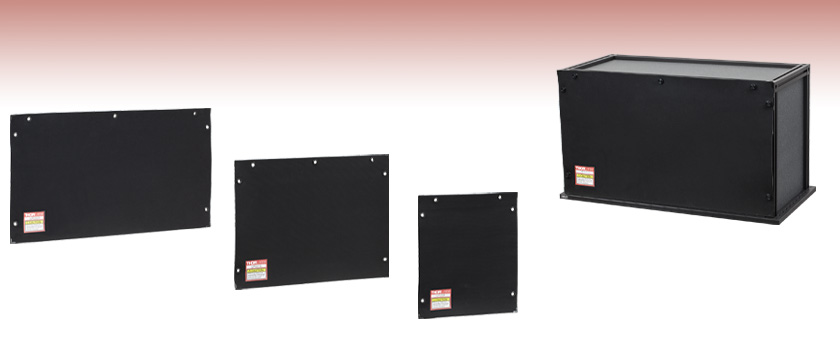

Laser Safety Fabric Panels for Optical Enclosures

- Replace Optical Enclosure Panels with Laser Safety Fabric

- Flame Retardant and Certified to EN Specifications

- Easily Access Enclosure Interior After Installing

LPCE21B

For 21" x 12" Enclosure Side

LPCE15B

For 15" x 12" Enclosure Side

LPCE9B

For 9" x 12" Enclosure Side

Application Idea

Each fabric panel replaces one side of an optical enclosure. The panels can also be used in custom-built enclosures.

Please Wait

| Fabric Panel Item # |

Dimensions | Compatible Enclosures |

|---|---|---|

| LPCE9B | 10.96" x 12.99" | XE25C7 XE25C8 |

| LPCE15B | 16.97" x 12.99" | XE25C7 XE25C9 |

| LPCE21B | 22.97" x 12.99" | XE25C8 XE25C9 |

| LPCE225B/M | 275.0 mm x 325.0 mm | XE25C7/M XE25C8/M |

| LPCE375B/M | 425.0 mm x 325.0 mm | XE25C7/M XE25C9/M |

| LPCE525B/M | 575.0 mm x 325.0 mm | XE25C8/M XE25C9/M |

Features

- Flame Retardant

- Certified to EN 12254: 2012(B)*

- Sized to Fit Stock Optical Enclosures

- Fastener Kits Attach Panels to 25 mm Rails

- 1.6 mm Typical Fabric Thickness

- For Custom Sizes, Contact Tech Support

These laser safety fabric panels are designed to replace the side panels of our optical enclosures. Using the fasteners sold separately below, the panels can be attached to the 25 mm rails that make up the enclosure frame. The eyelets on the fabric panels are positioned to align with the channels on the sides of the rails. The table to the right shows compatible stock enclosures for each size panel. If building a custom enclosure using 25 mm rails, please see the complete drawings by clicking on the red Docs icon (![]() ) below.

) below.

Thorlabs' laser safety fabric is designed to withstand high laser energy up to EN 12254: 2012(B) certification. The laser rated material is made of a rubber compound fabric, which is the same material used to make our laser safety fabric and laser safety curtains.

For instructions on attaching a fabric panel to an enclosure, please refer to the manual.

*DISCLAIMER

This laser safety fabric has been tested by a third party using EN specifications; see the Certifications tab above for details. Due to manufacturing variances, mechanical wear, and laser damage, Thorlabs assumes no responsibility for laser material failure. Please consult your local laser safety specialist before purchasing to ensure that the fabric is suitable for your application. To minimize risk, inspect the material before each use and ensure that it is in excellent condition.

DISCLAIMER

These laser safety fabric panels have been tested by third parties using a variety of state regulations and EN specifications. Due to manufacturing variances, mechanical wear, and laser damage, Thorlabs assumes no responsibility for laser safety fabric failure. Please consult your local laser safety specialist before purchasing to ensure that the fabric is suitable for your application. To minimize risk, inspect the fabric before each use and ensure that it is in excellent condition.

| EN Certificationa | ||||

|---|---|---|---|---|

| Certification Requirements | Test Parameters | Damage Threshold | Maximum Spectral Transmittance Ratio |

Certification Levela |

| EN 12254: 2012 (B), 180 - 315 nm Range | 266 nm (CW) | 1 x 106 W/m2 | 10-9 | D AB9 |

| EN 12254: 2012 (B), 180 - 315 nm Range | 266 nm, 230 ms Pulses (Square), 2 Hz | 3 x 105 J/m2 | 10-4 | I AB4 |

| EN 12254: 2012 (B), 180 - 315 nm Range | 266 nm, 5 ns Pulses (Square), 10 Hz | 3 x 104 J/m2 | 10-3 | R AB3 |

| EN 12254: 2012 (B), 180 - 315 nm Range | 266 nm, 600 ps Pulses (Square), 10 Hz | 3 x 1013 W/m2 | 10-3 | M AB3 |

| EN 12254: 2012 (B), 315 - 1050 nm Range | 532 nm (CW) | 1 x 106 W/m2 | 10-6 | D AB6 |

| EN 12254: 2012 (B), 315 - 1400 nm Range | 1064 nm, 7 ns Pulses (FWHM), 10 Hz | 5 x 104 J/m2 | 10-7 | R AB7 |

| EN 12254: 2012 (B), 315 - 1400 nm Range | 1070 nm, 200 ms Pulses (Square), 2 Hz | 5 x 105 J/m2 | 10-8 | I AB8 |

| EN 12254: 2012 (B), 315 - 1400 nm Range | 1064 nm, 600 ps Pulses (Square), 10 Hz | 1.5 x 104 J/m2 | 10-8 | M AB8 |

| EN 12254: 2012 (B), 1050 - 1400 nm Range | 1070 nm (CW) | 2.5 x 107 W/m2 | 10-6 | D AB6 |

| EN 12254: 2012 (B), 1400 - 106 nm Range | 10.6 µm (CW) | 1 x 107 W/m2 | 10-4 | D AB4 |

| EN 12254: 2012 (B), 1400 - 106 nm Range | 10.6 µm, 5 ms Pulses (Square), 10 Hz | 1 x 106 J/m2 | 10-4 | I AB4 |

| EN 12254: 2012 (B), 1400 - 106 nm Range | 10.6 µm, 60 ns Pulses (Square), 2 Hz | 1 x 105 J/m2 | 10-3 | R AB3 |

| Other EN Certificationsa | |||

|---|---|---|---|

| Certification Type | Test Wavelength | Pulse Width (FWHM) |

Comments |

| Mechanical Strength | N/A | N/A | UV-exposed protected fabric. No tearing observed in samples. |

| Resistance to Ignition | N/A | N/A | Samples exposed as required to flame. Flame self extinguished within 1 second. Flame did not reach test mark during ignition. |

| Spectral Transmission | 190 nm - 20 000 nm | N/A | Samples measured for spectral transmission using multiple spectrophotometers over wavelength range 190 nm - 20 µm. Samples blocked all radiation to the limits of the instrumentation over the wavelength range. |

| Stability to Elevated Temperature | Various | Various | Samples maintain resistance to laser radiation (scale number) after temperature exposure commensurate with data generated on samples not exposed to elevated temperature. |

| Stability to UV Radiation | N/A | N/A | Samples exhibited similar optical density to reported laser scale number. |

| Additional Certifications | |

|---|---|

| Certification Requirements | Comments |

| Boston Fire Department Classification Fire Test: BFD IX-1 | After flame shall not exceed two seconds. Flame propagation (char length) and after flame shall not extend beyond six inches from the bottom edge of the specimen. Propagating afterglow shall not exceed forty seconds; non-propagating afterglow in the charred area shall not exceed eighty seconds. |

| California Administrative Code Title 19: Public Safety, Section 1237.1 | The char length may not exceed 6.0 inches for any individual specimen and the average afterflame time may not exceed 4.0 seconds in the length or width directions. |

| NFPA No. 701 Standard Methods of Fire Test for Flame Propogation of Textiles and Films, 2023 Edition, (Test 1)a | The average percent weight loss cannot exceed 40% and the weight loss of individual specimens cannot exceed mean value plus three standard deviations. The average residual flame cannot exceed 2.0 seconds. |

| NYC Cal. No. 294-40-SR | No flashing shall occur at any time on the length of the test specimen. The average continuation of flaming shall not exceed three (3) seconds. The average continuation of glow at the edge of the charred area shall not exceed an additional twenty (20) seconds after the cessation of flaming. |

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Jessica Ross

(posted 2023-10-24 09:59:31.027) Hello,

Similar to the below comment I am also looking to use the laser safety fabric in a cleanroom environment. Is it compatable and are you able to send me some further information? Thanks do'neill

(posted 2023-10-31 05:18:38.0) Response from Daniel at Thorlabs. Our laser safety fabric has not been tested or certified for clear room use. I will reach out to you directly to discuss your application and see if there is anything we can suggest. Juriy Hastanin

(posted 2023-05-31 14:03:38.613) Hello,

1. As the optical enclosure panel to be used in my experimental setup (involving a 1-2 W power laser), I have chosen in your products catalog the ‘Laser Safety Fabric Panel’: LPCE375/M .

My optical setup is dedicated to operate in a Clean Room. Fortunately, not in a vacuum, but in a normal atmosphere. However, operation in such an atmosphere still imposes a number of restrictions on the materials used, in particular, on the level of emitted contamination from the material (especially if this material is fabric).

Accordingly, could you tell me if the selected panel fabric (LPCE375/M) is compatible with cleanroom environment?

If not, please, could you me a quotation for black-anodized aluminum panel of the same geometrical design (sizes + holes for mounting, and 2-3 mm thick) as LPCE375/M?

2. My second question:

In my setup, to connect two multimode optical fibers, I use the connector ‘ADASMA - SMA to SMA Mating Sleeve’ (see: https://www.thorlabs.com/thorproduct.cfm?partnumber=ADASMA).

The laser power to be transmitted is about 1 Watt. Could you tell me if I can to use your index matching gel ‘G608N3’ to refill this fiber connector (to reduce optical losses)? And/or what is the maximal optical power density which can be transmitted in the case of this index matching gel? (see: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=6775)

Thanks in advance.

Best regards, do'neill

(posted 2023-06-07 11:38:43.0) Response from Daniel at Thorlabs. We will reach out to you directly to discuss your application and your questions. |

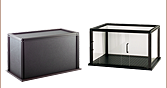

Click to Enlarge

LPCE21B Panel Used to Replace One Hardboard Side of an Optical Enclosure. The thumbscrews can be easily removed in order to access the inside of the enclosure.

- Flame Retardant

- Certified to EN 12254: 2012(B) (See Disclaimer on Overview Tab Above)

- Attach to 25 mm Rails for Optical Enclosures

- Fasteners Sold Separately Below

These laser safety fabric panels are designed for the sides of our optical enclosures, as shown in the image to the right. Alternatively, the panels can be attached to custom-built enclosures using 25 mm rails. The table on the Overview tab above shows compatible enclosure sizes for each curtain panel; if building a custom enclosure using 25 mm rails, please see the complete drawings by clicking on the red Docs icon (![]() ) below.

) below.

While the fabric panel attaches to the outside of the 25 mm rails, be sure to remove the included black hardboard, which fits inside the channels of the rails, from inside. Failure to do so could cause the hardboard to ignite if exposed to a high-power laser.

All imperial curtain panels are 12.99" tall and designed for an enclosure using vertical XE25L12 rails. All metric curtain panels are 325.0 mm tall and designed for an enclosure using vertical XE25L300/M rails.

If the sizes offered here are not suitable for your enclosure application, you can request custom sizes by contacting Tech Support.

The curtain panels can be attached to the 25 mm rails using the fasteners sold separately below.

- Attach Laser Safety Fabric Panels to 25 mm Rail Channels

- Each LPCEF(/M) Kit Includes:

- Seven 8-32 (M4 x 0.7) Thumbscrews

- Seven 8-32 (M4 x 0.7) T-Nuts

- Seven 8-32 (M4 x 0.7) Setscrews

- Replacement 8-32 (M4 x 0.7) Thumbscrews Available [Item # LPCET(/M)]

The LPCEF(/M) fastener kit contains seven sets of thumbscrews, T-nuts, and setscrews. One fastener kit is enough to affix one laser safety fabric panel to the side of a compatible enclosure. Please see the manual for instructions.

The setscrews can be tightened using a 5/64" (2.0 mm) hex key or balldriver, while the thumbscrews do not have a hex socket.

Replacement thumbscrews for the fastener kit are also available in packs of 10.

Products Home

Products Home

Zoom

Zoom

Laser Safety Fabric Panels for Optical Enclosures

Laser Safety Fabric Panels for Optical Enclosures