Active Isolation Breadboard Support Frames

- Designed to Maximize Vibration Isolation

- Pneumatic Self-Leveling Design

- Provides Vertical & Horizontal Vibration Isolation

- Load Capacity: 700 kg (1,545 lbs)

Active Workstation

Please Wait

Features

- Vertical and Horizontal Vibration Isolation

- Support Frames Accommodate Breadboard Sizes as Large as 1200 mm x 1800 mm (48" x 72")

- Available in 700 mm or 800 mm Frame Heights

- Sturdy, All Steel Construction

- Manually Leveling Feet to Compensate for Uneven Floors

- Set of Casters Available (PWA061)

These workstations are designed to support Thorlabs breadboards up to 48" x 72" (1200 mm x 1800 mm) in size. They can carry loads of up to 700 kg (1545 lbs) and have a frame height of 700 mm (27.5") or 800 mm (31.5"). The systems are based on four independent, air mounted, active vibration isolators which are self leveling with a repeatability of ±0.25 mm (0.010"). With vertical and horizontal resonance frequencies of 1.6 Hz and 1.2 Hz (accordingly) these isolators are an ideal solution for interferometry, cell injection, non-contact surface measurement, microscopy and other motion-sensitive measurements. The pneumatic isolators in the active isolation support frames require a constant source of pressurized air, such as that provided by our compressor.

| Specification | Value |

|---|---|

| Vertical Resonant Frequency | <1.6 Hz |

| Horizontal Resonant Frequency | <1.2 Hz |

| Vertical Transmissibility at Resonance | <13 dB |

| Horizontal Transmissibility at Resonance | <8 dB |

| Vertical Transmissibility at 5 Hz | -18 dB (87.5%) |

| Horizontal Transmissibility at 5 Hz | -18 dB (87.5%) |

| Vertical Transmissibility at 10 Hz | -34 dB (98%) |

| Horizontal Transmissibility at 10 Hz | -34 dB (98%) |

| Load Capacity | 700 kg (1,545 lbs) |

| Height | 800 mm (31.5"). 700 mm (27.5") |

| Isolators Height Adjustment Range | ±6 mm (0.25") |

| Self Leveling Repeatability | ±0.25 mm (0.010") |

| Legs Height Adjustment Range | ±10 mm (0.4") |

| Air Pressure Required | 690 kPa (100 psi) Maximum |

| Finish | Black Paint |

A vibration isolation system is subjected to continuous vibrational impulses from the laboratory floor. These vibrations may be caused by large machinery within the building or even by wind or traffic excited building resonances (swaying). Transmissibility is a measure of the isolators efficiency at damping out these vibrations and is defined as the ratio of the amplitude of the transmitted vibration to that of the forcing vibration.

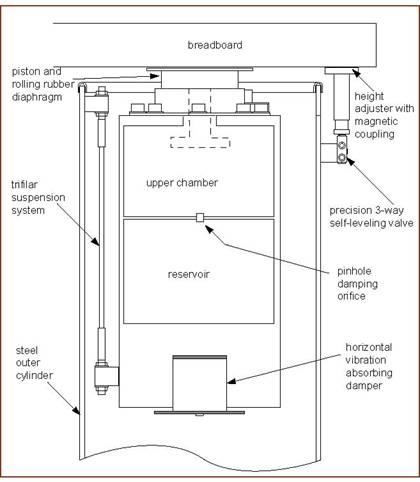

Vertical damping is achieved by the use of a dual chamber, damped pneumatic spring. The breadboard is supported by the air pressure in these chambers, and sits on a piston which is sealed to the upper chamber with a rolling rubber diaphragm. This allows virtually friction free motion between piston and chamber. Floor or tabletop motion forces air to flow from the upper chamber to the reservoir bottler through a high-resistance damper.

This restriction of airflow damps oscillatory motion between the floor and breadboard, dramatically reducing settling time. The volume ratio of the chambers has been optimized to maximize damping performance for our complete range of breadboards while preserving a low resonant frequency.

Damping of horizontal vibrations is accomplished by supporting the pneumatic vertical isolator on a trifilar suspension system. This innovative pendulum design uses gravity to provide the restoring force after horizontal disturbances. Horizontal oscillations at the system’s resonant frequency are damped by linking the base of the vertical isolator to the outer cylinder with an oil-free vibration-absorbing damper.

To allow for changes in load distribution, SuperDamp™ isolators also feature a self-levelling system incorporating precision three way valves that do not compromise vertical isolation when the system is at rest. Because these valves are actuated by worksurface movement, the system returns to its original level position within ±0.25mm (0.01in.) after disturbances. The valves also compensate automatically for any changes in load distribution.

Additionally, this system allows the breadboard height to be adjusted over a range of 26mm (1.02in) and can be used to compensate for an uneven floor. These isolators require a constant supply of air. When the air supply is removed, the breadboard rests securely on top of the frame with the isolation system disabled.

Please see the Vibration Isolation Tutorial for more information the design of our products and the theory of vibration isolation and damping.

Selecting a Vibration System

Thorlabs offers three types of breadboard support systems: Active Isolation, Passive Isolation and a rigid support system.

The Active and the Passive isolation systems are both based on compressed air, providing vibration isolation in frequencies above 2 Hz and 10 Hz (respectively) making them ideal systems for demanding photonic experiments or for work in a noisy environment. In addition, Thorlabs also offers rigid support systems with no vibration isolation for less demanding applications which require only breadboard isolation. The table below compares the isolation performance of our different isolation systems.

| Active Vibration Isolators |

Standard Passive Vibration Isolators |

Heavy Duty Passive Vibration Isolators |

Rigid, Non-Isolating |

Optics a la Cart Rigid Lab Cart |

|

|---|---|---|---|---|---|

| Vertical Resonant Frequency | <1.6 Hz | 3.5 Hz | 3.5 Hz | N/A | N/A |

| Horizontal Resonant Frequency | <1.2 Hz | N/A | N/A | N/A | N/A |

| Vertical Transmissibility at Resonance |

<13 dB | 24 dB | 24 dB | N/A | N/A |

| Horizontal Transmissibility at Resonance |

<8 dB | N/A | N/A | N/A | N/A |

| Vertical Transmissibility at 10Hz | -34 dB | -16 dB | -16 dB | N/A | N/A |

| Horizontal Transmissibility at 10Hz | -34 dB | N/A | N/A | N/A | N/A |

| Isolation Type | Active | Passive | Passive | N/A | N/A |

| Damping Efficiency | Best | Good | Good | N/A | N/A |

| Height | 700 mm (27.5") 800 mm (31.5") |

700 mm (27.5") 800 mm (31.5") |

700 mm (27.5") 800 mm (31.5") |

700 mm (27.5") 800 mm (31.5") |

870 mm (34.3") |

| Load Capacity | 700 kg (1540 lbs) | 24 to 260 kg (50 to 570 lbs) |

135 to 700 kg (300 to 1540 lbs) |

700 kg (1540 lbs) | 320 kg (705 lbs) |

| Mobility | N/A | N/A | N/A | N/A | Lockable casters |

| Storage | N/A | N/A | N/A | N/A | Bottom Shelf Optional Drawer |

Vibration Isolation

Vibration isolation is needed to isolate between noises originating around the workstation and breadboard surface. Such vibrations may result from machinery in the building such as elevators or compressors, pedestrians, building vibrations and nearby street traffic. The role of the vibration system is to dampen, both horizontally and vertically, the noises generated by the surrounding environment. Such noises are typically in the range of 10 - 100 Hz. the table below depicts common vibration sources:

| Types | Frequency (Hz) | Amplitude (inches) |

|---|---|---|

| Air Compressors | 4 - 20 | 10-2 |

| Handling Equipment | 5 - 40 | 10-3 |

| Pumps* | 5 - 25 | 10-3 |

| Building Services | 7 - 40 | 10-4 |

| Foot Traffic | 0.5 - 6 | 10-5 |

| Acoustics | 100 - 10 000 | 10-2 to 10-4 |

| Punch Presses | Up to 20 | 10-2 to 10-5 |

| Transformers | 50 - 400 | 10-4 to 10-5 |

| Elevators | Up to 40 | 10-3 to 10-5 |

| Building Motion | 46/Height in meters | 10-1 |

| Building Pressure Waves | 1 - 5 | 10-5 |

| Railroad | 5 - 20 | ±0.15 g |

| Highway Traffic | 5 - 100 | ±0.001 g |

*Vacuum, Compressed, or Non-Compressed Fluids

| Posted Comments: | |

Sebastian Reparaz

(posted 2022-11-30 10:18:23.847) Hi, I have bought a couple of years ago an optical frame with active isolation. Currently, one of the legs is leaking air and, hence, the table cannot float on that leg. Would you please advice on how we should proceed here. Is there any easy solution to this we could implement?

Movil: +34 654 831 536

email: jsreparaz@icmab.es

Thanks in advance,

Sebatian Reparaz

Institute of Materials Science of Barcelona

Spain DCroxford

(posted 2022-12-01 05:04:44.0) Response from Daniel at Thorlabs: Thank you for your query. There can be a few causes of such a leak and a member of technical support will reach out to you to help with troubleshooting. The main checks will be with regards to the tubing and connections. Initial checks you can do yourself include:

- Check the tubing connections are fully inserted into the push-fit connections. This can require some force to get the tube past the O-ring.

- Check if air is leaking from the valve or the top of the leg. Valves are easily replaced. Stuart Cole

(posted 2019-10-16 12:57:45.823) Would it be possible to mount four swivel jacks on each of the four legs? https://www.etrailer.com/Trailer-Jack/Dutton-Lainson/DL22800.html or something similar. cwright

(posted 2019-10-17 06:34:09.0) Hello Stuart,

thank you for contacting us. These jacks you suggest appear to mount to the horizontal bars of the frame. In that case this may be possible but we would recommend the use of our PWA061 caster set instead. If you intend to screw these directly into the legs then I would advise that this material is only a few millimetres thick and it is unlikely to be a secure fit. I will contact you directly to offer further support. ingcarlosgordon

(posted 2016-01-26 15:22:30.79) Dear

Thorlabs.

We are from the University Carlos III of Madrid.

Actually, we have an Optical Table of Melles Griot (1200x1200mm) and we need to provide an active isolation.

Please, could you suggest us a suitable Active Isolation Breadboard Support Frame for our optical table?.

Thanks in advance. besembeson

(posted 2016-02-01 12:14:58.0) Response from Bweh at Thorlabs USA: One of our active vibration isolation supports at the following link should be suitable. We will follow-up with you: http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1095 bray

(posted 2015-02-12 11:35:28.313) We purchased two air tables about 3 years ago and recently one of them has an air leak in the anchor leg piston. We've removed the piston and found the leak but now we need to replace the defective piston. Could you have one of your table experts contact me ASAP to deal with this? My name is Doug Bray and I have messages in to Rob Grant who we ordered the tables from but he is unavailable so I thought I should send a formal request to deal with the problem quickly. My office phone # is 403-329-2740 and my cell phone is 403-331-0789.

Thanks, Doug Bray rcapehorn

(posted 2015-02-16 08:44:04.0) Response from Rob at Thorlabs: Hi Doug, I am sorry you haven't been able to contact Rob Grant. I will contact you directly with further information on our repair procedure. jjurado

(posted 2011-02-16 18:28:00.0) Response from Javier at Thorlabs to Dra. Oropeza: Thank you very much for submitting your request. There are a couple of options to consider depending on the weight of the lithography equipment (I was not able to find this on the webpage you provided). You can use a 2.4" or 4.3" thick 4' x 5' breadboard. Please visit the links below for our Performance Series Breadboards:

PBH11119 - Performance Series I Breadboard - 5' x 4' x 2.4"

http://www.thorlabs.de/NewGroupPage9.cfm?ObjectGroup_ID=1873&pn=PFA51507#2819

PBH12119 - Performance Series II Breadboard - 5' x 4' x 4.3"

http://www.thorlabs.de/NewGroupPage9.cfm?ObjectGroup_ID=1858

The PFA51507 can properly support either breadboard. We also provide the compressor for active supports. The part number is PTA011:

http://www.thorlabs.de/NewGroupPage9.cfm?ObjectGroup_ID=1116

In terms of pressure, it is recommended to provide between 50 and 100 psi.

We provide detailed instructions in the manual for the frame.I will contact you directly for further support. loropeza

(posted 2011-02-16 16:39:57.0) I need to use this table to place an optical lithography equipment (http://www.intelligentmp.com/SF100XCEL.htm) that is 26x44 inches.

I consider this is the table I do need it, i would like to know your opinion about it and also which type of air compressor do i need in terms of size, power and pressure?

Do you also sell the compressor?

Thanks

******************************************************

Dra. Laura A. Oropeza-Ramos

Facultad de Ingeniería, UNAM

Centro UNAMems - Departamento de Electrónica

Edificio DIE-DIMEI 3er piso, Ciudad Universitaria, C.P. 04510 Mexico, DF

tel: (52.55)5622.31.20 , (DIE) 5622.31.12 , fax: (52.55)5622.35.96

******************************************** |

- Sturdy, All-Steel Construction

- 700 mm (27.5") Frame Heights

- Load Capacity: 700 kg (1545 lbs)

- Height Adjustment Range:

- Leveling Pads: ±9.5 mm (±0.375")

- Leveling Feet: ±5 mm (±0.2")

These 700 mm (27.5") high, active isolation frames offer the maximum isolation for vibration sensitive applications. They feature a pneumatic self-leveling design that provides both vertical and horizontal vibration isolation of the worksurface and effective attenuation of low frequency vibrations. These pneumatic isolators will require a constant source of pressurized air, such as that provided by our compressor.

Click More [+] on the table below to see frames suitable for each breadboard size. Custom sizes may also be available upon request; please contact Tech Support with your requirements and for pricing.

| Compatible Breadboards |

|---|

- Sturdy, All-Steel Construction

- 800 mm (31.5") Frame Heights

- Load Capacity: 700 kg (1545 lbs)

- Height Adjustment Range:

- Leveling Pads: ±9.5 mm (±0.375")

- Leveling Feet: ±5 mm (±0.2")

These 800 mm (31.5") high, active isolation frames offer the maximum isolation for vibration sensitive applications. They feature a pneumatic self-leveling design that provides both vertical and horizontal vibration isolation of the worksurface and effective attenuation of low frequency vibrations. These pneumatic isolators will require a constant source of pressurized air, such as that provided by our compressor.

Click More [+] on the table below to see frames suitable for each breadboard size. Custom sizes may also be available upon request; please contact Tech Support with your requirements and for pricing.

| Compatible Breadboards |

|---|

- 360° Swivel Allows Ease of Movement for Large Systems

- Highly Durable, Non-Marring Polyurethane Wheels

- Load Capacity: 200 kg (440 lbs) Each, 800 kg (1760 lbs) for a Set of Four

These casters are designed to permit easy relocation of the breadboard support frames, without removal of equipment or disassembly of the system. They are ideal for positioning the frames within tight spaces. Each caster rides on a non-marring wheel for smooth and quiet operation. Supplied as a set of four.

Products Home

Products Home

Click to Enlarge

Click to Enlarge

Zoom

Zoom

Self-Leveling, Active Isolation Frames

Self-Leveling, Active Isolation Frames