Liquid Crystal Polymer Depolarizers

- Randomize the Polarization of a Linearly Polarized Input Beam

- Designed for Laser Beams as Small as Ø0.5 mm

- Effective for Both Monochromatic and Broadband Light Sources

- AR Coated for 350 - 700 nm, 650 - 1050 nm, or 1050 - 1700 nm

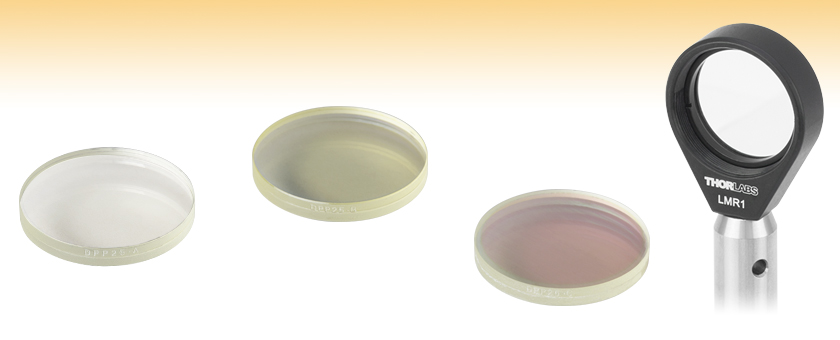

DPP25-A

AR Coating: 350 - 700 nm

DPP25-A Depolarizer

in an LMR1 Optic Mount

DPP25-B

AR Coating: 650 - 1050 nm

DPP25-C

AR Coating: 1050 - 1700 nm

US Patent 9,599,834 B2

Please Wait

| Specifications | ||||

|---|---|---|---|---|

| Item # | DPP25-A | DPP25-B | DPP25-C | |

| Material | Liquid Crystal Polymer Between N-BK7 Glass Plates |

|||

| Design Wavelength Range | 350 - 700 nma | 650 - 1050 nm | 1050 - 1700 nm | |

| AR Coating Reflectanceb | Ravg <0.5% Over Design Wavelength Range | |||

| Diameter | 1" (25.4 mm) | |||

| Thickness | 3.2 mm (0.13") | |||

| Clear Aperture | >90% of Diameter | |||

| Surface Quality | 60-40 Scratch-Dig | |||

| Surface Flatness | λ/4 at 632.8 nm | |||

| Strip Widthc | 25 µm | |||

| Retardation Variation | 250 - 300 nm | 380 - 430 nm | 720 - 770 nm | |

| Fast Angle Axis | 2° Increase From Pixel to Pixel | |||

| Beam Deviation | <5 arcmin | |||

| Laser Damage Thresholdd |

CWe | 5 W/cm (532 nm, CW, Ø0.004 mm) |

5 W/cm (810 nm, CW, Ø0.004 mm) |

- |

| Pulsed (ns) | 1.8 J/cm2 (532 nm, 8 ns, 10 Hz, Ø0.200 mm) |

8 J/cm2 (810 nm, 10 ns, 10 Hz, Ø0.08 mm) |

10 J/cm2 (1550 nm, 7.8 ns, 10 Hz, Ø0.191 mm) |

|

| Pulsed (fs) | 0.041 J/cm2 (532 nm, 100 Hz, 76 fs, Ø162 µm) |

0.041 J/cm2 (800 nm, 100 Hz, 36.4 fs, Ø189 µm) |

0.11 J/cm2 (1550 nm, 100 Hz, 70 fs, Ø145 µm) |

|

Click to Enlarge

The retardation pattern across a Ø10 mm section of the DPP25-A depolarizer is shown in the plot above.

Click to Enlarge

The fast-axis orientation across a Ø10 mm section of the DPP25-A depolarizer is shown in the plot above. 0° is parallel to the lines of constant fast-axis orientation.

Features

- Optic Axis Alignment Not Required

- Ideal for Both Broadband Light Sources and Monochromatic Beams

- Depolarize Beams with Diameters as Small as 0.5 mm

- Three AR Coatings Available

- 350 - 700 nm

- 650 - 1050 nm

- 1050 - 1700 nm

- Relatively Insensitive to Angle of Incidence (see LCP vs. Quartz Tab for Details)

Thorlabs' Liquid Crystal Polymer (LCP) Depolarizers (US Patent 9,599,834 B2) are patterned microretarder arrays designed to convert a linearly polarized beam of light into a pseudo-randomly polarized beam. The term pseudo-random is used since the transmitted beam does not become unpolarized; instead the polarization of the beam is randomized. Linearly polarized light from a monochromatic source that is transmitted through one of these depolarizers will have a polarization that varies spatially. Linearly polarized light from a broadband source that is transmitted through one of these depolarizers will have a polarization that varies spatially as well as with wavelength. These depolarizers will work with light incident on either side of the optic.

Design

Each LCP depolarizer consists of a thin film of liquid crystal polymer sandwiched between two Ø1", 1.6 mm thick N-BK7 glass plates. A pattern of varying retardation and fast-axis orientation is imprinted in the LCP material. Measurements of the retardation pattern and fast-axis orientation for a Ø10 mm section of the DPP25-A depolarizer are shown in the plots to the right. For this depolarizer, the angle of the fast axis is increased by 2° and the retardation has a periodic variation between 250 nm and 300 nm across each consecutive 25 µm strip. The DPP25-B and DPP25-C have a periodic retardation variation between 380 - 430 nm and 720 - 770 nm, respectively, and a 2° increase in the angle of the fast axis across 25 µm strips.

An AR coating is applied to both outer surfaces to improve the transmission of the optic across the specified wavelength range. Details are provided in the table to the right.

These depolarizers can be used with narrowband (monochromatic) laser light beams that have a beam diameter as small as 0.5 mm. For these beam sizes, the randomization of the output beam's polarization is achieved by producing a spatial variation in the polarization state across the laser beam (see the Tutorial tab for an example). In addition to the spatial variation in polarization state, broadband sources will also experience a wavelength-dependent variation in the output polarization. Two different wavelengths of light will experience the same absolute retardation in nanometers as different fractions of their total wavelengths. For example, a retardation of 250 nm corresponds to a relative retardance of 0.5λ for 500 nm incident light and 0.36λ for 700 nm incident light. Thus, an even higher degree of depolarization can be achieved for a broadband beam than a similarly sized monochromatic beam.

The pseudo-random polarization generated by these depolarizers may be more suitable than linearly polarized light for polarization-sensitive devices and applications, such as Raman Amplification and reducing polarization-dependent losses. Because of their effectiveness over a wide spectral range with both narrow and broadband sources, these depolarizers have been used with favorable results in applications involving polarization-sensitive spectrometers and LCD test systems. In addition, the depolarizer's design eliminates the need to align the optic with respect to the orientation of the linear polarization axis of the incident beam, making them highly adaptable to varying input polarizations.

Quartz-Wedge Depolarizers

These LCP depolarizers and our Quartz-Wedge Depolarizers each offer distinct advantages depending on your application. The LCP depolarizers are capable of effectively depolarizing monochromatic beams down to Ø0.5 mm, while depolarizers that use a quartz-wedge or other traditional design typically require input beam diameters of at least 6 mm. The patterned retarder design used in the LCP depolarizers is also less sensitive to the angle of incidence. The quartz-wedge depolarizers have a much better surface quality and a high damage threshold due to their use of a quartz substrate and air-gap design, which makes them suitable for high-power applications. See the LCP vs. Quartz tab for a more detailed performance comparison.

| Depolarizer Comparison Table | ||

|---|---|---|

| Depolarizer Type | LCP Patterned Retarder | Quartz-Wedge Design |

| Effective Beam Size | Down to Ø0.5 mm | Down to Ø6 mm |

| Surface Quality | 60-40 Scratch-Dig | 10-5 Scratch Dig |

| Thickness | 3.2 mm (0.13") | 7.35 mm (0.289") |

| Available Wavelengths | 350 - 700 nm (AR Coated) 650 - 1050 nm (AR Coated) 1050 - 1700 nm (AR Coated) |

190 - 2500 nm (Uncoated) 350 - 700 nm (AR Coated) 650 - 1050 nm (AR Coated) 1050 - 1700 nm (AR Coated) |

The following plots compare the degree of polarization (DOP) that can be achieved using the liquid crystal polymer (LCP) patterned depolarizers and our quartz-wedge depolarizers. Compared to the quartz wedge depolarizers, the LCP patterned depolarizers show greater performance stability with changing angle of incidence and can effectively depolarize smaller beam sizes, which is especially useful for laser applications. In contrast, the quartz-wedge depolarizers have a higher surface quality and damage threshold. They also provide better performance for depolarizing elliptically and circularly polarized light.

Degree of Polarization vs. Beam Size

Click to Enlarge

The DPP25-A is an LCP depolarizer and the DPU-25-A is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 532 nm CPS532 laser diode module (1 nm FWHM bandwidth).

Click to Enlarge

The DPP25-B is an LCP depolarizer and the DPU-25-B is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 780 nm CPS192 laser diode module (1 nm FWHM bandwidth).

Click to Enlarge

The DPP25-C is an LCP depolarizer and the DPU-25-C is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 1310 nm MCLS1-1310 laser diode module (1 nm FWHM bandwidth).

Degree of Polarization vs. Wavelength

Click to Enlarge

The DPP25-A is an LCP depolarizer and the DPU-25-A is one of Thorlabs' quartz-wedge depolarizers. This test was performed at three wavelengths using three different lasers with a Ø4 mm beam size: 405 nm (CPS405, 1 nm FWHM bandwidth), 532 nm (CPS532, 1 nm FWHM bandwidth), and 633 nm (former-generation HRS015*, <10 pm FWHM bandwidth).

Click to Enlarge

The DPP25-B is an LCP depolarizer and the DPU-25-B is one of Thorlabs' quartz-wedge depolarizers. This test was performed at three wavelengths using three different lasers with a Ø4 mm beam size: 670 nm (CPS186, 1 nm FWHM bandwidth), 780 nm (CPS192, 1 nm FWHM bandwidth), and 980 nm (CPS980, 1 nm FWHM bandwidth).

Click to Enlarge

The DPP25-C is an LCP depolarizer and the DPU-25-C is one of Thorlabs' quartz-wedge depolarizers. This test was performed at three wavelengths using three different lasers with a Ø4 mm beam size: 1064 nm (1.5 nm FWHM bandwidth), 1310 nm (MCLS1-1310, 1 nm FWHM bandwidth), and 1550 nm (former generation TLS001-1550 T-Cube™, 1 nm FWHM bandwidth).

*Replaced by the HRS015B stabilized HeNe Laser.

Depolarizer Transmission

Click to Enlarge

The DPP25-A is an LCP depolarizer and the DPU-25-A is one of Thorlabs' quartz-wedge depolarizers.

Click to Enlarge

The DPP25-B is an LCP depolarizer and the DPU-25-B is one of Thorlabs' quartz-wedge depolarizers.

Click to Enlarge

The DPP25-C is an LCP depolarizer and the DPU-25-C is one of Thorlabs' quartz-wedge depolarizers.

Degree of Polarization vs. Angle of Incidence

Click to Enlarge

The DPP25-A is an LCP depolarizer and the DPU-25-A is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 532 nm CPS532 laser diode module (1 nm FWHM bandwidth) with a beam size of Ø1 mm.

Click to Enlarge

The DPP25-B is an LCP depolarizer and the DPU-25-B is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 780 nm laser diode module (CPS192, 1 nm FWHM bandwidth) with a beam size of Ø1 mm.

Click to Enlarge

The DPP25-C is an LCP depolarizer and the DPU-25-C is one of Thorlabs' quartz-wedge depolarizers. This test was performed using a 1310 nm MCLS1-1310 laser diode module (1 nm FWHM bandwidth) with a beam size of Ø1 mm.

Degree of Polarization vs. Rotation Angle

The plot below is provided as an example of the variation in Degree of Polarization as the depolarizer is rotated. Actual performance will vary from depolarizer to depolarizer, depending on the alignment of the LCP pattern and the section of the depolarizer illuminated by the incident beam. Rotating a depolarizer around an axis perpendicular to its surface does cause some variation in performance, but overall, the LCP depolarizer still provides a lower degree of polarization for a Ø0.5 mm beam than the quartz-wedge design. Similar results can be expected from the -B and -C depolarizers.

Click to Enlarge

The plot above shows the performance of the depolarizer as it is rotated. The test was performed using a 532 nm CPS532 laser diode module (1 nm FWHM bandwidth) with a beam size of Ø0.5 mm. For the quartz-wedge depolarizer, 0° corresponds to the cut edge marking the fast axis of the thick wedge. For the LCP depolarizer, 0° corresponds to the line of parallel fast-axes orientations (see the Overview tab for a plot of the fast-axis orientations).

The spatial periodicity in the polarization of the output beam of the microretarder depolarizer array can be observed when a linearly polarized monochromatic light source is used. Our depolarizers can be used for typical laser applications without expanding the beam size. To observe this effect, place the depolarizer in the beam so that propagation direction of the beam is normal to the surface of the depolarizer.

Click to Enlarge

Figure 2: This contour plot shows the results of a theoretical calculation of the output polarization generated when a linearly polarized input beam passes through the DPP25-A depolarizer. The black arrow indicates the input polarization state.

Click to Enlarge

Figure 1: The fast-axis orientation across a Ø10 mm section of the DPP25-A depolarizer is shown in the plot above. 0° is parallel to the lines of constant fast-axis orientation.

To detect the spatial periodicity of the beam's polarization state, place a linear polarizer (analyzer) into the beam path after the depolarizer. The output will have a banded intensity variation. This banding occurs because the retardance and fast-axis orientation vary across the sheet of LCP material in the depolarizer, which produces polarization states that vary spatially over a cross section of the output beam.

Example

In this example, a DPP25-A depolarizer and a 532 nm, linearly polarized source with a Ø10 mm beam are used. The light is linearly polarized at a 45° angle to the lines of constant fast axis of the depolarizer. The fast-axis orientation across the a Ø10 mm section of the DPP25-A depolarizer is shown in Figure 1. A theoretical plot showing the spatially-dependent polarization angle is shown in Figure 2. This false-color plot shows the polarization angle of the output beam from the depolarizer based on the input beam characteristics described above.

Each band of color in the plot plot represents a region with the same polarization state. Moving across the surface of the depolarizer, the output polarization will vary periodically from -90° to +90° degrees, with 0° defined by the lines of constant fast axis orientation in the depolarizer. The separation between -90° and +90° is about 1 mm.

| Custom Capability | Custom Specification |

|---|---|

| Patterned Retarder Size | Ø100 µm to Ø2" |

| Patterned Retarder Shape | Any |

| Microretarder Size | ≥Ø30 µm |

| Microretarder Shape | Round or Square |

| Retardance Range @ 632.8 nm | 50 to 550 nm |

| Substrate | N-BK7, UV Fused Silica, or Other Glass |

| Substrate Size | Ø5 mm to Ø2" |

| AR Coating | -A: 350 - 700 nm -B: 650 - 1050 nm -C: 1050 - 1700 nm |

Click to Enlarge

Figure 1: Patterned Retarder with Random Distribution

Features

- Build a Custom Microretarder

- Customize Size, Shape, and Substrate Material

- Retardance Range: 50 - 550 nm

- Fast Axis Resolution: <1º

- Retardance Fluctuations Under 30 nm

Applications

- 3D Displays

- Polarization Imaging

- Diffractive Optical Applications: Polarization Gratings, Polarimetry, and Beam Steering

Thorlabs offers customizable patterned retarders, available in any pattern size from Ø100 µm to Ø2" and any substrate size from Ø5 mm to Ø2". These custom retarders are composed of an array of microretarders, each of which has a fast axis aligned to a different angle than its neighbor. The size and shape of the microretarders are also customizable. They can be as small as 30 µm and in shapes including circles and squares. This control over size and shape of the individual microretarders allows us to construct a large array of various patterned retarders to meet nearly any experimental or device need.

These patterned retarders are constructed from our liquid crystals and liquid crystal polymers. Using photo alignment technology, we can secure the fast axis of each microretarder to any angle within a resolution of <1°. Figures 1 - 3 show examples of our patterned retarders. The figures represent measured results of the patterned retarder captured on an imaging polarimeter and demonstrate that the fast axis orientation of any one individual microretarder can be controlled deterministically and separately from its neighbors.

The manufacturing process for our patterned retarders is controlled completely in house. It begins by preparing the substrate, which is typically N-BK7 or UV fused silica (although other glass substrates may be compatible as well). The substrate is then coated with a layer of photoalignment material and placed in our patterned retarder system where sections are exposed to linearly polarized light to set the fast axis of a microretarder. The area of the exposed sections depends on the desired size of the microretarder; the fast axis can be set between 0° and 180° with a resolution <1°. Once set, the liquid crystal cell is constructed by coating the device with a liquid crystal polymer and curing it with UV light.

Thorlabs' LCP depolarizers provide one example of these patterned retarders. In principle, a truly randomized pattern may be used as a depolarizer, since it scrambles the input polarization spatially. However, such a pattern will also introduce a large amount of diffraction. For our depolarizers, we designed a linearly ramping fast axis angle and retardance that can depolarize both broadband and monochromatic beams down to diameters of 0.5 mm without introducing additional diffraction. For more details, see the webpage for our LCP depolarizers.

By supplying Thorlabs with a drawing of the desired patterned retarder or an excel file of the fast axis distribution, we can construct almost any patterned retarder. For more information on creating a patterned retarder, please contact Tech Support.

Click to Enlarge

Figure 2: Patterned Retarder with a Spiral Distribution

Click to Enlarge

Figure 3: Patterned Retarder with a Pictoral Distribution

| Damage Threshold Specifications | ||

|---|---|---|

| Item # | Laser Type | Damage Thresholda |

| DPP25-Ab | CWc | 5 W/cm (532 nm, CW, Ø0.004 mm) |

| Pulsed (ns) | 1.8 J/cm2 (532 nm, 8 ns, 10 Hz, Ø0.200 mm) | |

| Pulsed (fs) | 0.041 J/cm2 (532 nm, 100 Hz, 76 fs, Ø162 µm) | |

| DPP25-B | CWc | 5 W/cm (810 nm, CW, Ø0.004 mm) |

| Pulsed (ns) | 8 J/cm2 (810 nm, 10 ns, 10 Hz, Ø0.08 mm) | |

| Pulsed (fs) | 0.041 J/cm2 (800 nm, 100 Hz, 36.4 fs, Ø189 µm) | |

| DPP25-C | Pulsed (ns) | 10 J/cm2 (1550 nm, 7.8 ns, 10 Hz, Ø0.191 mm) |

| Pulsed (fs) | 0.11 J/cm2 (1550 nm, 100 Hz, 70 fs, Ø145 µm) | |

Damage Threshold Data for Thorlabs' LCP Achromatic Depolarizers

The specifications to the right are measured data for Thorlabs' LCP Achromatic Depolarizers.

Laser Induced Damage Threshold Tutorial

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

Testing Method

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.

First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

The photograph above is a protected aluminum-coated mirror after LIDT testing. In this particular test, it handled 0.43 J/cm2 (1064 nm, 10 ns pulse, 10 Hz, Ø1.000 mm) before damage.

| Example Test Data | |||

|---|---|---|---|

| Fluence | # of Tested Locations | Locations with Damage | Locations Without Damage |

| 1.50 J/cm2 | 10 | 0 | 10 |

| 1.75 J/cm2 | 10 | 0 | 10 |

| 2.00 J/cm2 | 10 | 0 | 10 |

| 2.25 J/cm2 | 10 | 1 | 9 |

| 3.00 J/cm2 | 10 | 1 | 9 |

| 5.00 J/cm2 | 10 | 9 | 1 |

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

Continuous Wave and Long-Pulse Lasers

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

In order to use the specified CW damage threshold of an optic, it is necessary to know the following:

- Wavelength of your laser

- Beam diameter of your beam (1/e2)

- Approximate intensity profile of your beam (e.g., Gaussian)

- Linear power density of your beam (total power divided by 1/e2 beam diameter)

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

Pulsed Lasers

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

| Pulse Duration | t < 10-9 s | 10-9 < t < 10-7 s | 10-7 < t < 10-4 s | t > 10-4 s |

|---|---|---|---|---|

| Damage Mechanism | Avalanche Ionization | Dielectric Breakdown | Dielectric Breakdown or Thermal | Thermal |

| Relevant Damage Specification | No Comparison (See Above) | Pulsed | Pulsed and CW | CW |

When comparing an LIDT specified for a pulsed laser to your laser, it is essential to know the following:

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

- Wavelength of your laser

- Energy density of your beam (total energy divided by 1/e2 area)

- Pulse length of your laser

- Pulse repetition frequency (prf) of your laser

- Beam diameter of your laser (1/e2 )

- Approximate intensity profile of your beam (e.g., Gaussian)

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

You now have a wavelength-adjusted energy density, which you will use in the following step.

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).

[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).

[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).

[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

In order to illustrate the process of determining whether a given laser system will damage an optic, a number of example calculations of laser induced damage threshold are given below. For assistance with performing similar calculations, we provide a spreadsheet calculator that can be downloaded by clicking the button to the right. To use the calculator, enter the specified LIDT value of the optic under consideration and the relevant parameters of your laser system in the green boxes. The spreadsheet will then calculate a linear power density for CW and pulsed systems, as well as an energy density value for pulsed systems. These values are used to calculate adjusted, scaled LIDT values for the optics based on accepted scaling laws. This calculator assumes a Gaussian beam profile, so a correction factor must be introduced for other beam shapes (uniform, etc.). The LIDT scaling laws are determined from empirical relationships; their accuracy is not guaranteed. Remember that absorption by optics or coatings can significantly reduce LIDT in some spectral regions. These LIDT values are not valid for ultrashort pulses less than one nanosecond in duration.

A Gaussian beam profile has about twice the maximum intensity of a uniform beam profile.

CW Laser Example

Suppose that a CW laser system at 1319 nm produces a 0.5 W Gaussian beam that has a 1/e2 diameter of 10 mm. A naive calculation of the average linear power density of this beam would yield a value of 0.5 W/cm, given by the total power divided by the beam diameter:

However, the maximum power density of a Gaussian beam is about twice the maximum power density of a uniform beam, as shown in the graph to the right. Therefore, a more accurate determination of the maximum linear power density of the system is 1 W/cm.

An AC127-030-C achromatic doublet lens has a specified CW LIDT of 350 W/cm, as tested at 1550 nm. CW damage threshold values typically scale directly with the wavelength of the laser source, so this yields an adjusted LIDT value:

The adjusted LIDT value of 350 W/cm x (1319 nm / 1550 nm) = 298 W/cm is significantly higher than the calculated maximum linear power density of the laser system, so it would be safe to use this doublet lens for this application.

Pulsed Nanosecond Laser Example: Scaling for Different Pulse Durations

Suppose that a pulsed Nd:YAG laser system is frequency tripled to produce a 10 Hz output, consisting of 2 ns output pulses at 355 nm, each with 1 J of energy, in a Gaussian beam with a 1.9 cm beam diameter (1/e2). The average energy density of each pulse is found by dividing the pulse energy by the beam area:

As described above, the maximum energy density of a Gaussian beam is about twice the average energy density. So, the maximum energy density of this beam is ~0.7 J/cm2.

The energy density of the beam can be compared to the LIDT values of 1 J/cm2 and 3.5 J/cm2 for a BB1-E01 broadband dielectric mirror and an NB1-K08 Nd:YAG laser line mirror, respectively. Both of these LIDT values, while measured at 355 nm, were determined with a 10 ns pulsed laser at 10 Hz. Therefore, an adjustment must be applied for the shorter pulse duration of the system under consideration. As described on the previous tab, LIDT values in the nanosecond pulse regime scale with the square root of the laser pulse duration:

This adjustment factor results in LIDT values of 0.45 J/cm2 for the BB1-E01 broadband mirror and 1.6 J/cm2 for the Nd:YAG laser line mirror, which are to be compared with the 0.7 J/cm2 maximum energy density of the beam. While the broadband mirror would likely be damaged by the laser, the more specialized laser line mirror is appropriate for use with this system.

Pulsed Nanosecond Laser Example: Scaling for Different Wavelengths

Suppose that a pulsed laser system emits 10 ns pulses at 2.5 Hz, each with 100 mJ of energy at 1064 nm in a 16 mm diameter beam (1/e2) that must be attenuated with a neutral density filter. For a Gaussian output, these specifications result in a maximum energy density of 0.1 J/cm2. The damage threshold of an NDUV10A Ø25 mm, OD 1.0, reflective neutral density filter is 0.05 J/cm2 for 10 ns pulses at 355 nm, while the damage threshold of the similar NE10A absorptive filter is 10 J/cm2 for 10 ns pulses at 532 nm. As described on the previous tab, the LIDT value of an optic scales with the square root of the wavelength in the nanosecond pulse regime:

This scaling gives adjusted LIDT values of 0.08 J/cm2 for the reflective filter and 14 J/cm2 for the absorptive filter. In this case, the absorptive filter is the best choice in order to avoid optical damage.

Pulsed Microsecond Laser Example

Consider a laser system that produces 1 µs pulses, each containing 150 µJ of energy at a repetition rate of 50 kHz, resulting in a relatively high duty cycle of 5%. This system falls somewhere between the regimes of CW and pulsed laser induced damage, and could potentially damage an optic by mechanisms associated with either regime. As a result, both CW and pulsed LIDT values must be compared to the properties of the laser system to ensure safe operation.

If this relatively long-pulse laser emits a Gaussian 12.7 mm diameter beam (1/e2) at 980 nm, then the resulting output has a linear power density of 5.9 W/cm and an energy density of 1.2 x 10-4 J/cm2 per pulse. This can be compared to the LIDT values for a WPQ10E-980 polymer zero-order quarter-wave plate, which are 5 W/cm for CW radiation at 810 nm and 5 J/cm2 for a 10 ns pulse at 810 nm. As before, the CW LIDT of the optic scales linearly with the laser wavelength, resulting in an adjusted CW value of 6 W/cm at 980 nm. On the other hand, the pulsed LIDT scales with the square root of the laser wavelength and the square root of the pulse duration, resulting in an adjusted value of 55 J/cm2 for a 1 µs pulse at 980 nm. The pulsed LIDT of the optic is significantly greater than the energy density of the laser pulse, so individual pulses will not damage the wave plate. However, the large average linear power density of the laser system may cause thermal damage to the optic, much like a high-power CW beam.

| Posted Comments: | |

Sergi M

(posted 2023-03-07 13:35:51.45) I got the same issue as the user (posted 2023-01-17 15:09:18.81). I was also planning to reduce the effect of polarization on the spectrometer, however my beam after the depolarizer splits in 2, rotation of the depolarizer also rotates the 2 beams around the optical access. Why does it happen and how to deal with it? cdolbashian

(posted 2023-04-03 12:14:39.0) Thank you for contacting Thorlabs. We will get in touch with you for more information to resolve your issue. user

(posted 2023-01-17 15:09:18.81) I purchased the DPP25-A . What I was hoping for when using this is to reduce the effect of polarization on the spectrometer. However, if this is used, one image is divided into two on the CCD and displayed. Why does this happen? Is this simply a ghost image? I haven't heard of any of these things. I don't see this phenomenon with my Lyot Depolarizers. cdolbashian

(posted 2023-01-23 01:34:28.0) Thank you for contacting Thorlabs. We are sorry to hear that you are encountering such issue. It is necessary to contact you directly to gather more information and determine the issue. However, we see that you didn't leave your contact information for us to reach out to you. Please feel free to contact TechSupport team ( techsupport@thorlabs.com ) to troubleshoot this issue if you see this post. Feancesco Michelotti

(posted 2022-01-28 05:12:36.527) We would like to know whether it would be possible to receive a DPP25-A depolarizer with a larger diameter, say 45mm or alternatively 2", for a custom application.

Thank you,

Francesco Michelotti cdolbashian

(posted 2022-02-07 09:22:43.0) Thank you for contacting Thorlabs Francesco. We can provide 2" diameter option for the DPP25-A. Our local techsupport team will reach out to you directly via email. Hao-Cheng Weng

(posted 2021-03-10 00:34:15.29) Hi, is the degree of polarization diminished again if a second LCP is placed after the first one? YLohia

(posted 2021-03-15 11:01:57.0) Thank you for contacting Thorlabs. The LCP depolarizers are designed to convert a linearly polarized beam of light into a pseudo-randomly polarized beam, and the polarization of the output beam is randomized. The retardance of the microretarders within the depolarizers have been tuned to provide maximum performance. Cascading multiple units are not expected to improve the performance too much. Soocheol Kim

(posted 2019-12-09 04:53:18.09) What is the fast-axis orientation and retardation information of the DPP25-A depolarizer for 633nm lasers? nbayconich

(posted 2019-12-11 02:16:38.0) Thank you for contacting Thorlabs, you may refer to the "Tutorial" tab for the fast-axis orientation information of DPP25-A, the retardance of DPP25-A is 250-300nm, that is about 0.39 to 0.47 waves at 633nm. Romain

(posted 2017-12-08 15:54:14.707) Dear Sir or Madam,

Would it be possible to have this microretarder depolarizer array with a diameter smaller to be adapted at the output of a collimator (RC08SMA-P01) ?

Thanks you nbayconich

(posted 2017-12-14 02:49:03.0) Thank you for contacting Thorlabs. We can provide smaller versions of these depolarizing arrays. Please provide us your contact information or contact us directly at techsupport@thorlabs.com for more information about custom options. Alternatively the standard Ø1" diameter microretarder depolarizer arrays can be mounted to the reflective collimators by using an SM1A6 adapter and a Ø1" lens tube. brad.kimbrough

(posted 2016-11-30 16:44:23.03) Dear Sir,

In your custom retarder arrays, can both the orientation and retardance be varied from cell to cell.

Regards,

Brad Kimbrough tfrisch

(posted 2016-11-30 05:14:50.0) Hello, thank you for contacting Thorlabs. Yes, both fast axis orientation and retardance can be changed for each cell of a custom microretarder array. I will contact you directly about your application. aayeb

(posted 2016-05-23 13:13:48.513) This product is quite efficient in terms of depolarization. However, the energy threshold that is given is not correct.

I ordered it 3 times and had the 3 of them damaged around 150mJ . The laser I am using is at 532nm with a pulse duration of 6ns and a frequency of 10Hz while the beam diameter was 12mm (so, approx 1cm²).

Also, it was used in normal temperature conditions.

Therefore we are quite far from the 5J/cm² that are mentioned in the product description. besembeson

(posted 2016-05-24 03:25:48.0) Response from Bweh at Thorlabs USA: It seems to me the peak powers that your laser is generating is too high compared to what we would recommend to be safe, especially if 150mJ corresponds to your pulse energy. Your beam size is also much larger compared to what we used for the tests so the probability of encountering in-homogeneity that could act as heat traps is higher. I have contacted you to determine your peak power intensity. olivier

(posted 2016-02-02 13:12:52.353) Dear Sir or Madam,

Does this microretarder depolarizer array exist without AR coating? Thank you. besembeson

(posted 2016-02-04 10:18:52.0) Response from Bweh at Thorlabs USA: Yes we can provide this without the AR coating. Please contact me at techsupport@thorlabs.com for a quotation. The AR coating is applied on both depolarizer surfaces to increase throughput over set wavelength ranges. |

Products Home

Products Home

Liquid Crystal Depolarizers

Liquid Crystal Depolarizers