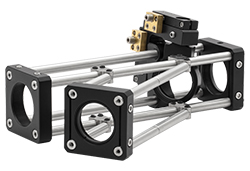

Gimbal Mount for 30 mm Cage

- True Gimbal Design

- Precision Angular Alignment of Optics

- 30 mm Cage System Compatible

CPA2

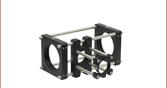

30 mm Cage Alignment Plate with Ø5 mm Hole

KC45D1

Gimbal Mount for Ø1" Optics

30 mm Cage Compatible

Please Wait

| Alternative Size Options |

|---|

| 16 mm Kinematic Cage Mounts |

| 30 mm Kinematic Cage Mounts |

| 60 mm Kinematic Cage Mounts |

Features

- Ø1" (Ø25.4 mm) Optic Mount

- Compatible with 30 mm Cage System

- ±30° Kinematic Adjustment

Thorlabs' KC45D1 30 mm-cage-compatible gimbal mount is designed to hold a beamsplitter or mirror that is being used to direct light into or out of a cage system. If the gimbal mount is being utilized to center light within a cage system, accurate positioning of the beam is made easier using one of the cage system alignment plates offered at the bottom of this page.

Thorlabs' Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment. Our mounts featured here have been designed to allow for the precise angular positioning of optics within a cage system. Thorlabs offers 16 mm, 30 mm, and 60 mm cage systems designed for Ø1/2", Ø1", and Ø2" optical components, respectively. The parts on this page are compatible with our 30 mm cage system and utilize Ø6 mm ER cage rods.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see image below). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

Thomas Dzelzainis

(posted 2020-11-02 12:29:17.973) Hi,

Is there anything that can function smilar to this product, but is contained within a cube, or is this the only way to insert a beam splitter with full x-y tilt control? This item does not really make it easy to use a beamsplitter in the system, as it provides no mounting options to build the cage system for the beam that is directed out of the original beam path, even if it had to go into a 60 mm cube due to space requirements, it would be preferable to this in my opinion.

Many thanks,

Tom. llamb

(posted 2020-11-04 03:37:07.0) Hi Tom, thank you for contacting Thorlabs. While we do not have a true beamsplitter gimbal mount that would be contained within the cage system as you've described, you could consider a non-gimbal kinematic cage option instead. Our C45P beamsplitter mount could be an alternative, or, using a kinematic cage cube platform (such as B4C) within a cage cube could work as well. user

(posted 2018-10-20 16:04:47.6) Can this be used to hold optics at 45 degrees, similarly to the C45P right angle kinematic beam splitter mount for 30 mm cage system (I'm asking because the C45P only allows for 1° of adjustment)? YLohia

(posted 2018-10-22 11:38:21.0) Hello, thank you for contacting Thorlabs. Yes, the KC45D can be used for this purpose since the optic holder has a full 360 deg adjustment capability. lily.d.yang

(posted 2014-06-09 08:28:28.467) Dear Sir or Madam,

I would like to be able to mount a pellicle beamsplitter in a gimble mount in the cage system. I hope either an adapter can be made or a mount for the pellicle beamsplitters can be designed.

Best,

-Lily cdaly

(posted 2014-06-12 02:28:03.0) Response from Chris at Thorlabs: I don't think an adapter would be feasible since the pellicle would not be able to sit in the plane which rotates with gimbal motion, but a different version dedicated to the pellicles perhaps may be something which we could do in the future. We will discuss the idea internally. Thank you very much for your suggestion. |

Click to Enlarge

Gimbal mounts in combination with our swivel couplers are ideal for creating non-45° incident angles within a cage system.

Click to Enlarge

The KC45D1 Gimbal Mount in a 30 mm Cage System

- True Gimbal Design

- Maximum Optic Thickness: 0.24" (6 mm)

- Mounts Ø1" Optics

- Compatible with Thorlabs' 30 mm Cage System

- Full 360° Rotation of Optic Holder

- ±30° Rotation on the Optic Holder Saddle

The KC45D1 Gimbal Mirror Mount is designed to allow a Ø1" optic to be rotated about a point in the center of a 30 mm cage assembly with true gimbal motion. The optic holder is free to rotate through 360°. Once its coarse angular orientation is set, the fine adjustment mechanism (i.e., two 100 TPI adjusters offering an adjustment per revolution of 13 mrad/rev) can be used for precise alignment, using the HKTS-5/64 hex key thumbscrew or any other 5/64" hex key or balldriver. The second angular degree of freedom is achieved by rotation of an intermediate saddle. This saddle connects the optic holder to the cage assembly and is free to rotate ±30°. The optic is secured against the back lip of the SM1 (1.035"-40) center tapped region using the included SM1RR Retaining Ring.

Click to Enlarge

Front View of VRC1CPT Drop-In Alignment Plate

- Drop-In Beam Alignment Tools

- Small Through Hole Aligned at Center of 30 mm Cage Assembly

The CPA1 and CPA2 Alignment Plates are convenient tools for aligning cage-based optical systems. These drop-in plates feature a small through hole at the exact center of the 30 mm cage assembly that is used for aligning visible beams. For easy alignment, the through hole is surrounded by engraved rings, which indicate Ø4 mm, Ø7 mm, Ø10 mm, and Ø13 mm. The CPA1 provides a Ø0.9 mm through hole, while the CPA2 provides a Ø5 mm through hole.

The VRC1CPT, VRC2CPT, VRC4CPT, and VRC6SCPT Alignment Plates are specifically designed to align UV to MIR beams in a cage-based optical assembly. These plates have concentric alignment ring engravings identical to the CPA1 (shown to the left) plate on the back. The fronts of the VRC1CPT, VRC2CPT, and VRC4CPT plates each include a Ø1/2" (Ø12.7 mm), non-rotating fluorescing alignment disk made of the same material used in our VRC1, VRC2, and VRC4 Viewing Cards, respectively. Alternatively, the front of the VRC6SCPT plate includes a Ø0.39" (Ø10.0 mm), non-rotating MIR alignment disk made of the same thermochromic liquid crystal material used in our VRC6S Viewing Card. The disk on the VRC1CPT, VRC2CPT, or VRC4CPT plate has a Ø1.5 mm hole centered on the plate's Ø0.9 mm hole, and the disk on the VRC6SCPT plate has a Ø2.0 mm hole centered on the plate's Ø0.9 mm hole.

Products Home

Products Home

Zoom

Zoom

Gimbal Mounts

Gimbal Mounts