Three-Axis VantagePro® Galvo System Scan Heads

- XYZ Scanning Using Galvanometers with Focus Adjustment

- Flexible Design Suitable for Many Applications

- Configured for Digital Commands

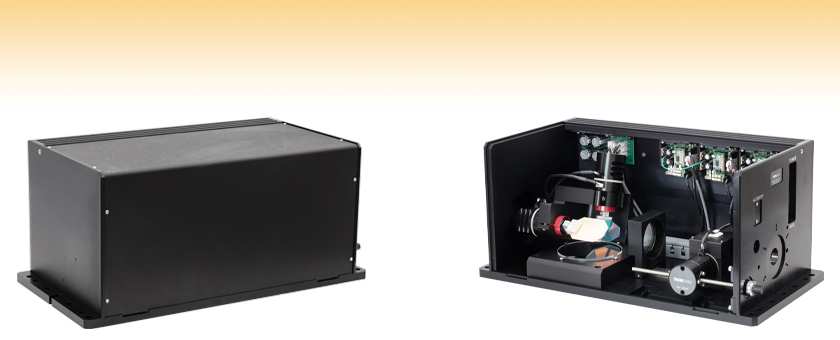

XG330-Y1

Dynamic Focusing 3-Axis Galvo Scan Head

Inside View

With Lid On

Please Wait

Applications

- Large Field Marking

- Contoured Surfaces Marking

- Micromachining

- Cutting and Embossing

- Solar Scribing

- Thin Film Scribing

- Rapid Prototyping

- Laser 3D Printing

- Surface Treatment

- Ablation

- Welding

- Mark-on-the-Fly Processing

Large-Volume Orders

For orders where a large quantity of an item is purchased and the delivery of that item is scheduled with our production (i.e., not taken directly from inventory), Thorlabs passes on to the customer the cost savings associated with planned production of high volumes of that item. Since the volume and planned production are key to realizing the cost savings, we ask that you contact us to obtain volume pricing.

Additional requests can include custom optic sizes and coatings, specialized tuning, and variable cable options.

Features

- XY Galvo Scanning with Dynamic Z-Axis Focusing

- Ideal for Large Field Sizes and Small Spot Sizes

These 3-Axis VantagePro® Galvo System Scan Heads include XY scanning mirrors and Z-axis focusing elements in order to achieve a large, three-dimensional field of view. Rather than a standard f-theta scanning lens, these scan heads use translating focusing elements to adjust the focal point of the system and maintain a flat scan area. See the 2-Axis vs. 3-Axis tab for details.

Our Dynamic Focusing Scan Heads are capable of achieving field sizes up to 1000 x 1000 mm² or spot sizes down to Ø22 µm, offering flexibility and making them suitable for many applications. The dynamic lens translator continuously adjusts the focus distance via a combination of manual and motorized actuators to produce a flat or contoured field; manual adjustment of the lens position determines the working distance and field size, while fine motorized adjustment provides focal correction while scanning. These scan heads are available with mirrors for Nd:YAG (1064 nm) or CO2 (10.6 µm) lasers.

Our High-Speed Focusing Scan Head is a scanning solution designed to offer 3-axis capabilities in a compact package for field sizes up to 450 x 450 mm². It includes the BLINK high-bandwidth Z-axis focuser for scanning highly contoured surfaces. The fully packaged design allows for easy integration into tabletop workstations and assembly lines. This scan head includes mirrors coated for Nd:YAG (1064 nm) lasers.

System Control

These scan heads are configured to accept inputs via the XY2-100 communication protocol. This industry-standard digital interface integrates with PC-based hardware and software packages for laser marking and micromachining. We recommend the SAMLight software package from SCAPS for operating these scan heads; click here for information on this software.

Power supplies and cables are sold separately.

For OEM or custom requests, please email techsales@thorlabs.com.

Galvo Specifications

| Item # | XG330-Y1 | XG345-CD | DCB320-Y1 |

|---|---|---|---|

| Maximum Input Beam Diameter | 8.5 mm | 14 mm | 8.5 mm |

| Input/Output Beam Offseta | 35.2 mm | 44.0 mm | 22.2 mm |

| Mirror Coating | Nd:YAG | CO2 | Nd:YAG |

| Wavelength | 1064 nm | 10.6 µm | 1064 nm |

| Absolute Reflectance | 99.5% at 1064 nm | 99.5% at 10.6 µm | 99.5% at 1064 nm |

| Z-Axis Step Response Time | 6 ms | 1.5 ms | |

| Compatible Power Supplyb | GPWR15 | GPWR24 | |

Field Size vs. Spot Size

| Item # | XG330-Y1 | XG345-CD | DCB320-Y1 | |

|---|---|---|---|---|

| Field Size | Working Distance | Spot Sizea,b | ||

| 150 x 150 mm² | 206.1 mm | - | - | 32 µm |

| 200 x 200 mm² | 274.7 mm | 22 µmc | - | - |

| 300 x 300 mm² | 412.1 mm | 30 µm | 165 µm | 64 µm |

| 400 x 400 mm² | 549.5 mm | 38 µm | 210 µm | - |

| 450 x 450 mm² | 618.2 mm | - | - | 96 µm |

| 500 x 500 mm² | 686.9 mm | 46 µm | 250 µm | - |

| 600 x 600 mm² | 824.2 mm | 54 µm | 295 µm | - |

| 700 x 700 mm² | 961.6 mm | 62 µm | 350 µm | - |

| 800 x 800 mm² | 1099.0 mm | 71 µm | 395 µm | - |

| 900 x 900 mm² | 1236.4 mm | 80 µm | 450 µm | - |

| 1000 x 1000 mm² | 1373.7 mm | 89 µm | 495 µm | - |

| GPWR15 Power Supply Unit Specs | |

|---|---|

| Input | 100 - 120 VAC or 220 - 240 VAC |

| Output | ±15 V at 5 A (150 W Max Power) |

| Operating Temperature | 0 to 50 °C |

| Dimensions | 14.0" x 4.9" x 3.5" (356 mm x 124 mm x 90 mm) |

| GPWR24 Power Supply Unit Specs | |

|---|---|

| Input | 100 - 120 VAC or 220 - 240 VAC |

| Output | ±24 V at 2.4 A (115 W Max Power) |

| Operating Temperature | 0 to 50 °C |

| Dimensions | 9.38" x 4.87" x 3.28" (238.3 mm x 123.7 mm x 83.3 mm) |

Click to Enlarge

Diagram Illustrating Dynamic Focusing to Achieve a Flat Field in Our XG300 Series and DCB320-Y1 Three-Axis Galvo Scan Heads

In a typical two axis laser scanning system, a collimated beam is reflected by the X and Y axis scanning mirrors before entering the focusing (objective) lens. The lens focuses the beam on the work surface. Rotation of the X and Y mirrors causes movement of the focused spot within a flat field. The size of the spot and the size of the field are determined by the lens (and other factors). This configuration is known as a pre-objective scanning system because the laser strikes the scanning mirrors before the focusing (objective) lens. An f-theta lens is a common choice for the lens in this configuration.

The architecture works well as long as the beam diameter and field size are relatively small. For example, applications using beam diameters less than 20 mm and field sizes less than 300 mm are well suited to Z-axis pre-objective scanning.

As the field size requirements grow, larger scan mirrors and laser beam diameters are needed to maintain a numerical aperture (NA) consistent with a small focused spot. F-theta scan lenses for these large laser beams would be big, costly, and impractical. For this reason, a 3-axis scanning solution should be considered.

In a 3-axis scanning system, as shown in the figure to the right, the XY mirrors are placed after the final focusing lens, and hence they are referred to as a post-objective scanning system. Since the laser beam does not move on the objective lens, the lens does not need to be very large; however, this arrangement does not create a flat field. To achieve a flat field, a third axis (Z-axis) of motion is introduced in the form of a linear lens translator.

The typical laser system uses a telescope to expand the laser beam to a diameter consistent with the required NA. The distance between the telescope input lens and objective lens determines the focal distance of the system. By mounting the input lens on a linear lens translator (the third axis), we gain dynamic control over the focal distance. See the diagram to the right for details.

By coordinating the motion of the linear lens translator with the rotation of the X and Y scanning mirrors, we achieve a focused laser spot throughout a flat field. Alternatively, the same configuration can be used to scan a three-dimensional surface. In this scenario, the Z-axis position is an arbitrary function of the X and Y galvo mirror positions, enabling the system to scan complex geometries.

XG300 Series Scan Heads

Click to Enlarge

DCB320 Scan Head

Click to Enlarge

Key Features of SurfBoard and

Pipeline Controllers

- Standard XY2-100 Communication

- Encoder Input for Mark-on-the-Fly

- Multi-Axis Mark-on-the-Fly

- Outputs for CW and Pulsed Lasers

- First Pulse Killer Output

- 16-Bit Position Resolution

- Analog and Digital Laser Power Control

- Multiple Scan Head Operation from a Single Controller

- Dedicated Step and Direction Outputs for 3-Axis Stepper Motor Control with Home Input

- Remote-Controlled or Stand-Alone Operation

- Dual Processor

- 1 GB Flash Memory

- 64 MB RAM

- 10/100 Ethernet

- 2-Channel XY2-100 3-Axis Digital Interface

- Six Inputs / Six Outputs, Optically-Isolated, 5 - 24 V Level

- Two 10-Bit Analog Inputs

- Two Analog Outputs (2, 5, 10 V Range)

- Ten Inputs / Ten Outputs Non-Isolated Digital TTL

- RS-232 Interface

Additional Key Features of

Pipeline Controller

- Laser Enable Key Switch with 5 Second Signal Delay

- Connector Ports for Simplified Wiring

- Controller-to-Laser Cable Options for Select Lasers

Thorlabs offers the SurfBoard and Pipeline galvo controllers for generating XY2-100 signals and system control of devices such as XY tables and rotary stages. Axes of motion may be controlled via I/O or RS-232. The hardware I/O can be configured to interact with other devices for handshaking and synchronizing functions. For assistance with ordering and configuring your galvo scanning hardware and software solution, please contact us.

SurfBoard Controller

The SurfBoard is a small form-factor, DIN rail mountable control card for the user that is looking for an increased level of flexibility in their integration. It is available with an enclosure for easy mounting or as a bare board for greater end-user customization.

Pipeline Controller

The Pipeline hardware is a 1U rack-mountable 19" controller and contains connector ports and safety features that allow for greater simplification of the wiring process. A front panel key switch with a 5-second delay, mark in progress indicator, and safety interlock loop are provided. The interface board implements key features necessary to manage fiber laser control signals.

Remote Control Software

Vectors and commands are uploaded from a host system over a USB or Ethernet connection. Execution is independent of the host computer, allowing for true real-time control. Jobs may be constructed and run from the WaveRunner GUI (click here to download) or by other user software through the Scan Card Interface option.

Standalone Operation

The Standalone/Flash option allows run-time operation without a PC. Up to 256 jobs may be stored and selected by either hardware or software methods. Ethernet connections allows remote access from any location for changing settings and job files. Combining Standalone/Flash with a WaveRunner dongle enables flexible embedded solutions for up to 16 laser-scanning stations. Only one WaveRunner software license is needed for job creation and editing where Standalone/Flash is implemented, providing significant cost savings for multiple workstation installations.

Click for Details

SurfBoard Galvo Controller

Click for Details

Pipeline Galvo Controller

Typical Galvo Scanning System with

Pipeline Controller

Features

- Accommodates TrueType Fonts, Serialization, Radial Text, and Vertical Text

- Graphics Import Filters for Wide Variety of Formats:

- AI, SVG, BMP, DXF, HPGL, JPG, JOB, MCL, PCX, PLT, and WMF

- Real-Time Calculation of Laser and Scanner Signals

- Online Grid Correction

- Control Signals for Every Type of Laser

- Stand-Alone Operation or Integration with Host Computers or PLCs

- Capable of Operating Motion Control Devices (e.g.: XY Tables or Rotary Indexers)

Optional Software Modules

- Mark-on-the-Fly

- 3-Axis Scanning – Enables Z-Axis Adjustments

- Client Interface – Allows for Remote Control from Other Software, Such as ActiveX

- MultiHead – Enables Simultaneous Marking on up to 4 Heads

- Optic 3D – Wrap Objects Around 3D Surfaces, Allows for DXF File Import

- 3D/Rapid Prototype – Enables Slicing of Solids into Layers (Requires Client Interface)

- Flash – Standalone Capability

WaveRunner Scan Control Software

This advanced, fully-featured laser scanning software package is designed for use with our SurfBoard and Pipeline galvo system controllers (please see the Controller Options tab for more details). It enables the creation and editing of job files for laser marking, micromachining, and processing. Use the WaveRunner GUI to assemble text, images, bar codes, and serial numbers into job files, assign laser scanning parameters, and build automation scripts within a single interface. Graphic objects can be drawn natively or imported with support for a wide variety of formats. Markable objects can be organized into sequences which include control objects such as timers, I/Os, and motion control automation. Each object can be assigned unique laser processing parameters.

The WaveRunner Scan Control software can be configured to work with all laser types. A library of correction files is included for popular scanning lenses and custom lens correction files can be easily created. WaveRunner can also be used with our SurfBoard or Pipeline scan controllers to operate 2- or 3-axis scan systems, which are then capable of stand-alone operation or integration with host computers or programmable logic controllers (PLCs).

| Posted Comments: | |

Mayur Patel

(posted 2021-05-22 19:00:25.667) I am looking for a CO2 laser compatible 3 axis scan head. my working area is 300 x 300mm. and i want to achieve spot diameter of 0.2mm to 0.5mm. My CO2 laser beam diameter is 6mm and i am also having variable beam expander. So, with what diameter of beam XG343-CD scan head can achieve spot diameter of 0.2mm-0.5mmm YLohia

(posted 2021-05-24 11:26:54.0) Thank you for contacting Thorlabs. The XG345-CD expects a 14 mm input beam diameter and we always recommend fully expanding the input beam to 14 mm to fill the aperture for two reasons: 1) It will offer the best power-handling capability and 2) It will allow for the smallest spot possible. Since you do not require the smallest possible spot size (0.165 mm), you could use a smaller input beam diameter with the 300 mm x 300 mm field size using your variable beam expander. Spot size is also proportional to field size. The larger the field, the larger the working distance. The further away the marking surface, the larger the spot. For example, to get to a 512 um spot size, with a fully expanded to 14 mm input beam, one can anticipate a maximum field size of 1076.87 x 1035.5 3mm and a Y-radius of 1250 mm. Mayur Patel

(posted 2021-05-22 18:59:41.087) I am looking for a CO2 laser compatible 3 axis scan head. my working area is 300 x 300mm. and i want to achieve spot diameter of 0.2mm to 0.5mm. My CO2 laser beam diameter is 6mm and i am also having variable beam expander. So, with what diameter of beam XG343-CD scan head can achieve spot diameter of 0.2mm-0.5mmm |

| Item # | XG330-Y1 | XG345-CD | |

|---|---|---|---|

| Field Size | Working Distance | Spot Sizea,b | |

| 200 x 200 mm² | 274.7 mm | 22 µmc | - |

| 300 x 300 mm² | 412.1 mm | 30 µm | 165 µm |

| 400 x 400 mm² | 549.5 mm | 38 µm | 210 µm |

| 500 x 500 mm² | 686.9 mm | 46 µm | 250 µm |

| 600 x 600 mm² | 824.2 mm | 54 µm | 295 µm |

| 700 x 700 mm² | 961.6 mm | 62 µm | 350 µm |

| 800 x 800 mm² | 1099.0 mm | 71 µm | 395 µm |

| 900 x 900 mm² | 1236.4 mm | 80 µm | 450 µm |

| 1000 x 1000 mm² | 1373.7 mm | 89 µm | 495 µm |

- 30 mm Max Beam Diameter with Nd:YAG Mirrors (Item # XG330-Y1)

- 45 mm Max Beam Diameter with CO2 Mirrors (Item # XG345-CD)

- XY Galvo Scanning with Manual and Automatic Z-Axis Adjustment

- High Field Size to Spot Size Ratio

- 6 ms Z-Axis Step Response Time

These 3-Axis VantagePro® Scan Heads use a dynamic focusing system, rather than an f-theta lens, to produce a flat field. Each scan head incorporates an XY galvo system plus a linear lens translator (the Z-axis) that can produce a flat or contoured field by dynamically focusing on the surface of the workpiece. The system is designed to create a large scan field with a relatively small spot; spot sizes as small as 30 µm or scan fields as large as 1 m x 1 m are achievable. Various field and spot size combinations can be selected simply by turning a knob to adjust the working distance, while motorized focusing elements can be automated to enable scanning of a flat or contoured surface. The ability to vary the field and spot size offers application flexibility and is ideal for process development and job shop settings.

The Scan Head is used for optical scanning in XY and XYZ applications with lasers of various wavelengths. Configurations are available for a 30 mm max beam diameter and mirrors coated for Nd:YAG (1064 nm) lasers or a 45 mm max beam diameter and mirrors coated for CO2 (10.6 µm) lasers.

The compatible power supply (item # GPWR15), power cable (item # CBLPA16F), and galvo command cable (item # CBLA16D) are sold separately.

| Item # | DCB320-Y1 | |

|---|---|---|

| Field Size | Working Distance | Spot Sizea,b |

| 150 x 150 mm² | 206.1 mm | 32 µm |

| 300 x 300 mm² | 412.1 mm | 64 µm |

| 450 x 450 mm² | 618.2 mm | 96 µm |

- Ø13 mm Input; Ø20 mm Mirror Aperture

- XY Galvo Scanning with Integrated BLINK High-Speed Focuser

- 1.5 ms Z-Axis Step Response Time

- Fully Packaged Design Suitable for Laboratory or Industrial Environments

The DCB320-Y1 is a scanning solution offering 3-axis capabilities in a compact package for small to medium field sizes. The integrated design features advanced galvanometer technology that provides superior bandwidth, accuracy, and flexibility, and incorporates a high bandwidth Z-axis voice coil actuator for marking on highly contoured surfaces. This 3-Axis scan head is designed to operate seamlessly with the SAMLight laser scan control software and process controllers, making for easy integration into workstations and assembly lines.

The compatible power supply (item # GPWR24) and cable set (item # CBLA16F) are sold separately.

Products Home

Products Home

Zoom

Zoom

3-Axis Galvo Scan Heads

3-Axis Galvo Scan Heads