FiberBench Polarization Controller Kits

- Deterministic Polarization Control

- Mechanically and Thermally Stable

- 360° Rotation and Precise Control

PC-FFB-1550

Polarization Controller Kit for 1100 - 1620 nm

PC-FFB-780

Polarization Controller Kit for 700 - 1050 nm

Please Wait

Click to Enlarge

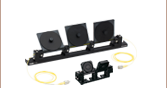

Figure 1.1 Both the PC-FFB-780 and the PC-FFB-1550 come with an included dust cover. The PC-FFB-780 with its dust cover is shown here.

| Included Componentsa | ||

|---|---|---|

| Item # | PC-FFB-780 | PC-FFB-1550 |

| FIberBench | FB-51W (Single Axis with Wall Plates) | |

| FiberPorts | 2 x PAF2-2B | 2 x PAF2-2C |

| Rotating Quarter-Wave Plates | 2 x FBR-AQ2 | 2 x FBR-AQ3 |

| Rotating Half-Wave Plate | FBR-AH2 | FBR-AH3 |

Features

- 700 - 1050 nm or 1100 - 1620 nm Operating Ranges

- Supports Both FC/PC and FC/APC Connectors

- Deterministic Polarization Control Allows Transformation of

Arbitrary Polarization States - Mechanically and Thermally Stable with Precise Polarization Control Through 360° of Rotation

- Please Contact Tech Support for Special Wavelengths or Custom-Aligned Kits

Thorlabs' FiberBench Polarization Controller Kits allows you to transform an arbitrary input polarization state into an arbitrary output polarization state. These controllers use two FiberPorts mounted on either side of a Single-Axis FiberBench with HCA3 Wall Plates. Any input polarization state can be deterministically rotated into a known output polarization state using a quarter-wave, half-wave, and another quarter-wave plate mounted (in this order) between the two FiberPorts. Each plate can be precisely and continuously rotated through 360°.

Advantages over Traditional Fiber Paddle Controllers

The FiberBench Polarization Controller Kits have the same function as paddle controllers, while offering more deterministic and stable polarization manipulation. Since it does not have any hysteresis, it is possible to predict the FiberBench Polarization Controller's output State of Polarization (SOP) at any instant in time given only its input SOP. Without a polarimeter, the SOP from the paddle controller cannot be determined directly. Unlike the conventional fiber paddle controllers, the FiberBench polarization controllers can be used with PM or SM fiber without the need for splicing. Additionally, it benefits from the advanced design of the FiberBench series and has high thermal and mechanical stability. The continuous, 360° rotation and precise adjustment capabilities offered by the wave plates allow the user more control and a more stable platform than is possible with the paddle controllers.

| Fiber Polarization Control Selection Guide | ||||||

|---|---|---|---|---|---|---|

| Polarization Controllers | Linear Polarizers | |||||

|

|

|

|

|

|

|

| Motorized Fiber Polarization Controllers | Manual Paddle Fiber Polarization Controllers | In-Line Manual Fiber Polarization Controller | Free-Space FiberBench | Faraday Mirrors | In-Line Fiber Polarizers | Polarizing Fiber |

| FiberBench Accessories | |||

|---|---|---|---|

| FiberPorts | Optic Mounts | Alignment Tools | Polarizers |

| Beamsplitter Modules | Mirror Modules | Rotating Wave Plates | FiberBenches |

Figure 2.1 Smart Pack Logo

Smart Pack

- Reduce Weight of Packaging

- Increase Usage of Recyclable Materials

- Improve Packing Integrity

- Decrease Shipping Costs

Thorlabs' Smart Pack Initiative is aimed at minimizing waste while providing adequate protection for our products. By eliminating any unnecessary packaging, implementing design changes, and utilizing eco-friendly materials, this initiative seeks to reduce the environmental impact of our product packaging.

The updated PC-FFB-780 and PC-FFB-1550 packaging primarily consists of recycled paper and cardboard and weighs 7.51% less than the original packaging. This weight change results in a 0.34 kg reduction in travel-based CO2 emissions per year, based on typical product sales.

As we move through our product line, we will indicate re-engineered, eco-friendly packaging with our Smart Pack logo, which can be seen in Figure 2.1.

| Posted Comments: | |

Louis Bouet

(posted 2024-10-01 20:02:10.43) Dear Thorlabs,

Do you propose a motorized rotator that would be compatible with your polarisation controller kits and that would have a limited to no impact on the fiber coupling output (no beam displacement)?

Many thanks jpolaris

(posted 2024-10-03 12:47:02.0) Thank you for contacting Thorlabs. Unfortunately, at this time we do not offer a motorized rotator compatible with our FiberBench product line. If your goal is to adjust the polarization state in a single-mode fiber, you might consider our motorized fiber polarization paddle controllers found at the following link. Your feedback has been passed along to our design engineers and will be taken in to consideration as we expand our motorized rotation stage product line. https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=12896 议焕 施

(posted 2024-07-15 20:39:31.767) 请问如果某一偏振态的激光通过这个PC后偏振态变为另一偏振态,这个变化后的偏振态反向通过这个PC会被这个PC变为初始的偏振态吗? 薛 英泽

(posted 2020-10-14 19:39:24.693) PC-FFB 的光纤偏振控制器 能否定制532nm工作波长的器件 YLohia

(posted 2020-10-14 11:28:07.0) Thank you for contacting Thorlabs. An applications engineer from our team in China (techsupport-cn@thorlabs.com) will reach out to you directly. user

(posted 2020-09-14 20:56:51.893) Hello, we try to collimate a beam coming from a fiber P3-780PM-FC-1 using one of the fiber port on FBP-B-FC. However, it doesn't seem to collimate the beam. Here is what we did and result: 1.We prealigned the tilt plate so that it is orthogonal to the optical axis as suggested by the alignment procedure. 2. We adjusted the x-y adjusters such that the beam can go though a 1mm pin hole located at the center of the other fiber port on the bench. 3. We put a beam profiler at about 10cm away from the fiber port to measure the beam size. We found that when moving the beam profiler closer to the lens (to 8cm), the beam size is decreasing (to <0.43mm). 4. We turn the z adjusters clockwise by the same amount (1/4 turn) each time and found the beam size at 10cm always increasing. This seems to show that at the prealigned z position, the lens is still more than a focal length away from the fiber end. We doubt the lens is incorrectly mounted. Do you have any suggestions? We also tried to do fiber coupling on the other end starting from the prealigned position. However, we could only get <40% coupling by just turning the x-y adjusters while turning z adjusters will only decrease the coupling. (Our guess is that the prealigned position is not very stable as the z adjusters are just in contact with the tilt plate) Thank you! YLohia

(posted 2020-09-15 01:10:01.0) Hello, thank you for contacting Thorlabs. From your description, it is possible that the connector key on the fiber is not fully seating into the key receptacle on the FiberPort. I have reached out to you directly to troubleshoot further. Jeff Chen

(posted 2019-06-05 09:25:08.057) Hi,

The insertion loss of the FBP-C-FC is 0.6dB. Is there a typical minimum loss of the PC-FFB-1550 at the best condition for reference? I adjusted it to the best condition was ~2dB loss. I would like to know if it could be better or it is just normal.

Thank you.

Jeff Sai Kanth Dacha

(posted 2019-05-07 17:11:27.92) Can I replace the HWP with a rotatable linear polarizer? I would like to use this setup for measurement of Stokes parameters of (pulsed) light in a fiber. YLohia

(posted 2019-05-08 09:59:27.0) Hello, thank you for contacting Thorlabs. Yes, you can replace the HWP with a linear polarizer. I have reached out to you directly regarding this. alantunsw

(posted 2018-11-25 03:18:36.29) How to remove the quarter-wavelength plates on the Fiberbench Polarization Controller Kit?

The accessory screw-drivers are not matched with the screws under the waveplates. YLohia

(posted 2018-11-30 08:37:24.0) The waveplate module does not need any screw drivers to be removed from the FiberBench -- you can simply pull it off by hand. I have reached out to you via email to get more details on what you're attempting to do. thomas.juhasz

(posted 2018-04-06 13:35:26.263) Could you explain the working principle of your FiberBench Polarization Controller Kit for incident light with linear polarization? I see two borderline cases:

1. input pol axis not aligned to material axis of 1st l/4 plate -> elliptically polarized light -> counter clockwise elliptically polarized light after l/2 plate -> linearly polarized light after 2nd l/4 plate

2. input pol axis aligned to material axis of 1st l/4 plate -> linearly polarized light -> pol axis is rotated about 2 alpha after l/2 plate -> elliptically or linearly polarized light after 2nd l/4 plate depending on rotation

So could you describe a practical procedure how to control the polarization state with this setup deterministically? And what is the advantage compared to using a single l/2 plate?

Thanks, Thomas nbayconich

(posted 2018-04-11 09:34:07.0) Thank you for contacting Thorlabs. A 1/4 retarder will transform any elliptical state into a linear state. The 1/2 wave will then rotate the axis of any incident state. If you have fiber in and free space out then you could get by with 1/4, 1/2 to produce any state at any orientation. If you output to SM fiber then you need 1/4, 1/2, 1/4 and the last 1/4 will undo any ellipticity that the output fiber introduces into the beam

A practical way to control your polarization state for example would be say using a PM fiber with linearly polarized light input onto the first quarter waveplate. If you align the input linear polarized light to 45º of the fast or slow axis of the first quarter waveplate your output will become circularly polarized. After the first quarter waveplate you can then use the half waveplate to change from left hand circularly polarized light to right hand and vice versa. The position of the fast and slow axis of the half waveplate will not matter. Of course if your linear polarization is not aligned at 45º to your quarter waveplates axis you will get an elliptical state. Assuming you maintain circular polarization (right hand) upon the half waveplate then change your circular polarization to left hand circular, once your left hand circular beam is incident on the second quarter waveplate you can change back to linear polarization but with the plane of polarization rotated by 90 degrees, in other words changing your initial vertical linear polarization to horizontal polarization or vice versa.

The advantage to this setup compared to just using a single half waveplate is that if only using a half waveplate with a linearly polarized source you can only rotate the orientation of the linear polarization but not change from linear to circular or an elliptical state. In order to get and elliptical state or change from linear to circularly polarized light you will need a combination of quarter and half waveplates. hkchiu

(posted 2017-10-05 20:03:11.603) Hello:

I am interested in your "FiberBench Polarization Controller Kit" products(PC-FFB-1550).

Could you please give us the product's spec. (We want to know the PER of this element).

Thank you~

Hua-Kung Chiu tfrisch

(posted 2017-10-06 04:00:13.0) Hello, thank you for contacting Thorlabs. The waveplates will change the polarization state, but not the degree of polarization. I will reach out to you directly to discuss how you might define PER for a system like this, but the degree of polarization should be very similar on the input and output. pisomwan

(posted 2017-01-24 10:57:14.83) Dear Concern person,

Could you explain more detail about "FiberBench Polarization Controller Kit".

I can use it for connector PR measurement ,Right?

Do you have another connector adapter for change? (LC , SC , MU etc...)

Best regards,

Pinyo Somean tfrisch

(posted 2017-01-26 03:27:52.0) Hello, thank you for contacting Thorlabs. I will reach out to you about this application. jjurado

(posted 2011-06-21 19:26:00.0) Response from Javier at Thorlabs to ygyang2004: Thank you very much for contacting us. The components in the PC-FFB-1550 polarization controller can certainly be disassembled. Also, we can offer a version with different components as required in your application (we actually use the PAF-X-2-C in this controller). Keep in mind that at different wavelengths the resulting insertion loss will most likely be different. I will contact you directly for further support. ygyang2004

(posted 2011-06-21 01:44:18.0) Hello. Im Yoon seok Yang in ajou university master course.

I wonder that PC-FFB-1550, fiber bench model can be separated. And I wonder that PC-FFB-1550 model can be assemble with another component(for example PAF-X-2-C-Fiberport, PCB-2.5-VIS etc..). Customer Email: ygyang2004@ajou.ac.kr Laurie

(posted 2008-07-11 11:06:58.0) Response from Laurie at Thorlabs to srubin: Thank you for your post. We have updated the .pdf drawing so that the entire drawing can be seen. We apologize for any inconvenience. srubin

(posted 2008-07-10 23:08:01.0) The PDF drawing of the FBR05 looks like it is cut in the middle |

Products Home

Products Home

FiberBench Polarization Controller Kits

FiberBench Polarization Controller Kits