95 mm Optical Construction Rails

- Stock Lengths from 66 mm to 2000 mm

- 1- or 4-Sided Rails

- Precision Rails with Higher Parallelism Tolerance Available

- Custom Lengths Available

XT95SD-500

One-Sided Rail

XT95-250

Standard

95 mm Rail

Eight M6

Taps on

Each End

Side-Located T-Slots Accept

Rail Plates, Adapters, or T-Nuts

XT95EC1

95 mm Rail End Plate

Please Wait

| XT95 95 mm Optical Rail Accessories | |||

|---|---|---|---|

|

|

|

|

| Rails | Angle Adapters | Leveling Feet | |

|

|

|

|

| Breadboard Mounting |

Mounting Platforms |

T-Nuts and Screws |

Size Adapters |

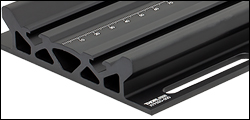

Click to Enlarge Clamping Mechanism Using T-Slots and T-Nuts

Click to Enlarge

95 mm Optical Rails with XT95EC1 End Plates (Sold Separately)

Features

- 95 mm Optical Construction Rails

- Stock Lengths Range from 66 mm to 2000 mm

- Accommodates Optomechanical Components using T-Slots, Outer Wings, or M6 Taps

- Clear-Anodized or Black-Anodized Versions Available

- One-Sided Version Features Clearance Slots for Mounting to an Optical Table

- Custom Rail Lengths Offered

Thorlabs' XT95 Optical Rails are our largest and most rigid construction rails. They consist of extruded lengths of aluminum, and each rail side features a linear mounting surface with two T-slots and two outer wings that span the rail length. Their precision construction allows large-scale optical assemblies to be translated along the rail axis with excellent mechanical stability. Originally designed for vacuum-tight flight paths, these optical rails are ideal building blocks for three-dimensional, load bearing structures; large-scale optical instrumentation setups; or modular, expandable assemblies that require the highest degree of support. The outer wings, which provide additional stability against longitudinal and torsional pressures, are tapped with eight M6-threaded holes.

The standard four-sided rails measure 95 mm to a side and are available in six stock lengths, ranging from 250 to 2000 mm. Precision rails, which have a ±10 arcmin parallelism tolerance on the rail ends, are available in lengths ranging from 66 to 600 mm. Upon request, we can ship the finished standard four-sided rails in any length from 50 to 2000 mm, or we can provide the raw rail extrusion in lengths up to 3.048 m (10'). Precision rails can also be customized up to 2000 mm in length. Finished standard rails feature a durable, clear-anodized coating, while the precision rails feature a black-anodized coating.

Our standard one-sided rails include clearance slots for securing the rails horizontally to an optical table. They are available in either 500 mm or 1000 mm lengths with a durable, clear-anodized coating or in 250 mm, 500 mm, or 750 mm lengths with a black-anodized coating. The one-sided black-anodized rails feature an engraved scale in 1 mm increments for precise and repeatable positioning along the length of the rail. Custom one-sided clear-anodized rails from 50 mm to 2000 mm lengths and custom black-anodized rails from 50 mm to 750 mm lengths can be ordered by contacting Tech Support.

Thorlabs' product family for 95 mm rails includes angle adapters, leveling feet, and breadboard mounting adapters. In addition, we manufacture mounting platforms and T-nuts that provide compatibility with standard optomechanics. Together with size adapters that incorporate 66 mm rails into an XT95 setup, these tools provide a complete family of rigid, versatile building blocks suited for virtually any optomechanical setup.

An end plate is available below for our 95 mm Construction Rails and 95 mm Precision Construction Rails. The end plate covers the entire end of the rail, decreasing the risk of harm due to sharp edges.

| Optical Rail Selection Guide | ||||||

|---|---|---|---|---|---|---|

| 19 mm Dovetail | 25 mm Square | 34 mm Square & Dovetail | 50 mm Square & Rectangular | 66 mm Square & Dovetail | 75 mm Square & Rectangular | 95 mm Square & Dovetail |

| Posted Comments: | |

Carlos Reyes

(posted 2022-02-16 03:57:11.387) Hello, I am currently designing an optomechanical setup using two xt95-20 90deg to each other. Could you contact me so I can double check that the rail will be able to hold all the weight of the rest of the optical components? Thanks jdelia

(posted 2022-02-23 01:50:06.0) Thank you for contacting Thorlabs. I have contacted you directly to discuss your application. Fatih Toy

(posted 2021-01-27 19:23:37.06) Hello, What is the tolerance of the length for XT95B-500 and XT95-500? We would like to use couple of them (either XT95-500 or XT95B-500) as the legs of a setup where the top is required to be level. Thanks YLohia

(posted 2021-01-27 10:21:38.0) Hello, thank you for contacting Thorlabs. The length tolerances for both the XT95B-500 and the XT95-500 is 19.685" +/- 0.005". user

(posted 2019-09-23 06:29:40.027) Hi - I agree with ludoangot's 2016 post regarding the need for a 95mm rail adapter plate to SM3 internal threads. Any chance of this please?

(a 6-way corner cube, or a lid for the XT95C1 would also be very useful)

Thanks nbayconich

(posted 2019-09-24 10:04:18.0) Thank you for contacting Thorlabs. I will reach out to you directly to discuss our custom capabilities. mikael.malmstrom

(posted 2019-02-05 10:00:01.143) Does the Eight holes on the ends go through the hole length of the rail. In other words, can I send cooling water through the holes? llamb

(posted 2019-02-05 03:13:17.0) Thank you for contacting Thorlabs. The M6 tapped holes on the ends of our 95 mm rails are not thru holes, but in fact have a thread depth of 1". ludoangot

(posted 2016-11-16 14:49:26.467) Hello, I welcome the introduction of your precision construction rail, anodized in black. Besides their intended use as optical rails (I've ordered one), I see the possibility to use them as long lens tube. For this it would be very useful that you offer a lens tube adapter plate, the equivalent of your XT66SM2, either or both for SM2 and SM3. If you make such adapter, how long would it take to see it in your catalog? tfrisch

(posted 2016-11-28 02:38:26.0) Hello, thank you for contacting Thorlabs. I see that you are already in contact with Technical Support about this custom request. We will also post this in our engineering forum. martin.gersing

(posted 2016-10-21 12:22:29.21) Dear Thorlabs,

could you provide me with information about the manufacturing tolerances (especially the straightness-tolerances) of your XT95SP-1000 one-sided rail? Thanks in advance. jlow

(posted 2016-10-24 04:27:32.0) Response from Jeremy at Thorlabs: The straightness specification for the 1m long rail is 0.041". jbrooker

(posted 2013-09-11 09:11:35.27) please post the center to center dimension on the rail drawing for the t slot nut so I can fabricate my own adaptor jlow

(posted 2013-09-11 09:45:00.0) Response from Jeremy at Thorlabs: The center to center distance of the T-nut slots is 46mm. We will get the drawings updated. yosuf.ahmed

(posted 2011-04-14 17:50:55.0) So far so good jjurado

(posted 2011-02-18 17:32:00.0) Response from Javier at Thorlabs to kendra.albers@gtri.gatech.edu: Thank you for submitting your request. The XT95P1 rail plate and XT95P2 right angle carriage are tapped with M6 holes. However, we can provide versions of these plates with 1/4"-20 holes. I will contact you directly to set up a formal quotation.

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=2302 kendra.albers

(posted 2011-02-18 16:18:29.0) Are there any rail carriages/ rail plates that work with the XT95SP rails that have 1/4-20 holes? Thorlabs

(posted 2010-08-05 17:17:44.0) Response from Javier at Thorlabs to o.suttmann: Thank you for your feedback. The manufacturing of an XT95-CUSTRAIL requires a customized tool setup. Due to that, the overall price per rail significantly goes down when ordering quantities of 3 or more, since the same setup can be used for all rails. Regarding the lead time, we can try to expedite your order without any additional charges. o.suttmann

(posted 2010-08-03 13:33:18.0) To whom it may concern,

In my opinion, your XT95-CUSTRAIL is way too expensive. Especially, when taking into account up to four weeks of delivery time.

Kind Regards,

Oliver |

- Outer Wings Effectively Form Dovetail Mounting Surfaces

- Tapped with Eight M6 Holes on Both Sides

- Durable, Clear-Anodized Coating

- Weight: 7.0 kg per Meter

Our standard 95 mm Construction Rails have outer wings along their edges that form four effective dovetails (see image to the right). In addition, each rail side features two parallel T-slots spaced 1.81" (46.0 mm) apart. These features allow standard optomechanical components to be mounted directly to the rails, using rail carriages, rail plates, or T-nuts.

In addition, the outer wings are M6-tapped in eight locations. These tapped holes are positioned for direct mechanical compatibility with our leveling feet and base plate, which are designed to mount rail assemblies on flat surfaces.

The standard, four-sided rails are offered from stock in six lengths ranging from 250 to 2000 mm. If our pre-cut lengths do not suit your application, custom lengths from 50 mm to 2000 mm can be ordered by using the XT95-CUSTRAIL field in the price box below. Unanodized rails of custom lengths up to 3.048 m (10') can also be ordered by contacting Technical Support.

These construction rails are also offered as a rough-cut, unanodized extrusion (see below) for our customers who prefer to machine and finish the rails themselves. We also offer precision construction rails below which have a ±10 arcmin angular deviation tolerance.

- ±10 arcmin Parallelism for Rail End Surfaces

- Outer Wings Effectively Form Dovetail Mounting Surfaces

- Tapped with Eight M6 Holes on Both Ends

- Four Ø3.0 mm Alignment Holes for Dowel Pins on Both Ends

- Black-Anodized Coating

- Weight: 7.0 kg per Meter

These 95 mm Precision Construction Rails are similar to the rails sold above, but are designed to a higher angular tolerance for sensitive experimental setups. Precision 95 mm rails are used in the construction of our Cerna® Microscope Bodies. Each rail side features two parallel T-slots spaced 1.81" (46.0 mm) apart. These features allow standard optomechanical components to be mounted directly to the rails, using rail carriages, rail plates, or T-nuts.

The outer wings are M6-tapped in eight locations. These tapped holes are positioned for direct mechanical compatibility with our leveling feet and base plate, which are designed to mount rail assemblies on flat surfaces. Precision rails additionally feature four Ø3.0 mm holes on each wing for use with alignment pins on Cerna components or custom setups.

The standard, four-sided rails are offered from stock in six lengths ranging from 66 to 600 mm. If other lengths up to 2000 mm are needed, please contact Tech Support with inquiries.

- Unanodized Extrusion for Custom Applications

- 2 m (6.6') Length

- Rail Ends are Not Tapped

The XT95RL2 is an unanodized, rough-cut extrusion for customers who prefer to machine and finish their own rails. Their aluminum construction makes it easy to machine them in your own machine shop.

Upon request, we can provide this extrusion in lengths up to 3.048 m (10'). Please contact Technical Support for a quote.

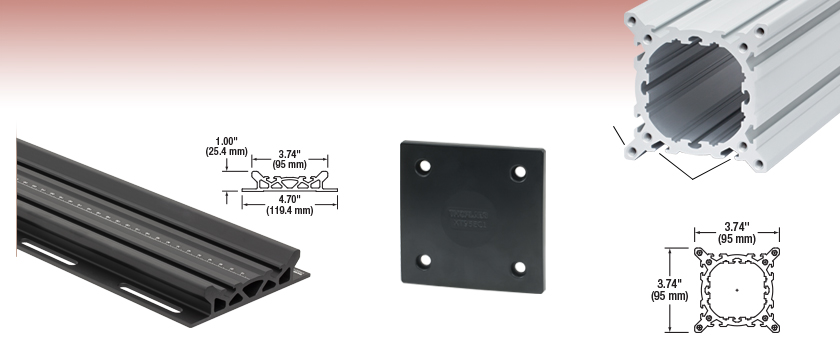

Click for Details

Common Single-Sided 95 mm Rail Dimensions

Click to Enlarge

The black-anodized rails feature engraved scales with lines at 1 mm increments.

- Smallest Footprint for One-Dimensional 95 mm Rail Constructions

- 2'' Long Clearance Slots for Securing to an Optical Table

- Bottom Relief Cut Provides Two Lines of Contact

- XT95SP: Clear-Anodized Finish

- XT95SD: Black-Anodized with Engraved Scale

Our One-Sided 95 mm Construction Rails feature the same mounting surface as our standard four-sided rails. Each side of the rail contains several 2.00" (50.8 mm) long clearance slots that are designed to accept 1/4"-20 (M6) cap screws, and the bottom features a relief cut that stabilizes the rail against the surface to which it is mounted. This compact, versatile design allows XT95-based assemblies to be easily built on top of an optical table or breadboard.

The XT95SP-500 and XT95SP-1000 rails are 500 mm and 1000 mm long, respectively, and have a durable clear-anodized finish. The XT95SD rails range from 250 mm to 750 mm in length and have a black-anodized finish. Each rail in the XT95SD series also includes an engraved scale in 1 mm increments for precise and repeatable positioning along the length of the rail, which can be seen in the image to the right. Custom XT95SP rails from 50 mm to 2000 mm and custom XT95SD rails from 50 mm to 750 mm can be ordered by contacting Tech Support.

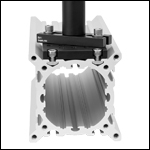

Click to Enlarge

End Plate Mounted onto a 95 mm Construction Rail

- Covers Ends of Most 95 mm XT95 Rails

- Smooth, Polystyrene Finish

- Four Counterbored Holes for M6 Cap Screws

The XT95EC1 end plate is designed for use with our XT95 and XT95B construction rails, sold above. This end plate covers the end of the construction rail, giving the rail a clean finish and preventing potential injury due to sharp edges. Using the four included M6 cap screws, the end plate mounts onto the counterbored holes located on each corner of the construction rail. Please note that using the XT95EC1 end plate with the XT95B Precision Construction Rails will cover up the four Ø3.0 mm dowel pin alignment holes.

This end plate is not compatible with our XT95RL2 or XT95SP rails.

Products Home

Products Home

Zoom

Zoom

95 mm Optical Rails

95 mm Optical Rails