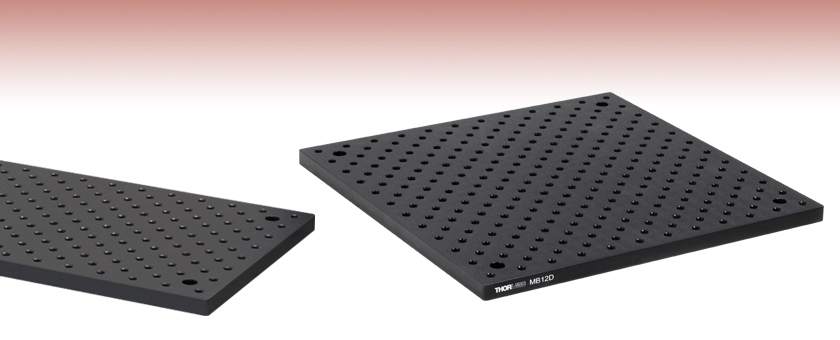

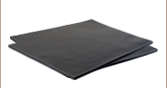

Solid Aluminum Optical Breadboards, Double-Density Holes

- Double-Density Hole Pattern

- Two Offset Grids of 1/4"-20 (M6) Tapped Holes

- Custom Sizes Available

MB824

8" x 24"

MB12D

12" x 12"

Please Wait

| Specificationa | Double-Density Aluminum Breadboards | |

|---|---|---|

| Threading | Imperial | Metric |

| Material | Aluminum Plate | |

| Finish | Matte Black Anodized | |

| Breadboard Thickness | 0.5" | 12.7 mm |

| Flatness | ±0.006" over 1 ft2 | ±0.15 mm over 0.09 m2 |

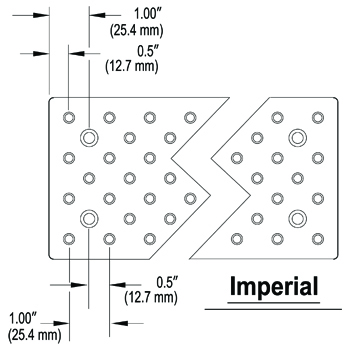

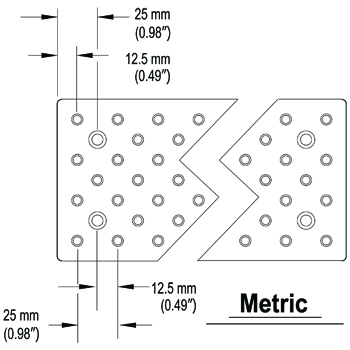

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers | M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Hole |

0.5" on All Sides | 12.5 mm on All Sides |

| Number of Counterbored Holes | One 1/4" Located at Centerb |

One M6 Located at Centerb |

Click to Enlarge

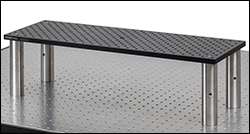

Figure 1.2 Double Density Breadboard Mounted onto an Optical Table Using Standoff Posts

Click to Enlarge

Figure 1.1 A Fifth Mounting Hole in the Middle of the Breadboard Increases Rigidity and Reduces Stress When Mounting Heavy Loads

Features

- Black Anodized Solid Aluminum Construction

- Metric Boards Manufactured & Stocked in Europe

- Counterbores for Mounting Breadboards

- Same Hole Pattern as Our Circular Optical Breadboards

- Standard, High-Density Versions, and Custom Sizes Available

Our Double-Density Breadboards are constructed from a 1/2" (12.7 mm) thick aluminum plate to maintain flatness over the full length and provide a double-density hole pattern 1/4"-20 (M6 × 1.0). See the Hole Patterns tab for information on tap spacing.

The small footprint and slim profile make these breadboards ideal for compact areas. Since the holes are threaded completely through these base plates, components can be mounted on both sides at once. Standoff posts allow the breadboards to be mounted above the surface of an optical tabletop (or breadboard), as shown in Figure 1.2, for access to components on both sides.

Each breadboard features four or five mounting holes, offset from the array of 1/4"-20 (M6) threaded holes, which are counterbored to create an uninterrupted surface for any intended application. The four standard mounting holes are located at each corner of the breadboard, inset 1" from each edge (25 mm on metric). All breadboards except the MB12D, MB1530/M, and MB3030D/M include a fifth counterbored mounting hole at the center of each board. Using the center mounting hole increases the mounting options available, reduces stress at the corner mounting holes, and increases rigidity when heavy loads are placed on the boards (see Figure 1.1). The mounting holes may be used to attach the breadboards to optical tables, other breadboards, mounting posts, brackets, or a variety of other surfaces or mounts.

One imperial and one metric breadboard below are designed for use with the EC2530C enclosure. They are thinner than the other breadboards on this page, and the mounting counterbores are positioned to allow the breadboards to be mounted within the enclosure. See our benchtop enclosures for custom electronics for details.

We also offer Mini-Series breadboards with high-density hole patterns. For vacuum applications, we recommend using our selection of unanodized breadboards.

Custom Breadboards

We offer a service for custom breadboard orders, with options that include hole pattern and spacing, size, thickness, and anodizing. For a quote, please fill out our custom breadboards form.

Note: the hole patterns on the EC2530BB and EC2530BB/M are different from those shown in the drawings above. See the following PDF drawings for details:

| Item # | Dimensions (L x W x H) | Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) | Weight (lbs) | Mass (kg)* | Weight (lbs)* | ||

| MB424 | 4" x 24" x 0.5" | 1.96 | 4.32 | 3.07 | 6.75 |

| MB436 | 4" x 36" x 0.5" | 2.95 | 6.50 | 4.09 | 9.00 |

| MB612 | 6" x 12" x 0.5" | 1.47 | 3.24 | 4.60 | 10.13 |

| MB824 | 8" x 24" x 0.5" | 3.92 | 8.64 | 5.11 | 11.25 |

| MB836 | 8" x 36" x 0.5" | 5.88 | 12.96 | 7.16 | 15.75 |

| MB12D | 12" x 12" x 0.5" | 2.94 | 6.48 | 3.36 | 7.4 |

| MB1060/M | 100 mm x 600 mm x 12.7 mm | 1.90 | 4.19 | 3.07 | 6.75 |

| MB1090/M | 100 mm x 900 mm x 12.7 mm | 2.86 | 6.31 | 3.47 | 7.64 |

| MB1530/M | 150 mm x 300 mm x 12.7 mm | 1.42 | 3.13 | 2.56 | 5.63 |

| MB2060/M | 200 mm x 600 mm x 12.7 mm | 3.80 | 8.38 | 5.11 | 11.25 |

| MB2090/M | 200 mm x 900 mm x 12.7 mm | 5.69 | 12.54 | 7.16 | 15.75 |

| MB3030D/M | 300 mm x 300 mm x 12.7 mm | 2.85 | 6.28 | 3.64 | 8.00 |

| EC2530BB | 9.06" x 9.06" x 0.37" | 1.50 | 3.30 | N/A | N/A |

| EC2530BB/M | 230 mm x 230 mm x 9.5 mm | 1.50 | 3.30 | N/A | N/A |

*These weights are approximate and are subject to change. The information is only to be used as a guideline.

| Posted Comments: | |

apcolom

(posted 2018-06-21 08:40:20.27) It would be great if these breadboards were also offered as unanodized. YLohia

(posted 2018-06-21 12:01:23.0) We are able to offer unanodized versions of these breadboards as specials. Please fill out the form here for a quote: https://www.thorlabs.com/CustomBreadboards.cfm. james.howell

(posted 2015-01-10 21:42:50.05) Greetings. I just thought you should rename these parts because it is not correct. It is called "double density" but is actually not twice the density of a standard breadboard. I think it is a bit misleading so why not change the name to high-density. myanakas

(posted 2015-01-21 11:35:18.0) Response from Mike at Thorlabs: Thank you for your feedback. We use many factors in deciding how to name our products, one being industry trends, to be sure that our customers can find products using the most common names. Though there is not exactly two times the amount of holes, the tapped mounting holes have a spacing of 0.5” instead of the 1” spacing used in our standard breadboards. The number of tapped holes in each breadboard can be found in the support drawing which can be found by clicking on the red “Docs” icon by the item number. We will keep your feedback in mind as we continue to monitor trends and consider changes to the presentation for this product line in the future. muellenbroich

(posted 2014-01-31 14:20:45.397) Is it possible to easily drill into these breadboards for example to allow a periscope to go through or do they have some sort of honeycomb structure inside them? Is it possible for you to make custom sized holes into standard sized breadboards? Cheers! jlow

(posted 2014-02-06 02:53:48.0) Response from Jeremy at Thorlabs: The MB series breadboards are solid aluminum breadboards with no honeycomb structure in them. It is fairly easy to bore a hole through these breadboards. We can custom make these with different size holes in the middle. We will contact you for some details and a quote. tcohen

(posted 2012-08-15 10:52:00.0) Response from Tim at Thorlabs to Cheol-Joo Kim: Thank you for your interest in our custom capabilities! We are able to offer these in custom sizes. I will contact you directly so that we can work on pricing/lead time of your custom. ck389

(posted 2012-08-15 08:49:47.0) Hi.

I am Cheol-Joo Kim in Cornell university.

Can I get a quote for a 4' wide x 10' long solid aluminum breadboards with double density holes?

May I call it "MB410"? Is it possible to get?

Thank you.

Best,

Cheol-Joo Kim

-------------------------------------------------------------------------

Cheol-Joo Kim,

Postdoctoral Associate,

G45, Physical Science Building,

Dept. of Chemistry and Chemical Biology,

Cornell University, Ithaca NY 14853

Email: ck389@cornell.edu

Phone: +1-607-255-0643

Mobile: +1-607-229-8035

------------------------------------------------------------------------- |

| Table G3.1 Specifications | ||

|---|---|---|

| Item # | EC2530BB | EC2530BB/M |

| Material | Aluminum | |

| Finish | Black Anodized | |

| Thickness | 9.5 mm | |

| Flatness | ±0.15 mm over Entire Surface | |

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers, Double Density Pattern |

M6 Tapped Holes on 25 mm Centers, Double Density Pattern |

| Distance from Edge to First Tapped Hole | 0.53" on All Sides | 15.0 mm on All Sides |

| Counterbored Holes | Four M3 Counterbores for Use with EC2530C | |

The EC2530BB and EC2530BB/M breadboards are designed to fit inside the EC2530C benchtop enclosure for custom electronics. The breadboards have a thickness of 9.5 mm, which is thinner than the standard aluminum breadboards sold above. In addition, these breadboards have four M3 counterbored mounting holes for compatibility with the EC2530C enclosure, rather than four 1/4" (M6) counterbored holes. See Table G3.1 for specifications, and see the PDF drawings for details by clicking on the red Docs icons (![]() ) below.

) below.

Products Home

Products Home

Breadboards with Double Density Holes

Breadboards with Double Density Holes