Zerodur® Broadband Dielectric Mirrors

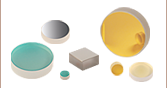

- Lower Coefficient of Thermal Expansion Than Fused Silica

- >99% Reflectance Over Specified Spectral Ranges

- Four Broadband Coatings Available

- Available in Ø1/2", Ø1", and Ø2" Sizes

BB0511-E02

Ø1/2" Mirror

BB111-E03

Ø1" Mirror

BB211-E04

Ø2" Mirror

BB111-E01

Ø1" Mirror

Please Wait

Click to Enlarge

Back View

Features

- Extremely Low Coefficient of Thermal Expansion

- Four Broadband Coatings Available:

- 350 - 400 nm

- 400 - 750 nm

- 750 - 1100 nm

- 1280 - 1600 nm

- Ravg > 99% for S- and P-Polarizations for Angles of Incidence from 0 to 45°

- Available in Ø1/2", Ø1", and Ø2" Sizes

- Designed for CW and Nanosecond Lasers

Zerodur®'s* coefficient of thermal expansion is 0 ± 0.100 x 10-6 /°C, which is significantly smaller than the value for fused silica, 0.55 x 10-6 /°C. This property makes these mirrors ideal for high-power systems like industrial machining lasers, as well as other applications that are sensitive to thermally induced beam drift. These Zerodur mirrors are available with one of four broadband coatings which offer excellent reflectance over the 350 - 400 nm, 400 - 750 nm, 750 - 1100 nm or 1280 - 1600 nm wavelength ranges (see the plot below for a comparison at near-normal incidence). Due to run-to-run coating variations, please note that the specified range listed for each coating is smaller than the actual spectral region over which the mirror is highly reflective. The plots shown under the Reflectance Plots tab show the performance characteristics of a typical mirror near the edges of its effective spectral range.

As seen in the photo to the right, the back of each mirror is engraved with its item number.

For applications which require broader reflective ranges and limited thermal expansion, Thorlabs also offers a line of metallic Zerodur mirrors. Customers can also purchase Zerodur® mirror blanks that do not have a mirror coating. For applications in which thermal expansion is not a concern, we also offer a line of standard broadband dielectric mirrors, metallic mirrors and other mirrors suitable for a wide variety of applications. Please note that these mirrors are not suitable for ultrafast applications; see our low GDD ultrafast mirrors for picosecond and femtosecond pulsed lasers.

*Zerodur® is a registered trademark of Schott.

| Mirror Specifications | ||

|---|---|---|

| Substratea | Zerodur® | |

| Surface Flatness | λ/10 @ 632.8 nm (Peak to Valley) | |

| Surface Quality | 10-5 Scratch-Dig | |

| Back Surface | Fine Ground | |

| Clear Aperture | >85% of Diameter | |

| Parallelism | ≤3 arcmin | |

| Thickness | Ø1/2" Optics | 6.0 mm (0.24") |

| Ø1" Optics | 6.0 mm (0.24") | |

| Ø2" Optics | 12.0 mm (0.47") | |

| Thickness Tolerance | ±0.2 mm | |

| Diameter Tolerance | +0.0 mm / -0.1 mm | |

| Coating Specifications | |||||

|---|---|---|---|---|---|

| Item # Suffix | -E01 | -E02 | -E03 | -E04 | |

| Wavelength Range | 350 - 400 nm | 400 - 750 nm | 750 - 1100 nm | 1280 - 1600 nm | |

| Reflectancea (Click for Graph) |

Rsand Rp >99% | Rsand Rp >99% | Rsand Rp >99% | Rs and Rp >99% | |

These plots show the reflectance of each of our dielectric coatings offered with Zerodur for a typical coating run. The shaded region in each graph denotes the spectral range over which the coating is highly reflective. Due to variations in each run, this recommended spectral range is narrower than the actual range over which the optic will be highly reflective. If you have any concerns about the interpretation of this data, please contact Tech Support. For temperature-sensitive applications that require a mirror that bridges the spectral range between two dielectric coatings, please consider a Zerodur metallic mirror.

-E01 Coating (350 - 400 nm)

-E02 Coating (400 - 750 nm)

-E03 Coating (750 - 1100 nm)

-E04 Coating (1280 - 1600 nm)

| Posted Comments: | |

Arto Salokatve

(posted 2023-11-09 11:40:44.537) What are the damage thresholds for this mirror operated with CW lasers ? jdelia

(posted 2023-11-10 08:23:36.0) Thank you for contacting Thorlabs. Unfortunately, we do not currently have enough data to characterize formal damage threshold ratings for these mirrors. I have reached out to you directly to discuss the suitability of these mirrors for your laser beam parameters. Veselin Aleksandrov

(posted 2023-01-27 12:53:47.577) Hello! Do you have an estimation of the absorption (in %) of the -E03 coating for CW laser beam at wavelength around 800 nm and incidence angles around 0? I want to estimate the heat induced surface deformations of a mirror with this coating. Thank you in advance! ksosnowski

(posted 2023-02-03 05:59:28.0) Hello Veselin, thanks for reaching out to Thorlabs. While we have not directly measured the absorption in these coatings, for the -E03 coating we have sampled some transmission data, and at 800nm and 0deg incidence the transmission is ~0.03%, which is very low. You can estimate the absorption as (1-%T-%R) for this coating. I have reached out directly to discuss this further. user

(posted 2022-12-19 17:14:07.933) Normal silver mirror(PF10-03-P01), I have experienced weakness in humidity,

We are considering buying some mirrors with zerodur glass substrates. Would you please share the information about (Humidity, Temperature) damage threshold values of BB1-E03 mirrors? ksosnowski

(posted 2022-12-28 04:06:56.0) Thanks for reaching out to Thorlabs. Silver mirror coatings are particularly sensitive to humidity and will have limited lifetime in moist environments as the coating tarnishes. Dielectric mirror coatings have significantly better lifetime than silver in elevated temperature and humidity conditions. Zerodur substrate can additionally help with issues of thermal expansion, though even fused silica substrate dielectrics may be an option for your application if humidity is the largest concern. We do not have formal damage thresholds for temperature or humidity, but the dielectric coatings are typically deposited at least at 200 degrees C, and batches are tested at 95% humidity according to MIL-PRF-13830B. pervin tüzün

(posted 2021-06-30 23:00:07.587) Dear authorities,

We are considering buying some dielectric coated mirrors with zerodur glass substrates. Would you please share the information about damage threshold values of BB1-E01, BB1-E02, BB1-E03 mirrors?

Sincerely.

Thank you. YLohia

(posted 2021-06-30 10:37:49.0) Hello, as mentioned in the comment below, unfortunately, we do not currently have enough data to characterize formal damage threshold ratings for these mirrors. I have reached out to you directly to discuss the suitability of these mirrors for your laser beam parameters. Van Rudd

(posted 2020-04-27 19:38:15.137) What are the damage thresholds for these coatings? YLohia

(posted 2020-04-29 08:35:52.0) Thank you for contacting Thorlabs. Unfortunately, we do not currently have enough data to characterize formal damage threshold ratings for these mirrors. I have reached out to you directly to discuss the suitability of these mirrors for your laser beam parameters. Chris McGahan

(posted 2019-09-17 13:13:45.557) On your page: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=9640

The first graph visible shows Reflectance vs Wavelength. The wavelength units are shown as nm. Do you mean um? YLohia

(posted 2019-09-17 02:43:43.0) Hello, thank you for your feedback and pointing out this error. We are working on updating the units to microns immediately. |

Products Home

Products Home

Zerodur Broadband Dielectric Mirrors

Zerodur Broadband Dielectric Mirrors