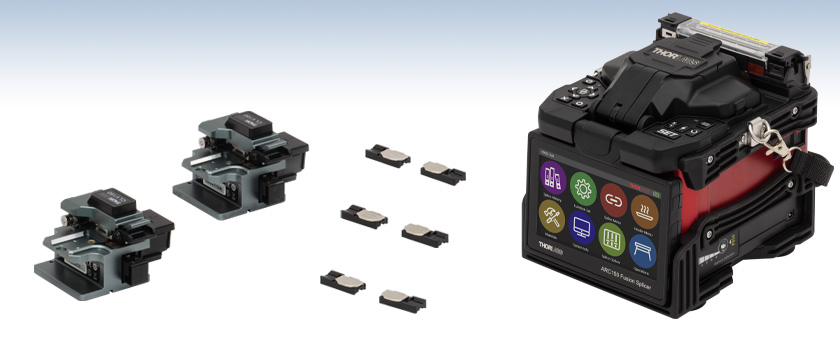

Portable Arc Fusion Splicer

- Splice Optical Fibers with Cladding Diameters Up to 150 µm

- Automated Fiber Inspection, Alignment, & Splicing

- Manual Cleavers and Transfer Clips Included

ARC150

Arc Fusion Splicer

with Cleavers & Clips

Cleaver for Fiber with

Ø80 µm Cladding

Cleaver for Fiber with

Ø125 µm Cladding

FHC165

Clips for 160 µm Buffered Fiber

FHC250

Clips for 250 µm Buffered Fiber

FHC900

Clips for 900 µm Buffered Fiber

Please Wait

Features

- Splice Standard Silica Optical Fibers with Cladding Diameters up to 150 µm

- Arc Fusion Ideal for Telecom and Datacom Applications

- Store Custom Splicing and Heating Profiles; Splice Results Storage

- Portable Splicing with Removable Battery, Shoulder Strap, and Carrying Case

- Automated Cleaved Fiber Inspection, Alignment, and Splicing

- Kit Includes Cleavers and Transfer Clip Sets for Fiber with Ø80 µm and Ø125 µm Cladding

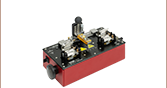

- Integrated Heater for Splice Protector Sleeve

- Compact: 164.4 mm x 155.7 mm x 144.4 mm (L x H x W)

Thorlabs' ARC150 Portable Arc Fusion Splicer Kit offers arc fusion splicing, manual scribe-and-bend cleavers, and simple operation in a portable package. This kit is ideal for basic splicing of common fibers as well as telecom and datacom applications in the field.

Manual Cleavers

Two manual cleavers are included and provide simple operation with a sliding blade for scribe-and-bend operation. The blade housing auto-returns when the cleaver cover is opened, and the circular blade can be rotated to expose new, unused cutting sections for a lifetime of 48k cleaves. A detachable waste bin is included to collect fiber waste. The fiber can be set onto the handheld transfer clip, or a set of pins can be installed onto which the transfer clip can be lowered so the fiber can be placed directly in the cleaver. The clip with the cleaved fiber can then be moved to the splicer.

Transfer Clips

Three sets of transfer clips are included for fiber with Ø80 µm cladding and Ø160 µm buffer/coating or fiber with Ø125 µm cladding and Ø250 µm or Ø900 µm buffer/coating. Each clip magnetically holds the fiber in place for cleaving and is then used to securely transfer the cleaved fiber to the splicer while retaining the proper amount of protruding fiber. Replacement clips are also available below.

Arc Fusion Splicer

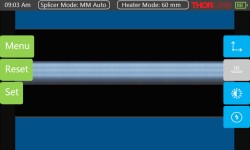

The arc splicer features automated fiber inspection, alignment, and splicing and is designed to fusion splice fibers with claddings from Ø80 to Ø125 µm. The touchscreen and button controls on the housing provide access to splicing modes, heating modes, results storage, and automated calibration procedures. Imaging is provided by two cameras with LED lighting for X and Y viewing, providing 500X magnification on the 5" swiveling LCD touchscreen. A pivoting cover protects the splicing components from wind, and a built-in heater behind the splicing electrodes allows for application of heat shrink onto the spliced fiber. Replacement electrodes are also available below.

Presets and Results Storage

The splicer includes 41 pre-configured splice modes; up to 100 modes can be saved. Each splice mode includes parameters for relative arc power and duration during the cleaning and splicing stages. Five heater presets covering temperature and duration for the application of heat-shrink sleeves are also included, with a capacity for up to 50 saved modes. Splice results can also be stored on the device, with storage for 20k records with up to 200 images.

| ARC150 Arc Fusion Splicer | |

|---|---|

| Applicable Fibers | SM (ITU-T G.652 & G.657), MM (ITU-T G.651), DS (ITU-T G.653), NZDS (ITU-T G.655) |

| Compatible Fiber Cladding | 80 - 150 µm |

| Coating Diameter | 0.125 - 1 mm |

| Fusion Method | Arc Fusion |

| Cleaved Length | 8 - 16 mm |

| Splicing Modes | 41 Presets with Storage for up to 100 Modes |

| Typical Splice Loss | SM: 0.02 dB; MM: 0.01 dB; DS: 0.04 dB; NZDS: 0.04 dB (Measured According to ITU-T Cutting Standard) |

| Return Loss | ≥60 dB |

| Illumination | 3 LED Lights |

| Splicing Time | SM Fast Mode: 6 - 9 seconds |

| Splice Loss Estimation | Via Fiber Imaging |

| Splicing Length | 20 - 60 mm |

| Sleeve Heater Modes | 5 Presets for 20 mm, 30 mm, 40 mm, 50 mm, and 60 mm Long Heat Shrink Tubing; Up to 50 Heating Modes Can Be Stored |

| Sleeve Heater Time | 20 - 900 seconds; Typical Heating Time is 30 seconds |

| Result Storage | 20000 Records with 200 Images |

| Pull Test | 1.5 - 2.0 N |

| Display | 5" Color Display with Touch Screen, 800 x 480 Pixel Resolution |

| Imaging | Perpendicular and Bi-Directional Views |

| Fiber View & Magnification | X, Y, X/Y, 500X |

| Automatic Calibration | Automatic Arc Calibration by Air Pressure and Temperature |

| No. of Cycles per Charge | >250 Splice and Heat Cycles (Typ.) |

| Electrode Life | 3000 Discharges |

| Data Connection (Service Only) | Mini USB 2.0 |

| Physical | |

| Size (L x H x W) | 164.4 mm x 155.7 mm x 144.4 mm (Including Rubber Bumper) |

| Weight | Splicer: 2.58 kg (Including Battery and Rubber Bumper) Battery: 0.38 kg; Rubber Bumper: 0.37 kg |

| Power | Universal Input: 100 - 240 VAC; Output: 12 - 15 VDC |

| Battery Capacity | 5200 mAh |

| Environmental | |

| Operating Temperature Range | 10 to 50 °C |

| Operating Altitude Range | From Sea Level to 5000 m |

| Operating Humidity Range | 0 to 95% Non Condensing |

| Storage Temperature Range | Splicer: -40 to 80 °C; Battery: -20 to 30 °C |

| Storage Humidity Range | 0 to 95% Non Condensing |

| Posted Comments: | |

Michele Epis

(posted 2024-01-05 10:11:08.39) Hi,

is the ARC150 suitable for splicing 105/125 fibers which carry 10W of optical power?

Or it is only suitable for telecom applications? jpolaris

(posted 2024-01-08 07:13:00.0) Thank you for contacting Thorlabs. The typical splice losses (measured according to ITU-T cutting standard) are as follows: SM: 0.02 dB; MM: 0.01 dB; DS: 0.04 dB; NZDS: 0.04 dB. In the multimode case of 0.01 dB, this equates to 99.77% efficiency (0.23% loss). This loss is translated into heat depending on the method used to protect the splice, which is a decision left up to the user. We would not be able to confidently evaluate if the heat generated in your application would become an issue in the general case. ARC150 is not strictly limited to telecom applications. |

Components Included

- Portable Splicer with Carry Strap and Two Sets of ARC150EL Electrodes

- Cleaver Marked CLV150 for FHC250 or FHC900 Clips for Ø250 µm or Ø900 µm Buffered Fibers, Respectively

- Cleaver Marked CLV100 for FHC165 Clip for Ø160 µm Buffered Fiber with Ø80 µm Cladding

- FHC165, FHC250, & FHC900 Fiber Clip Sets

- Strip Tool for Ø900 µm Buffer

- Strip Tool for Ø250 µm Coating on Ø125 µm Cladding Fiber

- Metal Heat Shrink Sleeve Tray

- Battery Charger

- Case with Carry Strap, Removable Accessory Shelf, and Keys

- TZ1 Tweezers

- Solvent Bottle

- Cleaning Brush

- Screwdriver

Optional Accessories

- Splice Sleeves

- Replacement Electrodes (Sold Separately Below)

- Additional Fiber Clips (Sold Separately Below)

- Replacement Cleaver Blade (Sold Separately Below)

- Splice Optical Fibers with Cladding Diameters from 80 to 150 µm

- X and Y Imaging with Automated Fiber Inspection & Alignment

- Manual Cleavers with Simple Button Operation and Auto Return

- Transfer Clips for Consistent Cleaved Fiber Positioning

- Carry Straps and Case for Portability

Thorlabs' ARC150 Arc Fusion Splicer Kit uses arc fusion technology to splice optical fibers with cladding diameters from 80 to 150 µm. The splicer features automated fiber alignment, inspection, and splicing with X and Y imaging. An integrated heater enables heat shrink sleeve application to strengthen the splice. Stripping tools, manual fiber cleavers, and transfer clips are included for a variety of fiber sizes (refer to the list to the right for details).

Click to Enlarge

Included Cleaver with Fiber Holding Clip and Stripped Fiber Ready to Cleave

Click to Enlarge

ARC150 Arc Splicer with

Fiber Holding Clips and Cleaved Fiber Ready to Splice

Click to Enlarge

Click to EnlargeSplice Inspection Screen After Splicing SMF-28 Fiber

- Replacement Electrodes for ARC150 Splicer with Typical Lifetime of 3000 Discharges

- Replacement Fiber Clips for ARC150 Splicer (Also Compatible with CLV150 Standalone Cleaver)

- FHC165 Clips Compatible with Ø80 µm Cladding, Ø160 µm Coating/Buffer Fiber

- FHC250 Clips Compatible with Ø125 µm Cladding, Ø250 µm Coating/Buffer Fiber

- FHC900 Clips Compatible with Ø125 µm Cladding, Ø900 µm Coating/Buffer Fiber

- Replacement Blade for Manual Cleavers Included with ARC150 Splicer

The ARC150EL electrode set, FHC series fiber clips, and cleaver blade can be used as replacements or additional pieces with the ARC150 Splicer Kit. The fiber clips and CLVB cleaver blade are also compatible with the CLV150 Standalone Fiber Cleaver; to use the transfer clips, the clip screwed onto the cleaver first needs to be removed.

Products Home

Products Home

Zoom

Zoom

Portable Arc Fusion Splicer

Portable Arc Fusion Splicer