Compact Laser Diode Driver with TEC and Mount for Butterfly Packages

- Compact, All-in-One Current Source, Temperature Controller, and Mount

- Compatible with Thorlabs' Butterfly Lasers

- Touch Screen Controlled and Remotely Programmable

CLD1015

Drives Butterfly

Packaged Laser Diodes

CLD1015

Shown with a

Butterfly Laser

(Not Included)

Main Operation Panel in Constant Power

Operating Mode

OVERVIEW

Click to Enlarge

Figure 1.2 Home Screen

Click to Enlarge

Figure 1.1 Menu Screen

Features

- Integrated Mount Compatible with Thorlabs' Butterfly Laser Diodes

- Operates in Constant Current or Constant Power Mode

- Controlled Locally with Touch Screen GUI or Remotely over USB

- Supports Laser Diode Drive Currents up to 1.5 A at 4 V

- Provides up to 3.0 A of TEC Current

- Compact Size: 111 mm x 73.5 mm x 169.9 mm (4.37" x 2.9" x 6.69")

Click to Enlarge

Figure 1.3 The CLD1015 shown with a butterfly laser installed.

The CLD1015 Laser Diode and Temperature Controller is a complete driver package designed to drive and cool pigtailed butterfly laser diodes (see the Pin Diagram tab for details). It contains a built-in mount for portability and mechanical stability. The CLD1015 accepts fiber-coupled lasers, superluminescent diodes, and laser amplifiers in both type 1 and type 2 butterfly packages. It supplies up to 1.5 A of drive current, making it compatible with Thorlabs' entire family of pigtailed butterfly diode lasers. This all-in-one unit provides a high degree of output stability and maintains the diode temperature with 0.005 °C of stability over 24 hours, prolonging the life of the diode. In addition to a full complement of safety features, such as a soft start mode, current and temperature limits, and external interlock compatibility, the CLD1015 laser diode driver includes a switchable noise reduction filter and a modulation input.

This laser diode driver is controlled with a built-in 4.3" diagonal, color touch screen, making it easy to tune, tweak, and optimize the laser output parameters. Operating parameters are set using the intuitive menu system, and the user is never more than two taps away from the home screen. For screenshots of the interface, please see the Display tab. A mini-USB interface on the rear of the unit enables remote control of all settings using several common programming languages, including LabVIEW™ and the Standard Commands for Programmable Instruments (SCPI) standard. For the full array of options, please refer to the Software tab. When using the CLD1015 to drive a laser, make sure that all of the operating parameters are set within the maximum ratings of your device.

| Compact LD Driver, TEC, and Mount Selection Guide | ||

|---|---|---|

| Item # | Accepted Package Configurations | Max Drive Current |

| CLD1015 | Type 1 and Type 2 Butterfly Packages | 1.5 A (@ 4 V) |

| CLD1010LP | TO Can Packages with an A, D, E, or G Pin Code | 1.0 A (@ 8 V) |

| CLD1011LP | TO Can Packages with a B, C, or H Pin Code | 1.0 A (@ 8 V) |

When fully assembled, this compact device measures just 4.37" x 2.9" x 6.69" (111 mm x 73.5 mm x 169.9 mm), ideal for tightly packed setups. Fiber cables can be fed through the ports on the back of the unit, which are also compatible with Thorlabs' FC-to-FC Mating Sleeves (not included). Two of the holes accept square flange mating sleeves, and two are designed for D-hole mating sleeves. A magnetically sealed lid encloses the laser package in the unit, protecting it from particulates and other lab hazards. Two mounting clips, compatible with 1/4"-20 and M6 bolts, are supplied with the laser diode driver to secure it to a breadboard.

For driver software, as well as programming reference guides for Standard Commands for the Programmable Instruments (SCPI) standard, LabVIEW™, Visual C++, Visual C#, and Visual Basic, please see the Software tab.

SPECS

Note: This laser diode driver may be controlled locally via the touch screen or remotely over USB. When controlled locally via the touch screen, the resolution of the laser diode driver is limited by the display; the full resolution can be accessed when the device is controlled remotely. The command sets that are accessible over USB - for example, via LabVIEW or the Standard Commands for Programmable Instruments (SCPI) - offer increased resolution, as shown in Table 2.3.

| Table 2.1 Laser Diode Driver Specifications | ||||

|---|---|---|---|---|

| Via Front Panela | Via Remote Controla | |||

| Current Control (Constant Current Mode) | ||||

| Control Range | 0 to 1.5 A | |||

| Compliance Voltage | >4 V | |||

| Resolution | 100 µA | 50 µA | ||

| Accuracy | ±(0.1% + 500 µA) | |||

| Noise and Ripple (Typical; 10 Hz to 10 MHz, RMS; @ 3.3 Ω Load, Current <1.2 A) |

10 µA without Noise Reduction Filter 5 µA with Noise Reduction Filter |

|||

| Drift (24 Hours) | <50 µA @ 0 - 10 Hz in Constant Ambient Temperature | |||

| Temperature Coefficient | <50 ppm/°C | |||

| Current Limit | ||||

| Setting Range | 1 mA to 1.5 A | |||

| Resolution | 100 µA | 50 µA | ||

| Accuracy | ±(0.12% + 800 µA) | |||

| Photodiode Input | ||||

| Photocurrent Measurement Rangesb | 0 to 2 mA (Low) 2 to 20 mA (High) |

|||

| Photocurrent Resolutionb | 100 nA (Low) 1 µA (High) |

70 nA (Low) 700 nA (High) |

||

| Photocurrent Accuracyb | ±(0.08% +0.5 µA) (Low) ±(0.08% +5 µA) (High) |

|||

| Photodiode Reverse Bias Voltage | 0.1 to 6 V | |||

| Photodiode Input Impedance | ~0 Ω (Virtual Ground) | |||

| Power Control (Constant Power Mode) | ||||

| Photocurrent Control Rangesb | 0 to 2 mA (Low) 0 to 20 mA (High) |

|||

| Laser Voltage Measurement | ||||

| Resolution | 1 mV | 200 µV | ||

| Accuracy | ±(1% + 40 mV) | |||

| Laser Overvoltage Protection | ||||

| Trip Voltage (Typical) | 4.2 V | |||

| Modulation Input | ||||

| Input Voltage | ±10 V | |||

| Input Impedance | 10 kΩ | |||

| 3 dB Small Signal Bandwidth (Constant Current Mode) |

DC to 250 kHz without Noise Reduction Filter DC to 7.5 kHz with Noise Reduction Filter |

|||

| Modulation Coefficient (Constant Current Mode) |

150 mA/V ± 5% | |||

| Modulation Coefficient (Constant Power Mode)c |

200 µA/V ± 5% (Low) 2 mA/V ± 5% (High) |

|||

| Table 2.2 TEC Specifications | ||

|---|---|---|

| Via Front Panela | Via Remote Controla | |

| TEC Current Output | ||

| Control Range | -3.0 to +3.0 A | |

| Compliance Voltage | >4.7 V | |

| Maximum Output Power | >14.1 W | |

| Resolution | 1 mA | 100 µA |

| Accuracy | ±(0.2% + 20 mA) | |

| TEC Current Limit | ||

| Setting Range | 5 mA to 3.0 A | |

| Resolution | 1 mA | 100 µA |

| Accuracy | ±(0.2% + 20 mA) | |

| NTC Thermistor Sensors | ||

| Resistance Measurement Range |

300 Ω to 150 kΩ | |

| Control Rangeb | -55 °C to +150 °C (Max) | |

| Temperature Resolution | 0.01 °C | |

| Resistance Resolution | 1 Ω | |

| Accuracy | ±(0.1% + 1 Ω) | |

| Temperature Stabilityb (24 Hours) |

<0.005 °C (Typical) | |

| Temperature Coefficient | <5 mK/°C | |

| Temperature Window Protection | ||

| Setting Range | 0.01 °C to 100.0 °C | |

| Protection Reset Delay | 0 to 600 s | |

| Table 2.3 General Specifications | |

|---|---|

| Interface | |

| USB 2.0 | Compliant with USBTMC/USBTMC USB488 Specification Rev. 1.0 |

| Protocol | SCPI-Compliant Command Set |

| Supplied Drivers | VISA VXI pnp™, MS Visual Studio™, MS Visual Studio.net™, LabVIEW™, LabWindows/CVI™ |

| General Data | |

| Safety Features | Interlock, Keylock Switch, Laser Current Limit, Soft Start, Short Circuit when Laser Off, Laser Overvoltage Protection, Over Temperature Protection, Temperature Window Protection |

| Display | 4.3" LCD TFT, 480 x 272 Pixels |

| Socket for Laser, Photodiode, NTC, TEC | Compatible with Butterfly Type 1 (Pump) and Butterfly Type 2 (Telecom) |

| Connector for DC Power Input | 2.0 mm Center Pin Connected to + |

| Connector for Modulation Input | SMA |

| Connector for Interlock & Laser On Signal | 2.5 mm Mono Phono Jack |

| Connector for USB-Interface | USB Type Mini-B |

| Chassis Ground Connector | 4 mm Banana Jack |

| Desktop Power Supply, Line Voltage, Line Frequency | AC: 100 to 240 V ± 10%, 47 to 63 Hz DC: 12 V ± 5% / 3.5 A |

| Maximum Power Consumption | 40 VA |

| Operating Temperature | 0 to +40 °C |

| Storage Temperature | -40 to +70°C |

| Warm-up Time for Rated Accuracy | 30 min |

| Weight (with Power Supply) | 1.0 kg |

| Weight (without Power Supply) | 0.75 kg |

| Dimensions without Operating Elementsa (W x H x D) | 111 mm x 73.5 mm x 153.3 mm (4.37" x 2.9" x 6.04") |

| Dimensions with Operating Elementsa (W x H x D) | 111 mm x 73.5 mm x 169.9 mm (4.37" x 2.9" x 6.69") |

DISPLAY

Control Interface

The laser controller's interface consists of a flat menu hierarchy that makes it easy to find parameters to adjust.

| Home Screen in Constant Current Mode | Home Screen in Constant Power Mode | ||

Click to Enlarge | In Constant Current Mode, the home screen emphasizes the laser diode current and temperature and displays their respective setpoints. The output power, measured by the monitor diode, is also displayed. Up to four setpoint combinations can be stored in memory. |  Click to Enlarge | In Constant Power Mode, the home screen emphasizes the laser output power and diode temperature. The laser diode current is also displayed. |

| Setpoint Entry | Menu Screen | ||

Click to Enlarge | Each setpoint is easily modified. Simply tap the value to be changed, and buttons appear on the right that allow the value to be set. The current value of the parameter remains displayed while tweaking. |  Click to Enlarge | The CLD1015 is configured through an intuitive two-level menu structure. All settings related to the laser and the thermoelectric cooler are made here, and several other system settings are provided. |

SOFTWARE

Software for Laser Diode Controllers

The Software button links to VISA VXI pnp™, MS Visual Studio™, MS Visual Studio.net™, LabVIEW™, and LabWindows/CVI™ drivers, firmware, utilities, and support documentation for Thorlabs' ITC4000 Series laser controllers, LDC4000 Series laser controllers, CLD1000 Series compact laser diode controllers, and TED4000 Series TEC controllers.

The software download page also offers programming reference notes for interfacing with compatible controllers using SCPI, LabVIEW, Visual C++, Visual C#, and Visual Basic. Please see the Programming Reference tab on the software download page for more information and download links.

The software packages support LabVIEW 8.5 and higher. If you are using an earlier version of LabVIEW, please contact Technical Support for assistance.

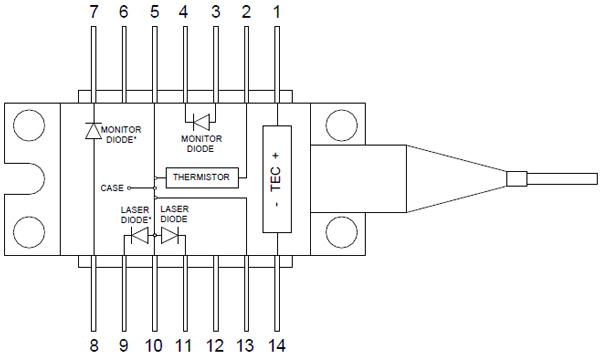

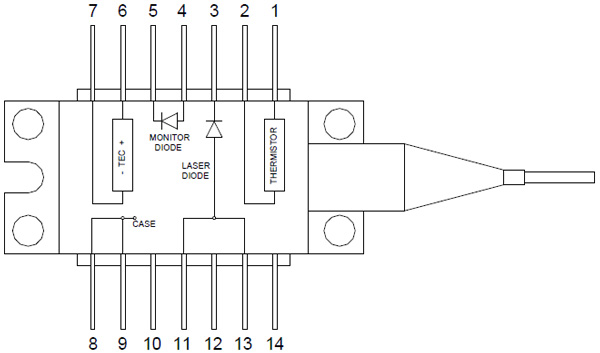

PIN DIAGRAMS

Butterfly Laser Diodes Compatible with the CLD1015

The CLD1015 Laser Diode Driver and Temperature Controller is compatible with Type 1 Pump Laser Diodes and Type 2 Telecom Laser Diodes. Please use the pin diagrams below to verify compatibility with your specific butterfly package. The interior of the CLD1015 is labeled with the correct installation orientation for Type 1 and Type 2 lasers.

Type 1: Pump Laser Diodes

| Pin | Connection | Pin | Connection |

|---|---|---|---|

| 1 | TEC+ (Thermoelectric Cooler) | 8 | Monitor Diode Anodea |

| 2 | Thermistor | 9 | Laser Diode Cathodeb |

| 3 | Monitor Diode Anodea | 10 | Laser Diode Anode |

| 4 | Monitor Diode Cathodea | 11 | Laser Diode Cathodeb |

| 5 | Thermistor | 12 | No Connection |

| 6 | No Connection | 13 | Ground |

| 7 | Monitor Diode Cathodea | 14 | TEC- (Thermoelectric Cooler) |

Type 2: Telecom Laser Diodes

| Pin | Connection | Pin | Connection |

|---|---|---|---|

| 1 | Thermistor | 8 | Ground |

| 2 | Thermistor | 9 | Ground |

| 3 | Laser Diode Cathode | 10 | No Connection |

| 4 | Monitor Diode Anode | 11 | Laser Diode Anodea |

| 5 | Monitor Diode Cathode | 12 | No Connection |

| 6 | TEC+ (Thermoelectric Cooler) | 13 | Laser Diode Anodea |

| 7 | TEC- (Thermoelectric Cooler) | 14 | No Connection |

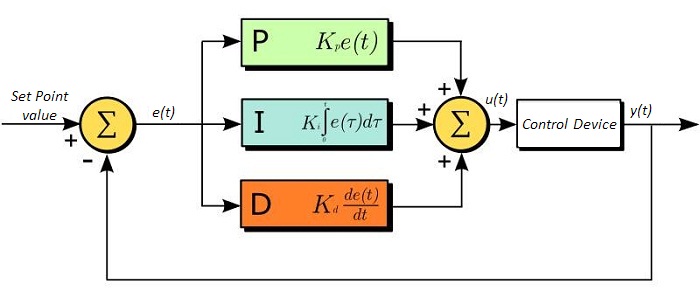

PID TUTORIAL

PID Basics

The PID circuit is often utilized as a control loop feedback controller and is commonly used for many forms of servo circuits. The letters making up the acronym PID correspond to Proportional (P), Integral (I), and Derivative (D), which represents the three control settings of a PID circuit. The purpose of any servo circuit is to hold the system at a predetermined value (set point) for long periods of time. The PID circuit actively controls the system so as to hold it at the set point by generating an error signal that is essentially the difference between the set point and the current value. The three controls relate to the time-dependent error signal. At its simplest, this can be thought of as follows: Proportional is dependent upon the present error, Integral is dependent upon the accumulation of past error, and Derivative is the prediction of future error. The results of each of the controls are then fed into a weighted sum, which then adjusts the output of the circuit, u(t). This output is fed into a control device, its value is fed back into the circuit, and the process is allowed to actively stabilize the circuit’s output to reach and hold at the set point value. The block diagram below illustrates the action of a PID circuit. One or more of the controls can be utilized in any servo circuit depending on system demand and requirement (i.e., P, I, PI, PD, or PID).

Through proper setting of the controls in a PID circuit, relatively quick response with minimal overshoot (passing the set point value) and ringing (oscillation about the set point value) can be achieved. Let’s take as an example a temperature servo, such as that for temperature stabilization of a laser diode. The PID circuit will ultimately servo the current to a Thermoelectric Cooler (TEC) (often times through control of the gate voltage on an FET). Under this example, the current is referred to as the Manipulated Variable (MV). A thermistor is used to monitor the temperature of the laser diode, and the voltage over the thermistor is used as the Process Variable (PV). The Set Point (SP) voltage is set to correspond to the desired temperature. The error signal, e(t), is then the difference between the SP and PV. A PID controller will generate the error signal and then change the MV to reach the desired result. For example, if e(t) states that the laser diode is too hot, the circuit will allow more current to flow through the TEC (proportional control). Since proportional control is proportional to e(t), it may not cool the laser diode quickly enough. In that event, the circuit will further increase the amount of current through the TEC (integral control) by looking at the previous errors and adjusting the output to reach the desired value. As the SP is reached (e(t) approaches zero), the circuit will decrease the current through the TEC in anticipation of reaching the SP (derivative control).

Please note that a PID circuit will not guarantee optimal control. Improper setting of the PID controls can cause the circuit to oscillate significantly and lead to instability in control. It is up to the user to properly adjust the PID gains to ensure proper performance.

PID Theory

The output of the PID control circuit, u(t), is given as

where

Kp= Proportional Gain

Ki = Integral Gain

Kd = Derivative Gain

e(t) = SP - PV(t)

From here we can define the control units through their mathematical definition and discuss each in a little more detail. Proportional control is proportional to the error signal; as such, it is a direct response to the error signal generated by the circuit:

Larger proportional gain results in larger changes in response to the error, and thus affects the speed at which the controller can respond to changes in the system. While a high proportional gain can cause a circuit to respond swiftly, too high a value can cause oscillations about the SP value. Too low a value and the circuit cannot efficiently respond to changes in the system.

Integral control goes a step further than proportional gain, as it is proportional to not just the magnitude of the error signal but also the duration of the error.

Integral control is highly effective at increasing the response time of a circuit along with eliminating the steady-state error associated with purely proportional control. In essence integral control sums over the previous error, which was not corrected, and then multiplies that error by Ki to produce the integral response. Thus, for even small sustained error, a large aggregated integral response can be realized. However, due to the fast response of integral control, high gain values can cause significant overshoot of the SP value and lead to oscillation and instability. Too low, and the circuit will be significantly slower in responding to changes in the system.

Derivative control attempts to reduce the overshoot and ringing potential from proportional and integral control. It determines how quickly the circuit is changing over time (by looking at the derivative of the error signal) and multiplies it by Kd to produce the derivative response.

Unlike proportional and integral control, derivative control will slow the response of the circuit. In doing so, it is able to partially compensate for the overshoot as well as damp out any oscillations caused by integral and proportional control. High gain values cause the circuit to respond very slowly and can leave one susceptible to noise and high frequency oscillation (as the circuit becomes too slow to respond quickly). Too low and the circuit is prone to overshooting the SP value. However, in some cases overshooting the SP value by any significant amount must be avoided and thus a higher derivative gain (along with lower proportional gain) can be used. The chart below explains the effects of increasing the gain of any one of the parameters independently.

| Parameter Increased | Rise Time | Overshoot | Settling Time | Steady-State Error | Stability |

|---|---|---|---|---|---|

| Kp | Decrease | Increase | Small Change | Decrease | Degrade |

| Ki | Decrease | Increase | Increase | Decrease Significantly | Degrade |

| Kd | Minor Decrease | Minor Decrease | Minor Decrease | No Effect | Improve (for small Kd) |

Tuning

In general the gains of P, I, and D will need to be adjusted by the user in order to best servo the system. While there is not a static set of rules for what the values should be for any specific system, following the general procedures should help in tuning a circuit to match one’s system and environment. A PID circuit will typically overshoot the SP value slightly and then quickly damp out to reach the SP value.

Manual tuning of the gain settings is the simplest method for setting the PID controls. However, this procedure is done actively (the PID controller turned on and properly attached to the system) and requires some amount of experience to fully integrate. To tune your PID controller manually, first the integral and derivative gains are set to zero. Increase the proportional gain until you observe oscillation in the output. Your proportional gain should then be set to roughly half this value. After the proportional gain is set, increase the integral gain until any offset is corrected for on a time scale appropriate for your system. If you increase this gain too much, you will observe significant overshoot of the SP value and instability in the circuit. Once the integral gain is set, the derivative gain can then be increased. Derivative gain will reduce overshoot and damp the system quickly to the SP value. If you increase the derivative gain too much, you will see large overshoot (due to the circuit being too slow to respond). By playing with the gain settings, you can maximize the performance of your PID circuit, resulting in a circuit that quickly responds to changes in the system and effectively damps out oscillation about the SP value.

| Control Type | Kp | Ki | Kd |

|---|---|---|---|

| P | 0.50 Ku | - | - |

| PI | 0.45 Ku | 1.2 Kp/Pu | - |

| PID | 0.60 Ku | 2 Kp/Pu | KpPu/8 |

While manual tuning can be very effective at setting a PID circuit for your specific system, it does require some amount of experience and understanding of PID circuits and response. The Ziegler-Nichols method for PID tuning offers a bit more structured guide to setting PID values. Again, you’ll want to set the integral and derivative gain to zero. Increase the proportional gain until the circuit starts to oscillate. We will call this gain level Ku. The oscillation will have a period of Pu. Gains for various control circuits are then given to the right in the chart.

Note that when using the Ziegler-Nichols tuning method with some devices like the DSC1 digital servo controller, the integral and derivative terms must be normalized by the sample rate. To do this, the integral term determined from the table should be divided by the sample rate in Hertz and the derivative term should be multiplied by the sample rate in Hertz.

LD SETUP

Video Insight: Setting Up a Pigtailed Butterfly Laser Diode

A laser diode packaged in a butterfly housing can be precisely controlled, in a compact package, when the laser is installed in a mount such as the CLD1015 that includes thermoelectric cooler (TEC) and current drivers. The mount can make it easier, and safer, to operate the laser, but the procedure for installing the laser in the mount and configuring the settings requires some care. This video provides a step-by-step guide, which begins with an introduction to the different components and concludes with the laser operating under TEC control and with the recommended maximum current limit enabled.

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

SELECTION GUIDE

Laser Diode Controller Selection Guide

Tables 137A and 137B are designed to give a quick overview of the key specifications for our laser diode controllers and dual diode/temperature controllers. For more details and specifications, or to order a specific item, click on the appropriate item number below.

| Table 137A Current Controllers | ||||||

|---|---|---|---|---|---|---|

| Item # | Drive Current | Compliance Voltage | Constant Current | Constant Power | Modulation | Package |

| LDC200CV | 20 mA | 6 V | External | Benchtop | ||

| VLDC002 | 25 mA | 5 V | - | Int/Ext | OEM | |

| LDC201CU | 100 mA | 5 V | External | Benchtop | ||

| LD2000R | 100 mA | 3.5 V | - | External | OEM | |

| EK2000 | 100 mA | 3.5 V | - | External | OEM | |

| LDC202C | 200 mA | 10 V | External | Benchtop | ||

| KLD101 | 230 mA | ≤10 V | External | K-Cube® | ||

| IP250-BV | 250 mA | 8 Va | External | OEM | ||

| LD1100 | 250 mA | 6.5 Va | - | -- | OEM | |

| LD1101 | 250 mA | 6.5 Va | - | -- | OEM | |

| EK1101 | 250 mA | 6.5 Va | - | -- | OEM | |

| EK1102 | 250 mA | 6.5 Va | - | -- | OEM | |

| LD1255R | 250 mA | 3.3 V | - | External | OEM | |

| LDC205C | 500 mA | 10 V | External | Benchtop | ||

| IP500 | 500 mA | 3 V | External | OEM | ||

| LDC210C | 1 A | 10 V | External | Benchtop | ||

| LDC220C | 2 A | 4 V | External | Benchtop | ||

| LD3000R | 2.5 A | -- | - | External | OEM | |

| LDC240C | 4 A | 5 V | External | Benchtop | ||

| LDC4005 | 5 A | 12 V | Int/Ext | Benchtop | ||

| LDC4020 | 20 A | 11 V | Int/Ext | Benchtop | ||

| Table 137B Dual Temperature and Current Controllers | |||||||

|---|---|---|---|---|---|---|---|

| Item # | Drive Current | Compliance Voltage | TEC Power (Max) | Constant Current | Constant Power | Modulation | Package |

| VITC002 | 25 mA | 5 V | >2 W | - | Int/Ext | OEM | |

| ITC102 | 200 mA | >4 V | 12 W | Ext | OEM | ||

| ITC110 | 1 A | >4 V | 12 W | Ext | OEM | ||

| ITC4001 | 1 A | 11 V | >96 W | Int/Ext | Benchtop | ||

| CLD1010LPa | 1.0 A | >8 V | >14.1 W | Ext | Benchtop | ||

| CLD1011LPb | 1.0 A | >8 V | >14.1 W | Ext | Benchtop | ||

| CLD1015c | 1.5 A | >4 V | >14.1 W | Ext | Benchtop | ||

| ITC4002QCLd | 2 A | 17 V | >225 W | Int/Ext | Benchtop | ||

| ITC133 | 3 A | >4 V | 18 W | Ext | OEM | ||

| ITC4005 | 5 A | 12 V | >225 W | Int/Ext | Benchtop | ||

| ITC4005QCLd | 5 A | 20 V | >225 W | Int/Ext | Benchtop | ||

| ITC4020 | 20 A | 11 V | >225 W | Int/Ext | Benchtop | ||

We also offer a variety of OEM and rack-mounted laser diode current & temperature controllers (OEM Modules, PRO8 Current Control Rack Modules, and PRO8 Current and Temperature Control Rack Modules).

Compact Laser Diode/Temperature Controller for Butterfly Packages

Part Number | Description | Price | Availability |

|---|---|---|---|

CLD1015 | Customer Inspired! Compact LD and Temperature Controller with Mount | $2,782.39 | Lead Time |