1" (25 mm) Travel Dovetail Translation Stages

- Dovetail Design for 1" (25 mm) of Smooth Motion

- Lockable Translation Platform

- Modular Design for Multi-Axis Configurations

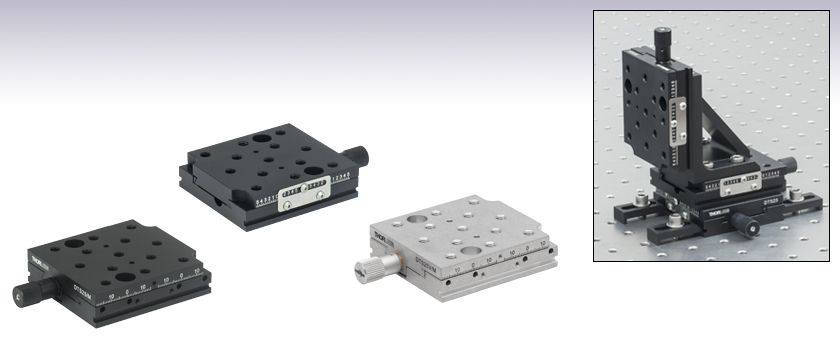

Application Idea

XYZ Configuration Built with Three DTS25 Stages and a DTSA03 Angle Bracket Secured with CL6 Dovetail Clamps

DTS25/M

Front View

DTS25

Back View with Locking Bracket

DTS25V/M

Vacuum Compatible Down to 10-6 Torr

Please Wait

| Item # | DTS25(/M) | DTS25V(/M) |

|---|---|---|

| Travel Range | 1" (25 mm) | |

| Mounting Holes | 1/4"-20 (M6 x 1.0) Taps, 13 Places | |

| Horizontal Load Capacity | 88 lbs (40 kg) | |

| Vertical Load Capacity | 22 lbs (10 kg) | |

| Travel per Revolution | 0.04" (1.0 mm) | |

| Top Surface Parallelism | 1700 µrad | |

| Angular Deviation | ±250 µrad | |

| Straightness | Horizontal: ±10.00 µm Vertical: ±5.00 µm |

|

| Stiffness | Pitch: 200.00 µrad / N·m Yaw: 725.00 µrad / N·m |

|

| Vacuum Compatibility | - | 10-6 Torr |

| Operating Temperature | - | 10 °C to 130 °C (50 °F to 266 °F) |

| Maximum Baking Temperature | - | 130 °C (266 °F) |

| Storage Temperature | - | 10 °C to 35 °C with <70% Humidity |

| Dimensions (Including Actuator) |

2.68" x 3.87" x 0.79" (68.0 mm x 98.3 mm x 20.0 mm) |

2.68" x 3.90" x 0.79" (68.0 mm x 99.1 mm x 20.0 mm) |

| Weight | 0.53 lbs (0.24 kg) | |

Features

- 1" (25 mm) Travel

- Array of 13 1/4"-20 (M6 x 1.0) Tapped Holes

- XYZ Configurable with Dowel Pins for Orthogonality

- Mounted to Optical Table Using 1/4" (M6) Counterbores or CL6 Table Clamps (Sold Separately)

- Vacuum-Compatible Stage Suitable for Pressures Down to 10-6 Torr

The DTS25(/M) and DTS25V(/M) dovetail translation stages are compact positioners for use in general purpose motion control applications. Both stages provide a travel range of 1" (25 mm) using a precision-rolled M6 x 1.0 mm pitch leadscrew for smooth linear positioning along the entire range of travel. Each stage is advanced 0.04" (1.0 mm) for each full revolution of the leadscrew. The top surface of the DTS25(/M) and DTS25V(/M) stages are equipped with an array of thirteen 1/4"-20 (M6 x 1.0) tapped holes to maximize the mounting options for moving components. The moving platform is lockable via a side-located screw in a locking bracket to guard against accidental movement. A scale with 1/40" (1.0 mm) graduations is etched onto each side of the moving platform, with the edge of the locking bracket providing a reference for relative positioning.

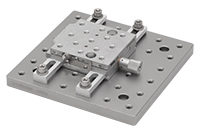

Mounting Options

These stages can be bolted directly to the optical table using four counterbored 1/4" (M6) holes that are revealed by translating the top plate of the stage to the proper position. Two of these mounting holes are accessed via clearance holes in the top plate, while the other two are directly accessible. Alternatively, the DTS25(/M) stage can be mounted using four CL6 clamps (two on each side) secured to the relief cut along the bottom of the stage, as shown in the picture at the top of the page. The DTSA01 and DTSA02 riser plates have four through holes and are designed to be placed between a mounting surface and the stage to increase the height of the system, as shown in the image above. The resulting stage height is 25 mm if the DTSA01 is in place or 30 mm if the DTSA02 is used.

Vacuum-Compatibility

The DTS25V(/M) stage is a vacuum-compatible version of the DTS25(/M) dovetail stage with identical mounting features, accomplished by using vacuum-compatible internal components. Each DTS25V(/M) stage is assembled in a clean environment and double vacuum bagged. Prior to use in a vacuum system, the stages can be baked to remove excess moisture and surface contaminants; however, please note that the maximum baking temperature is 130 °C. The stage can be mounted to a breadboard using Thorlabs' CL6V vacuum-compatible clamps and vacuum-compatible fasteners. Thorlabs offers vacuum-compatible breadboards, screws, and other optomechanics that can be can be used with the stage.

| Dovetail Translation Stages |

|---|

| 1/2" (12.7 mm) Travel |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Multi-Axis Configurations

The modular design of the DTS25(/M) allows multiple stages to be assembled in 2-axis and 3-axis configurations, while the DTS25V(/M) stage can be configured in 2-axis configurations. The DTS25V(/M) stage can be mounted in a 3-axis configuration using the non-vacuum compatible angle bracket as described below; however, the configuration would no longer be vacuum-compatible. Two dowel pins are included with each stage, and these can be used to ensure that orthogonality between the various translation directions is maintained during construction. In order to construct an XY configuration, two stages can be directly connected. For movement in the Z direction, the DTSA03(/M) angle bracket is required to mount a stage vertically. The bracket can be attached to a horizontal stage or optical table using four 1/4" (M6) counterbores and a stage can then be mounted vertically using four of eight 1/4"-20 (M6 x 1.0) tapped holes on the side of the bracket.

| Posted Comments: | |

Luya Zhang

(posted 2023-12-16 17:56:10.957) Hi, Would it be possible to use DTS25 + MPA1 + MP20? Thanks! spolineni

(posted 2024-01-03 06:36:06.0) Thank you for contacting Thorlabs. The DTS25 Translation Stage, MPA1 Adapter Plate, and MP20 Rigid Stand, are compatible and ideal for space-constrained microscopy systems. The DTS25 can accommodate the MPA1, which mounts a 200mm stand like the MP20. I will reach out to you directly by email to discuss further about your application. user

(posted 2020-08-31 13:06:28.05) Is the horizontal load the same if mounted upside down with a hanging load? cwright

(posted 2020-09-02 03:53:01.0) Response from Charles at Thorlabs: Hello and thank you for your query. Unfortunately we have not tested this and so cannot provide a true specification but we would advise that the load capacity is not so high in this configuration.

This is due to a the load being held by quite a thin bridge of material when upside-down and I will contact you directly to share an image of what I refer to. Certainly a few kilograms should be safe.

We would advise that if you need a high load in this configuration, then you may want to consider the LX10 or LNR25 and I will refer to these when I reach out to you. jdesousa

(posted 2019-01-30 10:30:13.17) Hi

my name is alejandro and work in spain in the ICMAB, i need to know if you have a product similar to DTS25/M. but with double precision sistem similar to the MBT616D, especificly the big travel similar to the DTS25/M and the presition traveler equal to MBT616. I need the traveler z the Z axis that couple with the other axis to DTS25/M. rmiron

(posted 2019-01-30 10:05:58.0) Response from Radu at Thorlabs: Thank you for contacting us, Alejandro. I think that PT1A/M is the best option we can offer you. It has the same course resolution as MBT616 and a fine resolution that is twice as good. It also has a 25 mm travel range and it can be mounted on the right-angle bracket designed for DTS25/M as long as it is fixed on top of a PT101/M plate before-hand. The only potential problem is that it has a vertical load capacity of 4 kg, whereas DTS25/M is specified for 10 kg. This is because it is made with ball bearings, as opposed to crossed roller bearings. Provided that the diminished load capacity is problematic, please contact our European tech support team, who might be able to suggest an alternative solution. julien.totems

(posted 2018-10-22 09:13:24.0) I have used the DTS25/M to support a heavy mirror, (2.5 kg, still below the advertized acceptable load), and I find both the rigidity of the platform and the angular deviation while travelling to be severely below specifications. The former makes my mirror (center of mass 100 mm above platform) move ~2 mm depending on the orientation of gravity, and the latter is about +/-5 mrad (80 times specs!) when travelling one way or the other. I would advise against using this stage for any application requiring stability, despite what is advertized. AManickavasagam

(posted 2018-10-23 10:34:19.0) Response from Arunthathi at Thorlabs: Thanks for your feedback. I suppose it is more to do with the torque your set up may be creating on the stage. It would be helpful to know the center of mass of your setup so we could understand the torque exerted. A crossed roller bearing stage such as our LNR50 might be more suitable for your application. michal.smid

(posted 2017-07-11 13:35:36.59) Hi,

is it possible to remove the leadscrew and attach a motorized actuator to the DTS25 stage?

Thanks. bhallewell

(posted 2017-07-12 10:19:48.0) Response from Ben at Thorlabs: Thank you for your feedback. The adjustment drive is fixed in place with the leadscrew. I would advise taking a look at either our XR25 or LNR* series stages which have a removable adjuster.

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=10211

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=4551 chuamemuk

(posted 2017-05-11 17:49:28.613) Hi there,

Could you please let us know the travel per revolution for the DT25?

Thank you very much. bwood

(posted 2017-05-12 05:38:09.0) Response from Ben at Thorlabs: Thank you for using our feedback feature. The lead screw of the stage has a 1 mm pitch which means that the top platform will move 1 mm (0.04") per revolution of the adjuster sean.whitehall

(posted 2013-05-27 12:33:29.16) The description says the orientation of the drive adjustment knobs makes this stage unsuitable for Z-axis translation. Is this because the actuators are on both sides, or are there internal parts that do not function when mounted vertically? Could it be used for Z-axis if care were taken to give the actuators adequate space? tcohen

(posted 2013-05-30 12:37:00.0) Response from Tim at Thorlabs: You can use the stage in Z if you are sure to give the actuators space. However, in an XYZ with three DT25 our closest stock option would likely be the AP90 and lifting the stage in the vertical on the slots and using nuts. Otherwise it would have to be offset to line with the taps. Although not necessary, when the stage is fully actuated it is typically easier to reach the knobs on one side over the other, which might need to be factored in when designing your spacing as well. Depending on your needs, our PT1 may be a better solution. I will contact you to discuss this further. Tyler

(posted 2008-08-12 17:36:36.0) A response from Tyler at Thorlabs to walter.allen: The XY configuration is created by purchasing two DT25 stages. The two stages can be easily assembled in an XY configuration because of their modular design and the included dowel pins that ensure that the stages are oriented perpendicular to each other. Thank you for your feedback, a note will be added to the presentation to clear up this issue. walter.allen

(posted 2008-08-12 17:17:30.0) Hello,

I am unable to find the X-Y version of the two one inch travel dovetail slides.

I have tried everything I can think of but no luck!

What am I doing wrong? |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

Click for Details

The DTSA02 Adapter Plate increases the stage height to 30 mm. Click the image above to see how to install the stage onto an optical table through an adapter plate.

- 1" (25 mm) Travel, Anodized Aluminum Stage

- XYZ Configurable Using DTSA03(/M) Angle Bracket

- Mounting Using 1/4" (M6) Counterbores or CL6 Table Clamps (Sold Separately)

- 5 mm and 10 mm Spacer Plates Available

The DTS25(/M) linear translation stage can support loads of 88 lbs (40 kg) or 22 lbs (10 kg) in the horizontal or vertical orientations, respectively. This stage includes a precision rolled M6 x 1.0 mm pitch leadscrew which provides 0.04" (1.0 mm) travel per revolution. Each stage has thirteen 1/4"-20 (M6 x 1.0) tapped holes on the top plate for mounting components to the moving platform and two 1/4" (M6) counterbores which can be used to mount the stage to one DTSA0x 5 mm or 10 mm thick spacer plates sold below, or to a breadboard or optical table. The stage is shipped with two Ø3.0 mm dowel pins to ensure the orthogonality when the stage is used in a multi-axis configuration. Please contact Tech Sales to purchase replacement or additional dowel pins.

The DTS25(/M) stage can be assembled into XZ and XYZ configurations using the included dowel pins and DTSA03(/M) angle bracket sold below. The DTSA03(/M) angle bracket features eight 1/4"-20 (M6 x 1.0) tapped holes on one side and four 1/4" (M6) counterbores on the other for mounting DTS25(/M) stages or other components. Dowel pin alignment holes are also provided to ensure orthogonal orientation of the stages when mounted together.

Click for Details

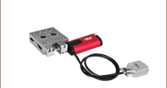

The DTS25V/M stage is mounted to an MB6S vacuum-compatible breadboard using vacuum-compatible table clamps and screws.

Click for Details

The DTS25V(/M) comes with a side locking plate that can be used to prevent accidental movement and as a relative positioning reference.

- Vacuum-Compatible Down to 10-6 Torr

- XY Configurable Using Included Dowel Pins for Orthogonality

- Mounted Using 1/4" (M6) Counterbores or CL6V Table Clamps (Sold Separately)

- Packed in a Clean Environment and Double Vacuum-Bagged

The DTS25V(/M) linear translation stage provides all the same motion and mounting features as the DTS25(/M) while using vacuum-compatible components to make this stage suitable for vacuum applications requiring pressures down to 10-6 Torr. The stage can support loads of 88 lbs (40 kg) and 22 lbs (10 kg) in the horizontal and vertical orientations, respectively; and features a precision rolled M6 x 1.0 mm pitch leadscrew which provides 0.04" (1.0 mm) travel per revolution. Each DTS25V(/M) stage is shipped with a side mounted locking plate that can be used to prevent accidental movement, and as a guide for relative positioning using the 0.025" (1.0 mm) graduated scale engraved on both sides of the stage, as shown above to the right. Each stage has thirteen 1/4"-20 (M6 x 1.0) tapped holes on the top plate for mounting components to the moving platform and two 1/4" (M6) counterbores which can be used to mount to a breadboard or optical table. The stage is shipped with two Ø3.0 mm dowel pins to ensure the orthogonality when the stage is used in a multi-axis configuration. Please contact Tech Sales to purchase replacement or additional dowel pins.

Vacuum-Compatibility

Each DTS25V(/M) stage is assembled in a clean environment and double vacuum bagged. Prior to use in a vacuum system, the stages can be baked to remove excess moisture and surface contaminants; however, please note that the maximum baking temperature is 130 °C. The stage can be mounted to a breadboard using Thorlabs' CL6V vacuum-compatible clamps and vacuum-compatible fasteners, shown above. Thorlabs offers vacuum-compatible breadboards, screws, and other optomechanics which can be can be used with the stage.

Products Home

Products Home

Zoom

Zoom

Dovetail Mechanism

Dovetail Mechanism