Solid Aluminum Breadboards with Access Aperture

- Ø2" (50 mm) or Ø4" (100 mm) Central Aperture for Laser Beams, Cable Routing, or Imaging Systems

- 1/4"-20 (M6) or Both 8-32 (M4) and 1/4"-20 (M6) Mounting Holes

- Matte Black Anodized Finish Reduces Unwanted Reflections

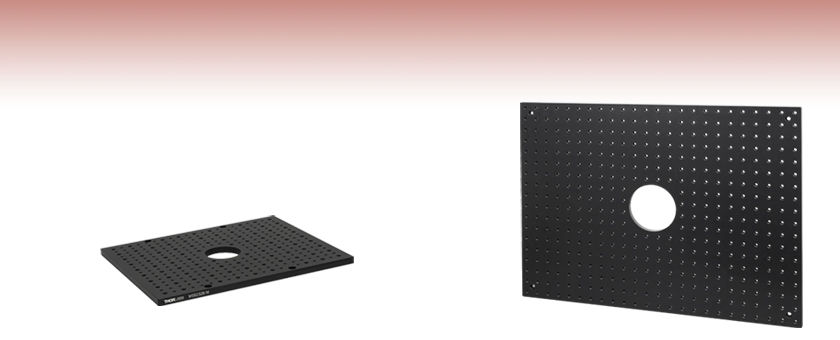

MB1824A

18" x 24"

1/4"-20 Taps

Ø2.00" Central Access Aperture

MSB2328/M

230 mm x 280 mm

8-32 and 1/4"-20 Taps

Ø50.0 mm Central Access Aperture

Please Wait

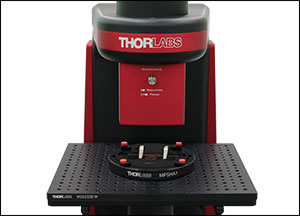

Click to Enlarge

Periscope Assembly Being Used to Reroute a Beam Through the Ø4" Center Access Hole of our MB1824A Breadboard

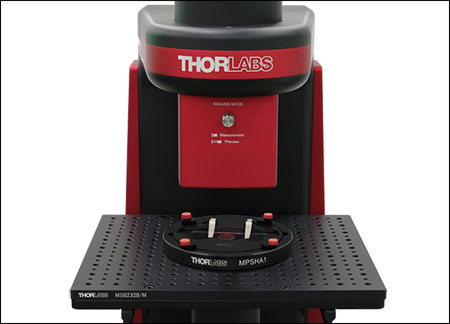

Click to Enlarge

MSB2328/M Aluminum Breadboard Integrated with the LCC7201B Birefringence Imaging System, MPSHA1 Slide Holder Insert Adapter, and a MPSH2 Slide Holder Insert.

Features

- Ø2" (Ø50 mm) or Ø4" (Ø100 mm) Central Aperture

- Access Aperture for Laser Beams, Cable Routing, or Imaging System Optical Paths

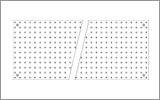

- Imperial or Metric Breadboard Hole Patterns

- 1/4"-20 (M6) Taps for Standard Components

- 8-32 (M4) and 1/4"-20 (M6) Taps for Both Standard and Mini-Series Components

- Offset Mounting Holes Allow a Full, Uninterrupted, Threaded Hole Matrix

- Solid Aluminum with Low Reflection Anodized Surface

- Custom Sizes and Options Available

These solid aluminum, nonmagnetic breadboards feature a central aperture for routing laser beams, for cable management, or for use in imaging systems. They provide a convenient and cost-effective platform for assembling prototype optical assemblies, performing experiments, and mounting small subsystems. These breadboards are offered with either 1/4"-20 (M6) tapped holes on a 1" (25 mm) hole pattern or a high-density pattern of both 8-32 (M4) and 1/4"-20 (M6) tapped holes.

Each breadboard features four counterbored mounting holes, offset from the array of threaded holes, which are counterbored to create an uninterrupted surface for any intended application. Four of these breadboards have four 1/4" (M6) mounting holes located at each corner of the breadboard, inset 1" (25 mm) from each edge. The mounting holes may be used to attach the breadboards to optical tables, other breadboards, mounting posts, brackets, or a variety of other surfaces or mounts. Because the threaded holes extend completely through these breadboards, components can be mounted on both sides at once. Ø1.5" Mounting Posts allow for adjustments to the height of the optical axis by mounting the breadboards above the surface of an optical tabletop (or another board). The breadboards can also be mounted vertically using 90° or Vertical Mounting Brackets. Please see the Mounting Options tab for more details.

Two specialty breadboards (Item #'s MSB2328(/M)) have four M5 mounting holes spaced for mounting on the LCC7201B Birefringence Imaging System. These breadboards can also be used in spaces requiring a central aperture along with high-density threaded holes and a smaller, thinner breadboard.

Other Breadboard Options and Accessories

For vacuum applications, we recommend using an unanodized breadboard; an unanodized breadboard with an access aperture must be ordered by contacting tech support. If the access aperture is not an essential feature, please consider our selection of standard Unanodized Breadboards.

Thorlabs also offers Double Hole Density Aluminum Breadboards with 1/2" offset hole spacing, doubling the density of mounting holes. These are offered in sizes ranging from 4" x 24" to 8" x 36" (100 mm x 600 mm to 200 mm x 900 mm) with thicknesses of 0.5" (12.7 mm). The same double-hole-density pattern is also available on our Circular Breadboards.

For limited space applications, Thorlabs offers a range of High-Density Breadboards. These breadboards feature increased tapped hole density,

4-40 (M3) or both 8-32 (M4) and 1/4"-20 (M6) tapped holes, and thinner breadboard thickness.

Optical Breadboard Enclosures are available to protect sensitive equipment from dust, stray light, acoustic noise, and thermal variations. Enclosures are offered completely sealed or with sliding door access.

Custom Breadboards

We offer a service for custom breadboard orders, with options that include hole pattern and spacing, size, thickness, and anodizing. For a quote, please fill out our custom breadboards form.

Mounting Options

Vertical Arrangement

Thorlabs' aluminum breadboards with four 1/4" (M6) counterbored mounting holes can be mounted vertically (or perpendicular to a mounting surface) using a wide variety of 90 degree mounting plates. For tall arrangements, we recommend the setup shown to the left. Here, the MB1218A breadboard is vertically oriented using two VB01 Vertical Brackets.

Vibration Isolating Feet

Thorlabs' aluminum breadboards with four 1/4" (M6) counterbored mounting holes may be mounted on a set of AV6 Sorbothane Feet, rated for 22.7 kg per foot. These vibration isolating feet may be used to isolate a small breadboard from its mounting surface.

Not shown: Standard RDF1 Rubber Damping Feet may also be used where high vibrational damping is not necessary.

Elevated Arrangement with Adjustable Mounting Feet

A set of Ø1.5" Post Mounts can be used to elevate an aluminum breadboard that has four 1/4" (M6) counterbored mounting holes off of the work surface. At left, an MB1218A breadboard is shown with four P6 Mounting Posts. An adjustable, self-leveling BMF4 Mounting Foot is attached to each mounting post. The self-leveling mounting feet feature rubberized feet and screw thread height adjustment.

Fixed Elevated Arrangement with Pedestal-Style Feet

A more permanent breadboard mounting option, for breadboards that have four 1/4" (M6) counterbored holes, is shown to the left and features pedestal-style Ø1.5" Post Mounts clamped to an optic bench. The MB1218A Aluminum Breadboard to the left is elevated off the optic bench surface using a set of four P6 Mounting Posts, each with a PB4 Pedestal Base Adapter and PF175B Clamping Fork.

Not shown: Ø1.5" Translating Posts may also be used in lieu of the P6 Mounting Posts for applications requiring further height adjustment.

Specialty Mounting in Imaging System

Two specialty breadboards (Item #'s MSB2328(/M)) have four M5 mounting holes spaced for mounting on the LCC7201B Birefringence Imaging System. These breadboards can also be used in spaces requiring the central aperture along with high-density threaded holes and a smaller, thinner breadboard.

| Item # | Dimensions (L x W x H) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) | Weight (lbs) | Mass (kg)a | Weight (lbs)a | ||

| MB1218A | 12" x 18" x 0.5" | 4.47 | 9.85 | 5.00 | 11.00 |

| MB1824A | 18" x 24" x 0.5" | 8.83 | 19.47 | 9.80 | 21.56 |

| MSB2328 | 9.06" x 11.02" x 0.37" | 1.46 | 3.22 | 3.21 | 7.07 |

| MB3045A/M | 300 mm x 450 mm x 12.7 mm | 4.33 | 9.55 | 4.90 | 10.78 |

| MB4560A/M | 450 mm x 600 mm x 12.7 mm | 8.55 | 18.85 | 9.50 | 20.90 |

| MSB2328/M | 230 mm x 280 mm x 9.5 mm | 1.46 | 3.22 | 3.21 | 7.07 |

| Posted Comments: | |

vivien loo

(posted 2019-11-08 03:30:06.817) Hello,

we want to use the center ø100 hole as a rotation bed for a ø100 cylindrical piece. Before we start machining anything, we would like to know what is your tolerance on the ø100 hole. And what is the chamfer size on this hole ? cwright

(posted 2019-11-12 07:52:39.0) Response from Charles at Thorlabs: Hello Vivien, the tolerance on this hole is ± 0.10mm and the chamfer is cut at 45° with a depth of 0.3 mm. mathieu.lemaire

(posted 2015-09-18 14:39:24.287) Hi - is it possible to get a customized version of this product? I would like to know if it would be possible to get the aperture to be located in one of the corners as opposed to the center.

Also - can you use thinner breadboard (0.25 inches)? besembeson

(posted 2015-10-05 02:49:44.0) Response from Bweh at Thorlabs USA: Yes that is possible. I will follow-up with you. keewah.chan

(posted 2014-04-03 04:03:23.3) Is there only two standard size (50mm and 100 mm) for central aperture of MB4560A/M?

Do you provide thicker MB4560A/M? jlow

(posted 2014-04-03 12:06:05.0) Response from Jeremy at Thorlabs: We can quote custom sizes (including thicker versions) breadboard. We will contact you directly to discuss about this. cbrideau

(posted 2014-03-06 13:23:20.623) This sure beats having to take a hole saw to a breadboard after the fact! Can you come up with a kinematic assembly that sits in the hole like a turret for periscoping a beam up onto the breadboard deck? msoulby

(posted 2014-03-07 11:12:18.0) Response from Mike at Thorlabs: Thank you for your feedback; we have offered custom breadboards for some time now, however due to popular demand from customers we decided to release a standard range of breadboards with aperture ports for passing beams or mechanical parts through. We also already have a periscope assembly with kinematic adjustment that would easily fit into this porthole, please see part RS99/M http://www.thorlabs.de/newgrouppage9.cfm?objectgroup_id=883 |

| Imperial Breadboards | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MB1218A | 12" x 18" | 0.50" | 2.00" | 1/4"-20 Tapped Holes on 1" Centers | 0.5" on All Sides | Four Ø1/4" Located at Corners Inset 1" | Aluminum Tooling Plate | Matte Black Anodized | ±0.006" Over 1 ft2 |

| MB1824A | 18" x 24" | 4.00" | |||||||

| Metric Breadboards | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MB3045A/M | 300 mm x 450 mm |

12.7 mm | 50.0 mm | M6 Tapped Holes on 25 mm Centers | 12.5 mm on All Sides | Four M6 Located at Corners Inset 25 mm | Aluminum Tooling Plate | Matte Black Anodized | ±0.15 mm Over 0.09 m2 |

| MB4560A/M | 450 mm x 600 mm |

100.0 mm | |||||||

The MSB2328(/M) breadboards are designed for use with Thorlabs' LCC7201B Birefringence Imaging System. They each have a thickness of 0.37” (9.5 mm), and the four mounting counterbores are positioned to allow the breadboards to be mounted in the LCC7201B system. These breadboards have a Ø1.97" (Ø50.0 mm) central access aperture aligned with the optical axis of this imaging system.

| Imperial Breadboard | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB2328 | 9.06" x 11.02" | 0.37" | 1.97" | 8-32 Taps with 1/2" Spacing and 1/4"-20 Taps with 1" Spacinga | 0.51" from the Short Edges and 0.53" from the Long Edges | Four M5b | Aluminum Plate | Matte Black Anodized | ±0.010" (0.25 mm) over Entire Surface |

| Metric Breadboard | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB2328/M | 230 mm x 280 mm |

9.5 mm | 50.0 mm | M4 Taps with 12.5 mm Spacing and M6 Taps with 25 mm Spacinga | 15 mm on All Sides | Four M5b | Aluminum Plate | Matte Black Anodized | ±0.010" (0.25 mm) over Entire Surface |

Products Home

Products Home

Solid Aluminum Breadboards with Central Aperture

Solid Aluminum Breadboards with Central Aperture