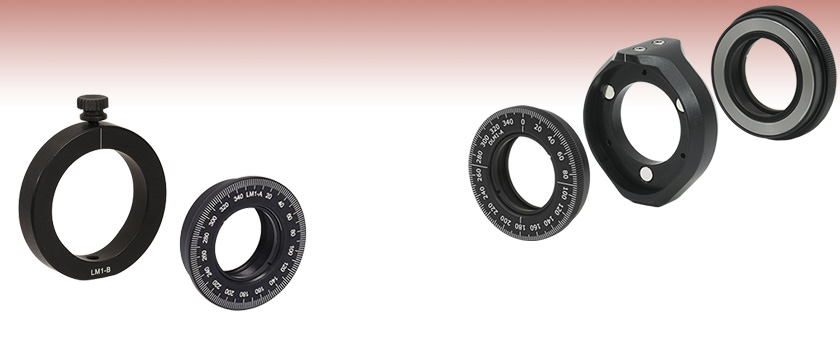

Nested Rotation Mounts

- Optic Carriage Rotates Within Mounting Ring

- Models Available for Ø1" and Ø2" Optics

- 8-32 (M4) Tap for Post Mounting

LM1-B

Mounting Ring with Thumbscrew Retention

LM1-A

Optic Carriage

DLM1

Mounting Ring with

Magnetic Retention

(Includes Two DLM1-A

Carriages)

DLM1-A

Optic Carriage

DLM1-A

Optic Carriage

Please Wait

Features

- Optic Mounts with Interchangeable Rotating Optic Carriage

- SM1- (1.035"-40) or SM2-Threaded (2.035"-40) Optic Carriage

- Retaining Ring(s) Included for Secure Optic Mounting

- Laser Engraved Scale with Graduations Every 2°, Labeled Every 20°

- 8-32 (M4) Tap for Post Mounting

These nested lens mounts systems consist of an inner optic carriage that rotates within the outer mounting ring. Single (LM1-B and LM2-B) and dual (DLM1) rotational optic versions are available. The optic carriages are radially laser engraved to allow for precise rotational changes. The optic carriages are retained within the mounting ring by either a thumbscrew or magnetic attachment. Additional optic carriages can be purchased and used for easy exchange of optics.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

Rotation Mount and Stage Selection Guide

Thorlabs offers a wide variety of manual and motorized rotation mounts and stages. Rotation mounts are designed with an inner bore to mount a Ø1/2", Ø1", or Ø2" optic, while rotation stages are designed with mounting taps to attach a variety of components or systems. Motorized options are powered by a DC Servo motor, 2 phase stepper motor, piezo inertia motor, or an Elliptec™ resonant piezo motor. Each offers 360° of continuous rotation.

Manual Rotation Mounts

| Rotation Mounts for Ø1/2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | MRM05(/M) | RSP05(/M) | CRM05 | PRM05(/M)a | SRM05 | KS05RS | CT104 |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

| Features | Mini Series | Standard | External SM1 (1.035"-40) Threads |

Micrometer | 16 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Compatible with 30 mm Cage Translation Stages and 1/4" Translation Stagesb |

| Additional Details | |||||||

| Rotation Mounts for Ø1" Optics | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | RSP1(/M) | LRM1 | RSP1D(/M) | DLM1(/M) | CLR1(/M) | RSP1X15(/M) | RSP1X225(/M) | PRM1(/M)a |

| Click Photo to Enlarge |

|

|

|

|

|

|

|

|

| Features | Standard | External SM1 (1.035"-40) Threads |

Adjustable Zero | Two Independently Rotating Carriages | Rotates Optic Within Fixed Lens Tube System |

Continuous 360° Rotation or 15° Increments |

Continuous 360° Rotation or 22.5° Increments |

Micrometer |

| Additional Details | ||||||||

| Rotation Mounts for Ø1" Optics | ||||||

|---|---|---|---|---|---|---|

| Item # | LM1-A & LM1-B(/M) |

CRM1T(/M) | CRM1LT(/M) | CRM1PT(/M) | KS1RS | K6XS |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Optic Carriage Rotates Within Mounting Ring | 30 mm Cage-Compatiblea | 30 mm Cage-Compatible for Thick Opticsa |

30 mm Cage-Compatible with Micrometera |

±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mounta |

| Additional Details | ||||||

| Rotation Mounts for Ø2" Optics | |||||||

|---|---|---|---|---|---|---|---|

| Item # | RSP2(/M) | RSP2D(/M) | PRM2(/M) | LM2-A & LM2-B(/M) |

LCRM2A(/M) | KS2RS | K6X2 |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Features | Standard | Adjustable Zero |

Micrometer | Optic Carriage Rotates Within Mounting Ring | 60 mm Cage-Compatible | ±4° Kinematic Tip/Tilt Adjustment Plus Rotation | Six-Axis Kinematic Mount |

| Additional Details | |||||||

Manual Rotation Stages

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | RP005(/M) | PR005(/M) | MSRP01(/M) | RP01(/M) | RP03(/M) | QRP02(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Standard | Two Hard Stops | ||||

| Additional Details | ||||||

| Manual Rotation Stages | ||||||

|---|---|---|---|---|---|---|

| Item # | XRNR1(/M) | XRR1(/M) | PR01(/M) | CR1(/M) | XYR1(/M) | OCT-XYR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Features | Fine Rotation Adjuster and 2" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and 3" Wide Dovetail Quick Connect |

Fine Rotation Adjuster and SM1-Threaded Central Aperture |

Fine Pitch Worm Gear | Rotation and 1/2" Linear XY Translation | |

| Additional Details | ||||||

Motorized Rotation Mounts and Stages

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | DDR25(/M) | PDR1C(/M) | PDR1(/M) | PDR1V(/M) | PDXR1(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM05 Lens Tubes, 16 mm Cage System, & 30 mm Cage System |

Compatible with 16 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

Vacuum-Compatible; Also Compatible with SM05 Lens Tubes & 30 mm Cage System |

Compatible with SM05 Lens Tubes & 30 mm Cage System |

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Central Clear Apertures | |||||

|---|---|---|---|---|---|

| Item # | K10CR1(/M) | PRM1Z8(/M)a | DDR100(/M) | ELL14 | HDR50(/M) |

| Click Photo to Enlarge |

|

|

|

|

|

| Features | Compatible with SM1 Lens Tubes & 30 mm Cage System | Compatible with SM1 Lens Tubes, 16 mm Cage System, 30 mm Cage System |

Compatible with SM1 Lens Tubes, Open Frame Design for OEM Applications |

Compatible with SM2 Lens Tubes |

|

| Additional Details | |||||

| Motorized Rotation Mounts and Stages with Tapped Platforms | ||

|---|---|---|

| Item # | PRMTZ8(/M)a | ELL18(/M)b |

| Click Photo to Enlarge |

|

|

| Features | Tapped Mounting Platform for Mounting Prisms or Other Optics | Tapped Mounting Platform, Open Frame Design for OEM Applications |

| Additional Details | ||

| Posted Comments: | |

jjurado

(posted 2011-09-02 14:06:00.0) Response from Javier at Thorlabs to wjlentz: Thank you very much for your feedback. We will look into offering a version for 3" diameter optics of our LM1 and LM2 mounts. I will contact you directly for further discussion. wjlentz

(posted 2011-09-01 14:38:13.0) I need the 3" version of the rotating optical mount. |

Click to Enlarge

Figure 274A The optic carriage is locked in place by a thumbscrew and can be easily removed from the main body of the mount.

- Mount Ø1" Optics up to 0.37" (9.4 mm) Thick

- Optic Carriage (LM1-A) and Mounting Ring (LM1-B or LM1-B/M) Sold Separately

- Rotating Optic Carriage is Interchangeable for Quick Swapping

- SM1-Threaded Optic Bore in Rotating Optic Carriage

- Post Mountable via 8-32 (M4) Tap

- Laser Engraved Graduation Marks Every 2°, Labeled Every 20°

The LM1-A optic carriage can be nested inside of the LM1-B (LM1-B/M) mounting ring and offers 360° of continuous rotation for Ø1" optics. The optic bore of the LM1-A carriage features internal SM1 (1.035"-40) threading and can hold an optic up to 0.37" (9.4 mm) thick with the included SM1RR retaining ring or an optic in an SM1-threaded housing. The carriage attaches to the main body of the mount using a thumbscrew. To remove the carriage from the mount, simply loosen the thumbscrew. Extra LM1-A interchangeable rotating carriages are available to allow optics to be swapped out quickly and easily.

Each carriage has a 360° laser-engraved scale marked at 2° increments for precise, repeatable positioning. The top-located thumbscrew can be tightened to lock the rotation of the optic carriage and, along with the double bore on the mount, maintains a stable, three-point contact to hold the optic carriage. When the

Click to Enlarge

Figure G2.1 The rotating optic carriages can be easily removed from the main body of the mount.

- Mount Two Ø1" Optics up to 0.25" (6.4 mm) Thick

- Two Optic Carriages (DLM1-A) Included with DLM1

- Each Optic Carriage Rotates Independently

- Rotating Optic Carriages are Interchangeable for Quick Swapping

- SM1-Threaded Optic Bore in Each Rotating Optic Carriage

- Two SM1RR Retaining Rings Included

- Post Mountable via 8-32 (M4) Tap

The DLM1(/M) Dual Rotation Mount includes two independently rotating carriages (item # DLM1-A) for Ø1" optics that offer 360° of continuous rotation. The optic bore of the DLM1-A carriage features internal SM1 (1.035"-40) threading and can hold an optic up to 0.25" (6.4 mm) thick with the included SM1RR retaining ring or an optic in an SM1-threaded housing. The carriages magnetically attach to the main body of the mount. To remove a carriage from the mount, simply pull the carriage off the main body. Another carriage can then be snapped on in its place. Extra DLM1-A interchangeable rotating carriages are available to allow optics to be swapped out quickly and easily.

Each carriage has a knurled edge for adjusting rotation and a 360° laser-engraved scale marked at 2° increments for precise, repeatable positioning. Two top-located setscrews can be tightened with a 5/64" (2.0 mm) hex key or balldriver to lock the rotation of the optic carriages independently. When the rotation is locked, the double bore on the mount maintains a stable, three-point contact to hold the optic carriage.

The DLM1 mount is designed to put the optic axis 1.00" (25.0 mm for the DLM1/M) above the top of the post When two optics are mounted, the separation between them is 0.30" (7.6 mm). The dual rotation mount is ideal for creating variable polarizers and attenuators by mounting linear polarizers and wave plates in close proximity without having to align the optic axes of two separate rotation mounts. We do not recommend using this mount with lens tubes, as the torque applied to the optic bore may overcome the magnetic attachment.

- Mount Ø2" Optics Up to 0.46" (11.7 mm) Thick

- Optic Carriage (LM2-A) and Mounting Ring (LM2-B or LM2-B/M) Sold Separately

- Rotating Optic Carriage is Interchangeable for Quick Swapping

- SM2-Threaded Optic Bore in Rotating Optic Carriage

- Post Mountable via 8-32 (M4) Tap

- Laser Engraved Scale with Graduations Every 2°, Labeled Every 20°

The LM2-A optic carriage can be nested inside of the LM2-B (LM2-B/M) mounting ring and offers 360° of continuous rotation for Ø2" optics. The optic bore of each carriage features internal SM2 (2.035"-40) threading and can hold an optic up to 0.46" (11.7 mm) thick with the included SM2RR retaining ring an optic in an SM2-threaded housing. The carriage attaches to the main body of the mount using a thumbscrew. To remove the carriage from the mount, simply loosen the thumbscrew. Extra LM2-A interchangeable rotating carriages are available to allow optics to be swapped out quickly at easily.

Each carriage has a 360° laser-engraved scale marked at 2° increments for precise, repeatable positioning. The top-located thumbscrew can be tightened to lock the rotation of the optic carriage and, along with the double bore on the mount, maintains a stable, three-point contact to hold the optic carriage. When the LM2-A is properly fastened in the LM2-B by the thumbscrew, the optic axis is 1.45" (36.8 mm for the LM2-B/M) above the top of the post.

Products Home

Products Home

Zoom

Zoom

Nested Mounts

Nested Mounts