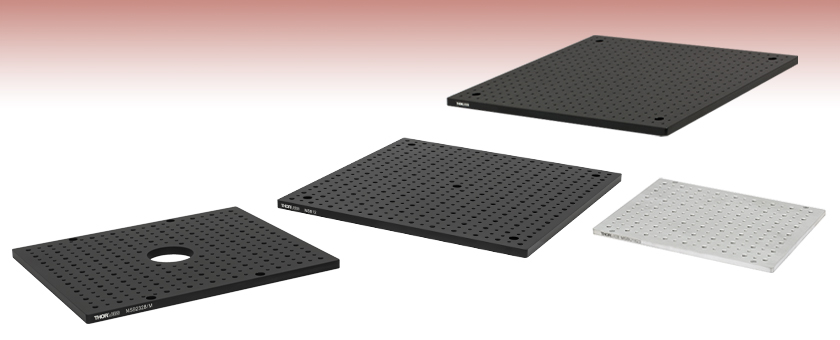

High-Density Optical Breadboards, Mini-Series and Standard Series Taps

- Designed to Mount Standard and Mini-Series Components

- 4-40 (M3) or Both 8-32 (M4) and 1/4"-20 (M6) Mounting Holes

- Versions for Electronics Enclosures or Imaging Systems

- Matte Black Anodized or Unanodized Finish

MSB12

12" x 12"

8-32 and 1/4"-20 Taps

MS12B

12" x 12"

4-40 Taps

MSBU1823

180 mm x 230 mm

8-32 and 1/4"-20 Taps

Unanodized Surface

MSB2328/M

230 mm x 280 mm

8-32 and 1/4"-20 Taps

Ø50.0 mm Central Access Aperture

Please Wait

Click for Details

A fifth mounting hole in the middle of larger breadboards increases rigidity and reduces stress when mounting heavy loads.

Features

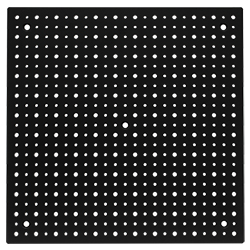

- High-Density Imperial or Metric Hole Patterns

- 4-40 (M3) Taps for Mini-Series Components

- 8-32 (M4) and 1/4"-20 (M6) Taps for Both Standard and Mini-Series Components

- 1/2" (12.5 mm) Hole Spacing for Additional Mounting Taps

- Counterbores for Mounting Breadboards to Optical Tables, on Mounting Feet, Inside Electronics Enclosures, or on Imaging Systems

- Black Anodized Solid Aluminum Construction Minimizes Reflectance

- Unanodized Breadboards for Electronics Enclosures Also Available

- Double-Density and Standard 1/4"-20 (M6) Tapped Versions Also Available

- Custom Breadboards Available; Contact Tech Support

Thorlabs' Mini-Series breadboards, designed for setups where space is a premium, offer increased tapped hole density with 1/2" (12.5 mm) spacing. These high-density breadboards are offered with either 4-40 (M3) tapped holes or both 8-32 (M4) and 1/4"-20 (M6) tapped holes.

Our Mini-Series line consists of components that are compatible with 4-40 (M3) or 8-32 (M4) threads. The 4-40 (M3) taps in the MS12B(/M) breadboard make it compatible with smaller 4-40 (M3) Mini-Series components, such as our Ø6 mm posts. Our other breadboards are compatible with 8-32 (M4) Mini-Series components, such as our Ø12 mm pedestal posts and MSL post holders, and also include 1/4"-20 (M6) taps for integrating larger optomechanical components, such as our Ø1/2”, Ø1”, and Ø1.5” post assemblies.

Each breadboard features two, four, or five counterbored mounting holes, depending on the size of the board, enabling these breadboards to be mounted onto our standard breadboards, mounting feet, or post assemblies. For breadboards that have a fifth counterbored hole, it is located at the center of the breadboard to reduce stress at the four corners and to increase system rigidity when mounted. Refer to the tables below for more specifications.

We also offer a selection of breadboards with 8-32 (M4) and 1/4"-20 (M6) mounting holes designed for use with Thorlabs' Customizable Electronics Enclosures or LCC7201B Birefringence Imaging System. These breadboards have counterbored mounting holes positioned to allow the breadboards to be mounted directly into the compatible system. The breadboards for the imaging systems also feature a Ø1.97" (Ø50.0 mm) central aperture aligned with the optical axis of the imaging system.

Custom Breadboards

We offer a service for custom breadboard orders, with options that include hole pattern and spacing, size, thickness, and anodizing. For a quote, please use our contact Tech Support.

| Posted Comments: | |

Thomas Nørskov Stoustrup

(posted 2022-04-05 11:37:04.8) Hey Thorlabs

I am mounting components that use two M4 taps next to each other (in order to secure alignment). For this, a "pure M4 edition" of the "Breadboards with 8-32 (M4) and 1/4"-20 (M6) Taps" would offer greatly enhanced flexibility. That is, an edition where all M6 taps are replaced by M4 taps.

Best regards

Thomas cwright

(posted 2022-04-06 08:57:08.0) Response from Charles at Thorlabs: Thank you for your query. I can see how this could be helpful and it is something we can perhaps offer as a custom item. Since you opted not to be contacted, please contact your local technical support team if you would be interested in a quote. Our contact details can be found here: https://www.thorlabs.com/supportcontact.cfm |

| Imperial Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MS12B | 12" x 12" | 3/8" | 4-40 Tapped Holes on 1/2" Centers | 0.5" on All Sides | Four 1/4"a | Aluminum Plate | Matte Black Anodized | 0.015" (0.38 mm) over 1 ft2 (0.09 m2) |

| Metric Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MS12B/M | 300 mm x 300 mm | 9.5 mm | M3 Tapped Holes on 12.5 mm Centers |

12.5 mm on All Sides | Four M6a | Aluminum Plate | Matte Black Anodized | 0.015" (0.38 mm) over 1 ft2 (0.09 m2) |

| Imperial Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB23 | 2" x 3" | 3/8" | 8-32 Taps with 1/2" Spacing and 1/4"-20 Taps with 1" Spacinga | 0.5" on All Sides | Two 1/4"b | Aluminum Plate | Matte Black Anodized | 0.015" (0.38 mm) over 1 ft2 (0.09 m2) |

| MSB34 | 3" x 4" | Four 1/4"b | ||||||

| MSB36 | 3" x 6" | |||||||

| MSB46 | 4" x 6" | |||||||

| MSB6 | 6" x 6" | |||||||

| MSB12 | 12" x 12" | Five 1/4"b,c | ||||||

| MSB1218 |

12" x 18" | |||||||

| Metric Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB5075/M | 50 mm x 75 mm | 9.5 mm | M4 Taps with 12.5 mm Spacing and M6 Taps with 25 mm Spacinga | 12.5 mm on All Sides |

Two M6b | Aluminum Plate | Matte Black Anodized | 0.015" (0.38 mm) over 1 ft2 (0.09 m2) |

| MSB7510/M | 75 mm x 100 mm | Four M6b | ||||||

| MSB7515/M | 75 mm x 150 mm | |||||||

| MSB1015/M | 100 mm x 150 mm | |||||||

| MSB15/M | 150 mm x 150 mm | |||||||

| MSB30/M | 300 mm x 300 mm | Five M6b,c | ||||||

| MSB3045/M | 300 mm x 450 mm | |||||||

The MSB1823(/M) and MSBU1823(/M) breadboards are designed to fit inside the EC2030A(R) or EC2030B(R) benchtop enclosures for custom electronics, and the MSBU3038(/M) breadboard is designed to fit inside the EC2U and EC3U 19" rack enclosures for custom electronics.The MSB1823(/M) and MSBU1823(/M) have a thickness of 0.28" (7.0 mm) while the MSBU3038(/M) has a thickness of 0.37" (9.5 mm). In addition, these breadboards have four M3 counterbored mounting holes for compatibility with the enclosure, rather than 1/4" (M6) counterbored holes. See the tables below for specifications, and see the PDF drawings for details by clicking on the red Docs icons (![]() ) below.

) below.

| Imperial Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB1823 | 7.09" x 9.06" | 0.28" | 8-32 Taps with 1/2" Spacing and 1/4"-20 Taps with 1" Spacinga | 0.54" and 0.53", Two Sides Each |

Four M3b | Aluminum Plate | Matte Black Anodized | ±0.006" (0.15 mm) over Entire Surface |

| MSBU1823 | None | |||||||

| MSBU3038 | 15.00" x 11.98" | 0.37" | 8-32 Taps with 1/2" Spacing and 1/4"-20 Taps with 1" Spacinga | 0.5" on All Sides | Four M3c | Aluminum Plate | None | ±0.012" (0.3 mm) over Entire Surface |

| Metric Breadboards | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB1823/M | 180.0 mm x 230.0 mm | 7.0 mm | M4 Taps with 12.5 mm Spacing and M6 Taps with 25 mm Spacinga | 15.0 mm on All Sides |

Four M3b | Aluminum Plate | Matte Black Anodized | ±0.006" (0.15 mm) over Entire Surface |

| MSBU1823/M | None | |||||||

| MSBU3038/M | 375.4 mm x 304.3 mm | 9.5 mm | M4 Taps with 12.5 mm Spacing and M6 Taps with 25 mm Spacinga | 12.9 mm and 14.9 mm, Two Sides Each | Four M3c | Aluminum Plate | None | ±0.012" (0.3 mm) over Entire Surface |

The MSB2328(/M) breadboards are designed for use with Thorlabs' LCC7201B Birefringence Imaging System. They each have a thickness of 0.37” (9.5 mm), and the four mounting counterbores are positioned to allow the breadboards to be mounted in the LCC7201B system. These breadboards have a Ø1.97" (Ø50.0 mm) central access aperture aligned with the optical axis of this imaging system.

| Imperial Breadboard | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB2328 | 9.06" x 11.02" | 0.37" | 1.97" | 8-32 Taps with 1/2" Spacing and 1/4"-20 Taps with 1" Spacinga | 0.51" from the Short Edges and 0.53" from the Long Edges | Four M5b | Aluminum Plate | Matte Black Anodized | ±0.010" (0.25 mm) over Entire Surface |

| Metric Breadboard | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Top Surface Dimensions | Breadboard Thickness | Central Aperture Diameter | Hole Threading and Spacing | Distance from Edge to First Hole | Number of Counterbored Holes | Material | Finish | Flatness |

| MSB2328/M | 230 mm x 280 mm |

9.5 mm | 50.0 mm | M4 Taps with 12.5 mm Spacing and M6 Taps with 25 mm Spacinga | 15 mm on All Sides | Four M5b | Aluminum Plate | Matte Black Anodized | ±0.010" (0.25 mm) over Entire Surface |

Products Home

Products Home

Mini Series Optical Breadboards

Mini Series Optical Breadboards