Molded Glass Aspheric Lenses: 1050 - 1620 nm or 1050 - 1700 nm AR Coating

- High NA (0.15 to 0.7)

- Diffraction-Limited Design

- Broadband AR-Coated for 1050 - 1620 nm or 1050 - 1700 nm

- Collimate or Focus Light with a Single Element

A375TM-C

A375-C

C140TMD-C

354140-C

C171TMD-C

354171-C

Application Idea

Aspheric Lens in a Fiber Launch Application

Please Wait

| Aspheric Lens Selection Guide |

|---|

| Uncoated |

| 350 - 700 nm (-A Coating) |

| 600 - 1050 nm (-B Coating) |

| 1050 - 1700 nm (-C Coating) |

| 1.8 - 3 µm (-D Coating) |

| 3 - 5 µm (-E Coating) |

| 8 - 12 µm (-F Coating) |

| 405 nm V-Coating |

| 1064 nm V-Coating |

| Webpage Features | |

|---|---|

| |

Click for complete specifications. |

| Performance Hyperlink | Click to view item-specific focal length shift data and spot diagrams at various wavelengths. |

| Click on the red Document icon next to the item numbers below to access the Zemax file download. Our entire Zemax Catalog is also available. |

Features

- Molded Glass Aspheric Lenses Designed for Infinite Magnification

- Focus or Collimate Light Without Introducing Spherical Aberration

- Available Unmounted or Pre-Mounted in Nonmagnetic 303 Stainless Steel Lens Cells

Engraved with the Item # - Broadband AR Coating for Either 1050 - 1620 nm or 1050 - 1700 nm

Aspheric lenses focus or collimate light without introducing spherical aberration into the transmitted wavefront. For monochromatic sources, spherical aberration often prevents a single spherical lens from achieving diffraction-limited performance when focusing or collimating light. Aspheric lenses are designed to mitigate the impacts of spherical aberration and are often the best single element solution for many applications including collimating the output of a fiber or laser diode, coupling light into a fiber, spatial filtering, or imaging light onto a detector.

All of the molded glass lenses featured on this page are available with an antireflection coating for either the 1050 - 1620 nm nm or 1050 - 1700 nm range deposited on both sides. Other AR coating options are listed in the Aspheric Lens Selection Guide table at right.

These lenses can be purchased unmounted or premounted in nonmagnetic 303 stainless steel lens cells that are engraved with the Item # for easy identification. All mounted aspheres have a metric thread that make them easy to integrate into an optical setup or OEM application; they can also be readily used with our SM1-threaded (1.035"-40) lens tubes by using our aspheric lens adapters. When combined with our microscope objective adapter extension tube, mounted aspheres can be used as a drop-in replacement for multi-element microscope objectives.

A selection of the lenses sold on this page are designed for collimating laser diodes. As seen in the tables below, a compatible laser window thickness is listed for these lenses. In these instances, the numerical aperture (NA), working distance (WD), and wavefront error of these lenses are defined based on the presence of a laser window of the indicated thickness (not included).

If an unmounted aspheric lens is being used to collimate the light from a point source or laser diode, the side with the greater radius of curvature (i.e., the flatter surface) should face the point source or laser diode. To collimate light using one of our mounted aspheric lenses, orient the housing so that the externally threaded end of the mount faces the source.

Molded glass aspheres are manufactured from a variety of optical glasses to yield the indicated performance. The molding process will cause the properties of the glass (e.g., Abbe number) to deviate slightly from those given by glass manufacturers. Specific material properties for each lens can be found by clicking on the Info Icon ![]() in the tables below and selecting the Glass tab.

in the tables below and selecting the Glass tab.

Choosing a Lens

Aspheric lenses are commonly chosen to couple incident light with a diameter of 1 - 5 mm into a single mode fiber. A simple example will illustrate the key specifications to consider when trying to choose the correct lens.

Example:

Fiber: P1-630A-FC-2

Collimated Beam Diameter Prior to Lens: Ø3 mm

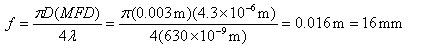

The specifications for the P1-630A-FC-2, 630 nm, FC/PC single mode patch cable indicate that the mode field diameter (MFD) is 4.3 μm. This specification should be matched to the diffraction-limited spot size given by the following equation:

![]()

Here, f is the focal length of the lens, λ is the wavelength of the input light, and D is the diameter of collimated beam incident on the lens. Solving for the desired focal length of the collimating lens yields

Thorlabs offers a large selection of mounted and unmounted aspheric lenses to choose from. The aspheric lens with a focal length that is closest to 16 mm has a focal length of 15.29 mm (Item # 354260-B or A260-B). This lens also has a clear aperture that is larger than the collimated beam diameter. Therefore, this option is the best choice given the initial parameters (i.e., a P1-630A-FC-2 single mode fiber and a collimated beam diameter of 3 mm). Remember, for optimal coupling, the spot size of the focused beam must be less than the MFD of the single mode fiber. As a result, if an aspheric lens is not available that provides an exact match, then choose one with a focal length that is shorter than the calculation above yields. Alternatively, if the clear aperture of the aspheric lens is large enough, the beam can be expanded before the aspheric lens, which has the result of reducing the spot size of the focus beam.

Click to Enlarge

Reference Drawing

Aspheric Lens Design Formula

| Definitions of Variables | |

|---|---|

| z | Sag (Surface Profile) as a Function of Y |

| Y | Radial Distance from Optical Axis |

| R | Radius of Curvature |

| k | Conic Constant |

| An | nth Order Aspheric Coefficient |

The aspheric surfaces of these lenses may be described using a polynomial expansion in Y, the radial distance from the optical axis. The surface profile or sagitta (often abbreviated as sag) is denoted by z, and is given by the following expression:

where R is the radius of curvature, k is the conic constant, and the An are the nth order aspheric coefficients. The sign of R is determined by whether the center of curvature for the lens surface is located to the right or left of the lens' vertex; a positive R indicates that the center of curvature is located to the right of the vertex, while a negative R indicates that the center of curvature is located to the left of the vertex. For example, the radius of curvature for the left surface of a biconvex lens would be specified as positive, while the radius of curvature for its right surface would be specified as negative.

Aspheric Lens Coefficients

Due to the rotational symmetry of the lens surface, only even powers of Y are contained in the polynomial expansion above. The target values of the aspheric coefficients for each product can be found by clicking either on the blue Info Icons in the tables below (![]() ) or on the red documents icon (

) or on the red documents icon (![]() ) next to each lens sold below.

) next to each lens sold below.

Choosing a Collimation Lens for Your Laser Diode

Since the output of a laser diode is highly divergent, collimating optics are necessary. Aspheric lenses do not introduce spherical aberration and are therefore are commonly chosen when the collimated laser beam is to be between one and five millimeters. A simple example will illustrate the key specifications to consider when choosing the correct lens for a given application. The second example below is an extension of the procedure, which will show how to circularize an elliptical beam.

Example 1: Collimating a Diverging Beam

- Laser Diode to be Used: L780P010

- Desired Collimated Beam Diameter: Ø3 mm (Major Axis)

When choosing a collimation lens, it is essential to know the divergence angle of the source being used and the desired output diameter. The specifications for the L780P010 laser diode indicate that the typical parallel and perpendicular FWHM beam divergences are 8° and 30°, respectively. Therefore, as the light diverges, an elliptical beam will result. To collect as much light as possible during the collimation process, consider the larger of these two divergence angles in any calculations (i.e., in this case, use 30°). If you wish to convert your elliptical beam into a round one, we suggest using an anamorphic prism pair, which magnifies one axis of your beam; for details, see Example 2 below.

Assuming that the thickness of the lens is small compared to the radius of curvature, the thin lens approximation can be used to determine the appropriate focal length for the asphere. Assuming a divergence angle of 30° (FWHM) and desired beam diameter of 3 mm:

|

|

||

| Θ = Divergence Angle | Ø = Beam Diameter | f = Focal Length | r = Collimated Beam Radius = Ø/2 |

Note that the focal length is generally not equal to the needed distance between the light source and the lens.

With this information known, it is now time to choose the appropriate collimating lens. Thorlabs offers a large selection of aspheric lenses. For this application, the ideal lens is a molded glass aspheric lens with focal length near 5.6 mm and our -B antireflection coating, which covers 780 nm. The C171TMD-B (mounted) or 354171-B (unmounted) aspheric lenses have a focal length of 6.20 mm, which will result in a collimated beam diameter (major axis) of 3.3 mm. Next, check to see if the numerical aperture (NA) of the diode is smaller than the NA of the lens:

0.30 = NALens > NADiode ≈ sin(15°) = 0.26

Up to this point, we have been using the full-width at half maximum (FWHM) beam diameter to characterize the beam. However, a better practice is to use the 1/e2 beam diameter. For a Gaussian beam profile, the 1/e2 diameter is almost equal to 1.7X the FWHM diameter. The 1/e2 beam diameter therefore captures more of the laser diode's output light (for greater power delivery) and minimizes far-field diffraction (by clipping less of the incident light).

A good rule of thumb is to pick a lens with an NA twice that of the laser diode NA. For example, either the A390-B or the A390TM-B could be used as these lenses each have an NA of 0.53, which is more than twice the approximate NA of our laser diode (0.26). These lenses each have a focal length of 4.6 mm, resulting in an approximate major beam diameter of 2.5 mm. In general, using a collimating lens with a short focal length will result in a small collimated beam diameter and a large beam divergence, while a lens with a large focal length will result in a large collimated beam diameter and a small divergence.

Example 2: Circularizing an Elliptical Beam

Using the laser diode and aspheric lens chosen above, we can use an anamorphic prism pair to convert our collimated, elliptical beam into a circular beam.

Whereas earlier we considered only the larger divergence angle, we now look at the smaller beam divergence of 8°. From this, and using the effective focal length of the A390-B aspheric lens chosen in Example 1, we can determine the length of the semi-minor axis of the elliptical beam after collimation:

r' = f * tan(Θ'/2) = 4.6 mm * tan(4°) = 0.32 mm

The minor beam diameter is double the semi-minor axis, or 0.64 mm. In order to magnify the minor diameter to be equal to the major diameter of 2.5 mm, we will need an anamorphic prism pair that yields a magnification of 3.9. Thorlabs offers both mounted and unmounted prism pairs. Mounted prism pairs provide the benefit of a stable housing to preserve alignment, while unmounted prism pairs can be positioned at any angle to achieve the exact desired magnification.

The PS883-B mounted prism pair provides a magnification of 4.0 for a 950 nm wavelength beam. Because shorter wavelengths undergo greater magnification when passing through the prism pair, we can expect our 780 nm beam to be magnified by slightly more than 4.0X. Thus, the beam will still maintain a small degree of ellipticity.

Alternatively, we can use the PS871-B unmounted prism pair to achieve the precise magnification of the minor diameter necessary to produce a circular beam. Using the data available here, we see that the PS871-B achieves a magnification of 4.0 when the prisms are positioned at the following angles for a 670 nm wavelength beam:

| α1: +34.608° | α2: -1.2455° |

Refer to the diagram to the right for α1 and α2 definitions. Our 780 nm laser will experience slightly less magnification than a 670 nm beam passing through the prisms at these angles. Some trial and error may be required to achieve the exact desired magnification. In general:

- To increase magnification, rotate the first prism clockwise (increasing α1) and rotate the second prism counterclockwise (decreasing α2).

- To reduce magnification, rotate the first prism counterclockwise (decreasing α1) and rotate the second prism clockwise (increasing α2).

| Posted Comments: | |

user

(posted 2024-03-19 09:28:54.087) Hi,

Do you know if your dielectric coatings (A,B, or C) are vacuum compatible for UHV applications?

Thank you cdolbashian

(posted 2024-03-29 01:52:00.0) Thank you for reaching out to us with this inquiry. While we have not tested these coatings at the pressure you are inquiring after (10^-10mbar), we do expect them to work. I have contacted you directly to discuss this further. Alexander Novikov

(posted 2023-05-15 14:59:06.16) Hi,

What is the transmission or reflection for the Coating C (for lens 355110-C) extended to 2 µm?

Thank you. jdelia

(posted 2023-05-16 09:15:18.0) Thank you for contacting Thorlabs. I have reached out to you directly with this data. For future reference, the reflectance data for the -C coating used in 351100-C up to 2 um can be found in our Optical Coatings Tutorial at the following link: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=5840&tabname=ARCoating. Gary Halama

(posted 2023-03-13 13:13:05.937) Please send the zemax file for a spheric lens C30TM-C. Thank you. jdelia

(posted 2023-03-23 04:01:11.0) Thank you for reaching out. I have contacted you directly with the relevant file for our obsolete lens C340TM-C. user

(posted 2022-06-02 06:33:35.567) Many of your aspheres list two values for the clear aperture (e.g. C240TMD has S1: 8 & S2: 6.94 [mm]). Does this mean the actual NA of this lens is not 0.5 but closer to 6.94/(2*8)=0.43? Should I rather choose another lens without the reduced clear aperture (e.g. A240TM) if I need high NA? cdolbashian

(posted 2022-06-06 10:31:42.0) Thank you for reaching out to us with this inquiry. I think there must be some mistake as the 8mm is indeed the smaller diameter side (curved side), and the larger side is 9.94mm rather than 6.94. Using the small angle approximation, NA is represented simply as D/(2*f), where D is the diameter of the lens, and f is the focal length. In order to find a lens with a high NA, you can select one with a shorter focal length or correspondingly larger diameter. I apologize if I have not addressed your question as intended, but as you have not left and email address, I am unable to reach out to you to clarify this. If you have additional inquiries regarding your inquiry, please feel free to email Techsupport@thorlabs.com. Ariel Lipson

(posted 2022-05-18 19:13:47.45) Hi,

Is it possible to get the zemax file for this lens?

Thanks cdolbashian

(posted 2022-05-20 04:45:00.0) Thank you for reaching out to us Ariel. I have contacted you with this information. We should have this updated to the website shortly as well! Chris Brooks

(posted 2021-10-12 04:15:10.883) Hello,

Some lenses with a C-coating are specified up to 1620nm, while others are specified up to 1700nm. What is the reason for this shift in wavelength coverage? Is it related to the lens geometry or glass?

Thanks in advance. YLohia

(posted 2021-12-22 02:55:44.0) Hello, thank you for contacting Thorlabs. I have reached out to you directly to discuss this further. Gregory Iu

(posted 2021-08-10 15:35:02.587) Unit Typo (nm) on Outer Diameter for 354560-C and C560TME-C. cdolbashian

(posted 2021-08-19 03:27:55.0) Thank you for your feedback on this! We strive to have our product pages contain as much accurate information as possible. This will be corrected asap! Alberto Carrasco

(posted 2019-08-30 15:29:47.227) Single-mode fibers typically have NAs around 0.1. However, all these lenses have much bigger NAs. I understand you can use them to collimate a laser, but I cannot understand how you can use them to focus a collimated laser into a single-mode fiber, because in all cases the NA of the fiber is smaller than the NA of the lens. nbayconich

(posted 2019-09-03 12:46:13.0) Thank you for contacting Thorlabs. Using a lens with a larger NA than a particular fiber with a smaller NA doesn't necessarily mean that you could not focus light into that type of fiber. As long as most of the light that is focused by the collimating lens does not exceed the acceptance angle of the selected fiber, which is determined by the numerical aperture, then you can still couple light into the fiber with relatively high coupling efficiency. The angle that light enters the fiber will be determined by several factors, one being the collimated beam diameter of your source and two the focal length of the selected lens. Reducing the collimated beam diameter will reduce the effective NA of the collimating lens in use, you can estimate NA by using the equation NA=Ø/(2*f).

You will also want to take into consideration the size of the focused spot that will be produced by your collimating lens so that it matches the MFD of the fiber. More information regarding how to calculate the focused spot size can be found under our "Fiber Coupling" tutorial section. Yitzi Calm

(posted 2019-07-01 08:13:04.25) Looking at part # C392TME-C, spec'ed NA = 0.64. If I use: NA = n*a/sqrt(a^2+f^2)

where:

a = 1.8 mm = CA/2

f = 2.75 mm

n = 1 (immersion index)

then I get NA = 0.55.

I understand the formula I used may not be correct. Actually that's the spirit of my inquiry, I'd like to learn what's the correct formula.

Best Regards,

Yitzi nbayconich

(posted 2019-07-01 02:11:16.0) Thank you for contacting Thorlabs, the calculation you provided is useful for thin lenses however cannot be used to accurately determine the NA of an aspheric lens with a high numerical aperture. To get a more accurate value you will have to take the sine of the marginal ray angle. It's easier to see how to calculate this through ray tracing, I will contact you directly to discuss your application. thha

(posted 2019-02-21 04:30:41.003) Hi...

let me know, refletcance value at 650 nm.

about ** % YLohia

(posted 2019-02-21 12:10:23.0) Hello, thank you for contacting Thorlabs. We will reach out with this out-of-range data directly. hij33153

(posted 2018-07-07 09:07:49.58) Hey... What is the spot size at focusing place in the A280TM-C?. Is it okay to understand the rms radius is same with the spot size at focusing place?? YLohia

(posted 2018-07-09 12:20:26.0) Hello, the focused spot size depends on the input beam diameter and the wavelength. Please see the spot diameter information we have on this lens here: https://www.thorlabs.com/images/TabImages/A280_Asph.pdf. RMS beam size is just a different way of characterizing a beam size. Alternate ways of characterizing beam size would be 1/e^2, FWHM, etc. ee14d209

(posted 2018-02-14 22:57:41.733) Dear Sir,

We are using C280TMD-C at 1064 nm, can you please let me know the refractive index and extension coefficient of the material used for C280TMD-C.

Thanks, nbayconich

(posted 2018-02-23 09:49:05.0) Thank you for contacting Thorlabs. The material used in C280TMD-C is D-ZK3 which has a refractive index of 1.574 at 1064nm along with an extinction coefficient of 1.6951 x 10^-8 and coefficient of thermal expansion of 7.6 x 10^-6 / °C. I'll reach out to you directly with more information. m.barrett

(posted 2017-08-10 13:00:40.207) What is the damage threshold for the A397TM-C? Thanks tfrisch

(posted 2017-08-16 05:53:32.0) Hello, thank you for contacting Thorlabs. While we don't have any formal damage threshold specs on the molded aspheric lenses, I would expect it to be lower than polished lenses. I will reach out to you directly to discuss the specs of your source. loic.merceron

(posted 2017-04-28 16:28:31.86) Do you have the damage threshold of those lenses? Thanks tfrisch

(posted 2017-05-16 11:16:42.0) Hello, thank you for contacting Thorlabs. I will reach out to you directly about your application. mchen

(posted 2015-07-14 10:32:57.98) Do you have the data of C-coating extended to 2 micron? Thanks! besembeson

(posted 2015-07-23 04:59:13.0) Response from Bweh at Thorlabs USA: We don't have data extended to 2um. I will followup with you regarding measuring this. tcohen

(posted 2012-04-16 12:49:00.0) Response from Tim at Thorlabs: The dispersion formula used for these materials is actually the Schott formula. I will contact you with the information including the coefficients and min/max wavelength ranges. hungwen

(posted 2012-04-16 03:59:45.0) Could you also send me the Sellmeier coefficients of these glasses too? (ex: D-ZK3, ECO-550) Thank you! bdada

(posted 2012-01-09 19:21:00.0) Response from Buki at Thorlabs:

The unmounted lens is 352280-1064 and the drawing is linked below. One surface is flat and the other surface is curved outward. Please refer to the drawing linked below for more information and contact TechSupport@thorlabs.com if you have any questions:

http://www.thorlabs.com/Thorcat/19700/19773-E0W.pdf niels.martinsen

(posted 2012-01-01 14:20:56.0) Hi

Is the C280TME-C lens plano convex/concave? In other words, can I regard it as a thin lens?

Cheers,

Niels. jjurado

(posted 2011-03-22 13:38:00.0) Response from Javier at Thorlabs to clarafly: Thank you very much for contacting us. I will send you this information shortly. clarafly

(posted 2011-03-22 18:57:18.0) Can you provide the Sellmeier coefficients of these glasses so that we can simulate the performance of these lenses? Thanks! |

| AR Coating Abbreviations | |

|---|---|

| Abbreviation | Description |

| U | Uncoated: Optics Do Not have an AR Coating |

| A | Broadband AR Coating for the 350 - 700 nm Range |

| B | Broadband AR Coating for the 600 - 1050 nm or 650 - 1050 nm Range |

| C | Broadband AR Coating for the 1050 - 1620 nm or 1050 - 1700 nm Range |

| V | Narrowband AR Coating Designed for the Wavelength Listed in the Table Below |

The table below contains all molded visible and near-IR aspheric lenses offered by Thorlabs. For our selection of IR molded aspheres, click here. The Item # listed is that of the unmounted, uncoated lens. An "X" in any of the five AR Coating Columns indicates the lens is available with that coating (note that the V coating availability is indicated with the AR coating wavelength). The table to the right defines each letter and lists the specified AR coating range. Clicking on the X takes you to the landing page where that lens (mounted or unmounted) can be purchased.

| Base Item # | AR Coating Options | Effective Focal Length |

NA | Outer Diameter of Unmounted Lens |

Working Distance | Clear Aperture of Unmounted Lens |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| U | A | B | C | V | Unmounted | Mounted | |||||

| 354710 | X | X | X | X | 1.5 mm | 0.5 | 2.650 mm | 0.5 mma | 0.4 mma,b | S1: Ø1.15 mm S2: Ø1.50 mm |

|

| 354140 | X | X | X | X | 1.5 mm | 0.6 | 2.400 mm | 0.8 mmc | 0.8 mmc | S1: Ø1.14 mm S2: Ø1.60 mm |

|

| 355151 | X | X | X | X | 2.0 mm | 0.5 | 3.000 mm | 0.5 mma | 0.3 mma,b | S1: Ø1.09 mm S2: Ø2.00 mm |

|

| 355440 | X | X | X | X | 2.8 mm | S1: 0.3 S2: 0.5 |

4.700 mm | S2: 7.1 mmc |

S1: 1.8 mma,b S2: 7.09 mmc |

S1: Ø3.76 mm S2: Ø4.12 mm |

|

| 355392 | X | X | X | X | 2.8 mm | 0.6 | 4.000 mm | 1.5 mmc | 1.0 mmb,c | S1: Ø2.50 mm S2: Ø3.60 mm |

|

| 355390 | X | X | X | X | 2.8 mm | 0.6 | 4.500 mm | 2.2 mmc | 2.0 mmb,c | S1: Ø3.60 mm S2: Ø3.60 mm |

|

| 355660 | X | X | X | X | 3.0 mm | 0.5 | 4.000 mm | 1.6 mmc | 1.3 mmb,c | S1: Ø2.35 mm S2: Ø3.60 mm |

|

| 354330 | X | X | X | X | 3.1 mm | 0.7 | 6.325 mm | 1.8 mmc | 1.8 mmb,c | S1: Ø3.84 mm S2: Ø5.00 mm |

|

| N414 | X | X | X | 3.30 mm | 0.47 | 4.50 mm | 1.94 mmc | 1.83 mmb,c | Ø3.52 mm | ||

| 354340 | X | X | X | 4.0 mm | 0.6 | 6.325 mm | 1.48 mma | 1.2 mma,b | S1: Ø3.77 mm S2: Ø5.10 mm |

||

| 357610 | X | X | X | 4.0 mm | 0.6 | 6.325 mm | 1.5 mma | 1.1 mma,b | S1: Ø3.39 mm S2: Ø4.80 mm |

||

| 357775 | X | X | X | 405 | 4.0 mm | 0.6 | 6.325 mm | 1.9 mma | 1.5 mma,b | S1: Ø3.45 mm S2: Ø4.80 mm |

|

| 354350 | X | X | X | 4.5 mm | 0.4 | 4.700 mm | 2.2 mmc | 1.6 mmb,c | S1: Ø2.05 mm S2: Ø3.70 mm |

||

| 355230 | X | X | X | X | 1064 | 4.5 mm | 0.6 | 6.325 mm | 2.8 mma | 2.4 mma,b | S1: Ø3.93 mm S2: Ø5.07 mm |

| A230 | X | X | X | X | 4.51 mm | 0.55 | 6.34 mm | 2.91 mmc | 2.53 mmb,c | Ø4.95 mm | |

| 354453 | X | X | X | X | 4.6 mm | 0.5 | 6.000 mm | 2.0 mma | 0.9 mma,b | S1: Ø3.38 mm S2: Ø4.80 mm |

|

| A390 | X | X | 4.60 mm | 0.53 | 6.00 mm | 2.70 mmc | 1.64 mmb,c | Ø4.89 mm | |||

| 354430 | X | X | X | 5.0 mm | 0.2 | 2.000 mm | 4.4 mmc | 4.0 mmb,c | S1: Ø1.40 mm S2: Ø1.60 mm |

||

| 354105 | X | X | X | X | 5.5 mm | 0.6 | 7.200 mm | 3.1 mma | 2.0 mma,b | S1: Ø4.96 mm S2: Ø6.00 mm |

|

| 354171 | X | X | X | X | 6.2 mm | 0.3 | 4.700 mm | 3.4 mma | 2.8 mma,b | S1: Ø2.72 mm S2: Ø3.70 mm |

|

| 355110 | X | X | X | X | 1064 | 6.2 mm | 0.4 | 7.200 mm | 2.7 mma | 1.6 mma,b | S1: Ø2.93 mm S2: Ø5.00 mm |

| A110 | X | X | X | X | 6.24 mm | 0.40 | 7.20 mm | 3.39 mmc | 2.39 mmb,c | Ø5.00 mm | |

| A375 | X | X | X | 7.50 mm | 0.30 | 6.51 mm | 5.90 mmc | 5.59 mmb,c | Ø4.50 mm | ||

| 354240 | X | X | X | X | 1064 | 8.0 mm | 0.5 | 9.950 mm | 4.9 mma | 3.8 mma,b | S1: Ø6.94 mm S2: Ø8.00 mm |

| A240 | X | X | X | X | 8.00 mm | 0.50 | 9.94 mm | 5.92 mmc | 4.79 mmb,c | Ø8.00 mm | |

| 354060 | X | X | X | X | 9.6 mm | 0.3 | 6.325 mm | 7.5 mma | 7.1 mma,b | S1: Ø5.13 mm S2: Ø5.20 mm |

|

| 354061 | X | X | X | X | 11.0 mm | 0.2 | 6.325 mm | 8.9 mma | 8.5 mma,b | S1: Ø4.63 mm S2: Ø5.20 mm |

|

| A220 | X | X | X | 11.00 mm | 0.26 | 7.20 mm | 7.97 mmc | 6.91 mmb,c | Ø5.50 mm | ||

| 354220 | X | X | X | X | 1064 | 11.0 mm | 0.3 | 7.200 mm | 6.9 mma | 5.8 mma,b | S1: Ø4.07 mm S2: Ø5.50 mm |

| 355397 | X | X | X | X | 11.0 mm | 0.3 | 7.200 mm | 9.3 mma | 8.2 mma,b | S1: Ø6.24 mm S2: Ø6.68 mm |

|

| A397 | X | X | X | 11.00 mm | 0.30 | 7.20 mm | 9.64 mmc | 8.44 mmb,c | Ø6.59 mm | ||

| 354560 | X | X | X | X | 13.86 mm | 0.2 | 6.325 mm | 12.1 mmc | 11.7 mmb,c | S1: Ø4.54 mm S2: Ø5.10 mm |

|

| A260 | X | X | X | 15.29 mm | 0.16 | 6.50 mm | 14.09 mmc | 13.84 mmb,c | Ø5.00 mm | ||

| 354260 | X | X | X | X | 15.3 mm | 0.2 | 6.500 mm | 12.7 mma | 12.4 mma,b | S1: Ø4.61 mm S2: Ø5.00 mm |

|

| A280 | X | X | X | 18.40 mm | 0.15 | 6.50 mm | 17.13 mmc | 16.88 mmb,c | Ø5.50 mm | ||

| 354280 | X | X | X | X | 1064 | 18.4 mm | 0.15 | 6.500 mm | 15.9 mma | 15.6 mma,b | S1: Ø5.15 mm S2: Ø5.50 mm |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354140-C | 1.5 mm | 0.58 | 2.400 mm | 0.8 mmd | S1: Ø1.14 mm S2: Ø1.60 mm |

1.020 mm | 780 nm | 1050 - 1700 nm | - | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C140TMD-C | 6.2 mm | M6 x 0.5 | SPW306 | |||||||||||

| 354710-C | 1.5 mm | 0.53 | 2.650 mm | 0.5 mme | S1: Ø1.15 mm S2: Ø1.50 mm |

0.863 mm | 1550 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C710TMD-C | 6.2 mm | 0.4 mme,f | M6 x 0.5 | SPW306 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 355151-C | 2.0 mm | 0.50 | 3.000 mm | 0.5 mmd | S1: Ø1.09 mm S2: Ø2.00 mm |

1.892 mm | 780 nm | 1050 - 1700 nm | 0.250 mm | D-ZLaF52LA | Focal Shift / Spot Size Cross Section |

- | - | |

| C151TMD-C | 6.2 mm | 0.3 mmd,e | M6 x 0.5 | SPW306 | ||||||||||

| 355390-C | 2.8 mm | 0.55 | 4.500 mm | 2.2 mmf | S1: Ø3.60 mm S2: Ø3.60 mm |

1.900 mm | 830 nm | 1050 - 1700 nm | - | D-ZLaF52LA | 390_Asph.pdf | - | - | |

| C390TME-C | 8.2 mm | 2.0 mme,f | M8 x 0.5 | SPW308 | ||||||||||

| 355392-C | 2.8 mm | 0.60 | 4.000 mm | 1.5 mmf | S1: Ø2.50 mm S2: Ø3.60 mm |

2.240 mm | 830 nm | 1050 - 1700 nm | - | D-ZLaF52LA | 392_Asph.pdf | - | - | |

| C392TME-C | 6.2 mm | 1.0 mme,f | M6 x 0.5 | SPW306 | ||||||||||

| 355440-C | 2.8 mm | S1: 0.26 S2: 0.52 |

4.700 mm | S1: 2.0 mmd S2: 7.1 mmf,g |

S1: Ø3.76 mm S2: Ø4.12 mm |

3.827 mm | 980 nm | 1050 - 1700 nm | 0.250 mm | D-ZLaF52LA | Focal Shift / Spot Size Cross Section |

- | - | |

| C440TMD-C | 8.2 mm | S1: 1.8 mmd,e S2: 7.1 mmf,g |

M8 x 0.5 | SPW308 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 355660-C | 3.0 mm | 0.52 | 4.000 mm | 1.6 mmd | S1: Ø2.35 mm S2: Ø3.60 mm |

2.500 mm | 1550 nm | 1050 - 1700 nm | - | D-ZLaF52LA | 660_Asph.pdf | - | - | |

| C660TME-C | 8.2 mm | 1.3 mmd,e | M8 x 0.5 | SPW308 | ||||||||||

| 354330-C | 3.1 mm | 0.70 | 6.325 mm | 1.8 mmd | S1: Ø3.84 mm S2: Ø5.00 mm |

3.214 mm | 830 nm | 1050 - 1700 nm | - | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C330TMD-C | 9.2 mm | M9 x 0.5 | SPW301 | |||||||||||

| N414-C | 3.30 mm | 0.47 | 4.50 mm | 1.94 mmf | S2: Ø3.52 mm | 3.87 mm | 670 nm | 1050 - 1700 nm | 0.25 mm | H-ZLaF52 | N414_Asph.pdf | - | - | |

| N414TM-C | 6.2 mm | 1.8 mme,f | M6 x 0.5 | SPW306 |

| Item # (Unmounted/ Mounted |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354350-C | 4.5 mm | 0.40 | 4.700 mm | 2.2 mmd | S1: Ø2.05 mm S2: Ø3.70 mm |

3.649 mm | 980 nm | 1050 - 1700 nm | - | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C350TMD-C | 8.2 mm | 1.6 mmd,e | M8 x 0.5 | SPW308 | ||||||||||

| 355230-C | 4.5 mm | 0.55 | 6.325 mm | 2.8 mmf | S1: Ø3.93 mm S2: Ø5.07 mm |

2.708 mm | 780 nm | 1050 - 1700 nm | 0.250 mm | D-ZLaF52LA | Focal Shift / Spot Size Cross Section |

- | - | |

| C230TMD-C | 9.2 mm | 2.4 mme,f | M9 x 0.5 | SPW301 | ||||||||||

| A230-C | 4.51 mm | 0.55 | 6.34 mm | 2.91 mmd | Ø4.95 mm | 2.94 mm | 780 nm | 1050 - 1620 nm | 0.25 mm | S-NPH1 | A230_Asph.pdf | - | - | |

| 354453-C | 4.6 mm | 0.50 | 6.000 mm | 2.0 mmf | S1: Ø3.38 mm S2: Ø4.80 mm |

3.135 mm | 655 nm | 1050 - 1700 nm | 0.275 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C453TMD-C | 9.2 mm | 0.9 mme,f | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354430-C | 5.0 mm | 0.15 | 2.000 mm | 4.4 mmd | S1: Ø1.40 mm S2: Ø1.60 mm |

0.991 mm | 1550 nm | 1050 - 1700 nm | - | D-ZK3 | 430_Asph.pdf | - | - | |

| C430TME-C | 6.2 mm | 4.2 mmd,e | M6 x 0.5 | SPW306 | ||||||||||

| 354105-C | 5.5 mm | 0.60 | 7.200 mm | 3.1 mmf | S1: Ø4.96 mm S2: Ø6.00 mm |

2.937 mm | 633 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C105TMD-C | 9.2 mm | 2.0 mme,f | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354171-C | 6.2 mm | 0.30 | 4.700 mm | 3.4 mmd | S1: Ø2.72 mm S2: Ø3.70 mm |

3.484 mm | 633 nm | 1050 - 1700 nm | 0.275 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C171TMD-C | 8.2 mm | 2.8 mmd,e | M8 x 0.5 | SPW308 | ||||||||||

| 355110-C | 6.2 mm | 0.40 | 7.200 mm | 2.7 mmd | S1: Ø2.93 mm S2: Ø5.00 mm |

5.158 mm | 780 nm | 1050 - 1700 nm | 0.275 mm | D-ZLaF52LA | Focal Shift / Spot Size Cross Section |

- | - | |

| C110TMD-C | 9.2 mm | 1.6 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| A110-C | 6.24 mm | 0.40 | 7.20 mm | 3.39 mmf | Ø5.00 mm | 5.36 mm | 780 nm | 1050 - 1620 nm | 0.275 mm | H-LaK54 | A110_Asph.pdf | - | - | |

| A110TM-C | 9.24 mm | 2.39 mme,f | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A375-C | 7.50 mm | 0.30 | 6.51 mm | 5.90 mmd | Ø4.50 mm | 2.75 mm | 810 nm | 1050 - 1620 nm | 0.275 mm | H-LaK54 | A375_Asph.pdf | - | - | |

| A375TM-C | 9.24 mm | 5.59 mmd,e | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354240-C | 8.0 mm | 0.50 | 9.936 mm | 4.9 mmd | S1: Ø6.94 mm S2: Ø8.00 mm |

3.434 mm | 780 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C240TMD-C | 12.2 mm | 3.8 mmd,e | M12 x 0.5 | SPW302 | ||||||||||

| A240-C | 8.00 mm | 0.50 | 9.94 mm | 5.92 mmf | Ø8.00 mm | 3.69 mm | 780 nm | 1050 - 1620 nm | 0.25 mm | D-LaK6 | A240_Asph.pdf | - | - | |

| A240TM-C | 12.24 mm | 4.79 mme,f | M12 x 0.5 | SPW302 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354060-C | 9.6 mm | 0.27 | 6.325 mm | 7.5 mmd | S1: Ø5.13 mm S2: Ø5.20 mm |

2.493 mm | 633 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C060TMD-C | 9.2 mm | 7.1 mmd,e | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354061-C | 11.0 mm | 0.24 | 6.330 mm | 8.9 mmd | S1: Ø4.63 mm S2: Ø5.20 mm |

2.434 mm | 633 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C061TMD-C | 9.2 mm | 8.5 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| 354220-C | 11.0 mm | 0.25 | 7.200 mm | 6.9 mmd | S1: Ø4.07 mm S2: Ø5.50 mm |

5.032 mm | 633 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C220TMD-C | 9.2 mm | 5.8 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| 355397-C | 11.0 mm | 0.30 | 7.200 mm | 9.3 mmd | S1: Ø6.24 mm S2: Ø6.68 mm |

1.947 mm | 670 nm | 1050 - 1700 nm | 0.275 mm | D-ZLaF52LA | Focal Shift / Spot Size Cross Section |

- | - | |

| C397TMD-C | 9.2 mm | 8.2 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| A397-C | 11.00 mm | 0.30 | 7.20 mm | 9.64 mmf | Ø6.59 mm | 2.20 mm | 670 nm | 1050 - 1620 nm | 0.275 mm | H-LaK54 | A397_Asph.pdf | - | - | |

| A397TM-C | 9.24 mm | 8.44 mme,f | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354560-C | 13.9 mm | 0.18 | 6.325 mm | 12.1 mmc | S1: Ø4.54 mm S2: Ø5.10 mm |

2.773 mm | 650 nm | 1050 - 1700 nm | D-ZK3 | 560_Asph.pdf | - | - | |

| C560TME-C | 9.2 mm | 11.7 mmc,d | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354260-C | 15.3 mm | 0.16 | 6.500 mm | 12.7 mmd | S1: Ø4.61 mm S2: Ø5.00 mm |

2.209 mm | 780 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C260TMD-C | 9.2 mm | 12.4 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| A260-C | 15.29 mm | 0.16 | 6.50 mm | 14.09 mmf | Ø5.00 mm | 2.20 mm | 780 nm | 1050 - 1620 nm | 0.25 mm | H-LaK54 | A260_Asph.pdf | - | - | |

| A260TM-C | 9.24 mm | 13.84 mme,f | M9 x 0.5 | SPW301 |

| Item # (Unmounted/ Mounted) |

Info | EFLa | NA | OD | WDb | CA | TC | DW | AR Range | LWTc | Glass | Performance | Thread | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 354280-C | 18.4 mm | 0.15 | 6.500 mm | 15.9 mmd | S1: Ø5.15 mm S2: Ø5.50 mm |

2.178 mm | 780 nm | 1050 - 1700 nm | 0.250 mm | D-ZK3 | Focal Shift / Spot Size Cross Section |

- | - | |

| C280TMD-C | 9.2 mm | 15.6 mmd,e | M9 x 0.5 | SPW301 | ||||||||||

| A280-C | 18.40 mm | 0.15 | 6.50 mm | 17.13 mmf | Ø5.50 mm | 2.17 mm | 780 nm | 1050 - 1620 nm | 0.25 mm | H-LaK54 | A280_Asph.pdf | - | - | |

| A280TM-C | 9.24 mm | 16.75 mme,f | M9 x 0.5 | SPW301 |

Products Home

Products Home

Molded Glass Aspheres: C Coated

Molded Glass Aspheres: C Coated