Kinematic Mirror Mounts with Vertical Drives

- Two-Adjuster Mounts with Vertical Drives that Keep Beam Path Clear

- Options for Ø1/2", Ø1", Ø1.5", and Ø2" Mirrors

- Ideal for Use with High-Power Lasers

VM1

Mirror Mount for Ø1" Optics

POLARIS-K05VS2L

Mirror Mount for Ø1/2" Optics, Left-Handed

(Right-Handed Version Available)

POLARIS-K2VS2

Mirror Mount for Ø2" Optics, Right-Handed

(Left-Handed Version Available)

VM05

Mirror Mount for Ø1/2" Optics

Please Wait

Features

- Kinematic Mirror Mounts with Two Vertical-Drive Adjusters

- Options for Ø1/2", Ø1", Ø1.5", or Ø2" Mirrors

- Compact Designs and Vertical Drives are Ideal for Tight Lab Set-Ups

- Polaris® Mirror Mounts with Vertical-Drive Adjusters are Designed for Exceptional Thermal and Long-Term Stability

Kinematic Mirror Mounts with Vertical Drives

Thorlabs offers kinematic mirror mounts with vertical drives for Ø1/2" or Ø1" optics. The adjusters for these mounts are located above the optical path, allowing for safe adjustment of the system without needing to place your hands near the incoming beam. The position of the actuators also makes these mounts ideal for compact setups. The VM05(/M) and VM1(/M) mounts feature an angular adjustment range of ±3° and are fabricated from black anodized aluminum. The thick main body design increases rigidity to prevent flexing during adjustment.

Polaris Kinematic Mirror Mounts with Two Vertical-Drive Adjusters

Vertical-drive Polaris mounts are designed for Ø1/2", Ø1", Ø1.5", or Ø2" optics and feature a patented vertical drive design (US Patent 11,320,621) and a patented optic bore design (US Patent 10,101,559) with a monolithic flexure arm. This design provides high holding force and pointing stability with minimal optic distortion. Polaris optic bores are precision machined to achieve a fit that will provide optimum beam pointing stability over changing environmental conditions such as temperature changes, transportation shock, and vibration. Machined from heat-treated stainless steel, Polaris mounts utilize precision-matched adjusters with ball contacts and sapphire seats to provide smooth kinematic adjustment, and are designed to be compatible with clearnroom and vacuum applications. Please see the full web presentation for details.

| Posted Comments: | |

Douglas Arbuckle

(posted 2024-08-28 15:33:44.94) Hi. Would you be able make mounts with the same form as VM1s for 2" optics? We would be interested in them if available. Many thanks jdelia

(posted 2024-08-30 08:18:42.0) Thank you for reaching out. While we unfortunately do not currently offer this, I have forwarded this request along to our design engineers via our internal suggestion forum for consideration as a future stock product. I have also reached out directly to discuss your application and whether our current vertical-drive mount for 2" diameter optics, POLARIS-K2VS2(L), may work for you. Choi Byungwon

(posted 2024-05-13 11:18:29.08) 初めまして、韓国H&J CorpのChoiと申します.

一つ、質問ですが、

既存は上部調整式キネマティックマウントが無いTypeでInch Renchで調整使用しました.

上部調整式キネマティックマウントを取り除く事も可能ですか.

韓国に出荷する条件で見積書(数量: 3個)をお願い致します. cdolbashian

(posted 2024-05-21 12:24:22.0) Thank you for reaching out to us with this custom request. I have contacted you directly in order to discern some specifics regarding your needs. melanie

(posted 2018-11-14 11:32:54.99) Are the adjustments lockable ?

There is a screw in the middle of the end of the micrometer head, which might be for locking the adjustment.

Is that what this screw is for ?

It looks like the exact same micrometer used with the gimbal mounts, which IS advertised as lockable. YLohia

(posted 2018-11-14 11:10:33.0) Hello, thank you for contacting Thorlabs. Unfortunately, these mounts are not lockable. The GMB1 gimbal mount is lockable with the side located locking thumbscrews. The actual adjuster knob is not intrinsically lockable. The GM100, which is the gimbal equivalent of the VM1, is not lockable and is not advertised as such. The hex on the top of the adjustment knob is often mistaken for a locking mechanism, but it is there for convenience so a ball driver can be used for adjustment. ivangr

(posted 2018-08-02 16:17:46.013) Hello,

I am contacting you concerning the VM1/M mount.

I was wondering whether it would be possible to have additional graduations on the actuators (similarly to standard micrometer screws) to keep track of how many rotations of the actuators have been done, in order to have a better 'absolute calibration' of the angle.

My application is the following: I need to align a nonlinear crystal to a reference position, and then detune it by a certain angle. The VM1 gives me a very good angular accuracy, however as soon as I need to detune by more than one rotation of the actuator, I need to pay extra attention and keep track of how many rotations I did in order to know the detuning angle. This easily gets unpractical, especially since I need to detune over a wide range of angles.

Best regards,

Ivan llamb

(posted 2018-08-03 08:57:18.0) Hello Ivan, thank you for contacting Thorlabs. We use the component with the engraved witness line in various other products as well, so a large scale modification would not be feasible because of the different graduated scales for each product that uses this component. We may be able to offer a one-off quote for a customized product, where the witness line has perpendicular engravings to keep track of your rotations. I will reach out to you directly to discuss further. arne.meyeraufderheide

(posted 2017-09-26 15:15:11.237) Hello Thorlabs,

do these top-driven mirror mounts also exist for 2" optics? Due to a lack of space we want to minimize the footprint of our 2" mounts, the usual 2" mirror mounts have the knobs behind the mirror which sometimes collide with other optomechanic in our setup.

Best regards nbayconich

(posted 2017-10-12 12:23:59.0) Thank you for contacting Thorlabs. We can offer this as a special made item. I will reach out to directly about our custom capabilities. werner.engel

(posted 2017-02-16 20:04:40.277) What I did not find at any optics shop is a device as slimm as the VM1, but also capable of the other 2 axis - like the K5X1.

The reason for this: Sometimes you need to build a very short cavity - in this case the screws behind the partly reflective mirror are much too long!! The length of the whole device should be as short as possible.

Has this been discussed allready?

Any plan to develop such a mount?

This would make optical cavities much shorter!

Waiting for your feedback,

Werner tfrisch

(posted 2017-02-20 09:53:59.0) Hello, thank you for contacting Thorlabs. I have posted your need in our internal engineering forum, and I will reach out to you directly to discuss this application. thbu

(posted 2016-12-20 07:09:36.823) For my design a VM05/M would be very suitable. On the other hand I consider the Polaris K05 mount for the well tested and documented stability. Do you have similar stability measurements for the VM05/M? How much better is the Polaris series?

Best regards. tfrisch

(posted 2016-12-22 06:13:18.0) Hello, thank you for contacting Thorlabs. The Polaris line was designed with stability in mind whereas VM05/M was intended to be a compact stage with the actuator knobs accessible from the same side. I will reach out to you directly for more details about your application. user

(posted 2013-03-05 16:06:01.21) FYI: The step model of VM1 seems to be a little messed up. The plate for mounting the optic is offset to the left, unphysically. cdaly

(posted 2013-03-07 16:13:00.0) Response from Chris at Thorlabs: Thank you for your feedback. The front plate does appear to be offset, looks like it was mated to the edge of the cutout rather than being centered. I will try to get this updated. Thank you for pointing this out. jlow

(posted 2012-08-03 16:07:00.0) Response from Jeremy at Thorlabs to Fran: The VM05 and VM1 use setscrews to hold the optic in place instead of retaining rings. Therefore, there's not really a maximum optic thickness. The minimum optic thickness is about 0.14" (3.6 mm). franxm

(posted 2012-08-03 10:29:05.0) What is the maximum thickness optic the VM05 and VM1 can support?

Thanks,

Fran |

- Mounts Ø1/2" Optics

- Minimum Optic Thickness: 0.14" (3.6 mm)

- Total Angular Range of ±3°

- 0.5° per Revolution Adjustment

- 8-32 (M4) and 4-40 (M3) Mounting Holes

Thorlabs' VM05(/M) Compact Kinematic Mount with Vertical Drive features top-mounted, 0.25 mm pitch actuators designed to keep the beam path clear, which is ideal for use with high-power lasers. Sensitivity is achieved by two fine adjustment screws that offer a 1/2° of angular adjustment per revolution. Each knob can be rotated by hand or by using a 5/64" (2.0 mm) hex key or balldriver. The VM05(/M) mount offers a total angular range of ±3° and a Ø0.44" (11.2 mm) clear aperture. A nylon-tipped locking setscrew secures the Ø1/2" optic. The mount's thick main body increases rigidity to prevent flexing during adjustment.

| Key Specificationsa | ||

|---|---|---|

| Accepted Optic Sizeb | Ø1/2", ≥0.08" (2 mm) Thick | |

| Adjustment per Revolutionc |

~11 mrad/rev | |

| Mechanical Angular Range (Nominal) |

+3°/-2.5° | |

| Beam Deviation After Thermal Cyclingd |

<2 μrad | |

| Vacuum Compatibilitye | 10-9 Torr at 25 °C with Proper Bake Out; 10-5 Torr at 25 °C without Bake Out; Grease Vapor Pressure:10-13 Torr at 20 °C, 10-5 Torr at 200 °C; NASA ASTM E595, Telcordia GR-1221 |

|

| Operating Temperature Range |

-30 to 200 °C | |

- Designed for use with Ø1/2" Optics

- +3°/-2.5° Mechanical Angular Range (Nominal)

- ~11 mrad/rev Resolution

- 130 TPI Matched Actuator/Body Pairs

- Less than 2 µrad Deviation after Temperature Cycling (See the Test Data Tab on the Full Web Presentation for Details)

- Patented Monolithic Flexure Arm Design (US Patent 10,101,559)

- Patented Vertical Drive Design (US Patent 11,320,621)

- Right- and Left-Handed Versions Available

These 2-Adjuster Ø1/2" Polaris Kinematic Mirror Mounts provide long-term stability and high-resolution adjustment using vertical drives. Right-handed and left-handed versions are available. The patented optic bore design with a monolithic flexure arm keeps wavefront distortion on the mounted optic to a minimum while providing strong optic retention force; the flexure arm can be actuated using the included screw and a 0.05" (1.3 mm) hex key. The Polaris design addresses all of the common causes of beam misalignment and is designed to be compatible with cleanroom and vacuum applications (see the table to the right).

The 130 TPI adjusters feature a 5/64" (2.0 mm) hex and may be adjusted with our HKTS-5/64 hex key thumbscrews, the hex on the end of the SA1 adjustment tool, or any other 5/64" (2.0 mm) hex wrench. These adjusters can be locked using the POLARIS-LNS05 locking collars. Two are pre-installed on each mount, one for each adjuster. The included locking collars can be loosened or tightened most easily using the POLARIS-T3 spanner wrench. The spanner wrench has a hole through its center which accepts a 5/64" (2.0 mm) hex key, allowing the adjuster to be held in place while the locking collar is tightened. For long-term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench.

Post mounting is provided by one #8 (M4) counterbore. Due to the shallow design of the counterbore, low-profile 8-32 and M4 cap screws are included for securing the mount to a post. Note that the 8-32 cap screw reduces the clear aperture to 0.39" (9.9 mm) and the M4 cap screw reduces it to 0.34" (8.6 mm). For custom mounting configurations, two Ø2 mm alignment pin holes are located on the mounting face for setting a precise location and mounting angle. Standard DIN 7-m6 ground dowel pins are recommended (click on the red documents icon below for details). We recommend using these mounts with stainless steel posts that also have Ø2 mm alignment pin holes, such as our Ø1" Posts for Polaris Mirror Mounts.

Mounts can also be customized with different face plates, such as those used in our in our low-distortion optic retention mounts, or with back plates that have mounting and alignment pin holes on the adjacent side so that the adjusters are oriented horizontally. Please contact Tech Support with inquiries.

For more details, please see the Polaris Vertical Drive Mounts page.

- Mounts Ø1" Optics

- Minimum Optic Thickness: 0.11" (2.8 mm)

- Total Angular Range of ±3°

- 0.25° per Revolution Adjustment

- Graduated Knobs with 50 Divisions per Revolution

- 8-32 (M4) Mounting Holes

Thorlabs' VM1(/M) Compact Kinematic Mount with Vertical Drive features top-mounted 100 TPI actuators designed to keep the beam path clear, which is ideal for use with high-power lasers. Sensitivity is achieved by two fine adjustment screws that offer a 1/4° of angular adjustment per revolution. Unlike the VM05(/M), the screws at the end of the knob cannot be used to rotate the knobs. The VM1(/M) mount offers a total angular range of ±3° and a Ø0.94" (23.9.2 mm) clear aperture. A nylon-tipped locking setscrew secures the Ø1" optic. The mount's thick main body increases rigidity to prevent flexing during adjustment.

| Key Specificationsa | ||

|---|---|---|

| Accepted Optic Sizeb | Ø1", ≥0.14" (3.5 mm) Thick | |

| Adjustment per Revolutionc | ~7.7 mrad/rev | |

| Mechanical Angular Range | ±4° (Nominal) | |

| Beam Deviation After Thermal Cyclingd |

<1 μrad | |

| Vacuum Compatibilitye | 10-9 Torr at 25 °C with Proper Bake Out 10-5 Torr at 25 °C without Bake Out Grease Vapor Pressure: 10-13 Torr at 20 °C; 10-5 Torr at 200 °C NASA ASTM E595, Telcordia GR-1221 |

|

| Operating Temperature Range | -30 to 200 °C | |

- Designed for use with Ø1" Optics

- ±4° Mechanical Angular Range

- ~7.7 mrad/rev Resolution

- 100 TPI Matched Actuator/Body Pairs

- Less than 1 µrad Deviation after Temperature Cycling (See the Test Data Tab on the Full Web Presentation for Details)

- Patented Monolithic Flexure Arm Design (US Patent 10,101,559)

- Patented Vertical Drive Design (US Patent 11,320,621)

- Right- and Left-Handed Versions Available

These 2-Adjuster Ø1" Polaris Kinematic Mirror Mounts provide long-term stability and high-resolution adjustment using vertical drives. Right-handed and left-handed versions of these mounts are available. The patented optic bore design with a monolithic flexure arm keeps wavefront distortion on the mounted optic to a minimum while providing strong optic retention force; the flexure arm can be actuated using the included screw and a 0.05" (1.3 mm) hex key. The Polaris design addresses all of the common causes of beam misalignment and is designed to be compatible with cleanroom and vacuum applications (see the table below).

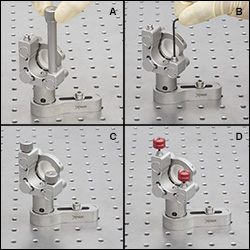

Click to Enlarge

Using the POLARIS-K1VS2 Ø1" Mount:

A: POLARIS-T2 Tool for Adjusting POLARIS-LNS1 Collars

B: 5/64" or 2.0 mm Hex Key in the End of an Adjuster

C: POLARIS-N5 Removable Knobs on the Adjusters*

D: HKTS-5/64 Hex Knobs on the Adjusters

A similar process can be used for the POLARIS-K1VS2L.

These mirror mounts come with 100 TPI adjusters that feature a 5/64" (2.0 mm) hex and may be adjusted with our HKTS-5/64 Hex Key Thumbscrews, the hex on the end of the SA1 Adjustment Tool, or any other 5/64" (2.0 mm) hex wrench. Alternatively, POLARIS-N5 removable, low-profile adjustment knobs can be threaded onto the adjusters for improved feel in fine-resolution adjustments; note that this may limit the mechanical angular range of the mount because the knobs screw directly onto the exposed threads of the adjuster screws.

The adjusters on these mounts can be locked using POLARIS-LNS1 locking collars. Two are pre-installed on the mounts, one for each adjuster. The included locking collars can be loosened or tightened most easily using the POLARIS-T2 spanner wrench.

Post mounting is provided by two #8 (M4) counterbores. For custom mounting configurations, two Ø2 mm alignment pin holes are located on each mounting face for setting a precise location and mounting angle. Standard DIN 7-m6 ground dowel pins are recommended (click on the red documents icon below for details). We recommend using these mounts with stainless steel posts that also have Ø2 mm alignment pin holes, such as our Ø1" Posts for Polaris Mirror Mounts.

Mounts can be also be customized with different face plates, such as those used in our in our low-distortion optic retention mounts, or with back plates that have mounting and alignment pin holes on the adjacent side so that the adjusters are oriented horizontally. Please contact Tech Support with inquiries.

For more details, please see the Polaris Vertical Drive Mounts page.

| Key Specificationsa | ||

|---|---|---|

| Accepted Optic Sizeb | Ø1.5", ≥0.24" (6.0 mm) Thick | |

| Adjustment per Revolutionc |

~5.5 mrad/rev | |

| Mechanical Angular Range (Nominal) |

±3° | |

| Beam Deviation After Thermal Cyclingd |

≤1 μrad | |

| Vacuum Compatibilitye | 10-9 Torr at 25 °C with Proper Bake Out; 10-5 Torr at 25 °C without Bake Out; Grease Vapor Pressure:10-13 Torr at 20 °C, 10-5 Torr at 200 °C; NASA ASTM E595, Telcordia GR-1221 |

|

| Operating Temperature Range |

-30 to 200 °C | |

- Designed for use with Ø1.5" Optics

- ±3° Mechanical Angular Range (Nominal)

- ~5.5 mrad/rev Resolution

- 100 TPI Matched Actuator/Body Pairs

- No Greater than 1 µrad Deviation after Temperature Cycling (See the Test Data Tab on the Full Web Presentation for Details)

- Patented Monolithic Flexure Arm Design (US Patent 10,101,559)

- Patented Vertical Drive Design (US Patent 11,320,621)

- Right and Left-Handed Versions Available

These 2-Adjuster Ø1.5" Polaris Kinematic Mirror Mounts provide long-term stability and high-resolution adjustment using vertical drives. Right-handed and left-handed versions of these mounts are available. The patented optic bore design with a monolithic flexure arm keeps wavefront distortion on the mounted optic to a minimum while providing strong optic retention force; the flexure arm can be actuated using the included screw and a 0.05" (1.3 mm) hex key. The Polaris design addresses all of the common causes of beam misalignment and is designed to be compatible with cleanroom and vacuum applications (see the table to the right).

These mirror mounts come with 100 TPI adjusters that feature a 5/64" (2.0 mm) hex and may be adjusted with our HKTS-5/64 Hex Key Thumbscrews, the hex on the end of the SA1 Adjustment Tool, or any other 5/64" (2.0 mm) hex wrench. Alternatively, POLARIS-N5 removable, low-profile adjustment knobs can be threaded onto the adjusters for improved feel in fine-resolution adjustments; note that this may limit the mechanical angular range of the mount because the knobs screw directly onto the exposed threads of the adjuster screws.

The adjusters on these mounts can be locked using POLARIS-LNS1 locking collars. Two are pre-installed on the mounts, one for each adjuster. The included locking collars can be loosened or tightened most easily using the POLARIS-T2 spanner wrench. Examples of these methods for turning or locking the adjusters on a POLARIS-K1VS2 Ø1" mirror mount, which has identical adjusters to the POLARIS-K15VS2(L) Ø1.5" mirror mounts, are shown above.

Post mounting is provided by one #8 (M4) counterbore. For custom mounting configurations, two Ø2 mm alignment pin holes are located on the mounting face for setting a precise location and mounting angle. Standard DIN 7-m6 ground dowel pins are recommended (click on the red documents icon below for details). We recommend using these mounts with stainless steel posts that also have Ø2 mm alignment pin holes, such as our Ø1" Posts for Polaris Mirror Mounts.

Mounts can be also be customized with different face plates, such as those used in our in our low-distortion optic retention mounts, or with back plates that have mounting and alignment pin holes on the adjacent side so that the adjusters are oriented horizontally. Please contact Tech Support with inquiries.

For more details, please see the Polaris Vertical Drive Mounts page.

| Key Specificationsa | ||

|---|---|---|

| Accepted Optic Sizeb | Ø2", ≥0.14" (3.5 mm) Thick | |

| Adjustment per Revolutionc |

~5 mrad/rev | |

| Mechanical Angular Range (Nominal) |

±3° | |

| Beam Deviation After Thermal Cyclingd |

≤2 μrad | |

| Vacuum Compatibilitye | 10-9 Torr at 25 °C with Proper Bake Out; 10-5 Torr at 25 °C without Bake Out; Grease Vapor Pressure:10-13 Torr at 20 °C, 10-5 Torr at 200 °C; NASA ASTM E595, Telcordia GR-1221 |

|

| Operating Temperature Range |

-30 to 200 °C | |

- Designed for use with Ø2" Optics

- ±3° Mechanical Angular Range (Nominal)

- ~5 mrad/rev Resolution

- 100 TPI Matched Actuator/Body Pairs

- No Greater than 2 µrad Deviation after Temperature Cycling (See the Test Data Tab on the Full Web Presentation for Details)

- Patented Monolithic Flexure Arm Design (US Patent 10,101,559)

- Patented Vertical Drive Design (US Patent 11,320,621)

- Right and Left-Handed Versions Available

These 2-Adjuster Ø2" Polaris Kinematic Mirror Mounts provide long-term stability and high-resolution adjustment using vertical drives. Right-handed and left-handed versions of these mounts are available. The patented optic bore design with a monolithic flexure arm keeps wavefront distortion on the mounted optic to a minimum while providing strong optic retention force; the flexure arm can be actuated using the included screw and a 0.05" (1.3 mm) hex key. The Polaris design addresses all of the common causes of beam misalignment and is designed to be compatible with cleanroom and vacuum applications (see the table to the right).

These mirror mounts come with 100 TPI adjusters that feature a 5/64" (2.0 mm) hex and may be adjusted with our HKTS-5/64 Hex Key Thumbscrews, the hex on the end of the SA1 Adjustment Tool, or any other 5/64" (2.0 mm) hex wrench. Alternatively, POLARIS-N5 removable, low-profile adjustment knobs can be threaded onto the adjusters for improved feel in fine-resolution adjustments; note that this may limit the mechanical angular range of the mount because the knobs screw directly onto the exposed threads of the adjuster screws.

The adjusters on these mounts can be locked using POLARIS-LNS1 locking collars. Two are pre-installed on the mounts, one for each adjuster. The included locking collars can be loosened or tightened most easily using the POLARIS-T2 spanner wrench. Examples of these methods for turning or locking the adjusters on a POLARIS-K1VS2 Ø1" mirror mount, which has identical adjusters to the POLARIS-K2VS2(L) Ø2" mirror mounts, are shown above.

Post mounting is provided by three #8 (M4) counterbores. For custom mounting configurations, two Ø2 mm alignment pin holes are located on the mounting face for setting a precise location and mounting angle. Standard DIN 7-m6 ground dowel pins are recommended (click on the red documents icon below for details). We recommend using these mounts with stainless steel posts that also have Ø2 mm alignment pin holes, such as our Ø1" Posts for Polaris Mirror Mounts.

Mounts can be also be customized with different face plates, such as those used in our in our low-distortion optic retention mounts, or with back plates that have mounting and alignment pin holes on the adjacent side so that the adjusters are oriented horizontally. Please contact Tech Support with inquiries.

For more details, please see the Polaris Vertical Drive Mounts page.

Products Home

Products Home

Zoom

Zoom

Vertical Drives

Vertical Drives