C-Mount Extension Tube Adapters and Accessories

- Couple C-Mount Extension Tube Systems

- Seal Light Path in Optical Systems

SC1L24

Slip-On Cover,

24" Long

SM1CPL

Flexure Sleeve Coupler,

3" Long

SM1B3

Bellows,

1.50" - 8.66" Long

CMCP2

C-Mount Cap

CMT10

C-Mount Coupler,

1" Long

Please Wait

Features

- Couplers, Caps, and Covers for C-Mount Extension Tubes

- Create Light-Tight Enclosures Between Extension Tubes

Thorlabs offers couplers, caps, and tube covers compatible with our C-Mount CMOS cameras, camera lenses, and extension tubes. These can be used to maintain a light-tight optical path in systems that use our C-Mount extension tubes.

The SC600 and SC1800RL Aluminum Lens Tube Covers can be easily cut to custom lengths using our SC1K Tool Kit, pictured below. This kit contains a tubing cutter and de-burring tool, jig, and pliers, allowing the user to cut the aluminum covers and then crimp the edges to form a light press fit. These lens tube covers, sold at the bottom of this page, can be cut to a desired length up to 1828.8 mm (for the unanodized aluminum version) or 609.6 mm (for the anodized aluminum version).

To Cut the Aluminum Cover Tubing:

Click to Enlarge

Step 1: Rotate the knob on the tubing cutter counterclockwise to open the cutter far enough to insert the tubing between the rollers and the blade.

Click to Enlarge

Step 2: Slide the tubing into the tubing cutter between the rollers and the circular blade. Position the blade along the tubing such that a cut will produce the desired length of tubing.

Click to Enlarge

Step 3: Rotate the knob on the tubing cutter clockwise until it begins to lightly cut into the tubing. Although you want the blade to be in good contact with the tubing, do not overtighten the cutter, as that may cause tube cover deformation.

Click to Enlarge

Step 4: Slowly rotate the tubing cutter to score the tubing, rotating the tool, blade first. Take care that the cutter completes its rotation where it began, making a closed ring around the tubing rather than a spiral that will fail to cut the tubing. Continue to carefully rotate the cutter around the tube until the blade has cut all the way through the thickness of the tubing. With each rotation, tighten the knob on the top of the cutter so that the blade remains in good contact with the tubing but avoid over tightening. Note that the knob will only need to be tightened about a half of a turn from its initial scoring position to cut through the tubing.

Click to Enlarge

Step 5: After the tubing is cut through, pull the deburring tool out of the body of the tubing cutter to deburr the cut edges.

Click to Enlarge

Step 6: Lightly press the flat edge of the deburring tool against the inside of the cut edge of the tubing. Maintaining pressure, rotate the tool around the inner edge of the tubing to remove any rough spots created by the cutting process.

To Crimp the Ends of the Aluminum Cover Tubing:

Click to Enlarge

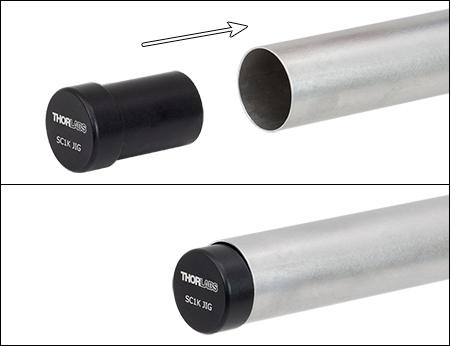

Step 1: Insert the jig into the end of the tubing so that the engraving faces outward. The lip of the jig should be pushed up against the dust cover tubing.

Click to Enlarge

Step 2: Using the soft jaw pliers supplied in the kit, squeeze the dust cover so that the two sides of the tubing make contact with the jig. The force applied by the pliers should be over the jig to ensure that the tubing is not deformed.

Click to Enlarge

Step 3: The end of the lens tube cover tubing is now crimped and will have a light press fit with all Thorlabs SM1 series lens tubes.

| Posted Comments: | |

| No Comments Posted |

The CMT1 is an internally C-Mount-threaded coupler for joining two externally threaded C-Mount (1.00"-32) components. Its length of 0.35" is designed for direct mating of two C-Mount Extension Tubes.

The CMT2 and CMT10 externally threaded couplers are designed for joining internally C-Mount-threaded components. These feature external threads along the entire length of the part, allowing the relative position and rotation of a camera and lens to be adjusted. Each coupler ships with two CMNT Locking Rings, which can be tightened by hand to secure the attached components. Additional locking rings can be purchased separately to limit the external thread depth of any C-Mount-threaded components. The use of multiple locking rings allows lens tubes to be locked independently, such as when using crossed polarizers (see the video above).

For applications where it is difficult to reach the locking ring by hand, we offer the CMNT1 Slotted Locking Ring and SPW502 Spanner Wrench. This locking ring contains slots for the 1¼" end of the spanner wrench.

The table below gives the specifications for all available couplers and locking rings.

- Internally or Externally C-Mount-Threaded (1.00"-32) Caps

- Black-Anodized Aluminum Construction

- Compatible with C-Mount Extension Tubes, Cameras, and Camera Lenses

These C-Mount Caps are designed to be used with our CMOS cameras, camera lenses, and other C-Mount-threaded (1.00" -32) components. The CMCP1 features internal C-Mount threading while the CMCP2 features external C-Mount threading. Each of these caps is made from black-anodized aluminum and has a knurled edge for secure hand tightening.

To use one of these caps with a C-Mount-threaded CMOS camera, please choose the externally threaded CMCP2 cap.

Click to Enlarge

Back View of CMEC2 Snap-On End Cap

- Plastic Snap-On C-Mount-Threaded (1.00"-32) Dust Cap

- Compatible with C-Mount Extension Tubes and Cameras

- Sold in Packs of Five

The CMEC2 plastic dust cap snaps onto internally C-Mount-threaded (1.00"-32) components, such as our CMOS cameras and C-mount extension tubes. By sealing off the end of C-Mount camera accessory or lens tube, this cap helps to protect optics against dust and debris while not in active use. The CMEC2 cap has an outer diameter of 30.5 mm (1.2").

The lens cap can be placed on an internally C-mount threaded component by squeezing the protruding edge of the cap, inserting the back of the cap into the threads, and then releasing the cap. To avoid deforming the cap, be sure to squeeze the protruding edge when removing it. Avoid using these caps in high heat environments as the cap can deform; use at temperatures between 0 °C to 40 °C for best results.

Click to Enlarge

Secure lens tube connections with hose clamps for long-term stability.

Click for Details

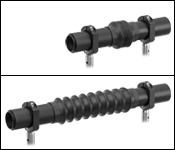

The SM1B3 bellows contracts and expands from 1.50" to 8.66" long.

- Light-Tight Rubber Bellows with Slip Cover Design

- SM1B3: Fits Over Ø1" Lens Tubes, C-Mount Extension Tubes, or Other 1.2" Outer Diameter Objects

- Adjustable in Length from 1.50" to 8.66" (38.0 - 220.0 mm)

- SM2B45: Fits Over Ø2" Lens Tubes or Other 2.2" Outer Diameter Objects

- Adjustable in Length from 1.26" to 4.92" (32.0 - 125.0 mm)

The SM1B3 and SM2B45 nitrile rubber bellows are designed to seal the gap between Ø1" and Ø2" lens tubes, respectively, and maintain a light-tight path. The SM1B3 features a 1.06" inner diameter that stretches over Ø1" lens tubes with either internal or external threads, and is adjustable in length from 1.50" to 8.66". The SM2B45 features a 2.05" inner diameter that stretches over Ø2" lens tubes with either internal or external threads, and is adjustable in length from 1.26" to 4.92". The stiff rubber construction ensures that the bellows do not reduce the clear aperture of the lens tube system while being compressed or stretched. These bellows can be used in temperatures from -30 to 100 °C.

Note: While soap and water is recommended to clean the SM1B3 and SM2B45, isopropyl alcohol may be used in moderate amounts as a cleaning agent. Acetone is not recommended, as it will cause damage to the nitrile rubber.

Click to Enlarge

SM1CPL Holding Two Ø1" Lens Tubes. A rubber gasket makes the coupler light tight.

Click to Enlarge

Lens Tubes Are Secured by Tightening Two 5/64" Hex Screws

- Flexure Coupler Holds Ø1" Lens Tubes, C-Mount Extension Tubes, or Other Ø1.2" Outer Diameter Cylindrical Objects

- Available in Three Lengths: 0.5", 1.0", and 3.0"

- RTV103 Black Silicone Gasket Provides Light-Tight Coupling

- Lens Tubes can be Positioned Along the Entire Length, Facing Either Direction

- 1.46" Outer Diameter

These Lens Tube Couplers are flexure-clamping sleeves that can hold any Ø1" lens tube, C-Mount extension tube, or other Ø1.2" outer diameter cylindrical object. A lens tube can be slid into each end of the coupler and secured by tightening the two 5/64" (2 mm) hex screws on the side of the sleeve.

Each coupler features a black silicone gasket along the clamping section to provide light-tight coupling of lens tubes (see photos to the right). Lens tubes can be clamped with either internal or external threads facing out and at any position along the length of the coupler as long as there are at least 6 mm of the tube inside the clamp.

Click to Enlarge

SC1L24 Tube Cover Spanning the Gap Between a Camera and Turning Mirror

- 24" Long Plastic Cover for C-Mount Extension Tubes

- Easy to Slip On and Off

The SC1L24 lens tube cover is designed to fit over our C-Mount extension tubes or SM1 (Ø1") lens tubes. They can be used to span the gap between any two fixed lens tubes, thereby enclosing the light path in an optical setup. These plastic covers are easy to slip on and off and are sold in 24" lengths, which can be easily cut to the desired length by the end user.

Please note that these lens tube covers are not light tight. Additionally, their plastic construction makes them unsuitable for high-power laser applications.

Click to Enlarge

SC600 Lens Tube Cover with SM1 Lens Tube Mounted in C127TC Clamp

- Non-Flammable Lens Tube Covers

- Raw Tubing Available in 6' (1828.8 mm) Length

- Anodized Tubing Available in 2' (609.6 mm) Length

- Fit Over Ø1" Lens Tubes, C-Mount Extension Tubes, or Other 1.2" Outer Diameter Objects

- Aluminum Dust Cover Kit Contains Tools for Cutting and Crimping Aluminum Lens Tube Covers

- 1.27" Outer Diameter

The SC600 and SC1800RL Aluminum Lens Tube Covers are designed to fit over SM1 (Ø1") lens tubes and are made from anodized and unanodized aluminum, respectively. These non-flammable covers can be easily cut to custom lengths using our SC1K Tool Kit. This kit contains a tubing cutter and de-burring tool, jig, and pliers, allowing the user to cut the aluminum covers and then crimp the edges to form a light press fit. For instructions on how to use these tools to cut and crimp the tubing to the desired length, please see the Cutting Tutorial tab at the top of the page.

These tube covers can be post-mounted using our C127RC(/M) Slip Ring or C127TC Tube Clamp. It is also possible to mount these to 30 mm cage components with 4-40 mounting taps using our C128CC Adapter Clamp (each sold below).

Products Home

Products Home

Zoom

Zoom

C-Mount Tube Accessories

C-Mount Tube Accessories