Mechanical Component Bases

- Direct Mounting of Mechanical Components on Base

- Studded or Tapped Versions Available

- Articulated Base Levels Mounted Components

SWB

Articulated

Mounting Base

BE2

Ø1.25", 8-32 Studded Base

BE1T

Ø1.25", 1/4"-20 Tapped Base

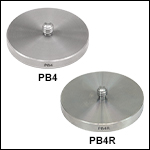

PB4

Ø1.85", 1/4"-20 Studded Base

±6°

BE1R

Ø1.25", 1/4"-20 Studded Magnetic Base

SBE2

Ø1", 8-32 and 1/4"-20 Tapped Base

Please Wait

Click to Enlarge

A Machined Ring on Metric Parts Allows for Easy Identification

Features

- Ø1" Bases

- SBE1(/M): 8-32 (M4 x 0.7) Tapped Thru Hole for 8-32 (M4 x 0.7)-Threaded Components

- SBE2(/M): Double Sided Base with Tapped Mounting Holes for 1/4"-20 (M6 x 1.0)- or 8-32 (M4 x 0.7)- Threaded Components

- Ø1.25" Bases

- Studded Bases for 1/4"-20 (M6 x 1.0) or 8-32 (M4 x 0.7) Tapped Components

- 8-32 (M4 x 0.7) or 1/4"-20 (M6 x 1.0) Tapped Hole for Counterbored Components

- Articulated Base for 1/4"-20 (M6 x 1.0) Tapped Components

- Ø1.85" Studded Bases for 1/4"-20 (M6 x 1.0) Tapped Components

- Fixed Bases Raise Components Only 0.19" (4.7 mm) or 0.24" (6.1 mm) above Optical Table

- Enables Close or Arbitrary Mounting of Mechanical Components on an Optical Table or Breadboard

Thorlabs offers a selection of bases on which mechanical components can be directly mounted. Each fixed Ø1" (Ø25.0 mm), Ø1.25" (Ø31.8 mm), or Ø1.85" (Ø47.0 mm) base is machined from a single piece of stainless steel for enhanced stability and provides either a threaded mounting hole or stud. We also offer a Ø1.25" (Ø31.8 mm) mounting base with an articulated 1/4"-20 (M6 x 1.0) threaded mounting stud that is ideal for leveling components on an optical table or breadboard. These bases can be secured to the optical table or breadboard using a clamping fork or a CL8 table clamp.

| Posted Comments: | |

| No Comments Posted |

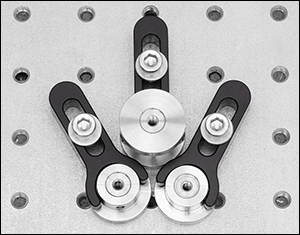

Click to Enlarge

Three SCF1 clamping forks hold three space-saving pedestal base adapters in close contact, providing a platform for mounting posts with only 1" center-to-center separation.

- SBE1(/M) and SBE2(/M) Adapters Convert Ø1" Posts to Pedestal-Style Mounts

- SBE1(/M): 8-32 (M4 x 0.7) Threads

- SBE2(/M): 8-32 (M4 x 0.7) and 1/4"-20 (M6 x 1.0) Threads

- Space-Saving Ø1" (Ø25.0 mm) Bases Support Mounting Optomechanical Components in Compact Setups

- Ø0.13" (Ø3.2 mm) Torque Hole for 7/64" (2.5 mm) Balldriver Provides Extra Leverage During Tightening

Click to Enlarge

The SBE2(/M) adapter can be flipped to utilize either the 8-32 (M4 x 0.7) mounting threads (left) or the 1/4"-20 (M6 x 1.0) mounting threads (right), as shown here.

The SBE1(/M) and SBE2(/M) Ø1" (25.0 mm) Pedestal Base Adapters are machined from non-magnetic 303 stainless steel and offer a low-profile option for mounting our Ø1" pillar posts, fixed lens mounts, Ø1/2" post holders, and any other optomechanical components that are compatible with either 8-32 (M4 x 0.7) or 1/4"-20 (M6 x 1.0) threads. They feature a Ø1" (25.0 mm) base that does not extend beyond the diameter of our Ø1" pillar posts and are designed to be held securely to a breadboard exclusively by our SCF1 Compact Clamping Fork, making them ideal for applications where table space is limited (see photo to the right).

The SBE1(/M) pedestal base adapter is 1/2" (12.5 mm) long and features an 8-32 (M4 x 0.7) tapped thru hole for directly mounting an 8-32 (M4 x 0.7)-threaded Ø1" pillar post via an 8-32 (M4 x 0.7) setscrew (such as Item # SS8S050 (SS4MS12)). The SBE2(/M) double pedestal base adapter is 1" (25.0 mm) long and features 8-32 (M4 x 0.7) internal threads with a depth of 0.30" (7.6 mm) on one end and 1/4"-20 (M6 x 1.0) internal threads with a depth of 0.38" (10.2 mm) on the other. With a pedestal base on both ends, the double pedestal base adapters can be flipped upside-down depending on which thread size is needed, as shown in the photo to the left. In addition to the 8-32 (M4 x 0.7) mounting options mentioned above, the added versatility of the 1/4"-20 (M6 x 1.0) threads enables direct mounting to 1/4"-20 (M6 x 1.0)-threaded Ø1" pillar posts or our standard Ø1/2" post holders via a 1/4"-20 (M6 x 1.0) setscrew (such as Item # SS25S050 (SS6MS12)).

Each of these pedestal base adapters also has a recessed Ø0.65" (Ø16.5 mm) central pillar above the 0.20" (5.1 mm) thick base, providing a clamping surface for the SCF1 clamping fork. All space-saving pedestal base adapters can also be mounted directly to a breadboard or optical table using the aforementioned setscrews.

Click to Enlarge

A TRB1 Locking Ball and Socket Mount is threaded onto a BE2 Base, which is secured by a CF125 Clamping Fork.

Click to Enlarge

The BE1R has a magnet in the base for stability in temporary setups.

- Mount 1/4"-30 (M6) or 8-32 (M4) Tapped Components in an Arbitrary Position 0.19" (4.7 mm) Above the Breadboard

- Clamping Fork or CL8 Table Clamp Secures Base to a Breadboard or Table

- 1/8" (3 mm) Hex Socket on Bottom for Tightening (Click the Zoom Link to the Left for Photograph)

- Machined Bottom Relief Cut for Added Stability

The BE1(/M), BE1R(/M), and BE2(/M) Studded Bases allow 1/4"-20 (M6) or 8-32 (M4) tapped optomechanical components to be mounted in an arbitrary position 0.19" (4.7 mm) above the breadboard. The BE1R(/M) adapters additionally have a magnet in the base that is sufficiently strong to securely hold the base in place without clamping to an optical table. These bases are Ø1.25" (Ø31.8 mm) and feature a 1/8" (3 mm) hex socket on the bottom for tightening.

To secure the base, a clamping fork (shown in the photo to the right) or a CL8 table clamp can be used. The BE1(/M) base adapter is available in a pack of five for ease of ordering.

| Item # | BE1(/M) | BE1R(/M) | BE2(/M) |

|---|---|---|---|

| Stud Thread | 1/4"-20 (M6) | 1/4"-20 (M6) | 8-32 (M4) |

| Stud Length | 0.30" (7.6 mm) | 0.30" (7.6 mm) | 0.15" (3.8 mm) |

Click to Enlarge A POLARIS-K05F6 Ø1/2" Mirror Mount is shown on a BE2T Base secured to the breadboard by two CL8 Table Clamps. Please note that a 3/8" (10 mm) long 8-32 (M4) low-profile cap screw is recommended for mounting the Polaris onto this base.

- Mount Counterbored Components in an Arbitrary Position 0.19" (4.7 mm) Above the Breadboard

- 8-32 (M4) and 1/4"-20 (M6) Tapped Versions Available

- CF125 or CF175 Clamping Fork or CL8 Table Clamp Secures Base to a Breadboard

- Machined Bottom Relief Cuts for Added Stability

The BE2T(/M) and BE1T(/M) Ø1.25" (31.8 mm) Tapped Bases allow counterbored optomechanical components to be mounted in an arbitrary position 0.19" (4.7 mm) above the breadboard. The BE2T(/M) offers an 8-32 (M4) tap, while the BE1T(/M) has a 1/4"-20 (M6) tap.

To secure these Ø1.25" (Ø31.8 mm) bases, a CF125 or CF175 clamping fork or a CL8 table clamp (shown in the photo to the right) can be used. However, using these items will restrict the width of the component being mounted to a maximum of 1".

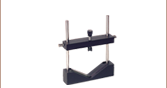

Click for Details

Mounting Base Being Used to Level and Secure an Optical Breadboard

- 0.66" Long, 1/4"-20 (M6) Threaded Mounting Stud

- CF125 or CF175 Clamping Fork (Sold Separately) Secures Base and Locks Swivel Joint

- ±6° Swivel Compensates for Uneven Surfaces

- Locking Nut Included for Height Adjustments

- 1/8" (3 mm) Hex Socket on Bottom for Tightening

- Machined Bottom Relief Cut for Added Stability

Thorlabs' SWB(/M) Ø1.25" (31.8 mm) Articulated Mounting Base can be used to stabilize and level a mounted component, such as a breadboard, or to correct for beam pointing errors. It features a 0.66" long, 1/4"-20 (M6) threaded mounting stud with ±6° of freedom in all directions to adjust for uneven work surfaces or compensate for angular misalignment. The base can be secured to an optical table or breadboard using a clamping fork, such as the CF125 or CF175, as shown in the photo to the right. Securing the base in place with a clamping fork will lock the articulated joint in position.

A Ø1" tapered locking nut is included for components requiring a larger support surface and provides 0.375" of vertical height adjustment. The tapered design prevents the locking nut from contacting a clamping fork when being secured in place. Additionally, torque holes that accept a 5/64" hex key are included in the lock nut and mounting stud to aid in securing a mounted component at a specific height. A 1/8" (3 mm) hex socket is also included on the bottom of the mounting base to actuate the threaded mounting stud.

Click to Enlarge

An FW102C Motorized Filter Wheel is mounted on a PB4 Base, which is secured to the table with a CL8 Table Clamp.

Click to Enlarge

The PB4R(/M) has a 3/16" (5 mm) hex socket and four magnets in the base.

- Mount 1/4"-20 (M6) Tapped Components in an Arbitrary Position 0.24" (6.1 mm) Above the Breadboard

- PF85B, PF125B, or PF175B Clamping Fork or CL8 Table Clamp Secures Base to a Breadboard or Table

- Hex Socket on Bottom for Tightening

- Machined Bottom Relief Cut for Added Stability

The PB4(/M) and PB4R(/M) Ø1.85" (47.0 mm) Studded Bases allow 1/4"-20 (M6) tapped optomechanical components to be mounted in an arbitrary position 0.24" (6.1 mm) above the breadboard. These Ø1.85" (Ø47.0 mm) bases have 0.26" (6.6 mm) long, 1/4"-20 (M6) studs on the top. The PB4(/M) adapter has a 1/8" (3 mm) hex socket on the bottom for tightening while the PB4R(/M) adapter has a 3/16" (5 mm) hex socket as well as four high strength magnets in the base that are sufficiently strong to securely hold the base in place without clamping to an optical table.

To secure the bases, a PF85B, PF125B, or PF175B clamping fork or a CL8 table clamp (shown in the photo to the right) can be used. However, using these items will restrict the width of the component being mounted to a maximum of 1.5".

Products Home

Products Home

Zoom

Zoom

Mechanical Components Bases

Mechanical Components Bases