Calibrated Integrating Spheres

- Insensitive to Beam Shape, Input Angle, and Polarization

- NIST- or PTB-Traceable Calibration

S142C

350 - 1100 nm

(Post Not Included)

S144C

800 - 1700 nm

(Post Not Included)

Application Idea

PM100D2 Power Meter Console and S140C Integrating Sphere Shown with Included FC/PC and FC/APC Adapter (Post, Post Holder, and Base Not Included)

S140C

PM100D2

S180C

2.9 - 5.5 µm

(Post Not Included)

S145CL

Ø22 mm Aperture with Baffle 400 - 1100 nm

(Post Not Included)

OVERVIEW

Compatible Power Meters

PM100A: Handheld Power Meter Console with an Analog Needle and Small Digital Display

PM100Dx: Handheld Power and Energy Meter Consoles with Touchscreen Color Display

PM400: Touchscreen Power and Energy Meter Console with Color Display and Multi-Touch

PM5020: Dual-Channel Digital Benchtop Power Meter Console with a Large LCD Display PM100USB: USB Computer Interface for Power Sensors, No Display

See the Console Selection tab for more information on compatible console options. These sensors may also be used with our previous generation PM200 console.

Features

- For Measurements Independent of Beam Shape and Entrance Angle

- Integrating Sphere Design Acts as a Diffuser with Minimal Power Loss

- Ø5 mm, Ø7 mm, Ø12 mm, or Ø22 mm Input Aperture

- Individually Calibrated with NIST- or PTB-Traceable Certificate of Calibration

- Over-Temperature Alert Sensor

- Spheres with Apertures ≤Ø12 mm Include a Removable S120-FC Fiber Adapter (FC/PC and FC/APC)

- Additional Fiber Adapters Available Separately (See Below)

- C-Series Connector Design for Quick Sensor Connection

- Recalibration Services Available

Integrating spheres are designed to provide precise optical power measurements independent of beam shape, entrance angle, and polarization. These photodiode sensors have a faster response time than thermal sensor heads while also offering a high damage threshold. These integrating spheres feature enhanced shielding to avoid electromagnetic interference and an over-temperature alert sensor to warn against damage and measurement errors due to overheating of the sensor.

Our integrating spheres are designed for wavelength ranges from the visible through the NIR. Sensor heads for use between 350 nm and 2500 nm use a single Ø1" or Ø2" sphere made from Zenith® PTFE and feature a black housing to minimize reflected light around the entrance aperture. These sensors use either a silicon photodiode for detection in the 350 nm - 1100 nm range or an InGaAs photodiode for detection in the 800 nm - 1700 nm, 900 nm - 1650 nm, or 1200 nm - 2500 nm wavelength range. The integrating sphere housing has separate or combined (see Specs tab) 8-32 and M4 taps that can be used to mount the sensor on a standard Ø1/2" post (not included).

Click to Enlarge

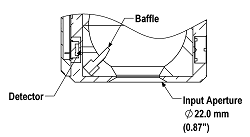

Figure 1.1 A baffle on the S142CL and S145CL spheres blocks light from directly hitting the detector.

The S180C integrating sphere for 2.9 µm - 5.5 µm uses two connected, gold-plated Ø20 mm spheres, with an entrance port in the first sphere and a port for the MCT (HgCdTe) detector located in the second sphere. Compared to single-sphere designs, the two-sphere configuration improves device sensitivity by minimizing the internal sphere surface area while still effectively shielding the detector from direct illumination. This design reduces the effect of input angle, divergence, and beam shape on the measurement result by effectively shielding the photodiode without the use of a baffle or other shielding mechanism. The integrating sphere housing has one universal 8-32 and M4 tap that can be used to mount the sensor on a standard Ø1/2" post (not included).

The integrating spheres with Ø5 mm, Ø7 mm, or Ø12 mm apertures include an adapter with external SM1 (1.035"-40) threads as well as an S120-FC fiber adapter for compatibility with FC/PC- and FC/APC-terminated patch cables, supporting easy integration with both free-space and fiber-coupled setups, as shown in Figure 4.1 in the Mounting Options tab. Additional fiber adapters for other connector types are available separately below. The externally SM1-threaded adapter can be removed using a size 1 screwdriver to place components closer to the window.

The S142CL and S145CL integrating spheres feature a large Ø22 mm input aperture and a baffle within the sphere which prevents direct illumination of the photodiode. The large aperture and baffle enable measurements of large and divergent beams, such as those emitted from LED and VCSEL light sources. The input face of the detectors have four 4-40 threads for mounting 30 mm cage system components. Additionally, insertion of a second or third port in the sensor head is possible on request, please contact Tech Support for details.

Compatibility and Calibration

These integrating spheres have C-Series connectors for compatibility with Thorlabs' line of power meter consoles; compatible consoles are outlined in the Compatible Power Meter Consoles box and details are provided on the Console Selection tab. Each sensor head is individually calibrated and is shipped with NIST- or PTB-traceable calibration data. The included data will match the calibration certification of the photodiode used to test the individual sensor. The calibration data and sensor identification information is stored in the red connector and read out automatically when the sensor is connected to a compatible Thorlabs power meter console.

Thorlabs also offers power sensor heads in a wide range of other formats as well as complete power meters that combine a sensor head and power meter electronics in a compact package. Our complete line of sensor heads, power meter consoles, and complete power meters is available here.

Recalibration Services

Thorlabs offers recalibration services for our integrating sphere power sensors. We recommend recalibrating your Thorlabs sensor and console as a pair; however, each may be recalibrated individually. All of the sensors on this page come with a manufacturer calibration by default, but we also offer an ISO 17025 accredited calibration for some items. For more information on calibration options, please see the Recalibration tab or the calibration sections at the bottom of this page.

SPECS

| Item # | S140C | S142C | S142CL | S144C | S145C | S145CL | S146C | S148C | S180C | |

|---|---|---|---|---|---|---|---|---|---|---|

| Technical Specs | ||||||||||

| Detector Type | Si Photodiode | Si Photodiode w/Baffle |

InGaAs Photodiode | InGaAs Photodiode w/Baffle |

InGaAs Photodiode | Extended InGaAs Photodiode | MCT (HgCdTe) Photodiode |

|||

| Wavelength Range | 350 nm - 1100 nm | 400 nm - 1100 nm | 800 nm - 1700 nm | 900 nm - 1650 nm | 1200 nm - 2500 nm | 2.9 µm - 5.5 µm | ||||

| Optical Power Range | 1 µW - 500 mW | 1 µW - 5 W | 10 µW - 5 W | 1 µW - 500 mW | 1 µW - 3 W | 10 µW - 3 W | 10 µW - 20 W | 1 µW - 1 W | 1 µW - 3 W | |

| Max Average Power Density |

1 kW/cm2 | 2 kW/cm2 | 1 kW/cm2 | 2 kW/cm2 | 1 kW/cm2 | |||||

| Max Pulse Energy Density |

1 J/cm2 | 7 J/cm2 | 1 J/cm2 | 7 J/cm2 | 1 J/cm2 | |||||

| Linearity | ±0.5% | |||||||||

| Resolutiona | 1 nW | 10 nW | 1 nW | 10 nW | 1 nW | 10 nW | ||||

| Measurement Uncertaintyb,c |

±3% (440 - 980 nm) ±5% (350 - 439 nm) ±7% (981 - 1100 nm) |

±3% (440 - 980 nm) ±5% (400 - 439 nm) ±7% (981 - 1100 nm) |

±5% | |||||||

| Responsivityd (Click for Plot) |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

Raw Data |

|

| General Information | ||||||||||

| Typical Application | Low- and Mid-Power Lasers / Fiber Lasers / LEDs |

Low- and Mid-Power Lasers / Fiber Lasers | ||||||||

| Laser Types | Diode, He-Cd, Ti-Sapphire |

Diode, He-Cd, Ti-Sapphire, VCSEL |

Diode, He-Cd, Ti-Sapphire |

Diode, He-Cd, Ti-Sapphire, VCSEL |

Diode, He-Cd, Ti-Sapphire |

QCL, ICL, HeNe, CO, Er:YAG, Co2+:ZnS |

||||

| Integrating Sphere Material (Size) |

Zenith® PTFE (Ø1") |

Zenith® PTFE (Ø2") |

Zenith® PTFE (Ø1") |

Zenith® PTFE (Ø2") |

Zenith® PTFE (Ø1") |

Gold Plating (Two Ø20 mm Spheres) |

||||

| Cooling | Convection | |||||||||

| Head Temperature Measurement |

NTC Thermistor, 4.7 kΩ | |||||||||

| Compatible Consolese | PM100A, PM100D2, PM100D3, PM400, and PM5020 | |||||||||

| Compatibile Interfacese | PM101, PM101A, PM101R, PM101U, PM103, PM103A, PM103E, PM103U, and PM100USB | |||||||||

| Response Time | <1 µs | |||||||||

| Mechanical Specs | ||||||||||

| Housing Dimensions | Ø45 mm x 30.5 mm | 70 mm x 74 mm x 70 mm | Ø45 mm x 30.5 mm | 70 mm x 74 mm x 70 mm | Ø45 mm x 30.5 mm | 59.0 mm x 50.0 mm x 28.5 mm |

||||

| Active Sensor Area | 3.6 mm x 3.6 mm | Ø2 mm | Ø3 mm | Ø1 mm | Ø1 mm | 1 mm x 1 mm | ||||

| Sensor Aperture | Ø5 mm | Ø12 mm | Ø22 mm | Ø5 mm | Ø12 mm | Ø22 mm | Ø12 mm | Ø5 mm | Ø7 mm | |

| Cable Length | 1.5 m | |||||||||

| Connector | Male 9-Pin D-Sub | |||||||||

| Weight | 0.2 kg | 0.6 kg | 0.2 kg | 0.6 kg | 0.2 kg | 0.25 kg | ||||

| Mounting and Accessories | ||||||||||

| Mounting Thread | Separate 8-32 and M4 Taps, Posts Not Included | Universal 8-32 / M4 Thread, Post Not Included | Separate 8-32 and M4 Taps, Posts Not Included | Universal 8-32 / M4 Thread, Post Not Included | Separate 8-32 and M4 Taps, Posts Not Included | Universal |

||||

| Aperture Thread | Included Adapter with SM1 (1.035"-40) External Thread | None | Included Adapter with SM1 (1.035"-40) External Thread | None | Included Adapter with SM1 (1.035"-40) External Thread | |||||

| Fiber Adapters (Optional) | FC (Included), SMA, ST®f, LC, SC, Ø2.5 mm Ferrule, Bare Fiber | None | FC (Included), SMA, ST®f, LC, SC, Ø2.5 mm Ferrule, Bare Fiber | None | FC (Included), SMA, ST®f, LC, SC, Ø2.5 mm Ferrule, Bare Fiber | |||||

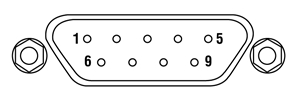

PIN DIAGRAMS

Sensor Connector

D-Type Male

| Pin | Connection |

|---|---|

| 1 | Not Used |

| 2 | EEPROM Digital I/O |

| 3 | Photodiode Anode and NTC Ground |

| 4 | Photodiode Cathode |

| 5 | Not Used |

| 6 | EEPROM Ground |

| 7 | NTC |

| 8 | Not Used |

| 9 | Not Used |

MOUNTING OPTIONS

Integrating Sphere Photodiode Sensor Mounting Options

Click to Expand

Figure 4.2 S140C and S140-BFA Fiber Adapter

Click to Expand

Figure 4.1 S140C and S120-FC Fiber Adapter

Thorlabs' Integrating Sphere Photodiode Sensors provide a low-loss cavity for diverging, non-uniform, or off-axis beam measurements. These integrating spheres are ideal for all fiber-based applications due to the beam divergence at the end of the fiber.

Shown in Figure 4.1 is an S140C Integrating Sphere with an S120-FC Fiber Adapter and shown in Figure 4.2 is an S140C with an S140-BFA Bare Fiber Adapter. The bare fiber adapter features a mounting clamp and light shield to decrease interference from ambient light.

CONSOLE SELECTION

Thorlabs offers a wide selection of power and energy meter consoles and interfaces for operating our power and energy sensors. Key specifications of all of our power meter consoles and interfaces are presented in this tab to help you decide which device is best for your application. We also offer self-contained wireless power meters and compact USB power meters.

When used with our C-series sensors, Thorlabs' power meter consoles and interfaces recognize the type of connected sensor and measure the current or voltage as appropriate. Our C-series sensors have responsivity calibration data stored in their connectors. The console will read out the responsivity value for the user-entered wavelength and calculate a power or energy reading.

- Photodiode sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current. The photodiode's responsivity is wavelength dependent, so the correct wavelength must be entered into the console for an accurate power reading. The console reads out the responsivity for this wavelength from the connected sensor and calculates the optical power from the measured photocurrent.

- Thermal sensors deliver a voltage proportional to the input optical power. Based on the measured sensor output voltage and the sensor's responsivity, the console will calculate the incident optical power.

- Thermal position and energy sensors incorporate four thermopiles arranged as quadrants of a square. By comparing the voltage output from each quadrant, the unit calculates the beam's position.

- Energy sensors are based on the pyroelectric effect. They deliver a voltage peak proportional to the pulse energy. If an energy sensor is recognized, the console will use a peak voltage detector, and the pulse energy will be calculated from the sensor's responsivity.

The consoles and interfaces are also capable of providing a readout of the current or voltage delivered by the sensor. Select models also feature an analog output.

Consoles

| Item # | PM100A | PM100D2 | PM100D3 | PM400 | PM5020 |

|---|---|---|---|---|---|

| (Click Photo to Enlarge) |  |

|

|

|

|

| Sensor Compatibility (Sensors Not Included) | |||||

| Photodiode Power |  |

|

|

|

|

| Thermal Power |  |

|

|

|

|

| Thermal Position & Power | - | - |  |

|

|

| Pyroelectric Energy | - |  |

|

a a |

|

| Key Features | |||||

| Housing Dimensions (H x W x D) |

7.24" x 4.29" x 1.61" (184 mm x 109 mm x 41 mm) |

6.42" x 3.87" x 1.38" (163.0 mm x 98.4 mm x 35.0 mm) |

5.35" x 3.78" x 1.16" (136.0 mm x 96.0 mm x 29.5 mm) |

9.97" x 4.35" x 11.56" (253.2 mm x 110.6 mm x 293.6 mm) |

|

| Channels | 1 | 2 | |||

| External Temperature Sensor Input (Sensor Not Included) | - | - | Readout and Record Temperature Over Time | ||

| External Humidity Sensor Input (Sensor Not Included) | - | - | Readout and Record Humidity Over Time | ||

| Analog Outputb | Amplified Input Signal, SMA, 0 to 2 V, Up to 100 kHz |

Amplified Input Signal or 12-bit DAC Corrected Input Signal, SMA, 0 to 2.5 V, Up to 100 kHz |

Amplified Input Signal, 12-bit DAC Corrected Input Signal, or 14-bit DAC Corrected X-Y Position Signal, SMA, 0 to 2.5 V (Power); -2.0 to 2.0 V (Position), Up to 100 kHz |

Amplified Input Signal or DAC Corrected Input Signal, 2p Audio 3.5 mm (Adapter to BNC included), 0 to 2 V, Up to 100 kHz |

Amplified Input Signal or DAC Corrected Input Signal, 2 x BNC, -2.5 to 10 V, Up to 250 kHz. Programmable AOc, 4 x BNC, -5 to 10 V, Up to 1 kHz |

| Input/Output Ports | - | 26-Pin AUX Connector With 4 GPIO, AN OUT for Power (Analog Input Signal and 12-bit DAC) and Position Sensor (14-bit DAC), I2C, UART, and Analog and Digital Supply Voltages | 14-Pin AUX Connector With 4 GPIO, Programmable, 2 x 10 bit ADC for External Temperature, Relative Humidity Sensor, +3.3 V, ±2.5 V (100 mA Max) |

10-Pin PCB Connector, 4 Configurable Digital I/O Channels, 1 Trigger In/Out, I2C (LVTTL / TTL) |

|

| Shutter Control | - | - | - | - | Support for SH05R(/M) or SH1(/M) Optical Shutter with Interlock Input |

| Fan Control | - | - | - | - | |

| Source Spectral Correction | - | ||||

| Attenuation Correction | - | ||||

| External Trigger Input | - | - | - | ||

| Display | |||||

| Type | Mechanical Needle and LCD Display with Digital Readout | 3.5" Full Color Touchscreen Display, 640 x 480 Pixels | 4.3" Protected Capacitive Touchscreen with Color Display, 400 x 272 Pixels | 5" IPS Touchscreen LCD Display, 854 x 480 Pixels | |

| Dimensions | Digital: 1.9" x 0.5" (48.2 mm x 13.2 mm) Analog: 3.54" x 1.65" (90.0 mm x 42.0 mm) |

2.80" x 2.10" (71.0 mm x 53.3 mm) |

3.7" x 2.1" (95 mm x 54 mm) |

4.32" x 2.43" (109.7 mm x 61.6 mm) |

|

| Refresh Rate | 20 Hz | 50 Hz | 10 Hz (Numerical) 25 Hz (Analog Simulation) |

25 Hz | |

| Measurement Viewsd | |||||

| Numerical | |||||

| Mechanical Analog Needle | - | - | - | - | |

| Simulated Analog Needle | - | ||||

| Bar Graph | - | ||||

| Trend Graph | - | ||||

| Statistics | |||||

| Pass/Fail | - | - | - | - | |

| Scope | - | - | - | ||

| Memory | |||||

| Type | - | eMMC Flash | NAND Flash | SD Card | |

| Size | - | 8 GB | 4 GB | 8 GB | |

| Power | |||||

| Battery | LiPo 3.7 V 2300 mAh | LiPo 3.7 V 2300 mAh | LiPo 3.7 V 2300 mAh | - | |

| External | 5 VDC via USB or Included AC Adapter | 5 VDC via USB-C Connector | 5 VDC via USB Mini B Connector | Line Voltage: 100 - 240 V | |

Interfaces

| Item # | PM101 | PM102 | PM103 | PM101A | PM102A | PM103A |

|---|---|---|---|---|---|---|

| (Click Photo to Enlarge) |  |

|

|

|

|

|

| Operation Protocol | USB, RS232, UART, and Analog |

USB and Analog SMA | ||||

| Sensor Compatibility | ||||||

| Photodiode |  |

- |  |

|

- |  |

| Thermal Power |  |

|

- |  |

|

- |

| Thermal Position & Power | - |  |

- | - |  |

- |

| Pyroelectric | - | - |  |

- | - |  |

| Item # | PM103E | PM101R | PM101U | PM102U | PM103U | PM100USB | |

|---|---|---|---|---|---|---|---|

| (Click Photo to Enlarge) |  |

|

|

|

|

|

|

| Operation Protocol | Ethernet, RS232, and Analog | USB and RS232 |

USB Operation | USB | |||

| Sensor Compatibility | |||||||

| Photodiode |  |

|

- |  |

|

||

| Thermal Power |  |

|

|

- |  |

||

| Thermal Position & Power | - | - |  |

- | - | ||

| Pyroelectric | - | - | - |  |

a a |

||

INSIGHTS

Insights into Best Lab Practices

Scroll down to read about things to consider when building integrating spheres into setups and analyzing data results.

- Ultraviolet and Blue Fluorescence Emitted by Integrating Spheres

- Sample Substitution Errors

Click here for more insights into lab practices and equipment.

Ultraviolet and Blue Fluorescence Emitted by Integrating Spheres

Click to Enlarge

Figure 182A Typical yields at each wavelength are around four orders of magnitude lower than the excitation wavelength. [4]

The spectral fluorescence yield relates the intensity of the fluorescence emitted within the integrating sphere with the intensity of the excitation wavelength. The yield is calculated by dividing the wavelength-dependent, total fluorescence excited over the entire interior surface of the sphere by the intensity of the light excitation.

Data were kindly provided by Dr. Ping-Shine Shaw, Physics Laboratory, National Institute of Standards and Technology, Gaithersburg, MD 20899, USA.

A material of choice for coating the light-diffusing cavities of integrating spheres is polytetrafluoroethylene (PTFE). This material, which is white in appearance, is favored for reasons including its high, flat reflectance over a wide range of wavelengths (see the Specs tab for details) and chemical inertness.

However, it should be noted that integrating spheres coated with both PTFE and barium sulfate, which is an alternative coating with lower reflectance, emit low levels of ultraviolet (UV) and blue fluorescence when irradiated by UV light. [1-3]

Hydrocarbons in the PTFE Fluoresce

It is not the PTFE that fluoresces. The sources of the UV and blue fluorescence are hydrocarbons in the PTFE. Low levels of hydrocarbon impurities are present in the raw coating material, and pollution sources deposit additional hydrocarbon contaminants in the PTFE material of the integrating sphere during its use and

Fluorescence Wavelength Bands and Strength

Researchers at the National Institute of Standards and Technology (NIST) have investigated the fluorescence excited by illuminating PTFE-coated integrating spheres. The total fluorescence output by the integrating sphere was measured with respect to fluorescence wavelength and excitation wavelength. The maximum fluorescence was approximately four orders of magnitude lower than the intensity of the exciting radiation.

The UV and blue fluorescence from PTFE is primarily excited by incident wavelengths in a 200 nm to 300 nm absorption band. The fluorescence is emitted in the 250 nm to 400 nm wavelength range, as shown by Figure 182A. These data indicate that increasing the excitation wavelength decreases the fluorescence emitted at lower wavelengths and changes the shape of the fluorescence spectrum.

As the levels of hydrocarbon contaminants in the PFTE increase, fluorescence increases. A related effect is a decrease of the light output by the integrating sphere over the absorption band wavelengths, due to more light from this spectral region being absorbed. [1, 3]

Impact on Applications

The UV and blue fluorescence from the PTFE has negligible effect on many applications, since the intensity of the fluorescence is low and primarily excited by incident wavelengths <300 nm. Applications sensitive to this fluorescence include long-term measurements of UV radiation throughput, UV source calibration, establishing UV reflectance standards, and performing some UV remote sensing tasks. [1]

Minimizing Fluorescence Effects

Minimizing and stabilizing the fluorescence levels requires isolating the integrating sphere from all sources of hydrocarbons, including gasoline- and diesel-burning engine exhaust and organic solvents, such as naphthalene and toluene. It should be noted that, while hydrocarbon contamination can be minimized and reduced, it cannot be eliminated. [1]

Since the history of each integrating sphere's exposure to hydrocarbon contaminants is unique, it is not possible to predict the response of a particular sphere to incident radiation. When an application is negatively impacted by the fluorescence, calibration of the integrating sphere is recommended. A calibration procedure described in [4] requires a light source with a well-known spectrum that extends across the wavelength region of interest, such as a deuterium lamp or synchrotron radiation, a monochromator, a detector, and the integrating sphere.

References

[1] Ping-Shine Shaw, Zhigang Li, Uwe Arp, and Keith R. Lykke, "Ultraviolet characterization of integrating spheres," Appl.Opt. 46, 5119-5128 (2007).

[2] Jan Valenta, "Photoluminescence of the integrating sphere walls, its influence on the absolute quantum yield measurements and correction methods," AIP Advances 8, 102123 (2018).

[3] Robert D. Saunders and William R. Ott, "Spectral irradiance measurements: effect of UV-produced fluorescence in integrating spheres," Appl. Opt. 15, 827-828 (1976).

[4] Ping-Shine Shaw, Uwe Arp, and Keith R. Lykke, "Measurement of the ultraviolet-induced fluorescence yield from integrating spheres," Metrologia 46, S191 - S196 (2009).

Date of Last Edit: Dec. 4, 2019

Sample Substitution Errors

Click to Enlarge

Figure 182B Measuring diffuse sample transmittance and reflectance as shown here can result in a distorted sample spectrum due to sample substitution error. The problem is that the reflectivity over the sample area is different during the reference and sample measurements.

Click to Enlarge

Figure 182C This configuration is not susceptible to sample substitution error, since the interior of the sphere is the same for reference and sample measurements. During the reference measurement the light travels along (R), and no light is incident along (S). The opposite is true when a sample measurement is made.

Absolute transmittance and absolute diffuse reflectance spectra of optical samples can be found using integrating spheres. These spectra are found by performing spectral measurements of both the sample of interest and a reference.

Measurement of a reference is needed since this provides the spectrum of the illuminating light source. Obtaining the reference scan allows the spectrum of the light source to be subtracted from the sample measurement.

The light source reference measurement is made with no sample in place for transmittance data and with a highly reflective white standard reference sample in place for reflectance measurements.

Sample substitution errors incurred while acquiring the sample and reference measurement sets can negatively effect the accuracy of the corrected sample spectrum, unless the chosen experimental technique is immune to these errors.

Conditions Leading to Sample Substitution Errors

An integrating sphere's optical performance depends on the reflectance at each point on its entire inner surface. Often, a section of the sphere's inner wall is replaced by the sample when its transmittance and diffuse reflectance spectra are measured (Figure 182B). However, modifying a section of the inner wall alters the performance of the integrating sphere.

Sample substitution errors are a concern when the measurement procedure involves physically changing one sample installed within the sphere for another. For example, when measuring diffuse reflectance (Figure 182B, bottom), a first measurement might be made with the standard reference sample mounted inside the sphere. Next, this sample would be removed and replaced by the sample of interest, and a second measurement would be acquired. Both data sets would then be used to calculate the corrected absolute diffuse reflectance spectrum of the sample.

This procedure would result in a distorted absolute sample spectrum. Since the sample of interest and the standard reference have different absorption and scattering properties, exchanging them alters the reflectivity of the integrating sphere over the samples' surface areas. Due to the average reflectivity of the integrating sphere being different for the two measurements, they are not perfectly compatible.

Solution Option: Install Sample and Reference Together

One experimental technique that avoids sample substitution errors acquires measurement data when both sample and reference are installed inside the integrating sphere at the same time. This approach requires an integrating sphere large enough to accomodate the two, as additional ports.

The light source is located external to the integrating sphere, and measurements of the sample and standard reference are acquired sequentially. The specular reflection from the sample, or the transmitted beam, is often routed out of the sphere, so that only the diffuse light is detected. Since the inner surface of the sphere is identical for both measurements, sample substitution errors are not a concern.

Alternate Solution Option: Make Measurements from Sample and Reference Ports

If it is not possible to install both sample and standard references in the integrating sphere at the same time, it is necessary to exchange the installed sample. If this must be done, sample substitution errors can be removed by following the procedure detailed in [1].

This procedure requires a total of four measurements. When the standard sample is installed, measurements are made from two different ports. One has a field of view that includes the sample and the other does not. The sample of interest is then subsituted in and the measurements are repeated. Performing the calculations described in [1] using these measurements removes the sample substitution errors.

References

[1] Luka Vidovic and Boris Majaron, "Elimination of single-beam substitution error in diffuse reflectance measurements using an integrating sphere," J. Biomed.Opt. 19, 027006 (2014).

Date of Last Edit: Dec. 4, 2019

SENSOR SELECTION

Click to Enlarge

Figure 113A The PM160 wireless power meter, shown here with an iPad mini (not included), can be remotely operated using Apple mobile devices.

This tab outlines the full selection of Thorlabs' power and energy sensors. Refer to Table 113B for power meter console and interface compatibility information.

In addition to the power and energy sensors listed below, Thorlabs also offers all-in-one, wireless, handheld power meters and compact USB power meter interfaces that contain either a photodiode or a thermal sensor, as well as power meter bundles that include a console, sensor head, and post mounting accessories.

Thorlabs offers four types of sensors:

- Photodiode Sensors: These sensors are designed for power measurements of monochromatic or near-monochromatic sources, as they have a wavelength dependent responsivity. These sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current.

- Thermal Sensors: Constructed from material with a relatively flat response function across a wide range of wavelengths, these thermopile sensors are suitable for power measurements of broadband sources such as LEDs and SLDs. Thermal sensors deliver a voltage proportional to the input optical power.

- Thermal Position & Power Sensors: These sensors incorporate four thermopiles arranged as quadrants of a square. By comparing the voltage output from each quadrant, the unit calculates the beam's position.

- Pyroelectric Energy Sensors: Our pyroelectric sensors produce an output voltage through the pyroelectric effect and are suitable for measuring pulsed sources, with a repetition rate limited by the time constant of the detector. These sensors will output a peak voltage proportional to the incident pulse energy.

| Table 113B Console Compatibility | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Console Item # | PM100A | PM100D2 | PM100D3 | PM400 | PM5020 | PM101 Series |

PM102 Series |

PM103 Series |

PM100USB |

| Photodiode Power |  |

|

|

|

|

|

- |  |

|

| Thermal Power |  |

|

|

|

|

|

|

- |  |

| Thermal Position | - | - |  |

|

|

- |  |

- | - |

| Pyroelectric Energy | - |  |

|

a a |

|

- | - |  |

a a |

Power and Energy Sensor Selection Guide

There are two options for comparing the specifications of our Power and Energy Sensors. Tables 113C, 113D, 113E, and 113F sort our sensors by type (e.g., photodiode, thermal, or pyroelectric) and provide key specifications.

Alternatively, the selection guide Figures 113G and 113H arrange our entire selection of photodiode and thermal power sensors by wavelength (Figure 113G) or optical power range (Figure 113H). Each box contains the item # and specified range of the sensor. These graphs allow for easy identification of the sensor heads available for a specific wavelength or power range.

| Table 113C Photodiode Power Sensors |

|---|

| Table 113D Thermal Power Sensors |

|---|

| Table 113E Thermal Position & Power Sensors |

|---|

| Table 113F Pyroelectric Energy Sensors |

|---|

Figure 113G Sensor Options Arranged by Wavelength Range

Figure 113G Sensor Options Arranged by Wavelength Range Figure 113H Sensor Options Arranged by Power Range

Figure 113H Sensor Options Arranged by Power RangeRECALIBRATION

Figure 796A DAkkS-accredited calibrations are performed in accordance with DIN EN ISO/IEC 17025:2018.

Recalibration Services

Thorlabs offers two types of recalibration services in-house for our power and energy meter electronics and photodiode power sensors: ISO 17025 accredited calibrations and manufacturer calibrations. Only the manufacturer calibration is available for the NS170C microscope slide peak power sensor, our thermal power sensors, and our pyroelectric energy sensors. All new products are delivered with a manufacturer calibration by default; if an ISO 17025 accredited calibration is desired for a new device, please contact Tech Sales.

ISO 17025 accredited calibrations are performed in-house in accordance with DIN EN ISO/IEC 17025:2018. Thorlabs GmbH's calibration laboratory is accredited by the German Accreditation Body (DAkkS), the national accreditation authority of the Federal Republic of Germany. The scope of services is described here in English or German. Accredited calibrated power and/or energy meter electronics come with a dedicated certificate of calibration proving the specified accuracy and traceability of calibration data. This certification may be required in certain applications or industries, such as the medical market.

In contrast, our manufacturer calibrations are subject to the quality management requirements of ISO 9001. The certificate of calibration lists the equipment used for the calibration procedure as well as the calibration data acquired. The manufacturer calibration of a power sensor includes recalibration of a single-channel console or interface at no additional cost. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually.

Both types of calibration can be offered for third-party equipment or adjusted for special requirements upon request. Please reach out to Tech Sales for further details.

We recommend recalibrating your Thorlabs sensor and console as a pair; however, each may be recalibrated individually. To ensure accurate measurements, we recommend recalibrating annually. To order one or more sensor recalibrations with a dual-channel console, we offer two options: either 1) fill out the Returns Material Authorization (RMA) form with each console and sensor Item # to be recalibrated and specify either manufacturer calibration or ISO 17025 accredited calibration in the "Further Details" field, or 2) separately add each recalibration service Item # offered below to your cart.

Integrating Sphere Power Sensors

| Item #a,b | Sphere Type |

Detector Type |

Wavelength Range |

Optical Power Range |

Max Average Power Density |

Max Pulse Energy Density |

Resolution | Integrating Sphere Material (Size) |

Input Aperture |

|---|---|---|---|---|---|---|---|---|---|

| S140C | Standard Sphere |

Silicon Photodiode |

350 nm - 1100 nm | 1 µW - 500 mW | 1 kW/cm² | 1 J/cm² | 1 nW | Zenith® PTFE (Ø1") | Ø5 mm |

| S142C | 350 nm - 1100 nm | 1 µW - 5 W | 2 kW/cm² | 7 J/cm² | 1 nW | Zenith® PTFE (Ø2") | Ø12 mm | ||

| S142CL | Large Aperture Sphere with Baffle |

400 nm - 1100 nm | 10 µW - 5 W | 2 kW/cm² | 7 J/cm² | 10 nW | Zenith® PTFE (Ø2") | Ø22 mm | |

| S144C | Standard Sphere |

InGaAs Photodiode |

800 nm - 1700 nm | 1 µW - 500 mW | 1 kW/cm² | 1 J/cm² | 1 nW | Zenith® PTFE (Ø1") | Ø5 mm |

| S145C | 800 nm - 1700 nm | 1 µW - 3 W | 2 kW/cm² | 7 J/cm² | 1 nW | Zenith® PTFE (Ø2") | Ø12 mm | ||

| S145CL | Large Aperture Sphere with Baffle |

800 nm - 1700 nm | 10 µW - 3 W | 2 kW/cm² | 7 J/cm² | 10 nW | Zenith® PTFE (Ø2") | Ø22 mm | |

| S146C | Standard Sphere |

900 nm - 1650 nm | 10 µW - 20 W | 2 kW/cm² | 7 J/cm² | 10 nW | Zenith® PTFE (Ø2") | Ø12 mm | |

| S148C | Extended InGaAs Photodiode |

1200 nm - 2500 nm | 1 µW - 1 W | 1 kW/cm² | 1 J/cm² | 1 nW | Zenith® PTFE (Ø1") | Ø5 mm | |

| S180C | Two Ø20 mm Spheres |

MCT (HgCdTe) Photodiode |

2.9 µm - 5.5 µm | 1 µW - 3 W | 1 kW/cm² | 1 J/cm² | 10 nW | Gold Plating (Two Ø20 mm Spheres) |

Ø7 mm |

Part Number | Description | Price | Availability |

|---|---|---|---|

S140C | Integrating Sphere Photodiode Power Sensor, Si, 350 - 1100 nm, 1 µW - 500 mW | $875.77 | In Stock Overseas |

S142C | Integrating Sphere Photodiode Power Sensor, Si, 350 - 1100 nm, 1 µW - 5 W | $1,215.15 | Today |

S142CL | Customer Inspired! Large Aperture Integrating Sphere Photodiode Power Sensor, Si, 400 - 1100 nm, 10 µW - 5 W | $1,309.68 | Today |

S144C | Integrating Sphere Photodiode Power Sensor, InGaAs, 800 - 1700 nm, 1 µW - 500 mW | $1,028.31 | Today |

S145C | Integrating Sphere Photodiode Power Sensor, InGaAs, 800 - 1700 nm, 1 µW - 3 W | $1,262.18 | Today |

S145CL | Customer Inspired! Large Aperture Integrating Sphere Photodiode Power Sensor, InGaAs, 800 - 1700 nm, 10 µW - 3 W | $1,358.79 | In Stock Overseas |

S146C | Integrating Sphere Photodiode Power Sensor, InGaAs, 900 - 1650 nm, 10 µW - 20 W | $1,262.18 | In Stock Overseas |

S148C | Customer Inspired! Integrating Sphere Photodiode Power Sensor, Extended InGaAs, 1200 - 2500 nm, 1 µW - 1 W | $1,056.27 | In Stock Overseas |

S180C | Integrating Sphere Photodiode Power Sensor, MCT (HgCdTe), 2.9 - 5.5 µm, 1 µW - 3 W | $4,592.40 | Today |

Compatible Fiber Adapters

Part Number | Description | Price | Availability |

|---|---|---|---|

S120-FC2 | FC/PC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads, Narrow Key (2.0 mm) | $49.57 | Today |

S120-FC | Customer Inspired! FC/PC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads, Wide Key (2.2 mm) | $49.57 | Today |

S120-APC2 | FC/APC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads, Narrow Key (2.0 mm) | $38.71 | Today |

S120-APC | Customer Inspired! FC/APC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads, Wide Key (2.2 mm) | $38.71 | Today |

S120-SMA | SMA Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads | $49.57 | In Stock Overseas |

S120-ST | ST/PC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads | $49.57 | Today |

S120-SC | SC/PC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads | $62.28 | Today |

S120-LC | LC/PC Fiber Adapter Cap with Internal SM1 (1.035"-40) Threads | $62.28 | Today |

S120-25 | Customer Inspired! Ø2.5 mm Ferrule Adapter Cap with Internal SM1 (1.035"-40) Threads | $49.57 | Today |

S140-BFA | Bare Fiber Adapter for Calibrated Integrating Sphere Power Sensors | $161.43 | In Stock Overseas |

Manufacturer Recalibration Service for Integrating Sphere Power Sensors

| Table G3.1 Specifications | ||

|---|---|---|

| Calibration Service Item # | Compatible Integrating Spheres |

Other Compatible Photodiode Sensors |

| CAL-PD | S140C, S142C, S142CL | S120C, S121C, S170C, S151C, S150C |

| CAL-IRPD | S144C, S145C, S145CL, S146C | S122C, S154C, S155C |

| CAL-MIRPD | S148C, S180C | - |

Thorlabs offers traceable recalibration services for our photodiode power sensors, including our integrating sphere power sensors. To ensure accurate measurements, we recommend recalibrating the sensors annually. Manufacturer recalibration of a single-channel power and/or energy meter console or interface is included with the manufacturer recalibration of a sensor at no additional cost. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually.

Refer to Table G3.1 for the appropriate calibration service Item # that corresponds to your integrating sphere power sensor.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #, and the Serial # of the item being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." In the Further Details field, please indicate "Manufacturer Calibration" or the desired calibration part number below in order to differentiate from the accredited calibration option. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Select the appropriate sensor calibration Item # below, enter the Part # and Serial # of the sensor that requires recalibration, and then Add to Cart. If you would like a console calibrated with your sensor, repeat this process for Item # CAL-PM1 or CAL-PM2 below, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate the return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

Part Number | Description | Price | Availability |

|---|---|---|---|

CAL-PD | Manufacturer Recalibration Service for Single-Power-Range Silicon Photodiode Power Sensors | $179.20 | Lead Time |

CAL-IRPD | Manufacturer Recalibration Service for Single-Power-Range Germanium or InGaAs Photodiode Power Sensors | $202.10 | Lead Time |

CAL-MIRPD | Manufacturer Recalibration Service for Extended InGaAs or MCT Photodiode Power Sensors | $360.99 | Lead Time |

In-House ISO 17025 Accredited Recalibration Service for Integrating Sphere Power Sensors

| Table G4.1 Specifications | ||

|---|---|---|

| Calibration Service Item # | Compatible Integrating Spheres |

Other Compatible Photodiode Sensors |

| CAL-PDD | S140C, S142C, S142CL | S116C, S120C, S121C, S170C, S150C, S151C, PM16-120, PM16-121, PM16-140 |

| CAL-IRPDD | S144C, S145C, S145CL, S146C | S122C, S154C, S155C, PM16-122, PM16-144 |

| CAL-MIRPDD | S148C | - |

Thorlabs offers in-house ISO 17025 accredited recalibration services for our photodiode power sensors, including our integrating sphere power sensors. If you wish to calibrate one or more sensors with a console, each sensor and console calibration service will need to be purchased individually. ISO 17025 accredited calibrations are performed in accordance with DIN EN ISO/IEC 17025:2018. Thorlabs GmbH's calibration laboratory is accredited by the German Accreditation Body (DAkkS), the national accreditation authority of the Federal Republic of Germany for the scope of services described here in English or German. For more details on these recalibration services, please see the Recalibration tab or click the Documents (![]() ) icons below.

) icons below.

Refer to Table G4.1 for the appropriate calibration service Item # that corresponds to your power sensor.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #, and the Serial # of each item being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." In the Further Details field, please indicate "ISO 17025 Accredited Calibration" or the desired calibration part number below in order to differentiate from the manufacturer calibration option. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Select the appropriate sensor calibration Item # below, enter the Part # and Serial # of the sensor that requires recalibration, and then Add to Cart. If you would like a console calibrated with your sensor, repeat this process for Item # CAL-PM1, CAL-PM1D, CAL-PM2, or CAL-PM2D below, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate the return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

Part Number | Description | Price | Availability |

|---|---|---|---|

CAL-PDD | ISO 17025 Accredited Calibration Service for Single-Power-Range Silicon Photodiode Power Sensors | $518.35 | Lead Time |

CAL-IRPDD | ISO 17025 Accredited Calibration Service for Single-Power-Range Germanium or InGaAs Photodiode Power Sensors | $584.57 | Lead Time |

CAL-MIRPDD | ISO 17025 Accredited Calibration Service for Extended InGaAs Photodiode Power Sensors | $921.23 | Lead Time |

Manufacturer Recalibration of Power & Energy Meter Electronics

| Table 719A Compatibility | |

|---|---|

| Calibration Service Item # | Compatible Consoles & Interfaces |

| Single-Channel | |

| CAL-PM1 | PM100D2, PM100D3, PM100A, PM400, PM100USB, PM100Da PM101 Series, PM102 Series, PM103 Series |

| Dual-Channel | |

| CAL-PM2 | PM5020 and PM320Ea |

These traceable recalibration services are for the power and/or energy meter electronics of our consoles and interfaces. To ensure accurate measurements, we recommend recalibrating annually. The manufacturer calibration of a power sensor includes recalibration of a single-channel console or interface at no additional cost; this is unavailable for the accredited calibration option. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually. For more details on these recalibration services, please click the Documents (![]() ) icons below.

) icons below.

Table 719A lists the power and/or energy meter consoles and interfaces that can be calibrated using the CAL-PM1 and CAL-PM2 recalibration services.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #, and the Serial # of each item being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." In the Further Details field, please indicate "Manufacturer Calibration" or the desired calibration part number below in order to differentiate from the ISO 17025 accredited calibration option. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Select the appropriate Item # below, enter the Part # and Serial # of the item that requires recalibration, and then Add to Cart. If you would like to calibrate one or more sensors with your console, repeat this process for the appropriate sensor recalibration service above, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

Part Number | Description | Price | Availability |

|---|---|---|---|

CAL-PM1 | Manufacturer Recalibration of Single-Channel Power and/or Energy Meter Electronics | $84.32 | Lead Time |

CAL-PM2 | Manufacturer Recalibration of Dual-Channel Power and Energy Meter Electronics | $224.83 | Lead Time |

In-House ISO 17025 Accredited Recalibration of Power & Energy Meter Electronics

| Table 792A Compatibility | |

|---|---|

| Calibration Service Item # | Compatible Consoles & Interfaces |

| Single-Channel | |

| CAL-PM1D | PM100D2, PM100D3, PM100A, PM400, PM100USB, PM100Da PM101 Series, PM102 Series, PM103 Series |

| Dual-Channel | |

| CAL-PM2D | PM5020 |

These ISO 17025 accredited recalibration services are for the power and/or energy meter electronics of our consoles and interfaces. If you wish to calibrate one or more sensors with a console, each sensor and console calibration service will need to be purchased individually. ISO 17025 accredited calibrations are performed in accordance with DIN EN ISO/IEC 17025:2018. Thorlabs GmbH's calibration laboratory is accredited by the German Accreditation Body (DAkkS), the national accreditation authority of the Federal Republic of Germany. The scope of services is described here in English or German. For more details on these recalibration services, please see the Recalibration tab or click the Documents (![]() ) icons below.

) icons below.

Table 792A lists the power and/or energy meter consoles and interfaces that can be calibrated using the CAL-PM1D and CAL-PM2D recalibration services.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #, and the Serial # of each item being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." In the Further Details field, please indicate "ISO 17025 Accredited Calibration" or the desired calibration part number below in order to differentiate from the manufacturer calibration option. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Select the appropriate Item # below, enter the Part # and Serial # of the item that requires recalibration, and then Add to Cart. If you would like to calibrate one or more sensors with your console, repeat this process for the appropriate sensor recalibration service above, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

Part Number | Description | Price | Availability |

|---|---|---|---|

CAL-PM1D | ISO 17025 Accredited Calibration for Single-Channel Power and/or Energy Meter Electronics | $244.22 | Lead Time |

CAL-PM2D | ISO 17025 Accredited Calibration for Dual-Channel Power and/or Energy Meter Electronics | $545.51 | Lead Time |