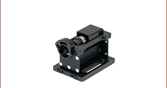

Voice Coil Translation Mount and Controller for 30 mm Cage System

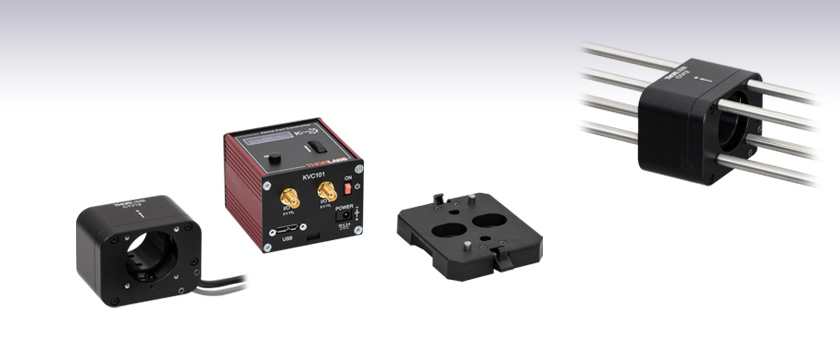

- Voice Coil Translation Mount for 30 mm Cage Systems

- Motorized Closed-Loop Position Control Over 12 mm of Travel

- Operation via Local Panel Controls or Remote PC via USB

CTV12

Voice Coil Translation Mount for 30 mm Cage Systems

KVC101

Voice Coil Motor Controller (Power Supply Sold Separately)

Table Mounting Plate

(Included with the KVC101)

Application Idea

The CTV12 translation mount can be integrated via cage rods into a 30 mm cage system.

Please Wait

Click to Enlarge

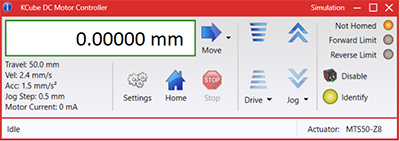

Figure 1.2 Back and Top Views of the KVC101 K-Cube

(See the Pin Diagrams Tab for More Information)

Click to Enlarge

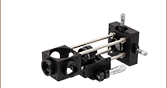

Figure 1.1 The CTV12(/M) Translation Mount can be post mounted using a 8-32 (M4) tapped hole located on the bottom of the mount.

Features

- Motorized Linear Translation Mount and Voice Coil Controller for Positioning or Scanning of Components Along the Optical Axis

- Closed-Loop Position Control Over 12 mm of Travel

- Absolute Optical Encoder for Positioning Eliminates Need for Homing

- 4-40 Taps for Integration into 30 mm Cage Systems

- SM1 Threading for Mounting SM1 Components and Ø1" Optics

- Post Mountable via 8-32 (M4) Tap on Bottom

- Compact Controller for Voice Coil Motors with Currents up to 2 A

- On-Unit Control and LCD Display

- Full Kinesis® Software Control Suite (See Kinesis Software Tab for Details)

- Position Control via External Analog Signal

- Digital Input and Output Triggers for Scanning Applications

- Software Compatible with other Kinesis Controllers for Integrated Systems Development

Thorlabs' CTV12(/M) Voice Coil Translation Mount is designed for use in 30 mm cage systems, providing translation along the optical axis for Ø1" optics and components with SM1-threading. This direct-drive translation mount provides 12 mm of motorized travel with 100 nm of resolution in closed-loop operation. The CTV12(/M) translation mount uses dual voice coil motors and low-friction, crossed-roller bearings to provide smooth, fast, and accurate motion. An absolute optical encoder is used to provide position feedback, eliminating the need for homing procedures. Internal SM1 threading (1.035"-40) on the moving world, along with two included SM1RR retaining rings, provide mounting options for a variety of optics.

The KVC101 K-Cube® Voice Coil Motor Controller is a part of Thorlabs' Kinesis® line of high-end, compact motion controllers. The controller is a compact, closed-loop precision motion controller designed to drive voice-coil operated actuators. This single-channel controller provides a trapezoidal velocity profile and offers absolute position control either manually or via Kinesis software. It is compatible with the CTV12(/M) voice coil cage translation mount, offering fast, accurate positioning within a 30 mm cage system. The controller unit has a highly compact 60.0 mm x 60.0 mm x 47.0 mm footprint, allowing it to be positioned close to the motorized system. Tabletop operation also allows minimal drive cable lengths for easier cable management. For convenience, a 1.5 m long Type A to Type Micro B USB 3.0 cable is included with the KVC101 cube.

Embedded software allows this unit to be fully operated using the on-unit menu button, LCD display, and control wheel or using external trigger signals. In addition to these on-unit controls, USB connectivity provides simple PC-controlled operation with the Kinesis software package. For more information on these connectors, see the Pin Diagrams tab.

Mounting Options

The CTV12(/M) mount features eight 4-40 taps (four on each side) that allow the unit to be mounted using the ER series of cage rods into a 30 mm cage system. An 8-32 (M4) tapped hole on the bottom of each translation mount provides post-mounting capabilites, as seen in Figure 1.1. Each KVC101 controller comes with a mounting plate that clips onto the base of the unit. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop. Please see the Specs for a mechanical drawing of the optical table mounting plate and the Mounting Options tab for how to mount the plate.

Power Supply Options

The preferred power supply (single channel or hub-based) for the KVC101 controller depends on the end user's application and whether you already own compatible power supplies. To that end and in keeping with Thorlabs' green initiative, we do not ship these controllers bundled with a power supply. Multiple units can be connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs, available below, for multi-axis motion control applications. The KCH301 allows up to three T- or K-Cube controllers to be used while the KCH601 allows up to six controllers to be used.

All power supply options compatible with the KVC101 Voice Coil Motor Controller can be found below.

| KVC101 Specifications | |

|---|---|

| Motor Output | |

| Drive Connector | 15 Pin D Type Female (Motor Phase Outputs, Stage ID Input) |

| Peak Current Output | 2 A |

| Pulse Width Modulation Frequency | 40 kHz |

| Control Algorithm | 16-Bit Digital PID Servo Loop |

| Position Feedback | Absolute Encoder |

| Encoder Bandwidth | 2.5 MHz / 10 MCounts/sec |

| Position Counter | 32 Bit |

| Operating Modes | Position and Scan |

| Velocity Profile | Trapezoidal |

| Front Panel Controls | |

| Spring Potentiometer Wheel | Bi-Directional Velocity Control, Forward/Reverse Jogging, or Position Presets |

| Input Power Requirements | |

| Voltage | 14.5 - 15.5 V Regulated DC |

| Current | 2 A (Peak) |

| Power Supplya | Item #s KPS201, KCH301, KCH601 |

| EXT IN | ±10 V |

| Monitor | ±10 V |

| I/O 1 and I/O 2 | 5 V TTL Levels |

| General Data | |

| Housing Dimensionsb (W x D x H) |

60.0 mm x 60.0 mm x 47.0 mm (2.36" x 2.36" x 1.85") |

| Weight | 170 g (0.37 lbs) |

| USB Connector Type | USB 3.0 |

| USB Connection Speed | USB 1.1 Full Speed (12 Mbps) |

| Operating Temperature | 5 °C to 40 °C |

| Maximum Humidity | 80% RH |

| Compatible Motors | |

| Type | Voice Coil Motors |

| Rated Phase Currents (Nominal) | 100 mA to 2 A |

| CTV12(/M) Specifications | |

|---|---|

| Travel | 12.0 mm (0.47") |

| Resolution | 100 nm |

| Bidirectional Repeatability | ±100 nm |

| Minimum Step | 200 nm |

| Accuracy | ±3 µm |

| Maximum Scanning Frequencya | 20 Hz |

| Pitch | ±125 µrad |

| Yaw | ±70 µrad |

| Maximum Payload (Horizontal) | 200 g (0.44 lbs) |

| Maximum Payload (Vertical)b | 50 g (0.11 lbs) |

| Continuous Motor Forcec | 1.0 N |

| Peak Motor Forced | 3.2 N |

| Physical Specifications | |

| Dimensions (L x W x H) | 39.0 mm x 62.0 mm x 47.0 mm (1.54" x 2.44" x 1.85") |

| Operating Temperature | 5 °C to 40 °C |

| Cable Length | 2.0 m (78.74") |

| Weight (With Cables) | 0.36 kg (0.79 lbs) |

Click to Enlarge

Figure 2.1 Mechanical Drawing of the KVC101 and Included Optical Table Adapter

Translation Stage Connector

D-Type Male

| Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|

| 1 | Reverse Limit Switch | 6 | Encoder A - | 11 | Encoder B + |

| 2 | Forward Limit Switch | 7 | Encoder A + | 12 | Encoder B - |

| 3 | Ground | 8 | RS232 TX | 13 | Encoder Index - |

| 4 | +5 V | 9 | RS232 RX | 14 | Encoder Index + |

| 5 | Motor + | 10 | Not Connected | 15 | Motor - |

Motor Controller Connector

D-Type Female

| Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|

| 1 | Reverse Limit Switch | 6 | Encoder A - | 11 | Encoder B + |

| 2 | Forward Limit Switch | 7 | Encoder A + | 12 | Encoder B - |

| 3 | Ground | 8 | RS232 TX | 13 | Encoder Index - |

| 4 | +5 V | 9 | RS232 RX | 14 | Encoder Index + |

| 5 | Motor + | 10 | Ground | 15 | Motor - |

I/O 1SMA Female |

I/O 2SMA Female |

|

|

| +5 V TTL | +5 V TTL |

| These connectors provide a 5 V logic level input and output that can be configured to support triggering into and out of external devices. Each port can be independently configured to control the logic level or to set the trigger as an input or output. | |

EXT INSMA Female |

MONITORSMA Female |

|

|

| ±10 V TTL | ±10 V TTL |

| Used to connect an external analog signal source to control the operation of the K-Cube®. The input voltage range is ±10 V and the input impedance is 32 kΩ. | This low-voltage (-10 V to +10 V) output can be used to monitor the actuator position. In its most common use, it can be connected directly to an oscilloscope. |

Computer Connection*

*The USB 3.0 port is compatible with a USB 2.0 Micro B connector if the Micro B connector is plugged into the shaded region in the photo above. A USB 3.0 type A to type Micro B cable is included with the KVC201.

K-Cube® Mounting Options

Two options are available to securely mount our K-Cube controllers onto an optical table. An optical table mounting plate, provided with every K-Cube, allows for a single controller to be attached to an optical table. Alternatively, three- and six-port USB controller hubs are offered (sold separately) that can mount and power our K-Cube controllers. These options are described in further detail below.

Optical Table Mounting Plate

Each K-Cube unit comes with a mounting plate that clips onto the base of the controller, as shown in Video 4.1. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for a more permanent placement on the tabletop. Please see the Specs tab for a mechanical drawing of the table mounting plate.

Kinesis USB Controller Hubs

Multiple units can be mounted and connected to a single PC by using the KCH301 or KCH601 USB Controller Hubs. They each consist of two parts: the hub, which can support up to three (Item # KCH301) or six (Item # KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. K-Cubes simply clip into place using the provided on-unit clips, while current- and previous-generation T-Cubes require the KAP101 Adapter Plate, shown in Video 4.2. The hub vastly reduces the number of USB and power cables required when operating multiple controllers.

K-Cube Table Mounting Plate

Video 4.1 Unlike T-Cubes, every K-Cube includes a mounting plate that clips onto the base of the controller. The plate contains two magnets for temporary placement on an optical table and two counterbores for 1/4"-20 (M6) cap screws for more permanent placement on the tabletop.

Kinesis USB Controller Hubs

Video 4.2 3- and 6-Port USB Controller Hubs allow multiple controllers to be connected to one PC for multi-axis applications. K-Cubes can be directly attached to the hubs while T-Cubes require a KAP101 Adapter Plate.

Software

Kinesis Version 1.14.52

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis system controllers.

Also Available:

- Communications Protocol

Figure 58A Kinesis GUI Screen

Thorlabs offers the Kinesis® software package to drive our wide range of motion controllers. The software can be used to control devices in the Kinesis family, which covers a wide variety of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes®) to high-power, multi-channel benchtop units and modular 19" rack nanopositioning systems (the MMR60x Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework and APIs are included with each install. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing this common software platform, Thorlabs has ensured that users can mix and match any of our motion control devices in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

| Posted Comments: | |

| No Comments Posted |

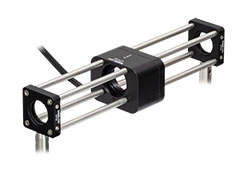

Click to Enlarge

Figure G1.1 CTV12 Translation Mount in a 30 mm Cage System Setup

- Direct-Drive Linear Translation Mount with Position Control over 12 mm

- Dual Voice Coil Motors Provide Smooth, Fast, and Accurate Motion

- Absolute Encoder for Position Feedback

- Eight 4-40 Taps for Integration into 30 mm Cage Systems

- Post Mountable via 8-32 (M4) Tap on Bottom

- SM1 Threaded for Direct Mounting of Optics and Components

The CTV12(/M) Voice Coil Translation Mount is designed to be used in 30 mm cage systems that require translation along the optical axis of the cage. This direct-drive linear translation mount provides closed-loop position control over 12 mm of travel, with a minimum step size of 200 nm. The mount uses dual voice coil motors and low-friction, crossed-roller bearings to provide smooth, fast, and accurate motion. An absolute position encoder is used, returning position values between 0 mm and 12 mm and preventing the need for homing protocols. The arrow on the top of the mount indicates the positive direction of travel. A set of eight 4-40 taps (four on each side) allow for the CTV12(/M) mount to be mounted into 30 mm cage systems, while an 8-32 (M4) tap on the bottom allows for post mounting. The moving world has internal SM1 threading (1.035"-40) for mounting Ø1" optics and SM1-threaded components; two SM1RR retaining rings are included for such mounting purposes.

This voice coil translation mount is designed to be controlled via the KVC101 controller, available separately below. A 15-pin D-Type male connector at the end of the 2 m cable attached to the CTV12(/M) mount is used to connect to the 15-pin D-type female connector on the back of the KVC101 controller. The KVC101 controller offers local manual control via a velocity wheel on the top panel, while remote PC control is available using a USB connection. With the use of the Kinesis Software, the position of the moving world can be moved via a scanning mode, allowing the position to follow different periodic waveforms at frequencies of up to 20 Hz.

Click to Enlarge

Figure G2.1 KCH301 USB Controller Hub (Sold Separately) with Installed K-Cube Modules

- Control Panel and LCD Screen for On-Unit Control

- Closed-Loop Position and Readout for Voice Coil Motors

- Interfaces with Computer Using Included USB Cable

- Fully Compatible with Kinesis® Software Package

- Compact Footprint: 60.0 mm x 60.0 mm x 47.0 mm

- Power Supply Not Included (See Below)

The KVC101 Voice Coil Motor Controller is designed to drive voice-coil operated actuators with currents up to 2 A. This controller features a top-mounted control panel for local control, with a velocity wheel that supports bidirectional control, forward and reverse jogging, and position presets. Each unit contains a front-located power switch that, when turned off, saves all user-adjusted settings; please note that this switch should always be used to power down the unit.

The front of the unit also contains two bidirectional trigger ports (I/O) that can be used to read a 5 V external logic signal or output a 5 V logic signal to control external equipment. Each port can be independently configured to control the logic level or to set the trigger as an input or output. A USB port on the front panel allows for system communications; for convenience, a 1.5 m long Type A to Type Micro B USB 3.0 cable is included. The back of the unit features two SMA connectors, a ±10 V external input for use with an external analog signal source to control the operation of the controller and a ±10 V low-voltage output for monitoring the actuator position. Additionally, the back panel includes a 15-pin D-Type connector to supply power to the motor of the CTV12(/M) mount and provide feedback for the closed loop. For more information on these connectors, see the Pin Diagrams tab.

The unit is fully compatible with our Kinesis software package. The Kinesis Software features new .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™ or any .NET compatible languages to create custom applications. For more details on the software package, please see the Kinesis Software tab.

Please note that this controller does not ship with a power supply. Compatible power supplies are listed below.

- individual Power Supply

- KPS201: For K-Cubes® or T-Cubes with 3.5 mm Jacks

- USB Controller Hubs Provide Power and Communications

- KCH301: For Up to Three K-Cubes or T-Cubes

- KCH601: For Up to Six K-Cubes or T-Cubes

The KPS201 power supply outputs +15 VDC at up to 2.66 A and can power a single K-Cube or T-Cube with a 3.5 mm jack. It plugs into a standard wall outlet.

The KCH301 and KCH601 USB Controller Hubs each consist of two parts: the hub, which can support up to three (item # KCH301) or six (item # KCH601) K-Cubes or T-Cubes, and a power supply that plugs into a standard wall outlet. The hub draws a maximum current of 10 A; please verify that the cubes being used do not require a total current of more than 10 A. In addition, the hub provides USB connectivity to any docked K-Cube through a single USB connection.

For more information on the USB Controller Hubs, see the full web presentation.

Products Home

Products Home

Zoom

Zoom

Voice Coil Translation Mount

Voice Coil Translation Mount