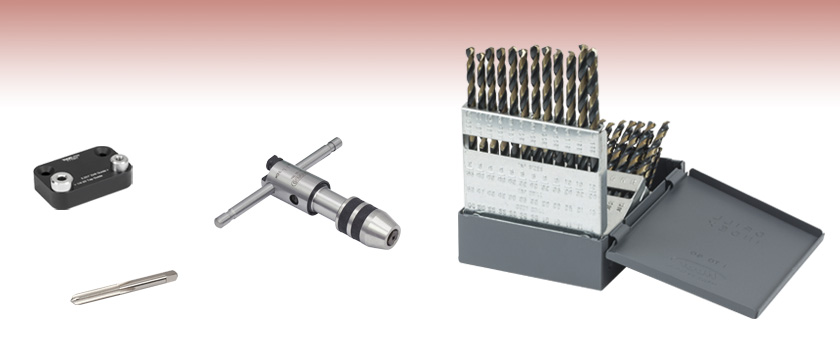

Taps and Drill Bit Kit

- Individual Imperial & Metric Plug Taps

- 60-Piece Drill Bit Kit

- Tap Guides Help Ensure Tapped Holes are

Perpendicular to Flat Surfaces

TTT001

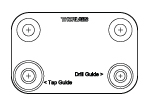

Tap Guide for Optical Tables and Breadboards

TAP1480

1/4"-80 Tap

TW25

Tap Wrench

DK3

60-Piece Drill Bit Kit

OVERVIEW

Click to Enlarge

Figure 1.2 The TAPSM1 Imperial Tap for Tapping Thorlabs' SM1 Standard Threads

Click to Enlarge

Figure 1.1 The TAPSM05 Imperial Tap for Tapping Thorlabs' SM05 Standard Threads

Features

- Wide Selection of Plug Taps Including Thorlabs' SM05 (0.535"-40) and SM1 (1.035"-40) Standards

- Drill Kit Includes 60 Drill Bits in an Embossed Steel Case

- Universal Tap Wrench is an Essential Tool for Custom Applications

- Table and Breadboard Tapping Guide for Repairing Damaged Tapped Holes

The items on this webpage can be used to add taps in user-selected locations and repair damaged tapped holes on breadboards and optical tables.

THREADING SPECS

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

Specialty Taps - Imperial

Click to Enlarge

Figure G1.1 Diagram of a Standard Tap

- Specialized Plug Taps

- Covers SM05, SM1, and Most Other Threads Used by Thorlabs

- Material: High-Speed Steel

These specialty taps aid in the integration of our optomechanical components into your custom-built devices. Our imperial taps selection includes many of the thread standards used by Thorlabs, including our SM05 (0.535"-40) and SM1 (1.035"-40) standards. Please see below for our metric taps.

Tapping Recommendations

To tap a hole, first machine a pilot bore, using Table G1.2 to find the recommended pilot bore diameter. The bore can be made using a drill bit or an end mill. For fine pitch threads, the pilot bore should be tightly toleranced because of the shallow thread depth; a reamer is also recommended in this case.

Next, secure the tap into a tap wrench, drill press, or lathe to create the threads. Lubricant or tapping fluid should be used to create the hole. If resistance is felt while tapping, carefully rotate the tap backwards to remove it, as broken taps are exceptionally difficult to remove.

If using these specialty taps for production, precision ring and plug gauges should be used to verify hole diameters. For additional details on threading and taps, please consult the Machinery's Handbook, available in many machine shops and bookstores.

Note: For larger thread standards, such as our SM2 thread (2.035"-40) standard, single point turning should be employed to ensure a high-quality thread. For that reason, we do not offer taps for diameters larger than our SM1 (1.035"-40) standard.

| Table G1.2 Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Thread Type | Thread Depth (T) |

Overall Length (L) |

Shank Size (S) |

Pilot Bore | Example Uses | ||

| Diameter | Tolerancea | Imperial Drill Sizeb | ||||||

| TAP080 | 0-80 | 0.31" | 1.63" | 0.141" | 0.049" | +0.003"/-0.002" | - | Holes for Locking Setscrews |

| TAP256 | 2-56 | 0.44" | 1.75" | 0.141" | 0.070" | ±0.004" | #50 (0.0700") |

Mounting Holes on Miniature Translation Stages |

| TAP440 | 4-40 | 0.56" | 1.88" | 0.141" | 0.089" | ±0.005" | #43 (0.0890") |

Holes for Cage Rod Locking Setscrews |

| TAP680 | 6-80 | 0.69" | 2.00" | 0.141" | 0.126" | ±0.002" | 1/8" (0.1250") |

Holes for 6-80 Adjustment Screws |

| TAP832 | 8-32 | 0.75" | 2.13" | 0.168" | 0.135" | +0.004"/-0.005" | #29 (0.1360") |

Mounting Holes for 8-32 Screws |

| TAP316100 | 3/16"-100 | 0.88" | 2.38" | 0.194" | 0.177" | +0.002"/-0.001" | #16 (0.1770") |

Holes for 3/16"-100 Adjustment Screws |

| TAP1420 | 1/4"-20 | 1.00" | 2.50" | 0.255" | 0.202" | +0.005"/-0.006" | #7 (0.2010") |

Mounting Holes for 1/4"-20 Screws |

| TAP1480 | 1/4"-80 | 1.00" | 2.50" | 0.255" | 0.238" | ±0.002" | B (0.2380") |

Holes for 1/4"-80 Adjustment Screws |

| TAP14100 | 1/4"-100 | 1.00" | 2.50" | 0.255" | 0.240" | +0.002"/-0.001" | - | Holes for 1/4"-100 Adjustment Screws |

| TAP51632 | 5/16"-32 | 1.13" | 2.72" | 0.318" | 0.282" | +0.004"/-0.003" | 9/32" (0.2812") |

Mounting Holes for 3/16"-100 Locking Bushings with 5/16"-32 External Threads |

| TAP3824 | 3/8"-24 | 1.25" | 2.94" | 0.381" | 0.335" | ±0.005" | Q (0.3340") |

Mounting Holes for Fiber Bulkhead Adapters with 3/8"-24 External Threads |

| TAP3840 | 3/8"-40 | 1.25" | 2.94" | 0.381" | 0.348" | ±0.003" | S (0.3480") |

Mounting Holes for 1/4"-80 Locking Bushings with 3/8"-40 External Threads |

| TAP38100 | 3/8"-100 | 1.25" | 2.94" | 0.381" | 0.365" | +0.002"/-0.001" | - | Holes for 3/8"-100 Fine Adjustment Screws |

| TAPSM05 | 0.535"-40 (SM05 Standard) |

1.66" | 3.59" | 0.429" | 0.511" | ±0.003" | - | Internal Threads on Ø1/2" Lens Tubes |

| TAPRMS | 0.800"-36 (RMS Standard) |

2.00" | 4.47" | 0.652" | 0.773" | +0.004"/-0.003" | - | Mounts for RMS-Threaded Objectives |

| TAPCM | 1.00"-32 (C-Mount Standard) |

2.50" | 5.13" | 0.800" | 0.970" | ±0.004" | - | Internal Threads on C-Mount Extension Tubes, Mounts for Machine Vision Camera Lenses |

| TAPSM1 | 1.035"-40 (SM1 Standard) |

1.50" | 4.00" | 0.896" | 1.011" | ±0.003" | - | Internal Threads on Ø1" Lens Tubes |

Part Number | Description | Price | Availability |

|---|---|---|---|

TAP080 | English (Imperial) Tap, 0-80 Thread | $25.42 | Today |

TAP256 | English (Imperial) Tap, 2-56 Thread | $19.07 | Today |

TAP440 | English (Imperial) Tap, 4-40 Thread | $12.72 | Today |

TAP680 | English (Imperial) Tap, 6-80 Thread | $38.95 | Today |

TAP832 | English (Imperial) Tap, 8-32 Thread | $10.23 | Today |

TAP316100 | English (Imperial) Tap, 3/16"-100 Thread | $38.39 | Today |

TAP1420 | English (Imperial) Tap, 1/4"-20 Thread | $18.60 | Today |

TAP1480 | English (Imperial) Tap, 1/4"-80 Thread | $34.89 | Today |

TAP14100 | English (Imperial) Tap, 1/4"-100 Thread | $45.50 | Today |

TAP51632 | English (Imperial) Tap, 5/16"-32 Thread | $31.79 | Today |

TAP3824 | English (Imperial) Tap, 3/8"-24 Thread | $46.62 | Today |

TAP3840 | English (Imperial) Tap, 3/8"-40 Thread | $33.65 | Today |

TAP38100 | English (Imperial) Tap, 3/8"-100 Thread | $64.74 | Today |

TAPSM05 | English (Imperial) Tap, 0.535"-40 Thread (SM05 Standard) | $106.99 | Today |

TAPRMS | English (Imperial) Tap, 0.800"-36 Thread (RMS Standard) | $109.65 | Today |

TAPCM | English (Imperial) Tap, 1.00"-32 Thread (C-Mount Standard) | $127.12 | Today |

TAPSM1 | English (Imperial) Tap, 1.035"-40 Thread (SM1 Standard) | $109.65 | Today |

Specialty Taps - Metric

Click to Enlarge

Figure G2.1 Diagram of a Standard Tap

- Specialized Plug Taps

- Covers Many Threads Used by Thorlabs

- Material: High-Speed Steel

These specialty taps aid in the integration of our optomechanical components into your custom-built devices. Our metric taps selection includes many of the thread standards used by Thorlabs. Please see above for our imperial taps, as well as taps for our SM05 (0.535"-40) and SM1 (1.035"-40) standards.

Tapping Recommendations

To tap a hole, first machine a pilot bore, using Table G2.2 to find the recommended pilot bore diameter. The bore can be made using a drill bit or an end mill. For fine pitch threads, the pilot bore should be tightly toleranced because of the shallow thread depth; a reamer is also recommended in this case.

Next, secure the tap into a tap wrench, drill press, or lathe to create the threads. Lubricant or tapping fluid should be used to create the hole. If resistance is felt while tapping, carefully rotate the tap backwards to remove it, as broken taps are exceptionally difficult to remove.

If using these specialty taps for production, precision ring and plug gauges should be used to verify hole diameters. For additional details on threading and taps, please consult the Machinery's Handbook, available in many machine shops and bookstores.

| Table G2.2 Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item # | Thread Type | Thread Depth (T) |

Overall Length (L) |

Shank Size (S) |

Pilot Bore | Example Uses | |||

| Diameter | Tolerancea | Metric Drill Sizeb | Imperial Drill Sizeb | ||||||

| TAPM202 | M2 x 0.2 | 11.35 mm | 44.7 mm | 2.72 mm | 1.805 mm | +0.013 mm/-0.026 mm | 1.80 mm (0.0709") |

- | Holes for M2 x 0.2 Adjustment Screws |

| TAPM2502 | M2.5 x 0.2 | 12.7 mm | 46.0 mm | 3.58 mm | 2.313 mm | ±0.030 mm | 2.3 mm (0.0905") |

- | Holes for M2.5 x 0.2 Adjustment Screws |

| TAPM302 | M3 x 0.2 | 16.0 mm | 49.3 mm | 3.58 mm | 2.813 mm | ±0.030 mm | 2.8 mm (0.1102") |

#34 (0.1110") |

Holes for M3 x 0.2 Adjustment Screws |

| TAPM3025 | M3 x 0.25 | 16.0 mm | 49.3 mm | 3.58 mm | 2.766 mm | ±0.037 mm | 2.75 mm (0.1083") |

7/64" (0.1093") |

Holes for M3 x 0.25 Adjustment Screws |

| TAPM4025 | M4 x 0.25 | 19.1 mm | 54.1 mm | 4.27 mm | 3.77 mm | ±0.037 mm | 3.75 mm (0.1476") |

#26 (0.1470") |

Holes for M4 x 0.25 Fine Adjustment Screws |

| TAPM407 | M4 x 0.7 (M4 Standard) |

19.1 mm | 54.0 mm | 4.27 mm | 3.332 mm | ±0.090 mm | 3.3 mm (0.1299") |

#30 (0.1285") |

Mounting Holes for M4 Screws |

| TAPM4505 | M4.5 x 0.5 | 22.4 mm | 60.5 mm | 4.93 mm | 4.029 mm | ±0.070 mm | 4.0 mm (0.1575") |

#21 (0.1590") |

Mounting Hole for M3 x 0.25 Adjuster Nutc |

| TAPM6025 | M6 x 0.25 | 25.4 mm | 63.5 mm | 6.48 mm | 5.575 mm | ±0.0165 mm | 5.6 mm (0.2205") |

#2 (0.2210") |

Holes for M6 x 0.25 Adjustment Screws |

| TAPM605 | M6 x 0.5 | 25.4 mm | 63.5 mm | 6.48 mm | 5.526 mm | ±0.068 mm | 5.5 mm (0.2165") |

7/23" (0.2187") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM610 | M6 x 1.0 (M6 Standard) |

25.4 mm | 63.5 mm | 6.48 mm | 5.035 mm | ±0.118 mm | 5.1 mm (0.2008") |

#8 (0.1990") |

Mounting Holes for M6 Screws |

| TAPM7505 | M7.5 x 0.5 | 28.7 mm | 69.0 mm | 8.08 mm | 7.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø7 mm Optic Mounts |

| TAPM805 | M8 x 0.5 | 28.7 mm | 69.1 mm | 8.08 mm | 7.526 mm | ±0.068 mm | 7.5 mm (0.2953") |

M (0.2950") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM905 | M9 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 8.526 mm | ±0.068 mm | 8.5 mm (0.3346") |

Q (0.3340") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM1005 | M10 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 9.526 mm | ±0.068 mm | 9.5 mm (0.3740) |

3/8" (0.3750") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM10505 | M10.5 x 0.5 | 31.8 mm | 74.7 mm | 9.70 mm | 10.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø10 mm Optic Mounts |

| TAPM1105 | M11 x 0.5 | 36.6 mm | 80.3 mm | 8.20 mm | 10.526 mm | ±0.068 mm | 10.5 mm (0.4133") |

Z (0.4130") |

Mounting Holes for Mounted Aspheric Lens Pair Housingsd |

| TAPM1205 | M12 x 0.5 | 42.1 mm | 85.7 mm | 9.32 mm | 11.526 mm | ±0.068 mm | 11.5 mm (0.4528") |

29/64" (0.4531") |

Mounting Bores for Aspheric Lens Housingsd |

| TAPM1405 | M14 x 0.5 | 42.2 mm | 91.2 mm | 10.90 mm | 13.526 mm | ±0.068 mm | 13.5 mm (0.5315") |

17/23" (0.5312") |

- |

| TAPM20505 | M20.5 x 0.5 | 50.8 mm | 113.5 mm | 16.56 mm | 20.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for for Ø20 mm Lens Mounts |

| TAPM25075 | M25 x 0.75 (M25 Standard) | 63.5 mm | 130.3 mm | 20.32 mm | 24.284 mm | ±0.096 mm | - | - | Mounts for M25-Threaded Objectives |

Part Number | Description | Price | Availability |

|---|---|---|---|

TAPM202 | Metric Tap, M2 x 0.2 Thread | $61.09 | Today |

TAPM2502 | Metric Tap, M2.5 x 0.2 Thread | $60.79 | Today |

TAPM302 | Metric Tap, M3 x 0.2 Thread | $62.02 | Today |

TAPM3025 | Metric Tap, M3 x 0.25 Thread | $45.50 | Today |

TAPM4025 | Metric Tap, M4 x 0.25 Thread | $46.89 | Today |

TAPM407 | Metric Tap, M4 x 0.7 Thread (M4 Standard) | $12.72 | Today |

TAPM4505 | Metric Tap, M4.5 x 0.5 Thread | $40.20 | Today |

TAPM6025 | Metric Tap, M6 x 0.25 Thread | $45.50 | Today |

TAPM605 | Metric Tap, M6 x 0.5 Thread | $33.65 | Today |

TAPM610 | Metric Tap, M6 x 1.0 Thread (M6 Standard) | $22.98 | Today |

TAPM7505 | Metric Tap, M7.5 x 0.5 Thread | $49.90 | Today |

TAPM805 | Metric Tap, M8 x 0.5 Thread | $38.95 | Today |

TAPM905 | Metric Tap, M9 x 0.5 Thread | $51.10 | Today |

TAPM1005 | Metric Tap, M10 x 0.5 Thread | $58.88 | Today |

TAPM10505 | Metric Tap, M10.5 X 0.5 Thread | $71.99 | Today |

TAPM1105 | Metric Tap, M11 x 0.5 Thread | $60.46 | Today |

TAPM1205 | Metric Tap, M12 x 0.5 Thread | $59.88 | Today |

TAPM1405 | Metric Tap, M14 x 0.5 Thread | $71.03 | Today |

TAPM20505 | Metric Tap, M20.5 x 0.5 Thread | $132.29 | Today |

TAPM25075 | Metric Tap, M25 x 0.75 Thread (M25 Standard) | $171.96 | Today |

Drill Bit Kit

- 60 Number-Sized Drill Bits Ranging from #1 Bit to #60 Bit

- Bit Material: High-Speed Steel

- 135° Point Angle

- Sizes Embossed in Steel Case

The DK3 Drill Bit Kit includes 60 drill bits of standard jobber length. The bits are constructed from high-speed steel and have a 135° point angle. This kit holds the bits in a compact, all-steel index case, with the bit sizes, tap sizes, tap drill sizes, and body drill (clearance) sizes embossed in the case.

Part Number | Description | Price | Availability |

|---|---|---|---|

DK3 | 60-Piece Drill Bit Kit | $153.28 | Today |

Universal Tap Wrench

Click to Enlarge

Figure G4.1 Ratcheting Selector Knob and Sliding Crossbar

- Universal Ratcheting Tap Wrench with Sliding Crossbar

- Accommodates Taps from #0 to 1/4" or M2 to M6

- Shank Size from 0.141" to 0.255" or 3.6 mm to 6.5 mm

This machinist-quality Hand Tap Wrench is ideally suited for everyday tapping requirements. The rugged stainless steel design provides durability and long life, and the crossbar conveniently slides to provide extra torque when required. Ratcheting in either direction can be selected using the knob at the top of the wrench (see Figure G4.1). The Hand Tap Wrench can accommodate taps as small as #0 or 2 mm and as large as 1/4" or 6 mm.

Part Number | Description | Price | Availability |

|---|---|---|---|

TW25 | Hand Tap Wrench | $72.77 | Today |

Table Tapping Guide

Repairing a Damaged Tapped Hole

Click to Enlarge

Figure G5.2 Once the TTT001(/M) guide is properly aligned over the hole, use the TW25 Hand Tap Wrench with a 1/4"-20 tap (Item # TAP1420) or an M6 tap (Item # TAPM610) to restore the threads.

Click to Enlarge

Figure G5.1 To repair a hole with the TTT001(/M) guide, first secure it to the optical table using the included countersunk screws. These screws are designed to center the steel bushing over the damaged hole.

Click for Details

Figure G5.3 TTT001(/M) Tap Guide Dimensions

- Repair 1/4"-20 or M6 Holes in Optical Tables and Breadboards

- Bushings Help Ensure Tapped Holes are Perpendicular to the Work Surface

- Two 1/4"-20 or M6 Countersunk Mounting Screws Supplied

The TTT001(/M) Tap Guide is designed to assist in the re-drilling and re-tapping of an optical table or breadboard damaged by broken screws or cross threading. Two countersunk mounting screws (also known as flat head socket cap screws) are supplied for bolting the guide to the existing 1/4"-20- or M6-threaded hole matrix. A toughened, tool-grade steel bushing insert acts as a precise guide for drilling the broken screw out of the damaged hole. Another steel bushing guides the tap into the drilled-out hole, restoring the threads and ensuring that the resulting tapped hole is perpendicular to the work surface.

The main cause of tap breakage is unwanted sideways motion when the operator attempts to rotate the tap while simultaneously applying a force not purely parallel to the drill axis. This device discourages this costly error. We advise the use of a sharp, carbide-tipped drill bit to drill out the broken screw. When mounting the tap guide, care should be taken not to overtighten the countersunk mounting screws.

Part Number | Description | Price | Availability |

|---|---|---|---|

TTT001/M | Table Tapping Guide for M6 Threads | $71.50 | Today |

TTT001 | Table Tapping Guide for 1/4"-20 Threads | $71.50 | Today |