XT66 66 mm Optical Construction Rails

- Five Stock Lengths up to 2000 mm for 4-Sided Rails

- 1-, 2-, or 4-Sided Rails

- Custom Lengths Available from 50 to 2000 mm

XT66DP-500

Double Dovetail

XT66SP-1000

Single Dovetail

XT66-500

Standard 66 mm Rail

XT66SD-250

Single Dovetail

Please Wait

| XT66 66 mm Optical Rail Accessories | |||||

|---|---|---|---|---|---|

|

|

|

|

|

|

| Rails | Clamps and Angle Brackets | Mounting Platforms |

Rail Platform Positioners |

Rail Carriage | |

|

|

|

|

|

|

| Breadboard Mounting |

Rotation Slide Platform |

Cage System Mounts |

Lens Tube Adapter |

Rail Joiner | Size Adapters |

Features

- 66 mm Optical Rails

- Stock Lengths Range from 100 mm to 2000 mm

- Dovetail Profile Enables Clamping to Optomechanical Assemblies or Other Rails

- Single and Double Dovetail Versions with Reduced Footprint

- Custom Rail Lengths Offered

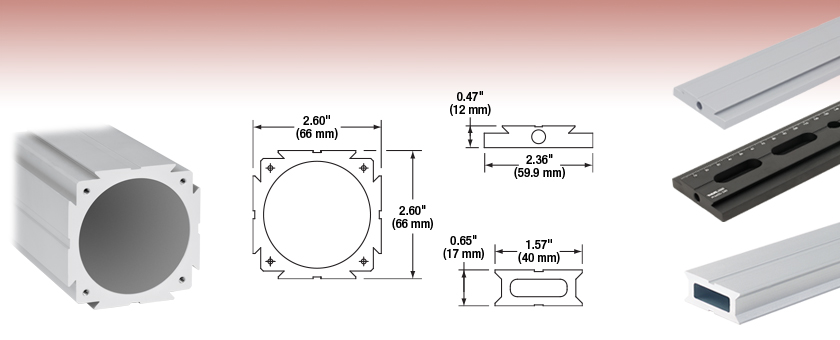

Thorlabs' XT66 Optical Rails provide the building blocks necessary for constructing stable, rigid, three-dimensional mechanical assemblies. They consist of extruded lengths of aluminum with a dovetail mounting surface that allows rails to be joined to each other, breadboards, or other optomechanical assemblies. Mounted objects can easily traverse the full length of these dovetails without interruption. The 66 mm rail series includes rails that have the dovetail on one, two, or four sides, as shown in the photos at the top of the page. These dovetail rails feature either a clear or a black anodized coating.

The standard four-sided clear anodized rails measure 66 mm to a side and are available from stock in lengths ranging from 100 to 1000 mm. Upon request, we can ship these rails in custom lengths from 50 mm to 2000 mm. The standard four-sided rails are also offered in a raw extrusion length of 2 m (6.6').

We offer two-sided rails with clear anodization in lengths of 500 or 1000 mm from stock. These rails are also offered as a 2 m (6.6’) rough-cut, unanodized extrusion for customers who prefer to machine and finish their own rails.

The single dovetail rails have a compact design that provides additional mounting flexibility when constructing optical rail systems. Thorlabs offers 500 mm and 1000 mm long rails with a durable clear anodized finish. They do not include counterbored holes for mounting or an engraved scale. We also offer one-sided rails that include counterbores for mounting to an optical table without the need for clamps. These counterbored rails have a black anodized finish and an engraved scale in 1 mm increments for precise and repeatable positioning along the length of the rail. They are available in lengths from 250 mm to 750 mm.

Thorlabs offers an extensive selection of accessories for 66 mm rails, including clamps and angle brackets, breadboard mounts, mounting platforms, rail carriages, rail platform positioners, rotation slide platforms, rail joiners, and lens tube adapters. Together with size adapters that incorporate 34 mm and 95 mm rails into an XT66 setup, these tools provide a complete family of rigid, versatile building blocks suited for virtually any optomechanical setup.

| Optical Rail Selection Guide | ||||||

|---|---|---|---|---|---|---|

| 19 mm Dovetail | 25 mm Square | 34 mm Square & Dovetail | 50 mm Square & Rectangular | 66 mm Square & Dovetail | 75 mm Square & Rectangular | 95 mm Square & Dovetail |

Application Idea: A Simple Periscope

The photographs to the left depict a simple periscope constructed using our 66 mm rail system. The two photos display the same setup from two different angles in order to clearly show how each part has been integrated. The labeled parts correspond to a row in the upper table, while the lower table shows the clamps and optical mounts used throughout the periscope.

Please note that lenses and mirrors, which are not shown in the tables below, would also be required.

| Label | Item # | Description | Product Image |

|---|---|---|---|

| 1 | XT66-500 | 66 mm Construction Rail, L = 500 mm |  |

| 2 | XT66D2 | 50 mm Long Slotted Dovetail with One Z-Axis Counterbored Slot |  |

| 3 | XT66D2-50 | 50 mm Long XT66 Platform with Three 1/4"-20 (M6) Counterbores |  |

| 4 | XT66RA2 | Right-Angle Clamp for 66 mm Rails |  |

| 5 | XT66DP-500 | 66 mm Double Dovetail Rail, L = 500 mm |  |

| 6 | XT66DE1 | 20 mm Long, 1/4"-20 Tapped Dovetail for 66 mm Rails |  |

| Additional Items | |||

| XT66C1 | 20 mm Long Double Dovetail Clamp for 66 mm Rails |  |

|

| XT66C2 | 40 mm Long Double Dovetail Clamp for 66 mm Rails |  |

|

| MA45-2 | 45° Mounting Adapter, Compatible with KM100 and KM200 |  |

|

| KM100 | Ø1" Kinematic Mirror Mount |  |

|

| LMR1 | Ø1" Lens Mount |  |

|

| Posted Comments: | |

tom.lummen

(posted 2018-07-25 13:48:22.12) Hi,

I was wondering if a longer version of this product (with L=1000mm) would be an option?

And if so, what would be the lead time?

Best,

Tom YLohia

(posted 2018-07-25 09:10:35.0) Hello Tom, thank you for contacting Thorlabs. I will reach out to you directly to discuss the possibility of offering this custom item. davyG

(posted 2018-04-20 09:45:52.71) I would like to see the following accessories:

1. Thumbscrew adjustable carriers (as Bennettd suggested previously. (See Newport X48 system)

2. Non-slip level adjustable feet and mid supports for the dovetail version(s). (Not all environments can justify having leveled optical tables/breadboards). (See Newport X48 system).

3. A way of joining the dovetail rails - in line and at right angles (I suggest separate products for cost reasons). The working surface of the rails should be on the same level. mmcclure

(posted 2018-04-20 10:16:54.0) This is a response from Matt at Thorlabs: Thank you very much for your valued feedback. I have posted your suggestions to our internal engineering forum, where we will discuss these ideas and consider them for future development. bennettd

(posted 2016-04-02 15:22:19.03) comparable rails from OWIS (http://www.owis.eu/home/) have counterbored holes down the middle for breadboard mounting. OWIS' rail carriers also have thumbscrews. Both of these features are extremely convenient and lacking from Thorlabs' otherwise excellent rail offerings. besembeson

(posted 2016-04-05 10:48:47.0) Response from Bweh at Thorlabs USA: Thanks for your feedback. We have these for the dovetail optical rails (http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=30). At the moment, we do provide several suitable mounting accessories for the XT66 series (http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=3717). We will review your suggested features for our XT66 rails. ludoangot

(posted 2016-02-03 12:00:44.397) Hello, I have questions about 2 topics:

1) Are rails (66mm and others) black inside, to avoid stray light when used as lens tubes? If not, could you offer this option (black anodization inside)? And if not, I would consider using your Black Flocked self-Adhesive Paper but I'm not sure it can easily be applied, do you have any other solution?

2) you offer 100, 200 then 500mm. 300mm is a convenient length too, could you offer it as a standard length, that would allow one not to have to pay about 3 times the price for a custom length compared to a standard length. Thank you! besembeson

(posted 2016-02-04 11:21:27.0) Response from Bweh at Thorlabs USA: The standard 66mm rails are not black anodized inside but this can be provided as a special item for now. You may also use the black flocked paper (varying short sections) like mentioned on the clear anodized one. Though a continuous 300mm version sounds convenient, you can get this using the 100mm and 200mm versions with a joiner, such as the XT66J (http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=6644) iain.tullis

(posted 2015-05-07 23:39:46.63) I'm interested in the XT66SP and XT66C4 combo.

What is the spacing between the bottom of the -SP and the top mounting surface of the C4?

This info might be useful for all the rail types and clamps. cdaly

(posted 2015-05-11 11:55:41.0) Response from Chris at Thorlabs: The height of XT66C4 mounted to XT66SP will be 0.937". cbrideau

(posted 2012-10-17 15:45:30.24) The only problem with that is it doesn't resist torque along the optical axis very well; the whole assembly would be a bit too free to rotate unless it was additionally supported. jlow

(posted 2012-10-12 16:43:00.0) Response from Jeremy at Thorlabs: One could possibly use the XT34SM1 and the XT66SM2 for this purpose. Since these are internally threaded, you could then use a coupler such as SM1T2 or SM2T2 to attach the 30mm or 60mm cage plates on it. cbrideau

(posted 2012-10-12 15:19:13.747) Something like the XT66RL2 joiner that transitions into the 60mm cage system would be useful. One that goes from XT34 to the 30mm cage system would also be nice. That way a long '34 or '66 series rail could support two cage assemblies at opposite ends. |

- Tapped with Four M3 Holes at the Corners on Both Sides for Mounting

- Ø55 mm Clear Aperture Through Rail

- Durable, Clear Anodized Coating

Our standard 66 mm Construction Rails have a dovetail mounting surface on all four sides for use in one-, two-, or three-dimensional constructions. Objects can be slid along the dovetail before being clamped into place. The rail ends are tapped with four M3 holes for mounting lens tube adapters, mounting plates, rail carriages, or rail joiners.

These rails are offered in five stock lengths: 100 mm, 200 mm, 500 mm, 750 mm, and 1000 mm. If our pre-cut lengths do not suit your application, custom lengths from 50 mm - 2000 mm can be ordered by either using the XT66-CUSTRAIL field in the price box below or contacting Technical Support.

These construction rails are also offered as a rough-cut, unanodized extrusion (see below) for our customers who prefer to machine and finish the rails themselves.

- Unanodized Extrusion for Custom Applications

- 2 m (6.6') Length

- Rail Ends Are Not Tapped

The XT66RL2 is an unanodized, rough-cut extrusion for customers who prefer to machine and finish their own rails. Their aluminum construction makes it easy to machine them in your own machine shop.

Upon request, we can provide this raw extrusion in lengths up to 3.0 m (9.84'). Please contact Technical Support for a quote.

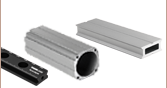

- Versatile Double Dovetail Profile, Ideal for Coupling Two XT66 Rails

- Durable, Clear Anodized Finish

The XT66DP's double dovetail design allows two 66 mm rails to be coupled together using Double Dovetail Clamps. As shown at right, this feature allows aligned optical assemblies to be coupled to a base rail and moved as a complete sub-assembly.

These rails are also offered as a rough-cut, unanodized extrusion (see below) for our customers who prefer to machine and finish the rails themselves.

- Unanodized Extrusion for Custom Applications

- 2 m (6.6') Length

The XT66DPRL2 is an unanodized, rough-cut double dovetail extrusion for customers who prefer to machine and finish their own rails. Their aluminum construction makes it easy to machine them in your own machine shop.

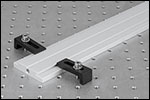

Click to Enlarge XT66SP Held with CL5 Table Clamps

Click to Enlarge

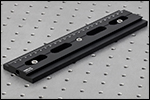

Click to EnlargeXT66SD-250 Mounted to Table with our Standard Cap Screws

- 66 mm Rail with Smallest Footprint for One-Dimensional Constructions

- XT66SP: Clear Anodized Finish

- XT66SD: Black Anodized Finish with Mounting Counterbores and Engraved Scale

These rails each have a compact, single dovetail design that provides additional mounting flexibility when constructing optical rail systems. The XT66SP-500 and XT66SP-1000 are 500 mm and 1000 mm long, respectively, and have a durable clear anodized finish. They do not include counterbored holes for mounting or an engraved scale. Each can be easily mounted to an optical table using our compact table clamps.

The XT66SD series of rails ranges from 250 mm to 750 mm in length and has a black anodized finish. These rails include 1 to 5 central 1/4" (M6) counterbored holes and 4 to 12 surrounding 1" long, 1/4" (M6) counterbored slots for direct mounting to an optical table with a metric or imperial hole pattern. A schematic diagram showing mounting hole locations can be downloaded by clicking on the red icon to the left of each part number below. When standard 1/4"-20 (M6) cap screws are used, as shown in the leftmost of the three images above, full uninterrupted travel along the length of the rails is possible. A scale with 1 mm increments is engraved along the length of each XT66SD rail for precise and repeatable positioning.

Products Home

Products Home

Zoom

Zoom

66 mm Optical Rails

66 mm Optical Rails