Clear-Edge Kinematic Mirror Mounts

- Design Provides 180° of Clear Edge

- Save Space in Laser Cavities and on Optical Tables

- Designed to Minimize Distortion in the Center of the Optic

KM2CE

Two Adjuster Mount

For Ø2" Optics

The clear edge design allows mirrors to be arranged in close proximity without clipping input and output beams.

KS1CE

Precision Three-Adjuster Mount

For Ø1" Optics

Please Wait

Click to Enlarge

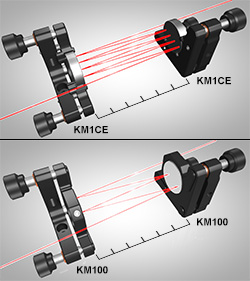

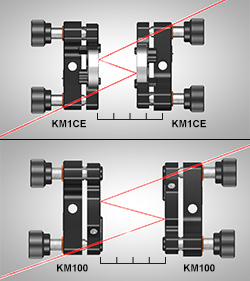

When two KM1CE (top) and two KM100 (bottom) mirror mounts are positioned at the same distance, the clear-edge design of the KM1CE allows more reflections to occur before the beam exits the two-mount system.

Click to Enlarge

For a two-mirror system designed to provide a single reflection off of each mirror surface, two KM1CE mounts (top) can be positioned in closer proximity than two KM100 mounts (bottom) while still allowing the beam to enter and exit without clipping.

Features

- 180° Clear Edge Mounts for Ø1" or Ø2" Optics

- Two-Adjuster and Precision Three-Adjuster Designs Available

- Optic Clamping Mechanism Designed to Minimize Distortion (See Performance Tab)

These Clear-Edge Mirror Mounts combine the functionality of our standard or precision mirror mounts with the added advantage of 180° of exposed optic edge. The clear-edge design allows close-proximity beam reflections to pass over the exposed outer radius of the optic without clipping on the mount's front face plate.

Some common applications are shown in the images to the right that compare our popular KM100 mount and the KM1CE. A pair of clear-edge mirror mounts can be placed much closer together than a pair of standard mounts. In addition, the beam can enter and exit the two-mirror system without clipping. Similarly, if two clear-edge mounts and two standard mounts are positioned with the same distance between each pair, the clear-edge design allows the beam to enter at a shallower angle. This provides a higher number of reflections before the beam exits the two-mirror system, an important feature for applications that use a pair of mirrors for dispersion compensation.

Each mount uses two nylon-tipped, 0.05" (1.3 mm) hex setscrews to secure an optic. The cavity that holds the optic is designed to reduce optic distortion in the center of the mirror. For more information on the clamping mechanism, see the Performance tab.

| Clear-Edge Mounts Selection Guide | ||||

|---|---|---|---|---|

| Clear Quadrant Rear-Loaded Kinematic Mounts (Ø1/2" Optics) | 180° Clear-Edge Kinematic Mounts (Ø1" and Ø2" Optics) | 142° Clear-Edge Polaris® Kinematic Mount (Ø1" Optics) | D-Shaped Mirror Mounts (Ø1/2" and Ø1" Optics) | 120° Clear-Edge, Pitch-Adjustable Flexure Mount (Ø1" Optics) |

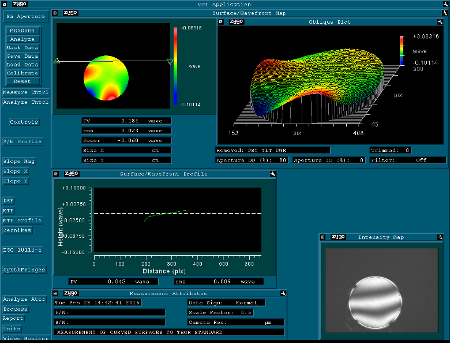

Simulation Results for KM1CE Clear-Edge Mount

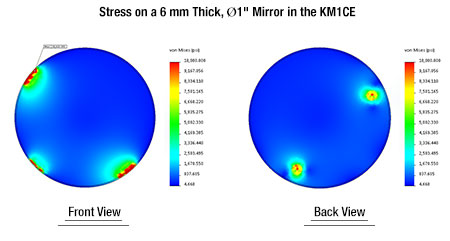

Finite element analysis (FEA) was used to design the optic-holding mechanism of the KM1CE, ensuring that stress on the optic surface is confined to the areas where the three front-located tabs and two setscrews make contact. Stress is the sum of all internal forces acting on a deformable object. The graphic below shows the results of an FEA of the distribution of stress on a BB1-E01 mirror mounted in a KM1CE. The KM2CE and KS1CE will show similar performance characteristics.

Click to Enlarge

The KM1CE mirror mount shown with a PF10-03-G01 protected aluminum mirror. The mount is designed for compatibility with Thorlabs' Ø1" mirrors and accepts Ø1" optics between 2.4 mm and 6.0 mm (0.10" and 0.25") thick.

Click to Enlarge

The plot above is an FEA calculation of the stress on a BB1-E01 mirror mounted in the KM1CE Mount. Note that the stress is isolated near the clamping points and the center and clear edge of the mirror are mostly unaffected.

| Setscrew Torque |

Peak-to-Valley Wavefront Distortiona |

RMS Wavefront Distortiona |

|---|---|---|

| 1.5 oz•in | 0.15λ | 0.020λ |

| 2.0 oz•in | 0.18λ | 0.023λ |

| 3.0 oz•in | 0.35λ | 0.041λ |

| 4.0 oz•in | 0.40λ | 0.052λ |

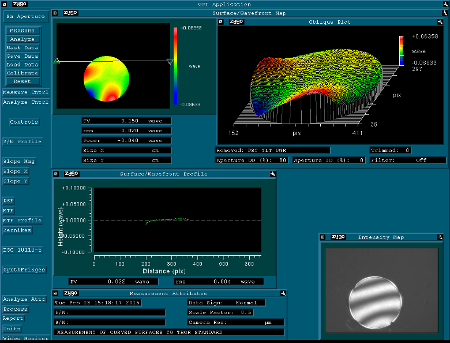

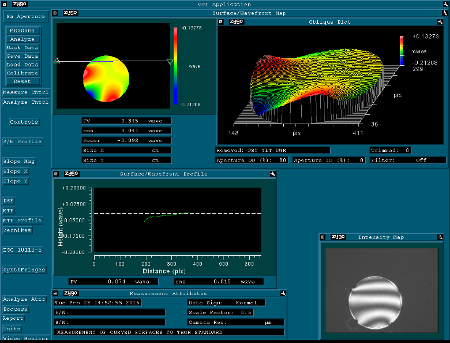

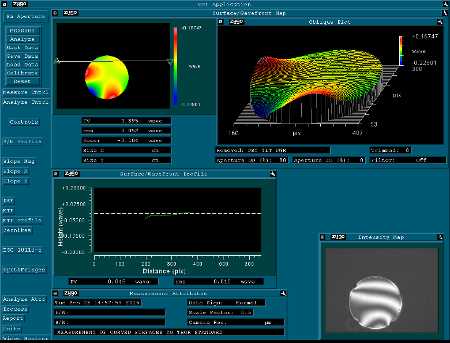

Optic Distortion Test

Procedure

A BB1-E01 mirror was installed in the KM1CE and the setscrews in the mount were tightened using the same torque. The wavefront distortion of the mounted mirror was measured using a Zygo interferometer (see the table to the right). The procedure was repeated for four torque values. Screenshots from the Zygo interferometer are shown below.

Results

As seen in the table to the right, the peak-to-valley wavefront distortion remains ≤ 0.4 waves. However, as shown in the stress plot above and four screenshots from the Zygo interferometer below, the majority of this distortion is confined to the edge of the optic where the tabs and setscrews are located, leaving the center and clear edge of the mirror with lower wavefront distortion.

Click to Enlarge

Setscrews Tightened to 1.5 oz•in

Click to Enlarge

Setscrews Tightened to 2 oz•in

Click to Enlarge

Setscrews Tightened to 3 oz•in

Click to Enlarge

Setscrews Tightened to 4 oz•in

| Posted Comments: | |

user

(posted 2024-02-07 10:47:18.15) Hi, we have lost the nylon-tipped, 0.05" (1.3 mm) hex setscrews for KM1CE. Can you please let me know the part number for the corresponding replacement hex setscrews? Thanks a lot. jdelia

(posted 2024-02-07 10:44:22.0) Thank you for contacting Thorlabs. The nylon-tipped set screw used in KM1CE is SS4N019: https://www.thorlabs.com/thorproduct.cfm?partnumber=SS4N019 Laurenz Kremeyer

(posted 2022-10-05 12:37:11.97) Clear edge post-centered mirror mounts, when? jdelia

(posted 2022-10-06 12:44:06.0) Thank you for contacting Thorlabs. While we do not currently have any immediate plans to release a post-centered version of these mounts, we do offer centering plates such as the KMCP which can be used to align any of our KM- series mounts so that the optical face is positioned in line with the post rotation axis. That being said, I could certainly forward your feedback along to our design engineers through our internal suggestion forum. Wenzel Jakob

(posted 2020-06-08 06:19:07.077) Can centering plates like KCP1 or KCP2 be used to post-center the clear-edge mounts (KM1CE, KM2CE) shown on this page? llamb

(posted 2020-06-09 08:28:33.0) Thank you for contacting Thorlabs. The KCP1 and KCP2 were primarily designed for the KM100 and KM200 kinematic mounts, and will not perfectly post-center these clear-edge mounts. The KCP1 will very nearly post-center the KM1CE, but still with an offset of ~0.01". However, the KS1CE and KM2CE would have >0.1" of offset when using the KCP1 and KCP2 plates. I would recommend the KMCP variable centering plate for these clear-edge kinematic mounts instead. |

Click to Enlarge

Front Face Plate View

- Mount Ø1" or Ø2" Optics

- KM1CE: Ø1" Optics Between 0.10" and 0.25" Thick

- KM2CE: Ø2" Optics Between 0.33" and 0.49" Thick

- Angular Adjustment: ±4° (KM1CE) or ±3° (KM2CE)

- Resolution:

- KM1CE: 8.3 mrad/rev

- KM2CE: 5.1 mrad/rev

- Two #8 (M4) Counterbores Allow Left- and Right-Handed Post Mounting

These Clear-Edge Mirror Mounts combine the functionality of our standard KM100 and KM200 mirror mounts with the added advantage of 180° of exposed optic edge. The clear-edge design allows close-proximity beam reflections to pass over the exposed outer radius of the optic without clipping on the mount's front face plate.

Each mount uses two nylon-tipped, 0.05" (1.3 mm) hex setscrews to secure an optic. The KM1CE can accept optics between 0.10" and 0.25" (2.5 mm and 6.4 mm) thick, while the KM2CE can accept optics between 0.33" and 0.48" (8.4 mm and 12.2 mm) thick.

A #8 (M4) counterbore is located on each side of the KM1CE mount, allowing it to be mounted in right- and left-handed orientations. The KM2CE mount offers six #8 (M4) counterbores (three on each arm) for the same purpose. Both mounts feature two 1/4"-80 actuators with removable adjuster knobs. The KM1CE provides ±4° of angular adjustment at a resolution of 0.48°/rev (8.3 mrad/rev) while the KM2CE provides ±3° of angular adjustment at a resolution of 0.29°/rev (5.1 mrad/rev). An optional accessory, the LN2580 bronze locking nut, is available to lock the adjusters once the desired position is reached.

- Thicker Back Plate and Stiffer Springs Provide Increased Stability Compared to Standard Mounts

- Mount Ø1" Optics Between 0.10" and 0.24" Thick

- Angular Adjustment: ±4°

- Resolution: 8.3 mrad/rev with Three Adjusters

- Two #8 (M4) Counterbores Allow Left- and Right-Handed Post Mounting

The KS1CE Clear-Edge Precision Mirror Mount combines the increased stability of our KS1 mirror mount with the added advantage of 180° of exposed optic edge. The clear-edge design allows close-proximity beam reflections to pass over the exposed outer radius of the optic without clipping on the mount's front face plate. The KS1CE mount incorporates a thicker back plate and stiffer springs than our KM1CE mount, as well as three lockable adjusters that reduce drift for stable, long-term operation.

The mount uses two nylon-tipped, 0.05" (1.3 mm) hex setscrews to secure Ø1" optics, and features three lockable 1/4"-80 actuators with removable adjuster knobs that provide ±4° of angular adjustment at a resolution of 0.48°/rev (8.3 mrad/rev). A #8 (M4) counterbore is located on each side of the KS1CE mount, allowing it to be mounted in right- and left-handed orientations.

Products Home

Products Home

Zoom

Zoom

180° Clear-Edge Kinematic Mirror Mounts

180° Clear-Edge Kinematic Mirror Mounts