Benchtop Stepper Motor Controllers

- Motor Speeds Up to 3000 RPM

- 409 600 Microsteps per Revolution of Motor

- Seamless Operation with Thorlabs Stages/Motors

Full Suite of Software Support Tools Included

BSC201

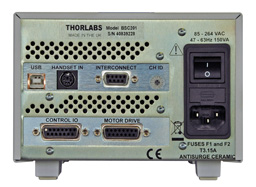

BSC201 Rear Panel

OVERVIEW

| Benchtop Motion Controllers |

|---|

| 1- and 2-Channel Brushless DC Servo Controllers |

| 1-, 2-, and 3-Channel Stepper Motor Controllers |

| 1- and 3-Channel Open Loop Piezo Controllers |

| 1- and 3-Channel Closed Loop Piezo Controllers |

| 2-Channel NanoTrak® Auto-Alignment Controller |

Figure 1.1 BSC203 (Use with Our DRV Series of Stepper Motors)

Features

- High-Resolution Microstepping Control for Very Fine Positioning Applications

- Differential Encoder Feedback (QEP Inputs) for Closed-Loop Positioning

- Motor Control I/O Port (Jogging, Interlocks)

- Full Software Control Suites Supplied with Intuitive Software Graphical Control Panels

- Fully Integrated Software for Use with Other Thorlabs Motion Controllers

The BSC200 Series of Benchtop Stepper Motor Controllers are ideal for driving high-power, 2-phase bi-polar stepper motors, either with or without encoder feedback. These controllers feature a choice between trapezoidal and S-shaped velocity profiles, a higher theoretical microstep resolution of 409 600 for a 200 full step motor, and speeds more than twice that achieved by their predecessors. These controllers have been designed for use with our DRV series of actuators (DRV208, DRV225, and DRV250*), as well as the higher power, stepper-motor-equipped nanopositioning actuators and stages offered by Thorlabs [e.g., LNR502(/M) and NRT150(/M)]. Alternatively, generic two-phase, bi-polar motors of varying step sizes can also be driven; see the Specs tab for compatible motor information.

Cables for connecting DRV series actuators to the controller are shipped with the actuators, however replacement cables are available: the 1 m long PAA612 and the 3 m long PAA613. Please note that these controllers are not suitable for use with our ZST or ZFS series of stepper motors.

USB connectivity provides easy plug-and-play PC operation. Multiple units can be connected to a single PC via standard USB hub technology for multi-axis motion control applications. Coupling this with our Kinesis or XA software applications allows the user to very quickly get up and running with reasonably complex move sequences in a short period of time. Advanced custom motion control applications and sequences are also possible using the extensive programming environments described in more detail in the Kinesis and XA Software and Kinesis Tutorials tabs.

Additionally, these controllers support Thorlabs' two-axis and three-axis joysticks, shown below. These joysticks provide intuitive, tactile, manual positioning of a stage. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box, with no need for further setup, thereby negating the requirement to be connected to a host PC and allowing true remote operation. However, depending on the actuator being driven, some software setting adjustment may be required. All cables are supplied. Please note this joystick is not compatible with former generation BSC10x series controllers.

Owners of our two-channel BSC202 controller may have their controllers upgraded by Thorlabs to support a third channel. Please contact Tech Support for more details.

*These stepper motor controllers are also compatible with our previous-generation DRV001, DRV013, and DRV014 actuators.

| Other Stepper Motor Controllers | ||

|---|---|---|

| K-Cube® Single-Channel Controller | 1-, 2-, and 3-Channel Benchtop Controller | Modular 2-Channel Rack System Module |

SPECS

| Item # | BSC201 | BSC202, BSC203 |

|---|---|---|

| Input and Output | ||

| Motor Drive Connector (15-Pin, D-Type Female) |

2-Phase Bipolar Motor Drive Output Differential Quadrature Encoder (QEP) Input Forward, Reverse Limit Switch Inputs Encoder 5 V (with Ground) |

|

| Control IO Connector (15-Pin, D-Type Female) |

Jog Forward/Back Input (TTL) User Logic Input/Output (TTL) Single-Ended Analog Input (0 - 10 V) User 5 V (with Ground) 100 mA Max Trigger Input/Output (TTL) |

|

| Motor Resolution | ||

| Microsteps per Full Step | 2048 | |

| For 200 Step Motor | 409 600 Microsteps/Rev | |

| Motor Drive Voltage | 48 V | |

| Motor Drive Power | Up to 50 W (Peak) / 25 W (Average) | |

| Motor Speeds | Up to 3000 RPM (200 Full Step Motor) | |

| Encoder Feedback Bandwidth | 500 KHz (500 000 Counts/s) | |

| Input Power Requirementsa | ||

| Voltage | 85 - 264 VAC | |

| Power | 100 W (Peak) | 200 W (Peak) |

| Fuse | 3.15 A | |

| General | ||

| Housing Dimensions (W x D x H) | 152 mm x 244 mm x 104 mm (6" x 9.6" x 4.1") | 240 mm x 360 mm x 133 mm (9.5" x 14.2" x 5.2") |

| Weight | 3.18 kg (7 lbs) | 6.7 kg (14.75 lbs) |

| Compatible Motor Specifications | ||

| Peak Powers | 15 to 50 W | |

| Average Power | 25 W (Max) | |

| Step Angle Range | 20° to 1.8° | |

| Coil Resistance (Typical) | 4 - 15 Ω | |

| Coil Inductance (Typical) | 4 - 15 mH | |

| Rated Phase Currents (Typical) | 0.1 - 1 A | |

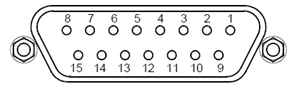

PIN DIAGRAMS

Control I/O Connector

|

Motor Drive Connector

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Computer ConnectionUSB Type B

USB Type B to Type A Cable Included |

Remote Handset ConnectorCompatible with MJC2 and MJC3 Joysticks

|

||||||||||||||

|

|

|

KINESIS AND XA SOFTWARE

Software

Kinesis Version 1.14.52

XA Version 1.0.0

The Kinesis and XA Software Packages, which include a GUI for control of Thorlabs' motion controllers.

Also Available:

- Communications Protocol

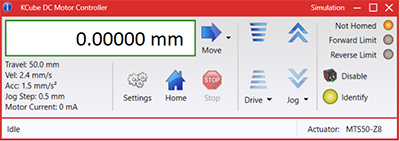

Figure 789A Kinesis GUI Screen

Thorlabs offers two platforms to drive our wide range of motion controllers: our XA software package and our Kinesis software package, which is being phased out. The Kinesis software supports most of Thorlabs' motion control products. The XA software is an improved platform for developers that currently supports some of our most popular motion control products (see the full list of supported products here). The software is undergoing continuous, intensive development and will eventually add support for our entire line of motion control products. The XA software application will be fully supported through the year 2040.

Kinesis Motion Control Software

The Kinesis software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

By providing a common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

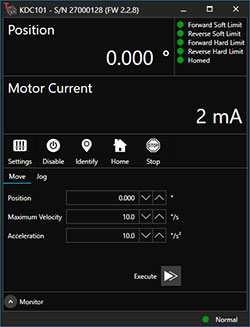

Click to Enlarge

Figure 789B XA GUI for KDC101 Brushed DC Servo Controller

The software package allows two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers out of the box, and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

XA Motion Control Software: Improved Platform for Developers

Designed from the ground up to be straightforward to understand, XA provides a thread-safe and language-paradigm-agnostic set of application programming interfaces in C, C++, and C#/.NET with language wrappers available to allow for easy integration into your native, .NET language, Python, or LabVIEW applications. This enables the same functionality as mentioned for the Kinesis software development kit (SDK) while providing a more streamlined toolkit for developers. Coupled with the included developer guides and code examples in the SDK, this software is tailored toward users interested in creating complex, customized applications and interfaces. Full API documentation is provided for the native C library, and the .NET wrapper documentation is currently under development. Please contact Tech Support for more details on using the .NET wrapper.

XA also features a comparable GUI to Kinesis while adding improvements to the user experience, like the ability to save device states and a more consistent interface across devices of different types. In addition, further improvements are planned as XA will be fully supported through the year 2040, whereas the Kinesis software is being phased out. The current version of the XA software can only drive select Thorlabs motion controllers. However, the software is undergoing continuous, intensive development and will eventually add support for our entire line of motion control products. Information on software compatibility can be found in the XA User Guide, and additional details about the software, including a list of compatible devices, can be found here.

KINESIS TUTORIALS

Thorlabs' Kinesis® software features new .NET controls which can be used by third-party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications.

C#

This programming language is designed to allow multiple programming paradigms, or languages, to be used, thus allowing for complex problems to be solved in an easy or efficient manner. It encompasses typing, imperative, declarative, functional, generic, object-oriented, and component-oriented programming. By providing functionality with this common software platform, Thorlabs has ensured that users can easily mix and match any of the Kinesis controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from the low-powered, single-axis to the high-powered, multi-axis systems and control all from a single, PC-based unified software interface.

The Kinesis System Software allows two methods of usage: graphical user interface (GUI) utilities for direct interaction and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

For a collection of example projects that can be compiled and run to demonstrate the different ways in which developers can build on the Kinesis motion control libraries, click on the links below. Please note that a separate integrated development environment (IDE) (e.g., Microsoft Visual Studio) will be required to execute the Quick Start examples. The C# example projects can be executed using the included .NET controls in the Kinesis software package (see the Kinesis Software tab for details).

|

Click Here for the Kinesis with C# Quick Start Guide Click Here for C# Example Projects Click Here for Quick Start Device Control Examples |

|

LabVIEW

LabVIEW can be used to communicate with any Kinesis-based controller via .NET controls. In LabVIEW, you build a user interface, known as a front panel, with a set of tools and objects and then add code using graphical representations of functions to control the front panel objects. The LabVIEW tutorial, provided below, provides some information on using the .NET controls to create control GUIs for Kinesis-driven devices within LabVIEW. It includes an overview with basic information about using controllers in LabVIEW and explains the setup procedure that needs to be completed before using a LabVIEW GUI to operate a device.

|

Click Here to View the LabVIEW Guide Click Here to View the Kinesis with LabVIEW Overview Page |

|

Benchtop Stepper Motor Controllers

- 1-, 2-, or 3-Channel Controllers for Stepper Motors

- Differential Encoder Feedback (QEP Inputs) for Closed-Loop Positioning

- Full Software Control Suite and USB Connectivity for Plug-and-Play PC Operation

- Ideal for Custom Applications Using Extensive Kinesis or XA Programming Interfaces

The BSC200 Series of Benchtop Stepper Motor Controllers are ideal for driving high-power, 2-phase bi-polar stepper motors, either with or without encoder feedback. These controllers have been designed to drive our DRV series of actuators (DRV208, DRV225, and DRV250*), as well as the higher power, stepper-motor-equipped nanopositioning actuators and stages offered by Thorlabs [e.g., LNR502(/M) and NRT150(/M)]. Please note that the controllers are not suitable for use with our ZST or ZFS series of stepper motors; see the Specs tab for compatible motor information.

USB connectivity provides plug-and-play PC operation and allows multiple units to be connected to a single PC using standard USB hub technology for multi-axis motion control applications. These controllers also come with extensive software support suites that includes a number of out-of-the-box user utilities, allowing for immediate operation of the unit without any detailed pre-configuration. Advanced custom motion control applications and sequences are also possible using the extensive Kinesis or XA† programming environments. Please see the Kinesis and XA Software tab for more details.

*These stepper motor controllers are also compatible with our previous-generation DRV001, DRV013, and DRV014 actuators.

†Please note BSC201 is not currently compatible with the XA software.

Part Number | Description | Price | Availability |

|---|---|---|---|

BSC201 | Customer Inspired! One-Channel Benchtop Stepper Motor Controller | $1,753.97 | Lead Time |

BSC202 | Customer Inspired! Two-Channel Benchtop Stepper Motor Controller | $2,861.79 | Lead Time |

BSC203 | Customer Inspired! Three-Channel Benchtop Stepper Motor Controller | $3,640.76 | Lead Time |

2-Axis and 3-Axis Joystick Consoles

- High-Reliability Joysticks Utilizing USB HID Protocol

- 2-Axis or 3-Axis Control Via a Joystick Knob

- Two Different Modes for Fast or High Precision Moves

- Speed Dial for Sensitivity Adjustment

- Allows Remote Manual Control

- Can be Reprogrammed Using a PC

- Ergonomic Design

The MJC2 and MJC3 Joysticks have been designed for microscope users and provide intuitive, tactile, manual positioning of a stage. The joysticks feature a two-axis joystick knob for XY control or a three-axis joystick knob for XYZ control, respectively. Both joystick knobs can be moved left or right and up or down, with the MJC3 joystick knob also twisting clockwise or counterclockwise for third axis control. A push button to switch between fast or high-precision movement and a speed dial to fine tune speed control are also integrated into the joysticks. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box with no need for further setup. This operation mode eliminates the need for connection to a host PC and allows for true remote operation. Parameter settings can also be reprogrammed and saved to a paired controller using a PC, allowing the controller to be disconnected from the computer and remote operation continued.

The MJC2 and MJC3 Joysticks are compatible with our Benchtop Brushless DC Servo Controllers, Rack-Mounted Brushless DC Servo Controller, and Stepper Motor Controllers. The joysticks have both a Mini-DIN and a USB Type-C port and are each shipped complete with two cables, a 6-pin Mini-DIN plug to plug cable and a USB 3.1 Type-A to Type-C cable, for use with these controllers as well as setups utilizing the USB HID class. For more information about configuring and setting up the joystick over USB HID, please see the manual by clicking on the red Docs icon (![]() ) below.

) below.

Part Number | Description | Price | Availability |

|---|---|---|---|

MJC2 | 2-Axis USB HID Joystick | $600.27 | Today |

MJC3 | 3-Axis USB HID Joystick | $638.47 | Today |