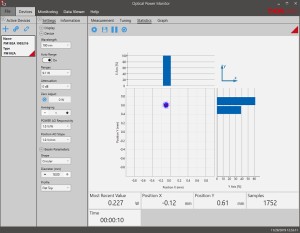

Multiple data measurement and analysis functions are integrated into the GUI package. The interface offers a user-friendly design with minimal use of color and low brightness that is ideal for use in dark lab environments while wearing laser safety glasses. Measured data can be displayed in real time as a simulated analog needle, digital values, line graph, or bar graph. Continuously logged and short-term measurements can be recorded for data viewing and analysis at a later point. A built-in statistics mode analyzes measured data and updates continuously to reflect new measurements within the pre-determined measurement period. Beam position measurements are also supported when used with our thermal position & power sensors.

The OPM software package installs the GUI, which then can be used to control the touchscreen, handheld, or USB-interface power meters and other compatible devices. Firmware updates for supported power meters are also available. Programming examples and drivers for interfacing with our power and energy meter consoles using LabVIEW, C/C++, Visual C#, and Python are installed with the software; refer to the manual for details.

Please note that the OPM Software uses different drivers than the Power Meter Utilities Software and Thorlabs recommends using the new driver TLPM.dll. For users who wish to use the legacy Power Meter Software or use custom software designed using the older PM100D.dll driver, a Power Meter Driver Switcher program is included for easy swapping of the installed driver between the two versions.

a. The PM61 Series, PM160, PM160T, and PM160T-HP power meters are equipped with Bluetooth® connections.

Click to Enlarge

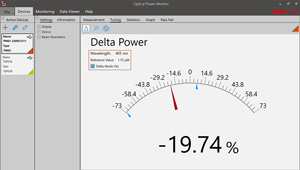

Figure 149B Power Tuning Mode

Simulated analog needle and digital measurement value provided. Delta Mode, enabled here, shows the fluctuation range during the measurement period.

Click to Enlarge

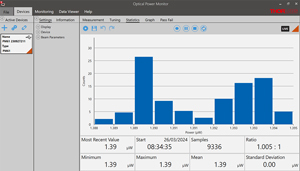

Figure 149C Power Statistics Mode

Calculate numerical statistics for a pre-determined measurement period. The panel displays the analyzed values in a bar graph and the results as numerical values.

Click to Enlarge

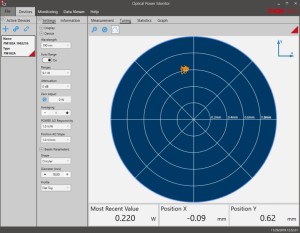

Figure 149D Position Tuning Mode

Tuning mode can be used with a thermal position & power sensor to aid in beam alignment.

Click to Enlarge

Figure 149E Position Statistics Mode

Statistics mode also provides aggregate information for thermal position & power sensors.

Click to Enlarge

Figure 149F Data Logging

Enable long-term measurement and simultaneous recording from up to eight power meters. Save data as .csv files for later processing while measurement results are displayed in a graph in real time.

Click to Enlarge

Figure 113A The PM160 wireless power meter, shown here with an iPad mini (not included), can be remotely operated using Apple mobile devices.

This tab outlines the full selection of Thorlabs' power and energy sensors. Refer to Table 113B for power meter console and interface compatibility information.

In addition to the power and energy sensors listed below, Thorlabs also offers all-in-one, wireless, handheld power meters and compact USB power meter interfaces that contain either a photodiode or a thermal sensor, as well as power meter bundles that include a console, sensor head, and post mounting accessories.

Thorlabs offers four types of sensors:

- Photodiode Sensors: These sensors are designed for power measurements of monochromatic or near-monochromatic sources, as they have a wavelength dependent responsivity. These sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current.

- Thermal Sensors: Constructed from material with a relatively flat response function across a wide range of wavelengths, these thermopile sensors are suitable for power measurements of broadband sources such as LEDs and SLDs. Thermal sensors deliver a voltage proportional to the input optical power.

- Thermal Position & Power Sensors: These sensors incorporate four thermopiles arranged as quadrants of a square. By comparing the voltage output from each quadrant, the unit calculates the beam's position.

- Pyroelectric Energy Sensors: Our pyroelectric sensors produce an output voltage through the pyroelectric effect and are suitable for measuring pulsed sources, with a repetition rate limited by the time constant of the detector. These sensors will output a peak voltage proportional to the incident pulse energy.

| Table 113B Console Compatibility | ||||||||

|---|---|---|---|---|---|---|---|---|

| Console Item # | PM100A | PM100D | PM400 | PM5020 | PM101 Series |

PM102 Series |

PM103 Series |

PM100USB |

| Photodiode Power |  |

|

|

|

|

- |  |

|

| Thermal Power |  |

|

|

|

|

|

- |  |

| Thermal Position | - | - |  |

|

- |  |

- | - |

| Pyroelectric Energy | - |  a a |

a a |

|

- | - |  |

a a |

Power and Energy Sensor Selection Guide

There are two options for comparing the specifications of our Power and Energy Sensors. Tables 113C, 113D, 113E, and 113F sort our sensors by type (e.g., photodiode, thermal, or pyroelectric) and provide key specifications.

Alternatively, the selection guide Figures 113G and 113H arrange our entire selection of photodiode and thermal power sensors by wavelength (Figure 113G) or optical power range (Figure 113H). Each box contains the item # and specified range of the sensor. These graphs allow for easy identification of the sensor heads available for a specific wavelength or power range.

| Table 113C Photodiode Power Sensors |

|---|

| Table 113D Thermal Power Sensors |

|---|

| Table 113E Thermal Position & Power Sensors |

|---|

| Table 113F Pyroelectric Energy Sensors |

|---|

Figure 113G Sensor Options Arranged by Wavelength Range

Figure 113G Sensor Options Arranged by Wavelength Range Figure 113H Sensor Options Arranged by Power Range

Figure 113H Sensor Options Arranged by Power RangeThorlabs offers a wide selection of power and energy meter consoles and interfaces for operating our power and energy sensors. Key specifications of all of our power meter consoles and interfaces are presented in this tab to help you decide which device is best for your application. We also offer self-contained wireless power meters and compact USB power meters.

When used with our C-series sensors, Thorlabs' power meter consoles and interfaces recognize the type of connected sensor and measure the current or voltage as appropriate. Our C-series sensors have responsivity calibration data stored in their connectors. The console will read out the responsivity value for the user-entered wavelength and calculate a power or energy reading.

- Photodiode sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current. The photodiode's responsivity is wavelength dependent, so the correct wavelength must be entered into the console for an accurate power reading. The console reads out the responsivity for this wavelength from the connected sensor and calculates the optical power from the measured photocurrent.

- Thermal sensors deliver a voltage proportional to the input optical power. Based on the measured sensor output voltage and the sensor's responsivity, the console will calculate the incident optical power.

- Energy sensors are based on the pyroelectric effect. They deliver a voltage peak proportional to the pulse energy. If an energy sensor is recognized, the console will use a peak voltage detector and the pulse energy will be calculated from the sensor's responsivity.

The consoles and interfaces are also capable of providing a readout of the current or voltage delivered by the sensor. Select models also feature an analog output.

Consoles

| Item # | PM100A | PM100D | PM400 | PM5020 |

|---|---|---|---|---|

| (Click Photo to Enlarge) |  |

|

|

|

| Key Features | Analog Power Measurements | Digital Power and Energy Measurements | Digital Power and Energy Measurements, Touchscreen Control | Dual Channel |

| Compatible Sensors | Photodiode and Thermal Power | Photodiode Power, Thermal Power, and Pyroelectric Energya | Photodiode Power, Thermal Power, Thermal Power and Position, and Pyroelectric Energya | Photodiode Power, Thermal Power, Thermal Power and Position, and Pyroelectric Energy |

| Housing Dimensions (H x W x D) |

7.24" x 4.29" x 1.61" (184 mm x 109 mm x 41 mm) |

7.09" x 4.13" x 1.50" (180 mm x 105 mm x 38 mm) |

5.35" x 3.78" x 1.16" (136.0 mm x 96.0 mm x 29.5 mm) |

9.97" x 4.35" x 11.56" (253.2 mm x 110.6 mm x 293.6 mm) |

| Channels | 1 | 2 | ||

| External Temperature Sensor Input (Sensor not Included) | - | - | Readout and Record Temperature Over Time | Readout and Record Temperature Over Time |

| External Humidity Sensor Input (Sensor not Included) | - | - | Readout and Record Humidity Over Time | Readout and Record Humidity Over Time |

| Input/Output Ports | - | 4 GPIO, Programmable | 4 Configurable Digital I/O Channels | |

| Shutter Control | - | - | - | Support for SH05R(/M) or SH1(/M) Optical Shutter with Interlock Input |

| Fan Control | - | - | - | |

| Source Spectral Correction | - | - | ||

| Attenuation Correction | - | - | ||

| External Trigger Input | - | - | - | |

| Display | ||||

| Type | Mechanical Needle and LCD Display with Digital Readout | 320 x 240 Pixel Backlit Graphical LCD Display | Protected Capacitive Touchscreen with Color Display | |

| Dimensions | Digital: 1.9" x 0.5" (48.2 mm x 13.2 mm) Analog: 3.54" x 1.65" (90.0 mm x 42.0 mm) |

3.17" x 2.36" (81.4 mm x 61.0 mm) |

3.7" x 2.1" (95 mm x 54 mm) |

4.32" x 2.43" (109.7 mm x 61.6 mm) |

| Refresh Rate | 20 Hz | 10 Hz (Numerical) 25 Hz (Analog Simulation) |

25 Hz | |

| Measurement Viewsb | ||||

| Numerical | ||||

| Mechanical Analog Needle | - | - | - | |

| Simulated Analog Needle | - | |||

| Bar Graph | - | |||

| Trend Graph | - | |||

| Histogram | - | - | - | |

| Statistics | ||||

| Memory | ||||

| Type | - | SD Card | NAND Flash | SD Card |

| Size | - | 2 GB | 4 GB | 8 GB |

| Power | ||||

| Battery | LiPo 3.7 V 1300 mAh | LiPo 3.7 V 2600 mAh | - | |

| External | 5 VDC via USB or Included AC Adapter | 5 VDC via USB | Line Voltage: 100 - 240 V | |

Figure 796A DAkkS-accredited calibrations are performed in accordance with DIN EN ISO/IEC 17025:2018.

Recalibration Services

Thorlabs offers two types of recalibration services in-house for our power and energy meter electronics and photodiode power sensors: ISO 17025 accredited calibrations and manufacturer calibrations. Only the manufacturer calibration is available for the NS170C microscope slide peak power sensor, our thermal power sensors, and our pyroelectric energy sensors. All new products are delivered with a manufacturer calibration by default; if an ISO 17025 accredited calibration is desired for a new device, please contact Tech Sales.

ISO 17025 accredited calibrations are performed in-house in accordance with DIN EN ISO/IEC 17025:2018. Thorlabs GmbH's calibration laboratory is accredited by the German Accreditation Body (DAkkS), the national accreditation authority of the Federal Republic of Germany. The scope of services is described here in English or German. Accredited calibrated power and/or energy meter electronics come with a dedicated certificate of calibration proving the specified accuracy and traceability of calibration data. This certification may be required in certain applications or industries, such as the medical market.

In contrast, our manufacturer calibrations are subject to the quality management requirements of ISO 9001. The certificate of calibration lists the equipment used for the calibration procedure as well as the calibration data acquired. The manufacturer calibration of a power sensor includes recalibration of a single-channel console or interface at no additional cost. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually.

Both types of calibration can be offered for third-party equipment or adjusted for special requirements upon request. Please reach out to Tech Sales for further details.

We recommend recalibrating your Thorlabs sensor and console as a pair; however, each may be recalibrated individually. To ensure accurate measurements, we recommend recalibrating annually. To order one or more sensor recalibrations with a dual-channel console, we offer two options: either 1) fill out the Returns Material Authorization (RMA) form with each console and sensor Item # to be recalibrated and specify either manufacturer calibration or ISO 17025 accredited calibration in the "Further Details" field, or 2) separately add each recalibration service Item # offered below to your cart.

| Posted Comments: | |

Mauricio B.

(posted 2025-01-17 14:51:08.69) Hi Thorlabs team,

First of all, you rock! I love all your products.

Second, I recently had some issues with my PM400. It was automatically disconnecting from the PC after being recognized on the Optical Power Monitor software for about 1-2 seconds. I thought it was a firmware issue, so I downloaded the latest firmware and proceeded to install it on the device. It again disconnected automatically in the middle of the installation process and now the power meter is stuck in the bootlader with "DFU error 10". Turning it on and off doesn't change the screen. Could you help me solve this issue?

Thanks in advance! you rockers! hkarpenko

(posted 2025-01-20 07:49:53.0) Dear customer,

thank you very much for your kind feedback. To resolve your issue I will contact you directly. Tom Shahaf

(posted 2024-09-15 22:41:28.29) hello, can you provide an example of a python code that use the device? jjadvani

(posted 2024-09-16 04:05:35.0) Dear Tom, Thank you for your feedback. Please find example code for python on the following link. https://github.com/Thorlabs/Light_Analysis_Examples/tree/main/Python/Thorlabs%20PMxxx%20Power%20Meters , Additional python code are included in the installation package of OPM software (https://www.thorlabs.com/software_pages/ViewSoftwarePage.cfm?Code=OPM ). You can find those example after installing software on this folder C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPMX\Examples\Python 李 李

(posted 2024-09-11 22:14:40.793) 功率计表头PM400语言无法切换,只能使用英文,请协助解决 jjadvani

(posted 2024-09-11 10:10:41.0) Dear Kangleek, Thank you for your feedback. Someone from local tech support team will contact you directly to troubleshoot your issue. Jideofor Odoeze

(posted 2024-08-17 04:07:57.11) Just asking if I cannot use this for LIV curve. I mean I know the Is current sweep. Having the console log the data, I can always figure out the x-axis. Is this console fast enough to respond to a fast sweep? 100kHz is fast enough I think.

Summarily, I want to know if I can use this for LIV curve measurement. hkarpenko

(posted 2024-08-19 11:23:24.0) Dear customer,

thank you very much for your feedback.

The bandwidth of the PM400 is limited to the USB bandwidth and CPU of your computer. You could achieve rates only up to 300Hz. The 100kHz full bandwidth can only be achieved when using the analog ouput of the console. In addition the bandwidth can even further decrease depending on the used sensor. I will contact you directly to find a solution with you. Boris Považay

(posted 2023-07-04 12:08:27.337) Any plans to offer this device with an USB-C-connector (especially for charging - mini-USB is already extinct)?

Best regards hkarpenko

(posted 2023-07-05 10:47:31.0) Dear Boris,

thank you very much for your feedback.

At the moment there is no plan for updating this device to USB-C, but we are logging your request and will definetly have this in mind for our next generation of power meters. But since we deliver this device with a mini-USB cable it should not be much of a problem of using the device. Ronald Sipkema

(posted 2023-05-02 13:32:20.657) I regularly use an S440C sensor in combination with the PM400 for laser beam alignment. I have the sensor mounted on a custom freely rotating "quick release" mount so I can position it at different locations in the beam path. The center of the four quadrants does not perfectly match the center of this mount though: I can find the center of the four quadrants by looking at the circular path the beam position makes when rotating the mount. It would be really nice if it were possible to "zero" the position the PM400 returns (either by zeroing it to the current position or by manual entry of the X and Y offsets). With that option added this would really be an ideal beam alignment tool. wskopalik

(posted 2023-05-03 02:50:10.0) Thank you very much for your feedback!

I will forward your suggestion to our engineering team so we can check if this feature can be added to the PM400 or to the GUI. user

(posted 2022-09-14 10:22:26.863) I can find two VI folders (TLPM and TLPMX) in the LabVIEW folder after installing the software for the power meter. Can you tell me the difference of these VIs? GBoedecker

(posted 2022-09-14 07:23:52.0) Thank you for your inquiry. TPLMX is the driver for the dual-channel power meter PM5020. For the other power meters, you can use TPLM. Y BoH

(posted 2021-03-09 02:59:53.623) It is such a shame that Thorlabs releases a product with such low quality language support. The Chinese translation is just garbage(Even google translation does a much better job than that!). If you have a colleague knowing Chinese, switch your PM400 with firmware 1.2.8 to Chinese(in display menu), and loop through other menus and pages, your colleague will sure laugh out loud.

I am willing to fix this for Thorlabs if Thorlabs give me a new PM400 for free. tcampbell

(posted 2021-03-10 08:26:27.0) Hello, and thank you for your honest feedback on our device's programming. We have begun working to improve the power meter console's Chinese translations. These improvements will be included in a firmware update in the near future. Michael L

(posted 2021-01-25 08:27:35.173) Hi,

how long does the startup take? I bought the previous model and that took extremely long to start up, compared to the older B/W screen models. soswald

(posted 2021-01-25 09:34:00.0) Dear Michael,

thank you for your feedback. The startup duration of the PM400 is typically a few seconds. zhaozhao mao

(posted 2020-12-08 01:01:28.267) 需要功率计表头和探头,1250~1550nm,mW级 wskopalik

(posted 2020-12-08 10:16:41.0) Thank you for your inquiry! We will contact you directly to provide further assistance. Juyoung Kim

(posted 2020-04-21 21:28:05.647) Dear PM400 support team,

I would like to confirm with the team with one question: Can C(++) talk to PM400 and get the power meter output and the instrument clock at the same time? I am pretty sure about this feature, but could you point me relevant C(++) functions? If possible, could you send me any example code for this basic operation? I would appreciate it much. Thank you.

Best regards,

Juyoung wskopalik

(posted 2020-04-22 11:49:39.0) This is a response from Wolfgang at Thorlabs. Thank you very much for your inquiry!

You would need to use two commands in this case. At first, you need to use one of the measurement commands, e.g. "TLPM_measPower" or "TLPM_measEnergy" depending on the sensor you use. After that, you can read the time by using "TLPM_getTime". This command is available on PM100D, PM200, and PM400 power meters and returns the time as it is set on the power meter. Alternatively, you can also read the time which is set on your computer by using a C/C++ library.

I will contact you directly to provide further assistance. Matt Dabrowski

(posted 2020-03-04 16:55:00.953) I am using a PM400. Recently, I went to update the firmware, and I connected the PM400 to the computer. When I used the latest OPM software to update the firmware I always got the following warning: "user abort the download operation" but I haven't done anything. Hoping for your answer. Thanks. Regards, Matt Dabrowski dpossin

(posted 2020-03-06 10:05:31.0) Dear Matt,

Thank you for your feedback. We are currently working on an firmware revision to eliminate this issue. We already contacted you regarding an solution. We will upload an firmware update on the website as soon as possible. user

(posted 2018-05-24 12:34:50.27) On your old PM100 Powermeters the display backlight could be turned off. Can the display on the PM400 also be turned off, while continuing to capture data via LabView/USB? mvonsivers

(posted 2018-06-07 03:56:07.0) This is a response from Moritz at Thorlabs. Thank you for your inquiry. The display cannot be completely turned off but the brightness can be dimmed to 1%. zahariev

(posted 2018-03-23 09:42:41.347) The power meter do the great job.

However I have a comment. Even been specified in the shipping list, the idea to sell it without power adapter (charger) could cos some inconvenience. swick

(posted 2018-04-16 04:40:04.0) This is a response from Sebastian at Thorlabs. Thank you for the feedback. We are glad to hear you are happy with our PM400.

The PM400 includes a USB cable which can be used to charge the device via USB ports. I understand that it would be helpful to have an USB charger included to the PM400. We will internally discuss your comment. arkke.eskola

(posted 2016-10-27 13:14:48.693) Hi,

I am thinking to buy PM400. Important option for my application would be to control it using LabVIEW, in my case LabVIEW2015. Do you have LabVIEW2015 drivers for PM400?

Thanks,

Arkke Eskola wskopalik

(posted 2016-10-28 03:59:43.0) This is a response from Wolfgang at Thorlabs. Thank you for your inquiry.

We provide LabView drivers as well as drivers for C/C++ and DotNet for the PM400. They are included in the installation package you can find here on the website.

I will contact you directly to provide further details. |

Click to Enlarge Figure G1.1 PM400 with S120C Photodiode Sensor (Available Below) and TSP-TH Temperature Sensor

- Compact Power Meter Console

- Projected Capacitive Touchscreen with Multi-Touch Technology

- Compatible with Over 30 Power and Energy Sensors (Available Below)

- Inputs for Third-Party and Custom Sensors

- 4 GB Internal Memory

- USB 2.0 Interface for Control via PC

Thorlabs' PM400 power meter console is compatible with over 30 power, position, and energy sensors, available below. When used with these sensors, the console will automatically detect and read the sensor calibration information stored in the sensor connector and combine this data with a user-set measurement wavelength to provide calibrated power or energy measurements. The console can also be used with third-party or custom sensors that meet the compatibility requirements outlined on the Specs tab.

Thorlabs offers recalibration services for the PM400 power and energy meter's electronics (see Item #s CAL-PM1 or CAL-PM1D below). Alternatively, if ordering a NIST traceable recalibration for a compatible sensor, the PM400 console recalibration can be included with the sensor recalibration at no additional cost (not available for the ISO 17025 accredited calibration option). See the bottom of the page for ordering information.

Click to Enlarge

Figure 614A S120C and CP44F Quick-Release Mount

- For General Purpose Optical Power Measurements

- Integrated Viewing Target for Easy Sensor Alignment

- Ø9.5 mm Sensor Aperture

- Sensor, Protective Cap, IR Target, and Thread Adapter Included

- Fiber Adapters Available Separately (See Table 614B)

- See the Full Web Presentation for More Information

These Standard Photodiode Power Sensors are ideal for metering low power coherent and incoherent sources from the UV to the NIR. Each NIST-Traceable, calibrated sensor features an integrated viewing target for easy alignment, enhanced shielding against electromagnetic interference, an over-temperature-alert device, and a large Ø9.5 mm sensor aperture. The sensors are compatible with 30 mm cage systems, Ø1/2" posts, and SM1 (1.035"-40) lens tubes, and are ideal for free-space and fiber-coupled sources.

Thorlabs offers recalibration services for these photodiode power sensors, which can be ordered below (see Item #s CAL-UVPD or CAL-UVPDD for UV-extended Si sensors, Item #s CAL-PD or CAL-PDD for Si sensors and Item #s CAL-IRPD or CAL-IRPDD for Ge sensors).

| Table 614B Specifications | ||||

|---|---|---|---|---|

| Item #a | S120VC | S120C | S121C | S122Ch |

| Sensor Image (Click the Image to Enlarge) |

||||

| Aperture Size | Ø9.5 mm | |||

| Wavelength Range | 200 - 1100 nm | 400 - 1100 nm | 400 - 1100 nm | 700 - 1800 nm |

| Power Range | 50 nW - 50 mW (200 - 450 nm) 50 nW - 20 mW (450 -1100 nm) |

50 nW - 50 mW | 500 nW - 500 mW | 50 nW - 40 mW |

| Detector Type | Si Photodiode (UV Extended) | Si Photodiode | Ge Photodiode | |

| Linearity | ±0.5% | |||

| Resolutionb | 1 nW | 10 nW | 2 nW | |

| Measurement Uncertaintyc | ±3% (440 - 980 nm) ±5% (280 - 439 nm) ±7% (200 - 279 nm, 981 - 1100 nm) |

±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

±5% | |

| Responsivityd (Click for Plot) | Raw Data |

Raw Data |

Raw Data |

Raw Data |

| Coating/Diffuser | Reflective ND (OD1.5)e | Reflective ND (OD1)f | Reflective ND (OD2)g | Absorptive ND (Schott NG9) |

| Head Temperature Measurement | NTC Thermistor 4.7 kΩ | |||

| Housing Dimensions | Ø30.5 mm x 12.7 mm | |||

| Cable Length | 1.5 m | |||

| Post Mountinge,f,g | Universal 8-32 / M4 Tap, Post Not Included | |||

| Aperture Thread | External SM1 (1.035"-40) | |||

| Compatible Fiber Adapters | S120-FC2, S120-FC, S120-APC2, S120-APC, S120-SMA, S120-ST, S120-LC, and S120-SC (Not Included) | |||

| Compatible Consoles | PM400, PM100D, PM100A, and PM5020 | |||

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | |||

Click to Enlarge Figure 615C S130C Sensor in a 30 mm Cage

Click for Details

Figure 615B SM1A29 SM1 Thread Adapter Mounted on a S130C Sensor

Click for Details Figure 615A S130C Photodiode Sensor Mounted in FiberBench System Using FBSM Mount

- For Optical Power Measurements in Confined Spaces

- Very Slim Design: 5 mm Thin on Sensor Side

- Ø9.5 mm Sensor Aperture

- Slideable ND Filter Automatically Changes Sensor Power Range

- Optional SM1A29 Adapter with VIS/IR Target and External SM1 Threading (More Details)

- Optional FBSM Mount with VIS/IR Target for FiberBench Systems (More Details)

- See the Full Web Presentation for More Information

These Slim Photodiode Power Sensors are designed to take optical source power measurements in locations where space and accessibility are at a premium. The 5 mm thin sensor end can fit between closely spaced optics, cage systems, and other arrangements where standard power meters may not fit. The NIST-Traceable, calibrated sensors also feature a large Ø9.5 mm sensor aperture and slideable neutral density filter for dual power ranges in one compact device.

A separately available SM1A29 adapter can be attached by 2 setscrews to any S130 series power sensor to mount fiber adapters, light shields, filters or any other SM1-threaded (1.035"-40) mechanics or optics. The FBSM Mount allows our S130 series power sensors to be mounted vertically into FiberBench systems for stable mounting with a minimal footprint.

Thorlabs offers recalibration services for these photodiode power sensors, which can be ordered below (see Item #s CAL-UVPD2 or CAL-UVPD2D for UV-extended Si sensors, Item #s CAL-PD2 or CAL-PD2D for Si sensors, and Item #s CAL-IRPD2 or CAL-IRPD2D for Ge sensors).

| Table 615D Specifications | |||||

|---|---|---|---|---|---|

| Item #a | S130VC | S130C | S132C | ||

| Sensor Image (Click the Image to Enlarge) |

|||||

| Aperture Size | Ø9.5 mm | ||||

| Wavelength Range | 200 - 450 nm | 450 - 1100 nm | 400 - 1100 nm | 700 - 1800 nmb | |

| Power Range (with Filter) |

500 pW - 0.5 mW (Up to 50 mW)c |

500 pW - 0.2 mW (Up to 20 mW)c |

500 pW - 5 mW (Up to 500 mW) |

5 nW - 5 mW (Up to 500 mW) |

|

| Detector Type | Si Photodiode (UV Extended) | Si Photodiode | Ge Photodiode | ||

| Linearity | ±0.5% | ||||

| Resolution | 100 pWd | 1 nWe | |||

| Measurement Uncertaintyf | ±3% (440 - 980 nm) ±5% (280 - 439 nm) ±7% (200 - 279 nm, 981 - 1100 nm) |

±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

±5% | ||

| Responsivityg (Click for Plot) | Raw Data |

Raw Data |

Raw Data |

||

| Coating/Diffuser | Reflective ND (OD1.5)c | Reflective ND (OD2)h | Absorptive ND (Schott NG9/KG3)b | ||

| Housing Dimensions | 150 mm x 19 mm x 10 mm; 5 mm Thickness on Sensor Side | ||||

| Cable Length | 1.5 m | ||||

| Post Mounting | 8-32 and M4 Taps | ||||

| Adapters (Not Included) | SM1A29: Add SM1 Thread and Viewing Target to Aperture Fiber Adapters Compatible with SM1A29 Adapter: S120-FC2, S120-FC, S120-APC2, S120-APC, S120-SMA, S120-ST, S120-SC, and S120-LC FBSM: Integrate Sensor into FiberBench Setups |

||||

| Compatible Consoles | PM400, PM100D, PM100USB, PM100A, and PM5020 | ||||

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | ||||

| Table 728A Specifications | ||

|---|---|---|

| Item #a | S116C | |

| Sensor Image (Click the Image to Enlarge) |

||

| Aperture Size | Ø6 mm | |

| Wavelength Range | 400 - 1100 nm | |

| Power Range | 20 nW - 50 mW | |

| Detector Type | Si Photodiode | |

| Linearity | ±0.5% | |

| Resolution | 1 nWb | |

| Measurement Uncertaintyc | ±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

|

| Responsivityd (Click for Plot) |

Raw Data |

|

| Coating/Diffuser | Absorptive ND (NG9) | |

| Housing Dimensions (L x W x T) |

70.0 mm x 11.0 mm x 8.9 mm; 10.0 mm Width and 4.5 mm Thickness on Sensor Side |

|

| Active Detector Area | 7 mm x 7 mm | |

| Cable Length | 1.5 m | |

| Mounting Threads | 2 Universal 8-32 / M4 Taps (One on the Back, One on the Bottom), Posts Not Included |

|

| Adapters (Not Included) |

SM05A29: Add SM05 Thread to Aperture Fiber Adapters Compatible with SM05A29 Adapter: PM20-FC2, PM20-FC, PM20-APC2, PM20-APC, PM20-SMA, PM20-ST, PM20-SC, and PM20-LC |

|

| Compatible Consoles | PM400, PM100D, PM100A, and PM5020 | |

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | |

- For Optical Power Measurements in Tiny Spaces Such as 16 mm Cage Systems

- Wavelength Range: 400 - 1100 nm

- Very Slim Design: 10.0 mm Wide and 4.5 mm Thin on Sensor Side

- Silicon Photodiode with Ø6 mm Sensor Aperture

- Designed for Power Measurements for Low Power Lasers

- Post Mountable via 8-32 (M4) Taps

- SM05A29 Adapter with External SM05 (0.535"-40) Threading Available Separately (More Details)

- See the Full Web Presentation for More Information

The S116C Compact Slim Photodiode Power Sensor is designed to take optical source power measurements in locations where space and accessibility are at a premium. The 4.5 mm thin photodiode sensor can fit between the rods of a 16 mm cage system, as seen in Figure 728C, as well as through the side openings of our slotted Ø1/2" lens tubes (Item #s SM05L20C and SM05L30C). This sensor also features a Ø6 mm sensor aperture.

A separately available SM05A29 adapter can be attached by two 0.05" (1.3 mm) hex setscrews to an S116C power sensor to mount fiber adapters, light shields, filters or any other SM05-threaded (0.535"-40) mechanics or optics. The adapter mounted on the S116C power sensor is shown in Figure 728B.

Each sensor is shipped with NIST- and PTB-traceable calibration data. The included data is determined with the help of a certified reference diode, which corresponds to the spectral range of the sensor to be calibrated. Thorlabs offers recalibration services for these photodiode power sensors, which can be ordered below (see Item #s CAL-PD or CAL-PDD for Si sensors).

Click to Enlarge Figure 728C S116C Sensor in a 16 mm Cage System

Click for Details

Figure 728B SM05A29 SM05 Thread Adapter (Sold Separately) Mounted on an S116C Sensor

Click for Details

Figure 616A Using the engraved alignment target on the back of the sensor housing, a user can position the stage so that when the sensor is flipped, the beam strikes the center of the sensor. The S170C sensor is shown in this image.

- Designed to Measure Optical Power at the Sample Plane of a Microscope

- Silicon Photodiode with Large 18 mm x 18 mm Active Area

- Sensor Housing Dimensions: 76.0 mm x 25.2 x 5.0 mm

- Novel Optical Design Accommodates High NA Objectives

- Information Stored in Connector

- Sensor Data

- NIST- and PTB-Traceable Calibration Data

- Post Mountable via 8-32 (M4 x 0.7) Tap

The Microscope Slide Power Sensor Heads with silicon photodiodes are designed to measure the power at the sample plane in microscopy setups. The S170C sensor can detect wavelengths from 350 nm to 1100 nm at optical powers from 10 nW to 150 mW. The NS170C sensor is designed to measure the relative peak power of femtosecond lasers with center wavelengths from 780 nm to 1300 nm and average powers from 0.5 mW to 350 mW. Each sensor head's 76.0 mm x 25.2 mm footprint matches that of a standard microscope slide and is compatible with most standard upright and inverted microscopes.

The photodiode used in the S170C sensor has 18 mm x 18 mm active area and is contained in a sealed housing behind a neutral density (ND) filter. A 20 mm x 20 mm indentation around the surface of the ND filter is sized to accept standard microscope cover slips. An immersion medium (water, glycerol, oil) may be placed in this well directly over the ND filter, or a cover slip may be inserted first to simplify clean up. The gap between the photodiode and the neutral density filter has been filled with an index matching gel in order to prevent internal reflections from causing significant measurement errors when using high NA objectives with oil or water.

The NS170C sensor is designed to measure the relative peak power of two-photon lasers by utilizing a second-order nonlinear β-BBO crystal to convert incident ultrafast NIR pulses into their visible second harmonic. Shortpass filters underneath the β-BBO crystal reject the residual NIR light, allowing only the second harmonic light to transmit down to a large area silicon photodiode sensor. At the entrance of the sensor is a 170 µm thick cover glass sealed to the sensor housing, allowing the sensor to be used with dry, water immersion, and oil immersion objectives. The working distance from the top of the cover glass to the β-BBO crystal is 0.22 mm.

The bottom of each sensor housing features a laser-engraved grid to aid in aligning and focusing the beam. In standard microscopes, this grid can be used for beam alignment before flipping the sensor head to face the objective for power measurements. In inverted microscopes, turn on the transmitted illuminator to align the grid on the detector housing with the beam, thereby centering the sensor in front of the objective. Alternatively, the diffusive surface of the ND filter can be used as a focusing plane.

To avoid damaging the sensor, we recommend positioning it in the light path at a location where the beam is not focused. It is important not to exceed the Max Average Power Density over the beam's spot size for the S170C sensor, and the Max Peak Power Density for the NS170C sensor (see Specs tab).

Each sensor is shipped with NIST- or PTB-traceable calibration data. The included data will match the calibration certification of the photodiode used to test the individual sensor. Sensor specifications and the included NIST- or PTB-traceable calibration data are stored in non-volatile memory in the sensor connector and can be read out by the latest generation of Thorlabs power meters. Please note that the NS170C sensor's NIST and PTB calibration is for the visible light incident on the detector; however, the magnitude of that visible light is specific to the illumination conditions of the NIR femtosecond pulses. We recommend yearly recalibration to ensure accuracy and performance, which can be ordered below (see Item #s CAL-PD or CAL-PDD for the S170C sensor, and Item # CAL-NS for the NS170C sensor). Please contact Tech Support for more information.

The complete set of specifications are presented on the Specs tab. Thorlabs also offers a Microscope Slide Sensor Head with a thermal sensor; the full presentation can be found here.

| Item #a | S170C | NS170C |

|---|---|---|

| Sensor Image (Click Image to Enlarge) |

|

|

| Dimensions | 76.0 mm x 25.2 mm x 5.0 mm (2.99" x 0.99" x 0.20") |

Base: 76.0 mm x 25.2 mm x 5.0 mm (2.99" x 0.99" x 0.20") Overall: 76.0 mm x 30.0 mm x 11.0 mm (2.99" x 1.18" x 0.43") |

| Active Detector Area | 18 mm x 18 mm | |

| Input Aperture | 20 mm x 20 mm | Ø4.5 mm |

| Wavelength Range | 350 - 1100 nm | Laser: 780 - 1300 nm SHG: 390 - 650 nm |

| Optical Power Working Range | 10 nW - 150 mW | Laser: 0.5 - 350 mWb SHG: 10 nW - 5 mW |

| Max Peak Power Densityc | - | 10 TW/cm2 |

| Detector Type | Silicon Photodiode | Second-Order Nonlinear Crystal with Silicon Photodiode |

| Linearity | ±0.5% | ±0.5%d |

| Resolution | 1 nWe | 1 nWd,e |

| Measurement Uncertaintyf | ±3% (440 - 980 nm) ±5% (350 - 439 nm) ±7% (981 - 1100 nm) |

±3% (440 - 650 nm)d ±5% (390 - 439 nm)d |

| Responsivityg (Click for Plot) |

Raw Data |

Raw Data |

| Neutral Density Filter | Reflective (OD 1.5) | N/A |

| Cable Length | 1.5 m | |

| Mounting Thread | Universal 8-32 / M4 x 0.7 Tap, Post Not Included | |

| Compatible Consoles | PM400, PM100D, PM100A, and PM5020 | |

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | |

| Table 617B Specifications | |

|---|---|

| Item #a | S175C |

| Sensor Image (Click Image to Enlarge) |

|

| Active Detector Area | 18 mm x 18 mm |

| Wavelength Range | 0.3 - 10.6 µm |

| Power Range | 100 µW - 2 W |

| Detector Type | Thermal Surface Absorber (Thermopile) |

| Linearity | ±0.5% |

| Resolutionb | 10 µW |

| Measurement Uncertaintyc | ±3% @ 1064 nm; ±5% @ 300 nm - 10.6 µm |

| Response Time | 3 s (<2 s from 0 to 90%) |

| Housing Dimensions | 76 mm x 25.2 mm x 4.8 mm (2.99" x 0.99" x 0.19") |

| Cable Length | 1.5 m |

| Housing Features | Integrated Glass Cover Engraved Laser Target on Back |

| Post Mounting | N/A |

| Cage Mounting | N/A |

| Aperture Thread | N/A |

| Compatible Consoles | PM400, PM100D, PM100A, and PM5020 |

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM102, PM102A, PM102U, and PM100USB |

Click to Enlarge

Figure 617A Typical absorption curve for the S175C (glass and absorber). Note that this curve is representative, and the actual absorption across the spectrum will vary from unit to unit.

Click to Enlarge

Figure 617C The back of the S175C housing is engraved with the sensor specifications and a target for centering the beam on the sensor.

- Wavelength Range: 300 nm - 10.6 µm

- Sensitive to Optical Powers from 100 µW to 2 W

- Designed to Measure Optical Power in the Sample Plane of a Microscope

- Thermal Sensor with 18 mm x 18 mm Active Area

- 76.0 mm x 25.2 mm Footprint Matches Standard Microscope Slides

- Information Stored in Connector

- Sensor Data

- NIST- and PTB-Traceable Calibration Data

- See the Full Web Presentation for More Information

The S175C Microscope Slide Thermal Power Sensor Head is designed to measure the power at the sample in microscopy setups. The thermal sensor can detect wavelengths between 300 nm and 10.6 µm at optical powers between 100 µW and 2 W. The sensor head's 76.0 mm x 25.2 mm footprint matches that of a standard microscope slide and is compatible with most standard upright and inverted microscopes.

The thermal sensor has an 18 mm x 18 mm active area and is contained in a sealed housing behind a glass cover. An immersion medium (water, glycerol, oil) may be placed over the glass cover plate.

As seen in Figure 617C, the bottom of the sensor housing features a laser-engraved target to aid in aligning and focusing the beam. In standard microscopes, the target can be used for beam alignment before flipping the sensor head to face the objective for power measurements. In inverted microscopes, turn on the trans-illumination lamp and align the target on the detector housing with the beam; this will center the sensor in front of the objective.

Sensor specifications and the NIST- and PTB-traceable calibration data are stored in non-volatile memory in the sensor connector and can be read out by the latest generation of Thorlabs power meters. We recommend yearly recalibration to ensure accuracy and performance. Calibration may be ordered using the CAL-THPY recalibration service available below. Please contact technical support for more information.

Thorlabs also offers a Microscope Slide Sensor Head with a photodiode sensor for low-power, high-resolution measurements; the full presentation may be found here.

Click to Enlarge

Figure 618B S142C and S140-BFA Bare Fiber Adapter (Sold Separately)

Click to Enlarge

Figure 618A S142C with the S120-FC Fiber Adapter (Included)

- For Measurements Independent of Beam Shape and Entrance Angle

- Integrating Sphere Design Acts as a Diffuser with Minimal Power Loss

- Ø5 mm, Ø7 mm, Ø12 mm, or Ø22 mm Input Sensor Aperture

- Spheres with Apertures ≤Ø12 mm Include a Removable S120-FC Fiber Adapter (FC/PC and FC/APC)

- Fiber Adapters for Terminated and Bare Fiber (See Table 618D) are Compatible with Spheres with Apertures ≤Ø12 mm

- See the Full Web Presentation for More Information

These Integrating Sphere Photodiode Power Sensors are the ideal choice for power measurements independent of beam uniformity, divergence angle, beam shape, or entrance angle, making them excellent for use with fiber sources and off-axis free space sources. They feature enhanced shielding to avoid electromagnetic interference and an over-temperature alert sensor to warn against damage and measurement errors due to overheating of the sensor.

Our integrating spheres are designed for wavelength ranges from the visible through the NIR. Sensor heads for use between 350 and 2500 nm use a single Ø1" or Ø2" sphere made from Zenith® PTFE and feature a black housing to minimize reflected light around the entrance aperture. These sensors use either a silicon photodiode for detection in the 350 - 1100 nm range or an InGaAs photodiode for detection in the 800 - 1700 nm, 900 - 1650 nm, or 1200 - 2500 nm wavelength range.

The S180C integrating sphere for 2.9 - 5.5 µm uses two connected, gold-plated Ø20 mm spheres, with an entrance port in the first sphere and a port for the MCT (HgCdTe) detector located in the second sphere. Compared to single-sphere designs, the two-sphere configuration improves device sensitivity by minimizing the internal sphere surface area while still effectively shielding the detector from direct illumination. This design reduces the effect of input angle, divergence, and beam shape on the measurement result by effectively shielding the photodiode without the use of a baffle or other shielding mechanism.

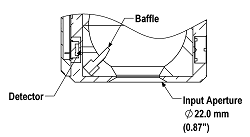

Click to Enlarge

Figure 618C A baffle on the S142CL and S145CL spheres blocks light from directly hitting the detector.

The integrating spheres with Ø5 mm, Ø7 mm, or Ø12 mm apertures feature large active detector areas, and externally SM1-threaded (1.035"-40) adapters for compatibility with the included S120-FC fiber adapter. Because of the large active detector areas of these sensors, the included S120-FC fiber adapter can be used with FC/PC- or FC/APC-terminated fiber. The externally SM1-threaded adapter can be removed using a size 1 screwdriver to place components closer to the window.

The S142CL and S145CL integrating spheres feature a large Ø22 mm input aperture and a baffle within the sphere which prevents direct illumination of the photodiode. The large aperture and baffle enable measurements of large and divergent beams, such as those emitted from LED and VCSEL light sources. The input face of the detectors have four 4-40 threads for mounting 30 mm cage system components. Additionally, insertion of a second or third port in the sensor head is possible on request, please contact Tech Support for details.

Each sensor is shipped with NIST- or PTB-traceable calibration data. The included data will match the calibration certification of the photodiode used to test the individual sensor. NIST- or PTB-traceable data is stored in the sensor connector. Thorlabs offers recalibration services for these photodiode power sensors, which can be ordered below (see Item #s CAL-PD or CAL-PDD for Si sensors, Item #s CAL-IRPD or CAL-IRPDD for InGaAs sensors, Item # CAL-MIRPD for extended InGaAs or MCT sensors, or Item # CAL-MIRPDD for extended InGaAs sensors).

| Table 618D Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item #a | S140C | S142C | S142CL | S144C | S145C | S145CL | S146C | S148C | S180C | |

| Sensor Image (Click the Image to Enlarge) |

|

|

|

|

|

|

|

|

|

|

| Aperture Size | Ø5 mm | Ø12 mm | Ø22 mm | Ø5 mm | Ø12 mm | Ø22 mm | Ø12 mm | Ø5 mm | Ø7 mm | |

| Wavelength Range | 350 - 1100 nm | 400 - 1100 nm | 800 - 1700 nm | 900 - 1650 nm | 1200 - 2500 nm | 2.9 µm - 5.5 µm | ||||

| Power Range | 1 µW - 500 mW | 1 µW - 5 W | 10 µW - 5 W | 1 µW - 500 mW | 1 µW - 3 W | 10 µW - 3 W | 10 µW - 20 W | 1 µW - 1 W | 1 µW - 3 W | |

| Detector Type | Si Photodiode | Si Photodiode with Baffle | InGaAs Photodiode | InGaAs Photodiode with Baffle | InGaAs Photodiode | Extended InGaAs Photodiode | MCT (HgCdTe) Photodiode |

|||

| Linearity | ±0.5% | |||||||||

| Resolutionb | 1 nW | 10 nW | 1 nW | 10 nW | 1 nW | 10 nW | ||||

| Measurement Uncertaintyc,d |

±3% (440 - 980 nm) ±5% (350 - 439 nm) ±7% (981 - 1100 nm) |

±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

±5% | |||||||

| Responsivitye (Click for Plot) |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

|

| Integrating Sphere Material (Size) |

Zenith® PTFE (Ø1") |

Zenith® PTFE (Ø2") |

Zenith® PTFE (Ø1") |

Zenith® PTFE (Ø2") |

Zenith® PTFE (Ø1") |

Gold Plating (Two Ø20 mm Spheres) |

||||

| Head Temperature Measurement |

NTC Thermistor 4.7 kΩ | |||||||||

| Housing Dimensions |

Ø45 mm x 30.5 mm | 70 mm x 74 mm x 70 mm | Ø45 mm x 30.5 mm | 70 mm x 74 mm x 70 mm | Ø45 mm x 30.5 mm | 59.0 mm x 50.0 mm x 28.5 |

||||

| Active Detector Area | 3.6 mm x 3.6 mm | Ø2 mm | Ø3 mm | Ø1 mm | Ø1 mm | 1 mm x 1 mm | ||||

| Cable Length | 1.5 m | |||||||||

| Mounting Thread | Separate 8-32 and M4 Taps, Posts Not Included | Universal 8-32 / M4 Thread, Post Not Included | Separate 8-32 and M4 Taps, Posts Not Included | Universal 8-32 / M4 Thread, Post Not Included | Separate 8-32 and M4 Taps, Posts Not Included | Universal |

||||

| Aperture Thread | Included Adapter with SM1 (1.035"-40) External Thread | None | Included Adapter with SM1 (1.035"-40) External Thread | None | Included Adapter with SM1 (1.035"-40) External Thread | |||||

| Compatible Fiber Adapters |

S120-FC (Included) S120-FC2, S120-APC2, S120-APC, S120-SMA, S120-ST, S120-SC, S120-LC, S120-25, and S140-BFA (Not Included) |

None | S120-FC (Included) S120-FC2, S120-APC2, S120-APC, S120-SMA, S120-ST, S120-SC, S120-LC, S120-25, and S140-BFA (Not Included) |

None | S120-FC (Included) S120-FC2, S120-APC2, S120-APC, S120-SMA, S120-ST, S120-SC, S120-LC, S120-25, and S140-BFA (Not Included) |

|||||

| Compatible Consoles | PM400, PM100D, PM100A, and PM5020 | |||||||||

| Compatible Interfaces | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | |||||||||

Click to Enlarge

Figure 619A PM100D with S150C Sensor and FC Cable

- For Fiber-Based Optical Power Measurements

- Compact Sensor Integrated into the Connector

- Integrated Design for Use in the Field and Lab

- Includes PM20-FC Fiber Adapter

- S150C and S151C Sensors also Include PM20-SMA Adapters

- Compatible FC/APC, LC/PC, SC/PC, and ST®* Fiber Adapters Also Available (See Table 619B)

- See the Full Web Presentation for More Information

The S15xC Compact Fiber Photodiode Power Sensor is designed to take power measurements from a wide variety of fiber coupled sources. The compact sensor, integrated into the power meter connector, features a unique integrated design housing the photodiode sensor, fiber coupling, and NIST-traceable data. Standard FC (and SMA - S150C and S151C) connectors are easily interchanged with a variety of standard fiber connectors.

Thorlabs offers recalibration services for these photodiode power sensors, which can be ordered below (see Item #s CAL-PD or CAL-PDD for Si sensors and Item #s CAL-IRPD or CAL-IRPDD for InGaAs sensors).

*ST® is a registered trademark of Lucent Technologies, Inc.

| Table 619B Specifications | ||||

|---|---|---|---|---|

| Item #a | S150C | S151C | S154C | S155C |

| Sensor Image (Click the Image to Enlarge) |

||||

| Included Connectors | FCb & SMA | FCb | ||

| Wavelength Range | 350 - 1100 nm | 400 - 1100 nm | 800 - 1700 nm | |

| Power Range | 100 pW to 5 mW (-70 dBm to +7 dBm) |

1 nW to 20 mW (-60 dBm to +13 dBm) |

100 pW to 3 mW (-70 dBm to +5 dBm) |

1 nW to 20 mW (-60 dBm to +13 dBm) |

| Detector Type | Si Photodiode | InGaAs Photodiode | ||

| Linearity | ±0.5% | |||

| Resolutionc | 10 pW (-80 dBm) | 100 pW (-70 dBm) | 10 pW (-80 dBm) | 100 pW (-70 dBm) |

| Measurement Uncertaintyd | ±3% (440 - 980 nm) ±5% (350 - 439 nm) ±7% (981 - 1100 nm) |

±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

±5% | |

| Responsivityf (Click for Details) | Raw Data |

Raw Data |

Raw Data |

Raw Data |

| Coating/Diffuser | N/A | Absorptive ND (Schott NG3) | N/A | |

| Head Temperature Measuremente | NTC Thermistor 3 kΩ | |||

| Aperture Thread | External SM05 (0.535"-40) | |||