Quick-Release Cage Plates for 60 mm Cage System

- Release Mechanisms: Magnetic or Spring Loaded

- SM2-Threaded Mounts for Ø2" Optics

- Insert or Remove from Assembled Cage Systems

LCP44F

Application Idea

The LCP44F cage plate consists of magnetically coupled front and back plates that allow optics to be easily removed and reinserted.

LCP360R

QRCA2

Please Wait

| Alternative Size Options |

|---|

| 16 mm Quick-Release Cage Mounts |

| 30 mm Quick-Release Cage Mounts |

| 60 mm Quick-Release Cage Mounts |

Features

- Compatible with 60 mm Cage Systems

- Easily Insert or Remove Components from a Cage System Without Disassembling the Structure

- Accepts Ø2" (50.8 mm) Optics

- SM2 (2.035"-40) Internal Thread Directly Compatible with Our SM2-Series Components

The LCP44F has a removable mounting carriage that magnetically couples to the back plate of the mount, which is not removable from the cage structure. The advantage to this mount is that the mounting carriage with the component mounted in it can be removed and reinserted into the cage system with a high degree of repeatability.

The QRC2A uses a spring-loaded dovetail clamping mechanism that allows the cage plate to be easily inserted or removed from a closed cage system. The primary advantage of this mount is that it can be removed from the cage system and reinserted into the cage system on the other side of a component that is fixed in the cage structure.

The LCP360R offers a snap-in design with a pivoting optic holder, which together permit the entire mount to be secured and removed without disassembling the cage system. Since the optic holder can pivot, it is possible to orient optics at any angle with respect to the cage axis.

Cage System Compatibility: Thorlabs offers 16 mm, 30 mm, and 60 mm cage systems designed for Ø1/2", Ø1", and Ø2" optical components, respectively. The parts on this page are compatible with our 60 mm cage system and utilize Ø6 mm ER cage rods.

Cage System Overview

The Cage Assembly System provides a convenient way to construct large optomechanical systems with an established line of precision-machined building blocks designed for high flexibility and accurate alignment.

16 mm, 30 mm, and 60 mm Cage System Standards

Thorlabs offers three standards defined by the center-to-center spacing of the cage assembly rods (see Figure 14A). The 16 mm cage, 30 mm cage, and 60 mm cage standards are designed to accommodate Ø1/2", Ø1", and Ø2" optics, respectively. Specialized cage plates that allow smaller optics to be directly inserted into our larger cage systems are also available.

Standard Threads

The flexibility of our Cage Assembly System stems from well-defined mounting and thread standards designed to directly interface with a wide range of specialized products. The three most prevalent thread standards are our SM05 Series (0.535"-40 thread), SM1 Series (1.035"-40 thread), and SM2 Series (2.035"-40 thread), all of which were defined to house the industry's most common optic sizes. Essential building blocks, such as our popular lens tubes, directly interface to these standards.

Figure 14A An example of the standard cage plate measurements determining cage system compatibility.

| Standard Cage System Measurements | |||

|---|---|---|---|

| Cage System | 16 mm | 30 mm | 60 mm |

| Thread Series | SM05 | SM1 | SM2 |

| Rod to Rod Spacing | 16 mm (0.63") | 30 mm (1.18") | 60 mm (2.36") |

| Total Length | 25 mm (0.98") | 41 mm (1.60") | 71.1 mm (2.80") |

| Cage Components | ||

|---|---|---|

| Cage Rods | 16 mm | These rods are used to connect cage plates, optic mounts, and other components in the cage system. The SR Series Cage Rods are compatible with our 16 mm cage systems, while the 30 mm and 60 mm cage systems use ER Series Cage Rods. |

| 30 mm | ||

| 60 mm | ||

| Cage Plates | 16 mm | These serve as the basic building blocks for a cage system. They may have SM-threaded central bores, smooth bores sized for industry standard optics or to accommodate the outer profile of our SM Series Lens Tubes, or specialized bores for other components such as our FiberPorts. |

| 30 mm | ||

| 60 mm | ||

| Optic Mounts | 16 mm | Thorlabs offers fixed, kinematic, rotation, and translation mounts specifically designed for our Cage Systems. |

| 30 mm | ||

| 60 mm | ||

| Cage Cubes | 16 mm | These cubes are useful for housing larger optical components, such as prisms or mirrors, or optics that need to sit at an angle to the beam path, such as beamsplitters. Our cage cubes are available empty or with pre-mounted optics. |

| 30 mm | ||

| 60 mm | ||

| Replacement Setscrews | Replacement setscrews are offered for our 16 mm (SS4B013, SS4B025, and SS4B038) and 30 mm (SS4MS5 and SS4MS4) cage systems products. | |

| Post and Breadboard Mounts and Adapters | Mounting options for cage systems can be found on our Cage System Construction pages. Cage Systems can be mounted either parallel or perpendicular to the table surface. | |

| Size Adapters | Cage System Size Adapters can be used to integrate components from different cage system and threading standards. | |

| Specialized Components | Thorlabs also produces specialized cage components, such as Filter Wheels, a HeNe Laser Mount, and a FiberPort Cage Plate Adapter, allowing a wide range of our products to be integrated into cage-mounted optical systems. Explore our Cage Systems Visual Navigation Guide to see the full range of Thorlabs' cage components. | |

| Posted Comments: | |

mkarakose

(posted 2016-04-25 14:20:54.563) Can you merge QRC2A with SLC60C self centering 60mm cage mount. At present QRC2A accepts only 2" outer threaded components, but if you can merge those two it would accept any component smaller than 2", and it would have quick release property. You can do this for other quick-release components also.

Thank you. besembeson

(posted 2016-04-25 09:42:09.0) Response from Bweh at Thorlabs USA: Thanks for your feedback. We will review this idea. |

Click to Enlarge

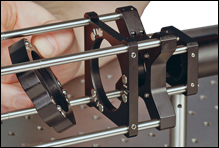

Figure 335A LCP44F Quick-Release Magnetic Plate Shown in 60 mm Cage System

- 60 mm Cage Compatible Back Plate

- Magnetically Coupled Mounting Carriage

- Accepts Ø2" (50.8 mm) Optics Up to 0.325" (8.3 mm) Thick

- Angular Repeatability Better Than 1 µrad

- Lateral Repeatability Better Than 10 µm in X, Y, and Z

- Back Plate and Mounting Carriage Have Internal SM2 Threading

- One SM2RR Retaining Ring Included

The LCP44F consists of a back plate compatible with the 60 mm cage system and a mounting carriage (front plate) that is magnetically coupled with pairs of rare earth magnets to the back plate. For stability, precision, and repeatability, the mounting carriage contacts the back plate at three points. Each point of contact is a ball bearing on the mounting carriage resting in the groove formed by two parallel steel pins. Since the axes defined by the three sets of pins share a common point of intersection, the system is properly constrained (kinematic). The mounting carriage can be easily inserted or removed from the fully assembled cage system by separating it from the back plate, rotating it sideways, and then extracting it from the cage.

The internal SM2 threading allows components up to 0.325" (8.3 mm) thick to be secured in the mounting carriage with the included SM2RR retaining ring. Components with external SM2 threading (OD = 2.2" (55.9 mm)) cannot extend more than 1" (25.4 mm) beyond the face of the mounting carriage without sacrificing the ability to remove the mounting carriage and component from a closed cage system. The lateral repeatability specification (10 µm) indicates that the X, Y, and Z position of the mount will not vary by more than 10 µm after being removed and replaced, while the 1 µrad angular repeatability refers to the rotation of the optic not changing by more than 1 µrad.

Both the LCP44F and LCP44F-B have four cage rod through holes that are each accompanied by a side-located locking M4 setscrew, which can be secured using a 2.0 mm hex key (such as Item # 564HK).

- Compatible with 60 mm Cage Systems

- Internal SM2 Threading

- Dovetail Design Provides Smooth Release and Clamping Action

- One-Handed Operation for Removal and Repositioning of an Optic

- Accepts Ø2" (Ø50.8 mm) Optics Up to 0.15" (3.8 mm) Thick

- One SM2RR Retaining Ring Included

The QRC2A cage mount is equipped with a spring-loaded dovetail clamp that secures or releases the cage mount to two of the four ER rods in the cage structure. The cage plate has internal SM2 threading that allows for components up to 0.15" (3.8 mm) thick to be secured with the included SM2RR retaining ring. In addition, components up to 1" (25.4 mm) thick [not including length of threaded stub, OD = 2.2" (55.9 mm)] with external SM1 threading can be attached without sacrificing the ability to remove the cage plate from a closed cage system.

- Quick-Release Cage Mount with Adjustable SM2-Threaded (2.035"-40) Optic Cell

- Compatible with Ø2" and Ø50 mm Mounted and Unmounted Optics Up to

8 mm Thick - On- and Off-Axis Alignment for use with Mirrors, Beamsplitters, Filters, and Lenses

- Quick-Release Flexure Clamping Mechanism for Secure Cage Mounting without Requiring Disassembly

- One SM2RR Retaining Ring Included

The LCP360R cage mount allows for 360° of manual rotation of an optic within a 60 mm cage system. Optics up to 8 mm thick can be mounted against a lip at the end of the 11.3 mm (0.45") long SM2-threaded (2.035"-40) optic cell using an included SM2RR retaining ring. The LCP360R mount uses a flexure-style clamp with two 3-48 cap screws (5/64" [2.0 mm] hex) to quickly connect the mount without disassembling the cage. Simply turn the optic perpendicular to the cage system's optical axis and loosen the setscrews enough to allow the flexure mechanism to snap onto the cage rods, as shown in Video G3.1. The LCP360R mount can be attached at any two of the four cage rods for either X- or Y-axis pivoting adjustment. The cage mount can be slid along the cage rods by loosening the setscrews in the flexure clamps.

The optic can be rotated via the knurled knob or via a 5 mm (3/16") hex key, and the optic mount's pivot position can then be locked via a 8-32 (5/64" [2.0 mm] hex) setscrew. An engraved scale indicates the angle of the optic, with tick marks every 5°. Please note that when using with beamsplitters, the clear aperture will be an ellipse with a minor axis of approximately 1" (25.4 mm) when used at a 45° AOI.

Products Home

Products Home

Zoom

Zoom

60 mm Quick Release Cage Plates

60 mm Quick Release Cage Plates