Differential Adjuster Screws

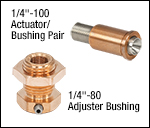

- 1/4"-80, 1/4"-100, or M6 x 0.25 Coarse Adjustment Thread

- 25 µm/rev Fine Adjustment Over 400 µm of Travel

- 1.02" Imperial or 25.6 mm Metric Adjuster Length

Use the DAS110 in

Our Kinematic Mirror

Mounts for Ultra-Fine

Differential Tip & Tilt

KM200

Post and

Post Holder

Not Included

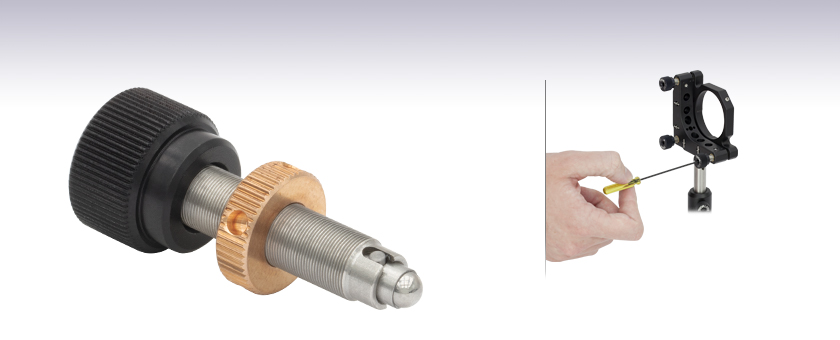

DAS110

1/4"-80 Externally Threaded Differential Adjuster

US Patent 7,421,918

Please Wait

Click to Enlarge

Figure 1.1 Coarse Thread Length and Adjuster Length (L)

Click for Details

Figure 1.2 A Cross-Section of a Differential Adjuster Screw,

Showing the Internal Components

Features

- Length of Screws:

- DAS110 and DAS25U: 1.02" (26.0 mm)

- DAS6M 1.01" (25.6 mm)

- 1/4"-80, 1/4"-100, or M6 x 0.25 Coarse Thread Options

- Fine Adjustment: 25 µm/rev Over ≥400 µm of Travel

- Ø0.49" (12.4 mm), 0.15" (3.8 mm) Thick Locking Ring

- On-Axis Load Capacity: 11.25 lbs (5.1 kg)

- Recommended Preload: 1 to 2 lbs (0.5 to 1 kg)

Thorlabs' Differential Adjuster Screws come pregreased to ensure smooth mating into compatible components. To install an adjuster, screw the threads into the bushing by hand. Ensure that cross threading does not occur in order to avoid damage to the adjuster and bushing. Additionally, each screw includes a Ø0.49" (Ø12.4 mm), 0.15" (3.8 mm) thick locking ring with a knurled surface for improved grip. Four Ø0.09" (Ø2.3 mm) blind holes in each ring allow a hex key to be inserted to assist with tightening.

The DAS110 Differential Adjuster Screw can replace the standard 1/4"-80 adjusters used on most Thorlabs' Kinematic Mirror Mounts.

Coarse Adjustment

When used with a compatible component, coarse adjustment is provided by the external threads on the main screw body, labeled B on Figure 1.2. The screw can be actuated using the attached knob, labeled A, or the 5/64" (2 mm) hex socket. The knob can also be removed if needed due to space constraints.

Fine Adjustment

The fine-adjustment mechanism provides a highly de-magnified displacement of 25 µm per revolution and can be actuated using a 1/16" hex accessible through the center of the 5/64" (2 mm) hex for coarse adjustment.

As illustrated in Figure 1.2, an intermediate actuator, labeled C, is threaded into the main body screw (B) and onto a push rod (D) that terminates with a ball tip. A pin on the push rod fits into a slot on the main body screw and prevents these two components from rotating relative to each other. As a result, when the intermediate actuator is rotated, it will be translated along the main body screw at a rate determined by the intermediate actuator's external thread pitch while the push rod is translated in the opposite direction at a rate determined by the intermediate actuator's internal thread pitch. Thus, differential movement is achieved between the intermediate actuator and the push rod.

In the case of the actuators below, the intermediate actuator has an external thread pitch of 400 µm and an internal thread pitch of 375 µm. When the intermediate actuator is rotated clockwise, it advances in the main body by 400 µm per revolution. At the same time, the push rod, which is restricted from rotating by the main body, retreats by 375 µm per revolution, providing a total displacement of 25 µm per revolution.

| Item # | Coarse Adjustment Thread | Adjuster Length (L) | Coarse Thread Lengtha | Coarse Adjustment Hex | Fine Adjustment Hex |

|---|---|---|---|---|---|

| DAS110 | 1/4"-80 | 1.02" (26 mm) | 0.76" (19.3 mm) | 5/64" (2 mm) | 1/16" |

| DAS25U | 1/4"-100 | ||||

| DAS6M | M6 x 0.25 | 1.01" (25.6 mm) |

OEM & Custom Precision Screws

Thorlabs manufactures custom and high volume OEM precision screws and bushings with various diameters, lengths, and threads. To inquire about custom or OEM precision screws, please contact Technical Sales or use the "Contact Us" button. A specialist will contact you within 24 hours or the next business day.

Precision Screw Capabilities

Thorlabs' in-house machine shop, located in Newton, NJ, gives us the ability to quickly produce large quantities of precision screws and bushings. We are equipped to manufacture screw diameters ranging from 2 mm to 20 mm with lengths up to 165 mm and a maximum thread pitch of 200 TPI. Our standard adjuster screw design has a hardened steel ball tip to provide a single point of contact; for other applications we are able to provide adjusters without the steel ball. Custom orders can be achieved on a case-by-case basis. For large orders of an item, Thorlabs passes on to the customer the cost savings associated with planned production of high volumes of that item. For more information on Thorlabs' discount pricing policy, click the "V" link in the OEM & Custom Precision Screws box. We also offer a large variety of stock precision screws, which are available here.

Fast Turn-Around Times

Our experienced, highly skilled machinists are running our on-site Citizen Swiss Screw Machines 24 hours a day, allowing us to produce high-volume custom and OEM orders. Each machine is capable of running unattended, producing one screw every 30 to 120 seconds. This flexibility allows us to fulfill multiple orders at once without sacrificing quality.

High Quality

Thorlabs inspects all of our fabricated precision screws and bushings after the initial fabrication process and right before packaging. All inspections adhere to the ANSI AQL1.5 acceptable quality level, which states that if a certain percentage, based upon the amount of product in a certain lot, does not meet specification, then the entire lot is not sold. This ensures that all customers receive the highest quality product every time and that all items will be of equal performance.

Video 33A Precision Screw Production

| Posted Comments: | |

Duane Dudley

(posted 2022-03-29 12:39:35.217) Does the internal mechanism have oil / grease lubricant? We were planning on having it sent out for vacuum-compatible cleaning.

Thank you! jdelia

(posted 2022-03-30 10:04:15.0) Thank you for contacting Thorlabs. We currently use an Apiezon grease mixture in our DAS110. I have contacted you directly to discuss your application further. Jeremy Canonge

(posted 2021-03-17 09:45:28.933) Hello,

I have a very sensitive optical application that will be subject to large changes in temperature. I was hoping to use these adjustors for fine alignment of the system, which will require that they remain as a part of the system during operation. I will need to know the CTE's of each component within the assembly to properly account for its dimensional changes over temperature. Can you please provide this information, or at a bare minimum, the material of each component used within the assembly?

Thank you,

Jeremy Canonge YLohia

(posted 2021-03-18 02:37:17.0) Hello Jeremy, thank you for contacting Thorlabs. Following are the components and materials used. Main Body, Pushrod, Actuator, and Adjuster Stop: 303 Stainless Steel. Steel Ball Bearing: 440 SS. Hex Knob: 6061-T6 Aluminum. Locking Nut: 510 Phosphor Bronze. user

(posted 2021-02-24 15:09:35.733) It would be great to have differential actuators similar to DAS110 that are compatible with the Polaris mirror mounts! YLohia

(posted 2021-03-12 04:03:51.0) Hello, thank you for your feedback. We will consider adding such an item to our catalog in the future. fabien.l.lalisse

(posted 2017-12-14 11:59:46.617) Hi,

I have a question. Can I use you product for aerospace application ? Is it vaccum proof ? If not why ? Dou you suggest a lubricate between screw and bushing ?

Thanks

Regards tfrisch

(posted 2017-12-15 08:47:38.0) Hello, thank you for contacting Thorlabs. Unfortunately, the stock version of DAS110 is not vacuum compatible as it has an anodized aluminum knob and glue to hold the ball and dowel pin. However, we can offer a ventilated and vacuum compatible version. We will reach out to you about your application and what level of vacuum you will be operating in. tcohen

(posted 2012-05-03 16:01:00.0) Response from Tim at Thorlabs: Thank you for providing your solution! This is the recommended way to remove the knob. user

(posted 2012-05-03 15:33:40.0) You can insert a 5/64" ball driver in the back to hold the screw stationary and then rotate the knob with your fingers to unscrew. This worked for me. inicolaescu

(posted 2012-05-03 15:01:04.0) I hust received my order of 8 Differential Adjuster Screws, DAS110. The overview on this page states that the knob can be removed. I could not do it and I don't want to try too hard and damage the thread. How can this be done?

Thank you,

Ion Nicolaescu user

(posted 2011-12-09 13:14:48.0) A response from Tyler at Thorlabs: Hello Sergio, the differential actuators on this page are not designed for use with a potentiometer. Instead they can be used to replace standard adjustors on optomechanical components to improve the resolution of the adjustment of that component. sergio

(posted 2011-12-08 11:57:09.0) Hello, I'm not an expert in electricity, but I'm working on a project and need some assistance. I have 10,000 and 100,000 OHM potentiometers to dim lighting in a room. My question is: Does this product work with potentiometers? and how is it installed? Your help will be greatly appreciated. bdada

(posted 2011-07-29 12:00:00.0) Response from Buki at Thorlabs:

Thank you for sharing your experience. user

(posted 2011-07-29 11:39:06.0) I had a little trouble getting the actuator to work: In addition to the 1/16" hex socket that turns the differential mechanism, the screw has a concentric 5/64" hex socket that drives the coarse thread. Thats not much bigger, and the 1/16" hex key I was using was a bit oversized, at 0.072". It was catching on the coarse adjust, and not letting the differential adjustment turn. The folks at tech support were very helpful, and all is good now. But I thought Id post here in case someone else has the same problem. jjurado

(posted 2011-07-07 13:24:00.0) Response from Javier at Thorlabs to brian: Thank you very much for your feedback! We will update the presentation of the DAS110 differential adjustment screw shortly to reflect all the changes you suggest here. brian

(posted 2011-07-07 09:56:09.0) I find that the picture on the right is too low resolution to easily understand the mechanism. The load rating mentioned here in the feedback area should probably be posted on the product description page. I also think it would be helpful if the matching brass inserts were shown in the related products. jjurado

(posted 2011-06-14 15:20:00.0) Response from Javier at Thorlabs to charley.hale: Thank you very much for contacting us. We currently do not have a concise value for the optimal preload when using this actuator. However, a preload of 1-2 lbs should provide enough support for the actuator to rotate smoothly. Keep in mind that this value should be subtracted from the maximum load capacity value of 11.25 lbs when using heavy loads. charley.hale

(posted 2011-05-09 13:56:44.0) I am also keen to know the optimal preload for this actuator; has it been posted elsewhere since the question noted earlier below? bdada

(posted 2011-04-13 14:19:00.0) Response from Buki at Thorlabs:

The maximum load on the screw is 11.25 lbs or 5.1 kg. We will post the recommended preload shortly. user

(posted 2011-04-12 15:59:51.0) What is the maximum load on the screw? What is the recommended preload for the screw? Greg

(posted 2011-01-11 11:07:45.0) A response from Greg at Thorlabs to carollo: We do not currently have a backlash specification for the DAS110. The adjuster is commonly used with a preload, which significantly minimizes backlash. However, I am working with our Mechanics group to see if they can give a nominal backlash value for you. carollo

(posted 2011-01-06 15:02:54.0) Is there a backlash specification for the coarse and fine adjustments? High spatial resolution is great, but if it comes with significant backlash that is an important consideration.

Thanks! apalmentieri

(posted 2010-03-09 12:17:32.0) A response from Adam at Thorlabs to rivale23: You do not need two actuators to perform fine movements. All you need is a 1/16" hex wrench. A description of how the fine adjustment is below.

The fine-adjustment (25 µm/rev) is actuated by inserting a hex wrench through the clearance hole in the adjuster knob. Each rotation of the DAS110 fine-adjustment mechanism yields a highly de-magnified displacement of just 25 µm.

The Main Body "B" is also internally threaded with an M3-0.40 thread, this thread holds the intermediate actuator "C", which may be rotated by a hex wrench. The key to the design is that the intermediate actuator is both internally and externally threaded allowing a differential movement to be achieved between the intermediate actuator "C" and the Push Rod "D". See image under the overview tab.

The external thread of the intermediate actuator is the same M3-0.40 mm thread internal to the Main Body. When the intermediate actuator is rotated clockwise, it moves out of the Main body by 400 µm per revolution. Connected to the internal thread of the intermediate actuator is the Push Rod; the Push Rod mates to the intermediate actuator via a M3-0.375 thread and is restricted from rotating by the main body. Now as intermediate actuatoris rotated, it advances at the rate of 400 µm/rev. but the Push Rod retreats at 375 µm/rev. This results in a differential motion of the Push Rod that is equal to the net difference of the pitch of the two threads for total displacement of 25 µm/rev. rivale23

(posted 2010-03-09 12:10:11.0) I need to know how does the fine movement works, i mean, once the wrench is inserted the movement turns to fine, do i need two moves to have the fine move?, or i need only one actuator to mke the screw move with the fine move klee

(posted 2009-09-29 10:04:00.0) A response from Ken at Thorlabs to john: We will send you the drawings in DWG format that should work with AutoCAD Rev 14. john

(posted 2009-09-29 09:16:29.0) I cannot open the DXF copy of the design drawing. Im using AutoCAD Rev 14. Is there a problem with this version klee

(posted 2009-08-26 15:37:27.0) A response from Ken at Thorlabs to mfaraday and aeinstein: The range of the fine adjustment for the DAS110 is about 250um. The locking nut is included with the DAS110. aeinstein

(posted 2009-08-25 22:07:26.0) Is a locking nut included, one is shown in photo at the top of the page but not down where the details of the product are provided. mfaraday

(posted 2009-08-25 22:04:12.0) Please add the approximate range of the fine motion portion of the DAS110.

FCA200 is still noted in bullets but seems to be removed from page. |

Products Home

Products Home

Differential Adjuster Screws

Differential Adjuster Screws