Fused Silica Microlens Arrays

- Plano-Convex Lens Shape

- Near Diffraction-Limited Spot Sizes

- AR Coated or Chrome Masked

- Mounted and Unmounted Versions

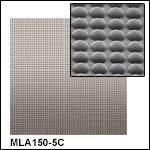

Magnified

View

MLA150-7AR

with AR Coating

MLA150-5C-M

Mounted Lens Array

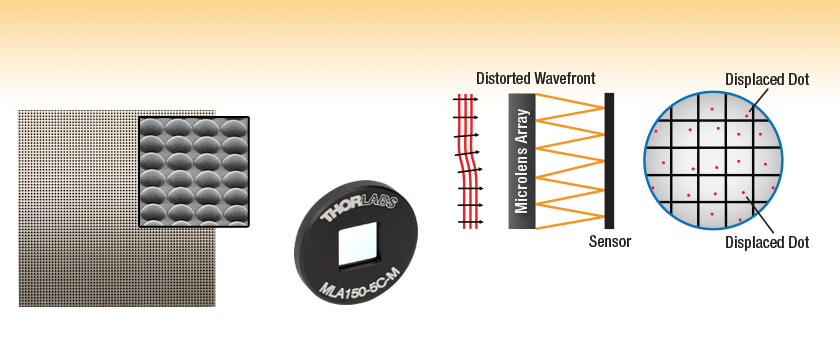

Ideally Suited for Wavefront Sensors

OVERVIEW

| Item # | MLA150-5C(-M) | MLA150-7AR(-M) | MLA300-14AR(-M) |

|---|---|---|---|

| Substrate Material | Fused Silica (Quartz) | ||

| Focal Length | 5.6 mm | 14.2 mm | |

| Effective (Optimal) Focal Length When Built into a Wavefront Sensor | 4.1 mm | 5.2 mm | 14.6 mm |

| Wavelength Range | 300 - 1100 nm | 400 - 900 nm | |

| Lens Type | Round, Refractive, Plano-Convex | Square, Refractive, Plano-Convex | |

| Lenslet Pitch | 150 µm | 300 µm | |

| Lens Size | Ø140 µm (Cr Mask Hole) |

Ø146 µm (Lens Diameter) |

295 µm (Square) |

| Fill Factor (Approximate)a | 68.4% | 74.4% | 96.7% |

| AR Coating | No | Reflectivity <1% for 400 - 900 nm | |

| Chrome Apertures | Yes, Around Microlenses | No | |

| Reflectivity | <25%b | <1% | |

| Array Size and Type | 10 mm x 10 mm x 1.2 mm, Square Grid | ||

| Mount Window Aperture (-M Versions Only) |

9 mm x 9 mm | ||

Features

- 10 mm x 10 mm High-Quality Microlens Array

- Available Unmounted or in a Ø1" Mount

- Two Wavelength Ranges Available:

- 400 - 900 nm with an AR Coating

- 300 - 1100 nm with a Chrome Mask

- Fused Silica Substrate

- Square Grid Arrangement of Microlenses

- Arrays with 150 µm or 300 µm Lenslet Pitches Available

- Near Diffraction-Limited Spot Size

- High Spot-to-Background Contrast

- Use for Custom-Built Shack-Hartmann Wavefront Sensors

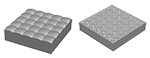

These Fused Silica Microlens Arrays are available mounted or unmounted (click here to see an enlarged photo). Fused silica offers excellent transmission characteristics from the UV to the IR. The microlenses have a plano-convex shape and are arranged in a square grid with a lens pitch of 150 µm or 300 µm. The microlens arrays with a pitch of 150 µm have round lenslets, whereas the microlens arrays with a pitch of 300 µm have square lenslets, allowing for a fill factor of 96.7%.

The MLA150-5C microlens array and its mounted counterpart have a chrome mask that blocks light from being transmitted through the spaces between microlenses, thereby increasing the contrast. The unmounted MLA150-7AR and MLA300-14AR lens arrays and their mounted versions have a broadband AR coating on both sides to reduce the surface reflections in the 400 - 900 nm spectral region to below 1%.

These lenses are formed using photolithographic techniques based on semiconductor processing technology, which allows for excellent uniformity in the shape and position of each microlens. Unlike some microlens arrays produced from molded epoxy, this method produces microlens arrays where the spot size of each microlens is nearly diffraction limited.

For the mounted versions, the microlens is glued into a Ø1", 3.5 mm thick mount plate that is compatible with all standard Ø1" optics mounts. The aperture of the lens window is 9 mm x 9 mm. Their unmounted counterparts are most easily held using one of our cylindrical lens mounts, which are specifically designed to hold square or rectangular optics.

For microlens arrays that are ideal for use in custom-built fly's eye homogenizers, please visit the PMMA Microlens Arrays page.

APPLICATION

A microlens array used in conjunction with a CCD array can constitute the core of a Shack-Hartmann wavefront sensor. As seen in the microlens array diagrams, a planar wavefront that is transmitted through a microlens array and imaged on a CCD sensor will form a regular pattern of bright spots. If, however, the wavefront is distorted, the light imaged on the CCD sensor will consist of some regularly spaced spots mixed with displaced spots and missing spots. This information can be used to calculate the shape of the wavefront that was incident on the microlens array. Shack-Hartmann type wavefront sensors can be used to characterize the performance of optical systems. In addition, they are increasingly used in applications where real-time monitoring of the wavefront is used to control an adaptive optic with the intent of removing the wavefront distortion before creating an image.

10 mm x 10 mm Unmounted Microlens Arrays

Click to Enlarge

Figure G1.1 The fill factor is dependent upon the geometry of the microlens array in the square grid. The MLA300's square microlens array (left) yields a higher fill factor than the MLA150's round microlens array (right).

- Fused Silica Substrate

- AR Coating (MLA150-7AR and MLA300-14AR) or Chrome Mask (MLA150-5C)

- Array Size: 10 mm x 10 mm x 1.2 mm

- Square Grid Arrangement of Microlenses

- Use in Custom-Built Shack-Hartmann Wavefront Sensors*

*Please Note: Pre-assembled Shack-Hartman wavefront sensors will need to be re-calibrated if these microlenses are used in place of the microlenses already built into the system. To order additional microlens arrays for Thorlabs' Shack-Hartmann Wavefront Sensors, please contact Tech Support

Part Number | Description | Price | Availability |

|---|---|---|---|

MLA150-5C | 10 mm x 10 mm Unmounted Lens Array, 300 - 1100 nm, Chrome Mask, Pitch = 150 µm, f = 5.6 mm | $518.60 | Today |

MLA150-7AR | 10 mm x 10 mm Unmounted Lens Array, ARC: 400 - 900 nm, Pitch = 150 µm, f = 5.6 mm | $518.60 | Today |

MLA300-14AR | 10 mm x 10 mm Unmounted Lens Array, ARC: 400 - 900 nm, Pitch = 300 µm, f = 14.2 mm | $518.60 | Today |

Ø1" (Ø25.4 mm) Mounted Microlens Arrays

- Compatible with Standard Ø1" Optic Mounts

- Lens Window Aperture: 9 mm x 9 mm

- Array Size: 10 mm x 10 mm x 1.2 mm

- Fused Silica Substrate

- AR Coating (MLA150-7AR-M and MLA300-14AR-M) or Chrome Mask (MLA150-5C-M)

- Square Grid Arrangement of Microlenses

- Use in Custom-Built Shack-Hartmann Wavefront Sensors*

*Please Note: Pre-assembled Shack-Hartman wavefront sensors will need to be re-calibrated if these microlenses are used in place of the microlenses already built into the system. To order additional microlens arrays for Thorlabs' Shack-Hartmann Wavefront Sensors, please contact Tech Support

Part Number | Description | Price | Availability |

|---|---|---|---|

MLA150-5C-M | Ø1" Mounted Lens Array, 300 - 1100 nm, Chrome Mask, Pitch = 150 µm, f = 5.6 mm | $574.54 | Today |

MLA150-7AR-M | Ø1" Mounted Lens Array, 400 - 900 nm AR Coating, Pitch = 150 µm, f=5.6 mm | $574.54 | Today |

MLA300-14AR-M | Ø1" Mounted Lens Array, 400 - 900 nm AR Coating, Pitch = 300 µm, f = 14.2 mm | $574.54 | Today |