Vytran® Polyimide Fiber Recoater with Linear Proof Tester

- Recoat Fusion-Spliced Fibers to Restore Strength and Flexibility

- Designed for Polyimide-Coated Fibers

- Features an Integrated Linear Proof Tester

- Fully Programmable and Automated Recoater

PRL201

Polyimide Fiber Recoater with Linear Proof Tester (Handset Controller Not Shown)

PRL201

Shown with Included Handset Controller

Please Wait

Click to Enlarge

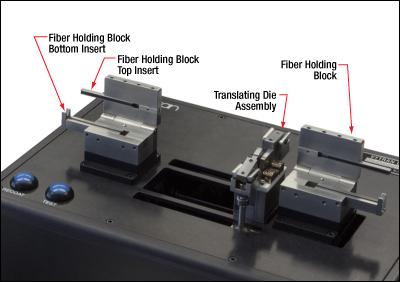

Figure 1.1 Thorlabs' PRL201 Polyimide Fiber Recoater detailing the die assembly, fiber block holders, and fiber block inserts.

Features

- Recoat Spliced Polyimide Fibers to Restore Flexibility

- Designed for Polyimide-Coated Fibers with Ø125 µm Cladding and Coatings up to Ø155 µm

- 35 mm Maximum Recoat Length

- Fully Programmable with Push Button Operation

- Features an Integrated Linear Proof Tester

Thorlabs' Vytran® Polyimide Fiber Recoater with Proof Tester offers an easy, integrated solution to recoat and test fusion-spliced fibers. The recoating process uses a translating die to apply a polyimide resin along the length of the recoated section, up to 35 mm in length. One pass can apply a Ø3 µm - Ø10 µm coat of resin, and multiple passes can be made for higher reliability and increased coating diameter. The recoat process is fully programmable; by setting parameters such as injection rate and the velocity of the die, the diameter of the recoat per pass can be set. Dual heater filaments in the die thermally cure the recoated section of fiber with each pass. The restored buffer coating gives the fiber the same flexibility as when originally manufactured, making this device ideal for applications that require handling and coiling of fusion-spliced fibers. Due to handling and storage constraints, we do not offer polyimide recoat material.

This recoater features an integrated linear proof tester, which can test each fiber up to 20 N (4.5 lbs) to ensure that it meets strength requirements for the required service load. The proof tester takes the fiber up to a predetermined load and then releases it. The testing process is fully programmable, allowing the user to select parameters such as the load, the rate at which the load is applied, and the hold time. To ensure the long-term reliability of the fiber, the proof test level should be about three times higher than the applied service load for the spliced fiber. Unlike standard heat shrink protection sleeves, a recoated fiber can be handled and coiled normally, while protecting the fusion-spliced section of fiber.

The recoating process starts with the fusion-spliced section of fiber being place in the middle of the die’s path (about midway between the fiber holding blocks). Once set in position, the tops of the fiber holding blocks are closed in order to secure the spliced fiber in place. Recoat material is pumped into the die (both undercoat and overcoat volumes can be set), which then coats the fiber as it passes. After each coat, the fiber is thermally cured in two steps. Each pass includes the recoat and two-stage thermal cure steps. The die is pneumatically actuated and requires an external 80 - 120 psi compressed air source (not included). Each system comes with a handset controller, which allows the user to program fully and control the unit. All recoat and proof test parameters can be set through the handset controller.

Customized dies for cladding sizes other than Ø125 µm are available; please contact Tech Support for more information.

| Item # | PRL201 |

|---|---|

| Recoater Type | Automatic Polyimide |

| Recoater Diea | Designed for Ø125 µm Cladded Fibersb |

| Recoat Diameter | ≤155 µmc, Programmabled |

| Maximum Recoat Length | 35 mm (1.38") |

| Recoat Material | Thermal Cure Polymide |

| Thermal Source | Dual Filament Heaters |

| Recoat Injection | Automatic |

| Total Cycle Time | 2 - 7 minc (Typical) |

| Dimensions (L × W × H) | 10.14" × 7.78" × 7.17" (257.4 mm × 197.5 mm × 182.2 mm) |

| AC Power | 110 - 120 V / 200 - 240 V, 47-63 Hz |

| Proof Tester Specifications | |

| Load Mechanism | 1.5" (38 mm) Linear Fiber Clamp |

| Fiber Spacing | 3.7" (94 mm) |

| Maximum Load | 20 N (4.5 lbs) 235 kpsi (1.6 GPa) for a Ø125 µm Fiber |

| Accuracy | ±2% |

| Ramp Rate | 22 N/s (5 lbs/s), Programmabled |

| Hold Time | 0.00 s - 9.99 s, Programmabled |

| Display Units | lbs, kg, N, kpsi, and GPa |

Thorlabs Vytran USA

|

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

Polyimide Fiber Recoater with Linear Proof Tester

Polyimide Fiber Recoater with Linear Proof Tester