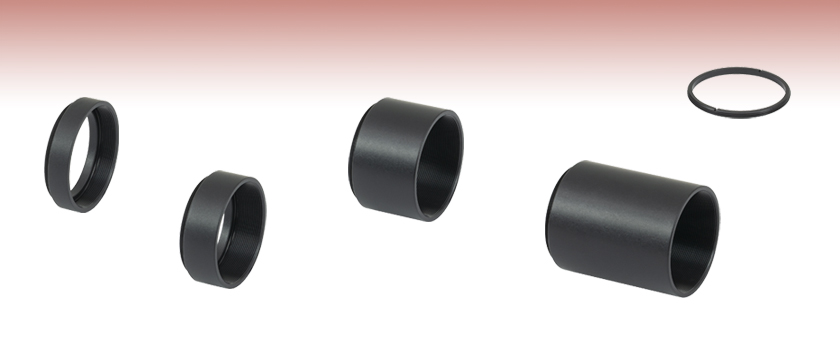

Ø1.5" Lens Tubes

- Lens Tubes Accept Ø1.5" (Ø38.1 mm) Optics

- Compatible with All SM1.5-Threaded Components

- Stackable Design Enables Construction of Multi-Element Optical Systems

SM1.5L03

0.3" Thread Depth

SM1.5L05

0.5" Thread Depth

SM1.5L10

1.00" Thread Depth

SM1.5L20

2.00" Thread Depth

SM1.5RR

SM1.5 (1.535"-40) Retaining Ring

Please Wait

Click to Enlarge

Figure 1.2 When an engraved lens tube is attached to another lens tube, the engraving of the connected end is no longer visible.

Features

- Lens Tubes in Lengths from 0.30" (7.6 mm) to 2.00" (50.8 mm)

- Tubes Directly Accept Ø1.5" (Ø38.1 mm) Optics

Lens tubes are ideal for creating compact optical subassemblies with light-tight beam paths. The Ø1.5" lens tubes sold here can be used to house one or several optical elements. Optics are separated and secured by retaining rings that are positioned at the desired depth within the lens tube using a spanner wrench. Each stackable lens tube ships with one retaining ring. Additional retaining rings can be purchased separately. In addition to the Ø1.5" lens tubes featured on this page, Thorlabs also offers versions from Ø1/2" to Ø3", each of which is equipped with an SM-series thread standard that depends on the tube diameter. Additional lens tube sizes can be found in Table 1.1.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

user

(posted 2024-03-13 13:29:46.193) Could slotted lens tubes like the ones available in 1" lens tube systems be made for 1.5" tube systems? jdelia

(posted 2024-03-14 08:17:24.0) Thank you for contacting Thorlabs. I have forwarded your request to our design engineers via our internal suggestion forum so that we may consider this as a catalog product line in the future. user

(posted 2019-06-17 01:31:08.07) Will you offer corresponding lens tube mounts (SM1.5 version of the SM1TC) and adapters to SM1 and 2? llamb

(posted 2019-06-17 05:01:01.0) Hello, thank you for contacting Thorlabs. We are indeed currently looking into offering thread adapters from SM1.5 to SM1 and SM2 threads. I have added your idea for SM1.5 lens tube mounts to our internal product forum as well. Thanks for the feedback! |

- Stackable Design Enables Multi-Element Optical Systems

- SM1.5-Threaded (1.535"-40) Bore Accepts Ø1.5" (Ø38.1 mm) Optics

These stackable Ø1.5" lens tubes provide a fast and easy means for building compact optical assemblies. They can directly interface with any SM1.5-threaded (1.535"-40) component to provide flexibility for complex optomechanical systems. One SM1.5RR Retaining Ring is included with each lens tube.

| Item # | L | Internal Thread Depth |

|---|---|---|

| SM1.5L03 | 0.33" (8.4 mm) | 0.30" (7.6 mm) |

| SM1.5L05 | 0.53" (13.5 mm) | 0.50" (12.7 mm) |

| SM1.5L10 | 1.03" (26.2 mm) | 1.00" (25.4 mm) |

| SM1.5L20 | 2.03" (51.6 mm) | 2.00" (50.8 mm) |

| Alternatives | Ø1/2", Ø1", Ø30 mm, Ø2", and Ø3" Stackable Lens Tubes | ||

|---|---|---|---|

- SM1.5RR Retaining Rings Secure Ø1.5" (Ø38.1 mm) Optics

- SPW608 Hollow Spanner Wrench Provides Unobstructed Beam Path During Adjustment

- SPW801 Adjustable Spanner Wrench can Accommodate Diameters from 0.12" (3.0 mm) to 2.89" (73.4 mm)

These Retaining Rings can be used to secure optical components into our SM1.5-threaded (1.535"-40) lens tubes. One retaining ring is included with in the purchase of a lens tube; however, additional rings enable multiple optics to be secured inside the same lens tube. The SPW608 Spanner Wrench or the SPW801 Adjustable Spanner Wrench can be used to position SM1.5RR retaining rings. Please note that the SPW801 wrench can withstand a maximum torque of 80 lb-in. We also offer the SPB1.5 SM1.5 Spanner Bit, which can be used with a standard 1/4" hex driver (sold separately).

Products Home

Products Home

Zoom

Zoom

Ø1.5" Lens Tubes

Ø1.5" Lens Tubes