Channel Screws and T-Nuts

- Low-Profile Channel Screws Feature Reduced Cap Height

- T-Nuts Accept 8-32, 1/4"-20, M4 x 0.7, or M6 x 1.0 Threaded Optomechanics

- Hammerhead Screws Provide Quick-Release Mounting Stud

XE25T1

Drop-In T-Nut, 1/4"-20

XE25T2

Drop-In T-Nut, 8-32

XT95N6

T-Nut for 95 mm Rails

XE25T3

Low-Profile T-Nut, 1/4"-20

XE25T4

Quick-Release T-Nut, 8-32

XT95N4

Drop-In T-Nut

for 95 mm Rails

SH25LP38

Low-Profile Screw,

1/4"-20

Drop-In T-Nut Fits into 95 mm Rail T-Slot

XE25H025

Hammerhead Screw,

1/4"-20

Please Wait

| Screws Selection Guide |

|---|

| Cap Screws & Nuts |

| Setscrews and Thumbscrews |

| Low Profile Screws & T-Nuts |

| Thread Adapter Screws |

| Screw Kits |

| Balldrivers and Hex Keys |

Our low-profile channel screws, hammerhead screws, and T-nuts are designed for our 25 mm, 50 mm, 75 mm, and 95 mm optical rail systems, but are also useful in applications where space is at a premium. The low-profile screws are also ideal for use with mounting platforms for our 34 mm and 66 mm rail systems. Our low-profile T-nuts are also compatible with slotted mounting platforms for 66 mm rails.

| Posted Comments: | |

weikeaep

(posted 2017-09-10 10:17:12.65) For the Low-Profile Channel Screws,only one standard is provided, could you have more options? 10mm screws is too long for me, can you provide shorter one? Such as 6 mm or 5mm. tfrisch

(posted 2017-09-20 04:19:06.0) Hello, thank you for contacting Thorlabs. I will contact you directly about your request for shorter low-profile screws. |

| Item # | Threading | Thread Length | Hex | Head Height | Quantity | Material |

|---|---|---|---|---|---|---|

| SH25LP38 | 1/4"-20 | 0.38" (9.7 mm) | 1/8" | 0.13" (3.2 mm) | 100 | Steel, Black Oxide Finish |

| SH25LP63 | 0.63" (15.9 mm) | 50 | ||||

| SH6M8LP | M6 x 1.0 | 8 mm (0.31") | 4 mm | 4 mm (0.16") | 50 | |

| SH6M10LP | 10 mm (0.39") | 100 | ||||

| SH6M16LP | 16 mm (0.63") | 50 |

Click to Enlarge

Low-Profile Screw in RM1G Construction Cube

Click to Enlarge

Standard Cap Screw in RM1G Construction Cube

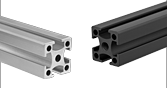

Our Low-Profile Channel Screws have a reduced cap head height relative to standard screws, permitting them to be used in tight spaces. In particular, they are recommended when neighboring screws are at a right angle and in close proximity, as in our XE25W3 Corner Cube or RM1G and RM1S Construction Cubes.

Shown to the right are a standard cap screw and a low-profile channel screw installed in an RM1G cube. The low-profile screw's shortened cap height prevents neighboring screws from interfering with each other.

The head of each screw also fits into XE rail channels for alternate construction methods, as outlined here.

Click for Details

Quick-Release T-Nut in Rail Channel

- Can Be Inserted and Removed from Any Exposed Rail Channel Without Accessing the Ends (See Animation to the Right)

- Drops into Position and Locks by Rotating

- More Surface Engagement than Drop-In and Low-Profile T-Nuts

- 8-32 (M4 x 0.7) Tapped Hole for Mounting

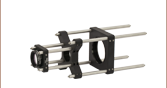

The XE25T4(/M) Quick-Release T-Nut is our most versatile option for mounting mechanics to rail channels. Its thin width profile allows it to be inserted into an exposed rail channel. After being inserted, a clockwise rotation by 90° prevents it from being removed again. Once rotated, screwing in a mechanical part draws the T-nut towards the part, eventually forcing the T-nut and rail channel to engage. The protruding edge of the 8-32 (M4 x 0.7) tapped hole centers the T-nut within the rail channel, ensuring even engagement on both sides.

To remove the quick-release T-nut, simply remove any attached mechanical parts and rotate the T-nut counterclockwise.

- Can Be Inserted and Removed from Any Exposed Rail Channel Without Accessing the Ends

- Drops into Position and Locks by Rotating

- 1/2" (12.7 mm) Long, 1/4"-20 (M6 x 1.0) Threaded Stud for Mounting

These quick-release hammerhead screws are versatile options for mounting mechanics to rail channels. Their thin width profile allows them to be inserted into an exposed rail channel. After being inserted, rotating the screw clockwise by 90° prevents it from being removed again. Once rotated, screwing on a mechanical part draws the hammerhead screw towards the part, eventually forcing the screw and rail channel to engage.

To remove the hammerhead screw, simply remove any attached mechanical parts and rotate the screw counterclockwise.

Click for Details

Drop-In T-Nut in Rail Channel

- Can Be Dropped into Any Exposed Portion of a Rail Channel Without Accessing the Ends

- Removal Requires Access to the Rail Ends

- 8-32 (M4 x 0.7) Tapped Hole or 1/4"-20 (M6 x 1.0) Tapped Hole for Mounting

Drop-in T-nuts can be dropped in along any point of an exposed rail channel, making them easy to install even if the rail ends are blocked. They are available with either an 8-32 (M4 x 0.7) tapped hole [Item # XE25T2(/M)] or 1/4"-20 (M6 x 1.0) tapped hole [Item # XE25T1(/M)].

Although these T-nuts can be easily inserted anywhere along the rail, access to the end of the rail is necessary for removal. This procedure is shown in the animation to the right. In contrast, our quick-release T-nuts, shown above, offer the added flexibility of being able to be removed when the rail ends are obstructed.

Click for Details

Low-Profile T-Nut in Rail Channel

- Can Only Be Inserted and Removed from the End of a Rail

- 1/4"-20 (M6 x 1.0) Tapped Hole for Mounting

- Economical Alternative to Drop-In and Quick-Release T-Nuts

The XE25T3(/M) Low-Profile T-Nut can be used when there is access to an XE Series rail end, which allows the T-nut to slip into place. Since installation (and removal) requires the rail end to be unobstructed, as shown in the animation to the right, this T-nut usually needs to be positioned before a mechanical construction is completed. Our quick-release and drop-in T-nuts, shown above, can be inserted even if the rail ends are blocked; the former can also be removed without access to the ends.

This T-nut is also compatible with our XT66 Series rail system mounting platforms.

Click for Details

Low-Profile T-Nut in T-Slot

- Can Only be Inserted and Removed from the End of a Rail

- M6 x 1.0 Tapped Hole for Mounting

The XT95N6 Low-Profile T-Nut slips into the T-slots along the rail side. Since installation (and removal) requires the rail end to be unobstructed, this T-nut usually needs to be positioned before a 95 mm rail assembly is completed. In contrast, the drop-in T-nut shown below can be installed and removed even if the rail ends are blocked.

Click for Details

Click for Details

- Can be Inserted and Removed from Any Exposed Portion of a T-Slot Without Access to the Rail Ends

- M4 x 0.7 Tapped Hole for Mounting

The XT95N4 Drop-In T-Nut has a thin width profile that allows it to be inserted into an exposed T-slot. After being inserted, a clockwise rotation by 90° prevents it from being removed again. The protruding edge of the M4 x 0.7 tapped hole helps to center the T-nut within the T-slot.

Products Home

Products Home

Zoom

Zoom

Low-Profile Screws and T-Nuts

Low-Profile Screws and T-Nuts