Benchtop NanoTrak® Active Auto-Alignment Controllers

- Advanced Active Alignment

- High-Voltage Piezo Output Channels for Precise Positioning

- IR (InGaAs) Detector Included

- Visible (Si) Detector Available Separately

Supplied with a Full Suite of Software Support Tools

BNT001/IR

Front Panel

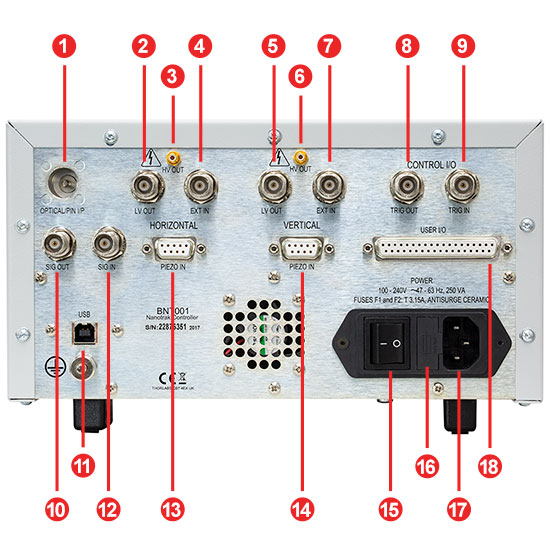

Back Panel

(See Front & Back Panel Tab)

Please Wait

Applications

- Fiber-to-Fiber Active Alignment

- Fiber-to-Free-Space Active Alignment

- Optical Device Alignment

- Waveguide Characterization

- Fiber Characterization and Testing

- Fiber Pigtailing of Active and Passive Devices

- Maintain High Power Throughput to an Entire Optical Setup

| Benchtop Motion Controllers |

|---|

| 1- and 2-Channel Brushless DC Servo Controllers |

| 1-, 2-, and 3-Channel Stepper Motor Controllers |

| 1- and 3-Channel Open Loop Piezo Controllers |

| 1- and 3-Channel Closed Loop Piezo Controllers |

| 2-Channel NanoTrak® Auto-Alignment Controller |

Features

- Active Alignment System with Advanced Light Search Algorithm

- Tracking Feature Maintains Optimum Throughput Indefinitely

- Latch Mode to Maintain Alignment Stability over Time

- Two Piezo Actuator Output Channels Provide Closed-Loop Feedback

- IR (InGaAs) Detector & SMB Connector for External Diodes Included

- Visible (Si) Detector Available Separately

- Full Software GUI Control Suite and Support for Third-Party Custom Applications

- 2-Axis Controller with Dual Controller Connection Capability for Upgrade up to 4 Axes

The NanoTrak® auto-alignment controller combines an intelligent, active-feedback, alignment control system and a two channel, piezoelectric controller into a single benchtop unit. This system is a basic building block from which advanced alignment systems can be quickly configured. It can be fully integrated with our extensive selection of motorized positioning systems, including our 3-Axis NanoMax and 6-Axis NanoMax flexure stages with piezo actuators.

The initial coupling of light from one device (e.g. fiber) to another involves searching a multidimensional space until a signal is detected. The NanoTrak support software offers a series of motor search algorithms for this first light detection. Although used primarily for aligning optical fibers and integrated optical devices, the NanoTrak is ideal for automating just about any labor intensive alignment task, such as waveguide characterization, fiber pigtailing of active and passive devices, as well as a multitude of other R&D applications.

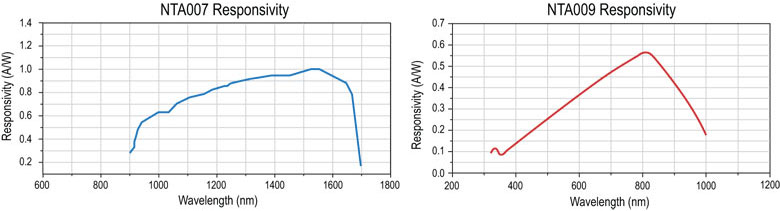

The NanoTrak is supplied with an infrared wavelength, InGaAs detector (Item # NTA007) and an SMB connector for use with external detector heads with a PIN diode. A visible wavelength, Si detector (Item # NTA009) is available separately as detailed in Table 1.1. Our PAA236R 36" long female SMB to male BNC cable is sold separately.

| Table 1.1 NanoTrak® Automated Fiber Alignment Controllers | ||

|---|---|---|

| K-Cube® 2-Channel Controllers | Benchtop 2-Channel Controller | Modular 2-Channel Rack System Module |

BNT001/IR Specifications

| Signal Measurement | |

|---|---|

| PIN Photo-Diode Input | |

| Connector Type | SMB male |

| Current Range | 1 nA to 10 mA Photocurrent |

| Visible Light Detector | |

| Connector Type | FC/PC |

| Detector Type | Silicon (Si) |

| Operating Wavelength | 320 - 1000 nm |

| IR Detector | |

| Connector Type | FC/PC |

| Detector Type | InGaAs |

| Operating Wavelength | 900 - 1700 nm |

| NanoTraking | |

| Circle Scanning Frequency | 1 to 300 Hz |

| Circle Position Range | <1% to >99% Maximum Piezo Extension (MPE) |

| Circle Diameter Adjustment Modes | Automatic and Manual |

| Signal Phase Compensation | -180° to 180° |

| Piezoelectric Input/Output | |

| Number of Piezo Channels | 2 |

| HV Output Connectors | |

| Connector Type | SMC male |

| Voltage Output | 0 to 75 VDC/Channel |

| Voltage Stability | 100 ppm over 24 Hours |

| Noise | < 3 mV (rms) |

| Output Current | 500 mA/Channel |

| Analog Output Monitors | |

| Connector Type | BNC |

| Voltage Range | 0 to 10 VDC |

| Analog Drive Inputs | |

| Connector Type | BNC |

| Voltage Range | 0 to 10 VDC |

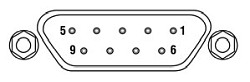

| Strain Gauge Position Feedback | |

| Connector Type | 9 Pin D-type Female |

| Feedback Type | AC |

| Other Input/Output | |

|---|---|

| Optical Power Monitor | |

| Connector Type | BNC |

| Voltage Range | 0 to 10 VDC |

| User Control | |

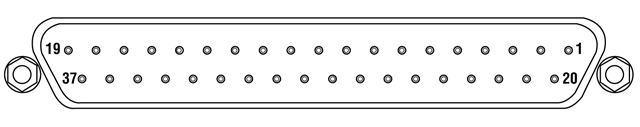

| Connector Type | 37 Pin D-Type Female |

| Isolated Digital Inputs | 8 off TTL |

| Isolated Digital Outputs | 4 off TTL |

| Trigger Input | 1 off TTL |

| Trigger Output | 1 off TTL |

| Potentiometer Channel Control Input | 1 kΩ to 10 kΩ (each channel) |

| Analog Channel Output Monitors | 0 to 10 VDC (each channel) |

| LV Channel1 Output / Trigger Output | |

| Connector Type | BNC |

| Voltage Range (LV Ch1 Mode) | 0 to 10 VDC |

| Trigger Output Mode | TTL |

| LV Channel 2 Output / Trigger Input | |

| Connector Type | BNC |

| Voltage Range (LV Ch2 Mode) | 0 to 10 VDC |

| Trigger Input Mode | TTL |

| USB Port | |

| Connector Type | Type B |

| Speed | USB1.1 |

| Power Requirementsa | |

| Voltage | 85 to 264 VAC |

| Frequency | 47 to 63 Hz |

| Power | 200 W |

| Fuse | 3A |

| General | |

| Dimensions (W x D x H) | 245 x 130 x 330 mm |

| Weight | 6 kg (13 lbs) |

NTA009 Specifications

| Spectral Range | Active Area | Fiber Input | Rise Time | NEP | Dark Current |

|---|---|---|---|---|---|

| 320 - 1000 nm | Ø 0.8 mm | FC/PC Bulkhead | 100 ps @ 12 V | 3.1 x 10-15 W/√Hz | 0.01 nA @ 10 V |

NTA007 Specifications

| Spectral Range | Active Area | Fiber Input | Rise Time | NEP | Dark Current |

|---|---|---|---|---|---|

| 900 - 1700 nm | Ø 0.12 mm | FC/PC Bulkhead | 300 ps @ 5 V | 4.5 x 10-15 W/√Hz | 0.05 nA @ 5 V |

User I/O Controller

D-type Female

| Pin | Description | Return | Pin | Description | Return | Pin | Description | Return |

|---|---|---|---|---|---|---|---|---|

| 1 | Ch 1 RS485 (-) | 20 | 14 | DIG I/P 3a | 27 to 37 | 27 | Isolated Groundb | - |

| 2 | Ch 2 RS485 (-) | 21 | 15 | DIG I/P 4a | 27 to 37 | 28 | Isolated Groundb | - |

| 3 | Not Used | - | 16 | DIG I/P 5a | 27 to 37 | 29 | Isolated Groundb | - |

| 4 | Potentiometer Wiper Ch 1 | - | 17 | DIG I/P 6a | 27 to 37 | 30 | Isolated Groundb | - |

| 5 | Potentiometer Wiper Ch 2 | - | 18 | DIG I/P 7a | 27 to 37 | 31 | Isolated Groundb | - |

| 6 | Channel 1 10 V O/Pd | - | 19 | DIG I/P 8a | 27 to 37 | 32 | Isolated Groundb | - |

| 7 | Channel 2 10 V O/Pd | - | 20 | Ch 1 RS485 (+) | 1 | 33 | Isolated Groundb | - |

| 8 | DIG O/P 1a | 27 to 37 | 21 | Ch 2 RS485 (-) | 2 | 34 | Isolated Groundb | - |

| 9 | DIG O/P 2a | 27 to 37 | 22 | Potentiometer Reference | 23 | 35 | Isolated Groundb | - |

| 10 | DIG O/P 3a | 27 to 37 | 23 | Analog Ground | - | 36 | Isolated Groundb | - |

| 11 | DIG O/P 4a | 27 to 37 | 24 | External Trigger O/Pc | - | 37 | Isolated Groundb | - |

| 12 | DIG I/P 1a | 27 to 37 | 25 | External Trigger I/Pc | - | |||

| 13 | DIG I/P 2a | 27 to 37 | 26 | 5 V User O/P (Isolated) | 27 to 37 |

Piezo Controller

D-type Female

| Pin | Description | Return | Pin | Description | Return | Pin | Description | Return |

|---|---|---|---|---|---|---|---|---|

| 1 | Wheatstone Bridge Excitation | 4 or 6 | 4 | d.c.(+) or Equipment Groundc | - | 7 | d.c.(-) or Actuator ID Signalb,c | 4 or 6 |

| 2 | +15Va | 4 or 6 | 5 | Feedback Signal In | 4 or 6 | 8 | RS485 (-) | 9 |

| 3 | -15Va | 4 or 6 | 6 | Equipment Ground | - | 9 | RS485 (+) | 8 |

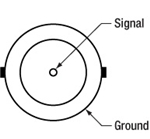

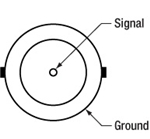

Sig In

BNC Female

0 to 10 V, 100 kΩ load. Used to receive a signal of optical power from an external power meter.

Sig Out

BNC Female

0 to 10 V, 2 mA. Can be connected to an oscilloscope to monitor the power signal received on the OPTICAL IN connection.

HV OUT

SMC

0 to 75 V, 0 to 250 mA. Provides the drive signal to the piezo actuator.

Ext In (+) and Ext IN (-)

BNC Female

Used to control the position of the piezo actuator from an external source. 0 to ±10 V 100 kΩ load. Polarity is selected in the Settings panel or in software by calling the Piezo SetIPSource method. The difference between the two signals is amplified internally before being routed to the HV OUT connector.

LV Ch1/Trig. Out

and LV Ch2/Trig. In

BNC Female

0 to +10 V. These outputs mirror the associated HV OUT, 10 V being equivalent to 75V on the HV outputs, and can be connected to an oscilloscope to enable the drive signal of the piezo actuator to be monitored.

Computer Connection

USB type A

USB Cable Included

Front Panel

| Callout | Description |

|---|---|

| 1 | Enable/Disable Channel 1 Button |

| 2 | Enable/Disable Channel 2 Button |

| 3 | Power LED |

Back Panel

| Callout | Description |

|---|---|

| 1 | 3.5 mm Jack for Optical/Pin I/Pa |

| 2 | BNC for Monitor Out for Horizontal Actuator |

| 3 | SMC Connector HV Out for Horizontal Actuator Drive Signal |

| 4 | BNC for Monitor In for Horizontal Actuator |

| 5 | BNC for Monitor Out for Vertical Actuator |

| 6 | SMC Connector HV Out for Vertical Actuator Drive Signal |

| 7 | BNC for Monitor In for Vertical Actuator |

| 8 | BNC for Control I/O Trigger Out |

| 9 | BNC for Control I/O Trigger In |

| 10 | BNC Signal Out for an External Power Meeter |

| 11 | USB Type-B Port for System Communications |

| 12 | BNC Signal In for an External Power Meter |

| 13 | 9-Pin D-Type Female Port Input for Horizontal Movement |

| 14 | 9-Pin D-Type Female Port Input for Vertical Movement |

| 15 | Main Power Switch |

| 16 | Fuse Holder |

| 17 | AC Power Cord Connector |

| 18 | 37-Pin D-Type Female Port for Programmable I/O |

Principle of Operation

During the auto-alignment process, the NanoTrak® uses gradient search algorithms to locate the direction of a peak signal. This operation is similar to that of a compass finding the north pole. The sensitivity of the search is such that even far away from the peak signal, where there are small power gradients, the NanoTrak can decide in which direction the peak signal is located. This information is then used to make positional corrections via the attached high speed piezo actuators without having to map or search a large area.

In the proximity of a peak signal, the signal gradient seen is much smaller, indicating that smaller positional correction is required. When peak signal is reached the gradient seen changes to zero, indicating that no positional correction is needed.

The dynamic behaviour of the NanoTrak allows it to continue the alignment process indefinitely. Should the alignment change, the gradient search will detect the change and make a corrective move.

Typical Application Example (Optical Device Alignment)

Optical power transmission through any system under alignment can be described as a Gaussian coupling. Coupled power lowers as a function of distance relative to the aligned position (dependent upon device). Discrete power level alignments can be thought of as positions about the ideal coupling position, where the distances from the aligned position are equal. These discrete power alignment positions form concentric circles. These concentric circles represent the power contours and can be thought of as the gradient contours of a hill on a topographic map.

By detecting the gradient of the power at any given position, the NanoTrak can adjust the position until the power is maximized and the gradient becomes zero. This is achieved by scanning over the contours in a circular path to establish the direction of the signal maximum on the circular trajectory. The origin of the scan circle is then moved in the direction of the signal maximum.

Continuous active alignment can be used to maintain alignment, or the search algorithms can be halted for next step assembly or R&D operations.

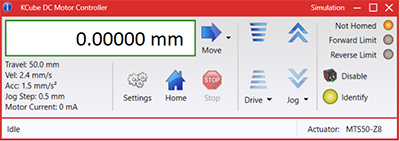

Software

Kinesis Version 1.14.53

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Figure 58A Kinesis GUI Screen

Thorlabs offers the Kinesis software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes®) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Thorlabs' Kinesis software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

| Posted Comments: | |

Anders Harpøth

(posted 2023-05-10 06:18:27.943) Dear Thorlabs

I have the NanoTrak® Auto-Alignment Controller (BNT001).

I would like the functionality of the NTA009 NanoTrak® Visible Light (Si) Detector Head, 320 - 1000 nm, but I would prefer to avoid the optical patch-cord and have the Si photodiode near the light source and then connect through the standard SMB connector on the controller.

So basically my question is what detector setup do I need to mimic what's inside the NTA009?

Thank you

Best regards

Anders do'neill

(posted 2023-05-15 07:00:16.0) Response From Daniel at Thorlabs. There is functionality with the BNT001 to connect to an external detector using the BNC "Sig In" connector that receives a 0 to 10 V signal. I will reach out to you directly to discuss your application. Vedavyas Sivakumar

(posted 2022-07-14 12:19:35.267) Can I get the wavelength/responsivity data for this detector? cwright

(posted 2022-07-15 08:18:12.0) Response from Charles at Thorlabs: Thank you for contacting us. We have reached out to you with the requested data. empire135

(posted 2016-10-25 12:36:39.393) I lost my software CD. Can i get a software? I have a serial number of BNT001(SN:22829095). bhallewell

(posted 2016-10-25 08:55:19.0) Response from Ben at Thorlabs: Thank you for your product feedback. You can download our new Kinesis software Motion Control software from the following link. Here you can also find further links to resources including example code as well as links to our legacy software package, APT.

https://www.thorlabs.de/software_pages/ViewSoftwarePage.cfm?Code=Motion_Control frederic.vandijk3-5lab.fr

(posted 2015-06-16 08:40:20.147) I finally succeeded in making the system work. It works very well. The software interface is very intuitive and efficient. We are going to save a lot of time during the numerous optical alignments. msoulby

(posted 2015-06-16 03:52:11.0) Response from Mike at Thorlabs: I am glad to hear that you have solved the problem and we appreciate your feedback on the software interface. Please feel free to contact us if you have any further questions. frrederic.vandijk

(posted 2015-06-13 09:40:40.387) We just acquired a BNT001/IR system. I installed the software downloaded from the net successfully (no CD delivered with the system), installed it on a windows7 os pc, re-started the pc after connecting the BNT001/IR and couldn't see the user interface when using the APT-user software. Can you help me with this big problem? msoulby

(posted 2015-06-16 03:45:45.0) Response from Mike at Thorlabs: If the user interface does not appear there are a few things that can typically cause this. 1) Please ensure all USB cables are connected prior to powering up the controller, this is to help ensure USB communication is established correctly. 2) Check that the simulator mode is disabled in APT config, having this enabled accidently will prevent you from using the actual unit. 3) In APT User if the interface is not displayed you can check the View menu and then expand the 'graphical panels' sub-menu, in here you will be able to open or close any active devices that are currently connected. Laurie

(posted 2009-02-05 17:12:29.0) Response from Laurie at Thorlabs to melsscal: Thank you for your interest in our BNT001 nano trak controller. Yes, it can be used with our MAX313/M. melsscal

(posted 2009-02-05 03:45:50.0) Can we use BNT001 as Nano Track Controller with MAX313/M ? Regards A.K.Bose |

Click to Enlarge

Figure G1.2 The NTA007 detector installed at the top left of a BNT001/IR Controller.

Click for Details

Figure G1.1 The SMB connector installed at the top left of a BNT001/IR Controller.

The NanoTrak® Auto-Alignment Controller optimizes the coupling power when aligning devices. The output piezo drive signal is used to position the input and output devices for optimum throughput. It is shipped with an NTA007 InGaAs detector for wavelengths from 900 nm to 1700 nm. The detector plugs into the back of the unit via a three-pole 3.5 mm jack. An NTA009 Si detector for wavelengths from 320 - 1000 nm is available separately (see below). The controller also includes an SMB connector, which can be used to incorporate an external detector with a PIN diode. We offer a PAA236R 36" long female SMB to male BNC cable which can be purchased separately.

Click to Enlarge

Click to EnlargeFigure 393A Detector Head, Back View

These infrared (NTA007) and visible (NTA009) wavelength detector heads are compatible with the benchtop (BNT001/IR), previous-generation T-Cube™ (TNA001/IR), and rack-mounted (MNA601/IR) NanoTrak® controllers. Both detector heads have an FC/PC optical fiber input and interface with the benchtop controller via a jack at the back of the detector, as shown Figure 393A.

| Item # | Wavelength Range | Active Area | Fiber Input | Dark Current | Junction Capacitance |

|---|---|---|---|---|---|

| NTA009 | 320 - 1000 nm | Ø 0.8 mm | FC/PC | 0.01 nA (Typ.) @ 10 V | 3.00 pF(Typ.) @ 10 V |

| NTA007 | 900 - 1700 nm | Ø 0.12 mm | FC/PC | 0.05 nA (Typ.) @ 5 V | 2.0 pF (Typ.) @ 5 V |

Products Home

Products Home

Zoom

Zoom

Benchtop NanoTrak® Controller

Benchtop NanoTrak® Controller