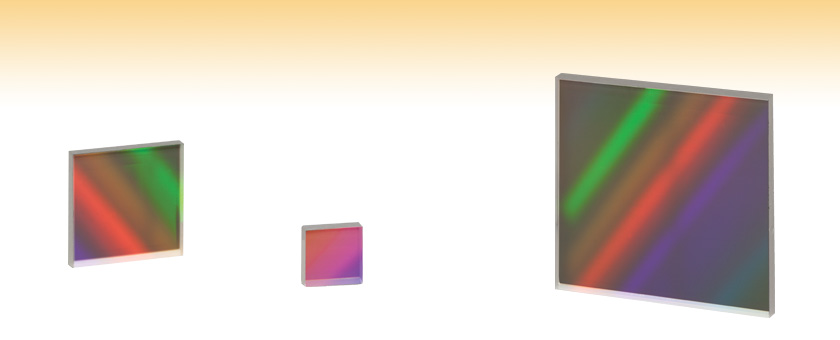

Visible Transmission Gratings

- Grating Designed for Optimum Performance in the Visible

- Four Groove Densities Available: 300, 600, 830, and 1200 Grooves/mm

- Three Sizes Available:

12.7 mm x 12.7 mm, 25 mm x 25 mm, and 50 mm x 50 mm

GT25-03

(25 mm x 25 mm)

GT13-03

(12.7 mm x 12.7 mm)

GT50-03

(50 mm x 50 mm)

Please Wait

| Selection Guide | |

|---|---|

| Transmission Gratings | |

| Ruled | UV |

| Visible | |

| Near IR | |

| Volume Phase Holographic |

Visible |

| Near IR | |

| Reflective Gratings | |

| Ruled | UV |

| Visible | |

| Near IR | |

| Mid IR | |

| Holographic | |

| Echelle | |

| Common Specifications | |

|---|---|

| Substrate Material |

Schott B270 |

| Thickness | 3 mm Nominal |

| Dimensional Tolerance |

± 0.5 mm |

| Thickness Tolerance |

± 0.5 mm |

Features

- Optimum Performance in the Visible Spectrum

- Ideal for Fixed Grating Applications such as Spectrographs

- Schott B270 Substrate

- Custom Sizes Available Upon Request

Thorlabs' Visible Transmission Gratings are ideal for fixed grating applications such as spectrographs. The incident light is dispersed on the opposite side of the grating at a fixed angle. Transmission gratings offer low alignment sensitivity, which helps minimize alignment errors. In most cases, the efficiency of these gratings is comparable to that of reflection gratings such as Ruled Gratings or Holographic Gratings when used in the same wavelength range.

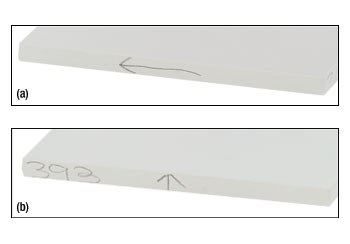

Click to Enlarge

Figure 1.1 On one edge of the grating, (a), an arrow parallel to the grating's surface indicates the blaze direction (as defined in the Gratings Tutorial tab). On the opposite edge of the grating, (b), an arrow perpendicular to the grating's surface indicates the transmission direction.

Transmission gratings require relatively low groove densities to maintain high efficiency. As the diffraction angles increase with higher groove densities, the refractive properties of the substrate material limits the transmission at the higher wavelengths and performance drops off. The grating dispersion characteristics, however, lend themselves to compact systems utilizing small detector arrays. These gratings are also relatively polarization insensitive. Our visible transmission gratings are offered with four different groove densities in three different sizes. Please see the Gratings Guide tab to choose the right grating type for your application.

Optical gratings can be easily damaged by moisture, fingerprints, aerosols, or the slightest contact with any abrasive material. Gratings should only be handled when necessary and always held by the sides. Latex gloves or a similar protective covering should be worn to prevent oil from fingers from reaching the grating surface. No attempt should be made to clean a grating other than blowing off dust with clean, dry air or nitrogen. Solvents will likely damage the grating's surface.

Thorlabs uses a clean room facility for assembly of gratings into mechanical setups. If your application requires integrating the grating into a sub-assembly or a setup, please contact us to learn more about our assembly capabilities.

Mounts and Adapters

Thorlabs' gratings can be mounted directly into the KM100C Right-Handed or KM100CL Left-Handed Kinematic Rectangular Optic Mount for precise and stable mounting and alignment.

Diffraction Gratings Tutorial

- Introduction

- Blazed (Ruled) Gratings

- Volume Phase Holographic Transmission Gratings

- Holographic Reflective Gratings

Introduction

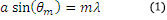

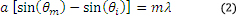

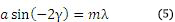

Diffraction gratings, either transmissive or reflective, can separate different wavelengths of light using a repetitive structure embedded within the grating. The structure affects the amplitude and/or phase of the incident wave, causing interference in the output wave. In the transmissive case, the repetitive structure can be thought of as many tightly spaced, thin slits. Solving for the irradiance as a function wavelength and position of this multi-slit situation, we get a general expression that can be applied to all diffractive gratings when = 0°,

known as the grating equation. The equation states that a diffraction grating with spacing will deflect light at discrete angles (

), dependent upon the value

λ, where

is the order of principal maxima. The diffracted angle,

, is the output angle as measured from the surface normal of the diffraction grating. It is easily observed from Equation 1 that for a given order

, different wavelengths of light will exit the grating at different angles. For white light sources, this corresponds to a continuous, angle-dependent spectrum.

Figure 48A Transmission Grating

Transmission Gratings

One popular style of grating is the transmission grating. The sample diffraction grating with surfaces grooves shown in Figure 48A is created by scratching or etching a transparent substrate with a repetitive series of narrow-width grooves separated by distance . This creates areas where light can scatter.

The incident light impinges on the grating at an angle , as measured from the surface normal. The light of order

exiting the grating leaves at an angle of

, relative to the surface normal. Utilizing some geometric conversions and the general grating expression (Equation 1) an expression for the transmissive diffraction grating can be found:

where both and

are positive if the incident and diffracted beams are on opposite sides of the grating surface normal, as illustrated in the example in Figure 48A. If they are on the same side of the grating normal,

must then be considered negative.

Figure 48B Reflective Grating

Reflective Gratings

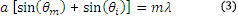

Another very common diffractive optic is the reflective grating. A reflective grating is traditionally made by depositing a metallic coating on an optic and ruling parallel grooves in the surface. Reflective gratings can also be made of epoxy and/or plastic imprints from a master copy. In all cases, light is reflected off of the ruled surface at different angles corresponding to different orders and wavelengths. An example of a reflective grating is shown in Figure 48B. Using a similar geometric setup as above, the grating equation for reflective gratings can be found:

where is positive and

is negative if the incident and diffracted beams are on opposite sides of the grating surface normal, as illustrated in the example in Figure 48B. If the beams are on the same side of the grating normal, then both angles are considered positive.

Both the reflective and transmission gratings suffer from the fact that the zeroth order mode contains no diffraction pattern and appears as a surface reflection or transmission, respectively. Solving Equation 2 for this condition, =

, we find the only solution to be

=0, independent of wavelength or diffraction grating spacing. At this condition, no wavelength-dependent information can be obtained, and all the light is lost to surface reflection or transmission.

This issue can be resolved by creating a repeating surface pattern, which produces a different surface reflection geometry. Diffraction gratings of this type are commonly referred to as blazed (or ruled) gratings. More information about this can be found in the section below.

Blazed (Ruled) Gratings

Figure 48D Blazed Grating, 0th Order Reflection

Figure 48C Blazed Grating Geometry

The blazed grating, also known as the echelette grating, is a specific form of reflective or transmission diffraction grating designed to produce the maximum grating efficiency in a specific diffraction order. This means that the majority of the optical power will be in the designed diffraction order while minimizing power lost to other orders (particularly the zeroth). Due to this design, a blazed grating operates at a specific wavelength, known as the blaze wavelength.

The blaze wavelength is one of the three main characteristics of the blazed grating. The other two, shown in Figure 48C, are , the groove or facet spacing, and

, the blaze angle. The blaze angle

is the angle between the surface structure and the surface parallel. It is also the angle between the surface normal and the facet normal. Note that Figure 48C also defines the direction of the "blaze arrow"; this arrow is visibly marked on one edge of all Thorlabs' blazed transmission gratings.

The blazed grating features geometries similar to the transmission and reflection gratings discussed thus far; the incident angle () and

th order reflection angles (

) are determined from the surface normal of the grating. However, the significant difference is the specular reflection geometry is dependent on the blaze angle,

, and NOT the grating surface normal. This results in the ability to change the diffraction efficiency by only changing the blaze angle of the diffraction grating.

The 0th order reflection from a blazed grating is shown in Figure 48D. The incident light at angle is reflected at

for

= 0. From Equation 3, the only solution is

= –

. This is analogous to specular reflection from a flat surface.

Figure 48F Blazed Grating, Incident Light Normal to Grating Surface

Figure 48E Blazed Grating, Specular Reflection from Facet

The specular reflection from the blazed grating is different from the flat surface due to the surface structure, as shown in Figure 48E. The specular reflection, , from a blazed grating occurs at the blaze angle geometry. This angle is defined as being negative if it is on the same side of the grating surface normal as

. Performing some simple geometric conversions, one finds that

Figure 48F illustrates the specific case where = 0°, hence the incident light beam is perpendicular to the grating surface. In this case, the 0th order reflection also lies at 0°. Utilizing Eqs. 3 and 4, we can find the grating equation at twice the blaze angle:

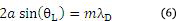

Littrow Configuration for Reflective Gratings

The Littrow configuration refers to a specific geometry for blazed gratings and plays an important role in monochromators and spectrometers. It is the angle at which the grating efficiency is the highest. In this configuration, the angle of incidence of the incoming and diffracted light are the same,

=

, and

> 0 so

Figure 48G Littrow Configuration

The Littrow configuration angle, , is dependent on the most intense order (

= 1), the design wavelength,

, and the grating spacing

. It is easily shown that the Littrow configuration angle,

, is equal to the blaze angle,

, at the design wavelength. The Littrow / blaze angles for all Thorlabs' Blazed Gratings can be found in the grating specs tables.

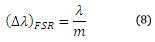

It is easily observed that the wavelength dependent angular separation increases as the diffracted order increases for light of normal incidence (for = 0°,

increases as

increases). There are two main drawbacks for using a higher order diffraction pattern over a low order one: (1) a decrease in efficiency at higher orders and (2) a decrease in the free spectral range,

![]() , defined as:

, defined as:

where is the central wavelength, and

is the order.

The first issue with using higher order diffraction patterns is solved by using an Echelle grating, which is a special type of ruled diffraction grating with an extremely high blaze angle and relatively low groove density. The high blaze angle is well suited for concentrating the energy in the higher order diffraction modes. The second issue is solved by using another optical element: grating, dispersive prism, or other dispersive optic, to sort the wavelengths/orders after the Echelle grating.

Figure 48H Volume Phase Holographic Grating

Volume Phase Holographic Transmission Gratings

Unlike traditional gratings, volume phase holographic (VPH) gratings do not have surface grooves. Instead, VPH gratings consist of a dichromated gelatin (DCG) film between two glass substrates. These VPH gratings are designed to reduce the periodic errors that can occur in blazed gratings. Surface gratings with high groove density also have an issue with polarization dependent loss. These unique transmission gratings deliver high first-order diffraction peak efficiency, low polarization dependence, and uniform performance over broad bandwidths.

The desired grating pattern is comprised of a repetitive series of lines separated by distance . The fringe planes for transmission gratings are perpendicular to the plane of the plate as seen in Figure 48H, allowing any frequency of light to pass through the plate. Diffraction occurs as incoming light crosses through the DCG film. Therefore, the three major factors that determine performance are film thickness, bulk index (the average index of refraction between Bragg planes), and index modulation (the difference of index of refraction between the Bragg planes). The incident light enters the grating at an angle of

, as measured from the surface normal. The light of order

exiting the grating leaves at an angle of

, relative to the surface normal. The grating expression mentioned above can be used to calculate diffraction angles for volume phase holographic gratings since dispersion is based on the line density. The quality of the grating is determined by the fringe contrast, with a poor fringe contrast resulting in low efficiency or no grating at all.

The DCG film is taken through multiple quality control steps to ensure it performs up to standard and then cut into the desired size. The film is sealed between two glass covers to prevent degradation of the material. Since the DCG film is contained between two glass substrates, VPH gratings have high durability and long lifetimes, as well as easy maintenance compared to other gratings that can be easily damaged.

Figure 48J Holographic Grating

Holographic Surface Reflective Gratings

While blazed gratings offer extremely high efficiencies at the design wavelength, they suffer from periodic errors, such as ghosting, and relatively high amounts of scattered light, which could negatively affect sensitive measurements. Holographic gratings are designed specially to reduce or eliminate these errors. The drawback of holographic gratings compared to blazed gratings is reduced efficiency.

Holographic gratings are made from master gratings by similar processes to the ruled grating. The master holographic gratings are typically made by exposing photosensitive material to two interfering laser beams. The interference pattern is exposed in a periodic pattern on the surface, which can then be physically or chemically treated to expose a sinusoidal surface pattern. An example of a holographic grating is shown in Figure 48J.

Please note that dispersion is based solely on the number of grooves per mm and not the shape of the grooves. Hence, the same grating equation can be used to calculate angles for holographic as well as ruled blazed gratings.

| Posted Comments: | |

Pavel AKSENTSEV

(posted 2024-10-10 10:21:00.923) I am interested in value of Grooves/mm tolerance. blarowe

(posted 2024-10-18 10:11:14.0) Thank you for contacting Thorlabs. These gratings are all created from a master, which will have a tolerance of +/-0.5% of the groove spacing, so in the case of the 1200 grooves/mm gratings, we'd expect a tolerance of +/- 6 grooves. That being said, each replica made will exactly match the master it is made from, so there will be no variation from piece to piece. ILIYA SHOFMAN

(posted 2024-09-29 10:35:41.713) Are the transmission grating efficiency test data (spectra) provided on the "Overview" page for the first diffraction order? What are the efficiencies for higher orders? EGies

(posted 2024-10-08 11:15:06.0) Thank you for contacting Thorlabs. The absolute efficiency test data is the efficiency of the first diffraction order. I have reached out to you directly regarding the absolute efficiency of these gratings at higher diffraction orders. Anna Ruder

(posted 2024-05-06 16:51:43.08) Hello, could you send me a downloadable Excel file with the transmission test data? In particular I'm looking for 300 and 1200 grooves/mm transmission data. Thanks cdolbashian

(posted 2024-05-24 01:20:50.0) Thank you for reaching out to us with this request. I have sent along the requested data to you. David Scott

(posted 2024-01-01 19:28:57.99) I am interested in one of your 25 mm visible transmission gratings but I am using it in an astronomy application. I was wondering if you have have any sort of circular mount that could be used in a telescope optical setup??

Thanks jpolaris

(posted 2024-01-02 04:12:24.0) Thank you for contacting Thorlabs. Transmission gratings are typically mounted in kinematic mounts designed for rectangular optics. Our KM100C mount is a common choice for 25 mm gratings. Kinematic mounts allow for fine angle tuning, and in the case of KM100C, the adjuster resolution is 8 mrad per revolution over a total range of ±4°. This kinematic control is helpful when homing in on the optimal AOI. If you are only looking for a mount with a circular outer geometry that is designed to hold a square optic, we have an SM-threaded adapter for square filters (part number: SM1FH) that would accomplish this, but SM1FH does not offer kinematic control on its own. Additionally, there is concern about causing damage to the surface of the grating due to the clamping mechanism of SM1FH that is used to retain the square optic. I have reached out to you directly to discuss further. Miguel León-Rodríguez

(posted 2023-05-04 08:47:10.68) I need to know the high of the grove. Can you help me?, Thanks jpolaris

(posted 2023-05-04 08:13:13.0) Thank you for reaching out to Thorlabs. Additional data and specifications can be requested by contacting techsupport@thorlabs.com or by calling tech support at (973) 300-3000. I have reached out to you directly to discuss the specifications of these visible transmission gratings. Jojo T.

(posted 2023-01-12 09:29:37.357) Do you also have grisms? jgreschler

(posted 2023-01-12 01:19:01.0) Thank you for reaching out to Thorlabs. At this time grating prisms are not a part of our product catalogue. Fabrizio Preda

(posted 2022-10-17 14:48:53.197) This .stl file also seems to be wrong cdolbashian

(posted 2022-10-24 08:47:09.0) Thank you for finding the dimensional errors with our 3d model. We will be correcting it in the near future. Fabrizio Preda

(posted 2022-10-17 14:47:33.937) .stl file is wrong! cdolbashian

(posted 2022-10-24 08:47:10.0) Thank you for finding another dimensional error for these gratings. We will update the dimensions shortly. Robert Holdsworth

(posted 2022-05-26 16:06:02.267) The Solidworks and Step models are not 25 x 25 mm as they should be but are 12.5 x 25mm in the models which is incorrect cdolbashian

(posted 2022-05-27 12:21:44.0) Thank you for finding this web-error Robert. I have informed out web team, and they should be updated in the near future. Linda Chai

(posted 2020-07-31 02:01:39.61) I would like to know if the parallel light is incident the transmission grating perpendicularly, does the penetrating light (0th order) still exit the grating perpendicularly?

By the way, the arrow is confusing. I would like to know how to use it correctly. nbayconich

(posted 2020-08-03 02:27:14.0) Thank you for contacting Thorlabs. The 0th diffraction order will transmit through the grating at an angle equal to the incident angle upon the grating. The diffracted angle can be determined by the equation below which can be found in tutorials section also linked below.

a*[sin(Θm) - sin(Θi)] = m*λ

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1123&tabname=gratings%20tutorial

Transmission gratings are intended to be used at normal incidence although if used at an angle it is best to use these gratings as shown below.

https://www.thorlabs.com/images/TabImages/Littrow_Configuration_D1-780.gif

The arrow mark on the side of your grating running parallel to the surface indicates the blaze direction. Sebastian Harenbrock

(posted 2020-05-05 07:52:31.18) Are there any square mounts for the 25x25mm grating that connect up to the SM1 lens tube system while being light tight? (Or the 50x50mm with SM2?) I notice somebody asked a similar question back in 2014 and was told that it was being looked into. Has there been anything new developed since then? YLohia

(posted 2020-05-05 10:53:56.0) Hello Sebastian, thank you for your suggestion. Unfortunately, this product has still not been developed. I have posted your request on our internal engineering forum to push the development of this along. Currently, we do, however offer similar adapters https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=4890, though these would not offer a light-tight solution. liangze pan

(posted 2020-04-26 09:33:52.45) I would like to know whether your company accept a conservation for a 50mm*50mm 1200 grooves/mm transmission grating with a groove angle that can improve the diffraction efficiency centered at 526nm and 351nm, since the corresponding diffraction efficiency of the product showed in the website doesn't meet our requirement. YLohia

(posted 2020-04-27 11:50:23.0) Hello, thank you for contacting Thorlabs. I have reached out to you directly to discuss the possibility of offering a custom item. Markus G

(posted 2019-10-22 17:03:54.14) Hi - could you please clarify what kind of grating your transmission gratings are?

(1) What is the spec for the transmitted wavefront distortion (which is important for spectrometer applications)? (Is the substrate float glass, or polished substrate? how flat?)

(2) suppose they are blazed (hence plotted efficiency is diffraction into +1 order only, correct)? (3)I assume they are not etched into glass (in which case they should be cleanable), but replicated into a polymer, is that correct?

Thanks, Markus nbayconich

(posted 2019-11-07 12:45:47.0) Thank you for contacting Thorlabs. While we do not specify flatness, we can state that it is typically λ/4 or better. I am unable to provide any data regarding the wave front error at this time.

Regarding your other questions our visible transmission gratings are designed for 1st order diffraction and only monitored for 1st order performance.

The visible grating design consists of polymer on float glass substrate, however we do not suggest direct contact of the grating surface for cleaning and advise to use compressed canned air as opposed to any optical wipes. Arumugam Govindaraji

(posted 2019-07-29 07:11:41.047) Hello,

I would like to know what is the period of the grating. and also is it possible to know the angle of transmission for a particular wavelength.

kindly let me know this information.

Best Regards! tcampbell

(posted 2019-07-29 11:08:02.0) Hello, thank you for contacting Thorlabs. You can find the period of the grating by taking the inverse of the groove density in grooves/mm. Information on transmission angle can be found on the Gratings Tutorial tab. Alex Krylov

(posted 2019-05-18 06:32:35.223) Hello!

Please tell me, at what temperatures is it possible to use the GT50-08 diffraction grating? Will this grating work at about 80 degrees centigrade?

Thanks! Sebastian Harenbrock

(posted 2019-04-26 12:12:26.113) Would you have a downloadable Excel file with the transmission test data? In particular I'm looking for the 300 grooves/mm transmission data. YLohia

(posted 2019-04-26 03:01:02.0) Hello, thank you for contacting Thorlabs. I have reached out to you with this data. v.l

(posted 2019-01-21 15:07:44.39) Hi,

would the efficiency curves change with the incident angle?

It would be useful to see the zeroth order effiency as well.

Best regards,

vl nbayconich

(posted 2019-02-25 08:43:31.0) Thank you for contacting Thorlabs. The Intended AOI of these transmission gratings is zero degrees and the absolute efficiency plots provided are also taken at 0 degrees angle of incidence. Changing the incident angle up to 15 degrees will have a minimal impact on the efficiency. As you move further away from a zero degree AOI the diffraction limit will decrease in wavelength as you increase AOI.

I will reach out to you with more information regarding the absolute efficiency of these gratings for different diffraction orders. liuyang9412

(posted 2017-04-15 23:08:03.17) I currently found it promising if I would have a visible grating with lower groove density, such as 150 grooves/mm. To this end, it is possible for Thorlabs to provide this custom-inspired gratings or just customized? - Yang Liu from China tfrisch

(posted 2017-04-28 03:04:37.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly to discuss your application. roman.wieser

(posted 2014-06-06 11:03:30.203) Dear Ladies and Gentlemen,

we are looking for diffraction gradings or transmission gradings. We need other dimensions then written on your web pages.

Dimensions are 5mm x 160 / 320mm.

You are able to deliver such sizes and if yes with how much grooves it will be possible. And logically how expensive it will be.

kind regards

Roman Wieser besembeson

(posted 2014-06-12 08:43:04.0) Response from Bweh at Thorlabs Newton-USA: Thanks for contacting Thorlabs. We do offer customized solutions for these gratings. I will follow up with you by email to get your complete specifications for a quotation. dsablowski

(posted 2014-02-10 18:19:46.167) Hey,

it would be very useful to have round sized gratings, which fit to your tube system! Or rectangular mounts which fit to the tube system. Additionally some more angled optics mounts which fit to the center wavelength of each grating. This would help to implement gratings to optical set-ups. besembeson

(posted 2014-02-12 04:15:03.0) Response from Bweh E at Thorlabs: Thanks for the suggestions. We will be looking into such mounts. We may be able to offer a special circular grating to you. I will follow-up with you by email to discuss your requirements for such circular gratins. jeffreyb

(posted 2013-09-24 13:46:32.203) Hi,

I have been using these gratings to make direct view, low-dispersion spectrographs. I couple the grating to the hypotenuse of 30 60 90 prism made from SF2 (ZF1 in china) The blaze angle of this grating nearly matches the 30 deg apex angle of a Littrow prism. You do not offer a SF2 prism (you used to have it in your catalog as a "Littrow dispersing prism") so, I had them made in China for ~$100 each. The hypotenuse face is 50mm x 50mm and un-coated (this face matches the grating size). The entrance face is anti reflection coated. I use an index matching grease to couple the grating to the prism (optical epoxy would be better).

I would think that you could market such a grism assembly for ~$600-$900 maybe more......given that the component parts would cost ~$300 or so.

Just having a high dispersion material (ZF1 or SF2) 30 60 90 prism would be very useful for those who would want to make the grism. A short tutorial could be made to demonstrate the principle of the grism... cdaly

(posted 2013-10-10 16:08:00.0) Response from Chris at Thorlabs: Thank you for your feedback. We greatly appreciate you suggestion, which I will share with our optical engineers. I will contact you directly to discuss this further. tcohen

(posted 2012-11-13 17:47:00.0) Response from Tim at Thorlabs: Gratings are very easily damaged on contact. They should be handled only on the sides and stored in the supplied case when not in use which suspends the grating. Cleaning should only be attempted by lightly blowing off dust with clean, dry air or nitrogen. mathieu.perrin

(posted 2012-11-13 07:54:29.123) Hello,

I own the 830 mm-1 transmission grating. Can it be cleaned and how? tcohen

(posted 2012-06-15 11:20:00.0) Response from Tim at Thorlabs: Thank you for your feedback! We are adding a photo to the overview tab explaining what the arrows are and we are revising our diagrams in our grating tutorial. We will also link the tutorial to this page and I have contacted you with this information on using your grating. jcanseco

(posted 2012-06-11 01:07:45.0) On the side surface of the grating, there is a long arrow. I assume this indicates the direction of the grating blaze. Do I have align the input beam in the same direction as arrow, or opposite to the arrow? In other words, should the propagation direction of the input beam follow the direction that the arrow is pointing at or go against it?

Thank you. |

Transmission Gratings

Thorlabs offers two types of transmission gratings: ruled and volume phase holographic. The ruled transmission gratings are created by scratching or etching a transparent substrate with a repetitive, parallel structure, creating areas where light can scatter. These gratings have a sawtooth diffraction profile and are made of epoxy and/or plastic imprints from a master copy, in a process called replication. Our volume phase holographic diffraction gratings consist of a dichromated gelatin (DCG) film between two glass substrates. These gratings have a sinusoidal wave diffraction pattern written on the DCG film using a laser setup. For more information, please refer to the Gratings Tutorial tab.

| Ruled Diffraction Gratings | ||

|---|---|---|

|

UV | Thorlabs' ruled transmission gratings disperse incident light on the opposite side of the grating at a fixed angle. They are ruled and blazed for optimum efficiency in their respective wavelength range, are relatively polarization insensitive, and have an efficiency comparable to that of a reflection grating optimized for the same wavelength. They are ideal for applications that require fixed gratings such as spectrographs. |

| Visible | ||

| Near IR | ||

| UV Ruled Transmission Blazed Diffraction Gratings |

|---|

| Visible Ruled Transmission Blazed Diffraction Gratings |

|---|

| NIR Ruled Transmission Blazed Diffraction Gratings |

|---|

| Volume Phase Holographic Diffraction Gratings | |||

|---|---|---|---|

|

Volume Phase Holographic | Thorlabs' volume phase holographic (VPH) gratings consist of a DCG film between two glass substrates. These unique transmission gratings are easy to maintain and deliver high first-order diffraction peak efficiency and uniform performance over broad bandwidths. | |

| Visible VPH Transmission Gratings |

|---|

| NIR VPH Transmission Gratings |

|---|

Reflective Gratings

Reflective grating master copies are made by depositing a metallic coating on an optic and ruling parallel grooves in the surface. Thorlabs' reflective gratings are made of epoxy and/or plastic imprints from a master copy, in a process called replication. In all cases, light is reflected off of the ruled surface at different angles corresponding to different orders and wavelengths. All of Thorlabs' ruled reflective diffraction gratings exhibit a sawtooth profile, also known as blazed, while our reflective holographic diffraction gratings exhibit a sinusoidal profile. For more information, please refer to the Gratings Tutorial tab.

| Ruled Diffraction Gratings | ||

|---|---|---|

|

UV | Ruled gratings can achieve higher efficiencies than holographic gratings due to their blaze angles. They are ideal for applications centered near the blaze wavelength. Thorlabs offers replicated ruled diffraction gratings in a variety of sizes and blaze angles. |

| Visible | ||

| Near IR | ||

| Mid IR | ||

| UV Ruled Reflective Blazed Diffraction Gratings |

|---|

| Visible Ruled Reflective Blazed Diffraction Gratings |

|---|

| Near-IR Ruled Reflective Blazed Diffraction Gratings |

|---|

| Mid-IR Ruled Reflective Blazed Diffraction Gratings |

|---|

| Holographic Diffraction Gratings | |||

|---|---|---|---|

|

Holographic | Holographic gratings have a low occurrence of periodic errors, which results in limited ghosting, unlike ruled gratings. The low stray light of these gratings makes them ideal for applications where the signal-to-noise ratio is critical, such as Raman Spectroscopy. | |

| Reflective Holographic Sinusoidal Diffraction Gratings |

|---|

| Echelle Diffraction Gratings | |||

|---|---|---|---|

|

Echelle | Echelle gratings are low period gratings designed for use in high diffraction orders. They are generally used with a second grating or prism to separate overlapping diffracted orders. They are ideal for applications such as high-resolution spectroscopy. | |

| Echelle Ruled Blazed Diffraction Gratings |

|---|

Selecting a grating requires consideration of a number of factors, some of which are listed below:

Efficiency:

Ruled gratings generally have a higher efficiency than holographic gratings. Holographic grating tend to have a lower efficiency but a broader effective wavelength range. The efficiency of ruled gratings may be desirable in applications such as fluorescence excitation and other radiation-induced reactions.

Blaze Wavelength:

Ruled gratings have a sawtooth groove profile created by sequentially etching the surface of the grating substrate. As a result, they have a sharp peak efficiency around their blaze wavelength. Holographic gratings are harder to blaze, and tend to have a sinusoidal groove profile resulting in a less intense peak around the design wavelength. Applications centered around a narrow wavelength range could benefit from a ruled grating blazed at that wavelength.

Stray Light:

Due to a difference in how the grooves are made, holographic gratings have less stray light than ruled gratings. The grooves on a ruled grating are machined one at a time which results in a higher frequency of errors. Holographic gratings are made through a lithographic process, which generally creates smoother grating masters free of tool marks. Replicants made from these masters exhibit less stray light. Applications such as Raman spectroscopy, where signal-to-noise is critical, can benefit from the limited stray light of the holographic grating.

Resolving Power:

The resolving power of a grating is a measure of its ability to spatially separate two wavelengths. It is determined by applying the Rayleigh criteria to the diffraction maxima; two wavelengths are resolvable when the maxima of one wavelength coincides with the minima of the second wavelength. The chromatic resolving power (R) is defined by R = λ/Δλ = n*N, where Δλ is the resolvable wavelength difference, n is the diffraction order, and N is the number of grooves illuminated. Due to their low groove density, Echelle gratings provide high resolving power.

Polarization Dependence:

Surface gratings that have high groove densities also have an issue with polarization dependent loss, often with significantly lower efficiency when exposed to parallel- versus perpendicularly-polarized light. Volume phase holographic gratings are designed for applications that require low polarization dependent loss at higher spatial frequencies.

For further information about gratings and selecting the grating right for your application, please visit our Gratings Tutorial.

Caution for Gratings with Surface Grooves:

The surface of a diffraction grating with surface grooves can be easily damaged by fingerprints, aerosols, moisture or the slightest contact with any abrasive material. Gratings should only be handled when necessary and always held by the sides. Latex gloves or a similar protective covering should be worn to prevent oil from fingers from reaching the grating surface. Solvents will likely damage the grating's surface. No attempt should be made to clean a grating other than blowing off dust with clean, dry air or nitrogen. Scratches or other minor cosmetic imperfections on the surface of a grating do not usually affect performance and are not considered defects. Conversely, volume phase holographic gratings can be cleaned using standard optics cleaning procedures and have high durability.

Products Home

Products Home

Visible Transmission Gratings

Visible Transmission Gratings