Kinematic Flexure Stage Mounts and Accessories

- Designed for Use with Our Family of Multi-Axis Stages

- Compact Design with Excellent Stability

- Precision Kinematic Control

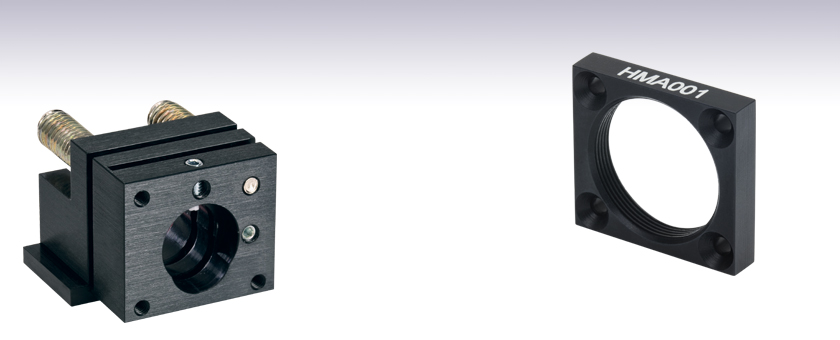

HMA001

RMS Adapter Plate

for HMM001

HMM001

Kinematic Ø1/2"

Optic Mount

Please Wait

Flexure stage mounts and accessories are products designed for use with our extensive line of multi-axis flexure stage systems. The central key-way that extends across the top mounting surface of the stage is designed to allow rapid system reconfiguration of flexure mounted optics and accessories, while maintaining system alignment.

Flexure stage mounts can be fixed in position using AMA010(/M) mounting cleats, which are sold below. Each cleat is designed with one edge milled flat, making it possible to insert or remove a flexure stage mount without removing the clamp. Simply loosen the clamp screw and rotate the flat side of the lock-down clamp inward to release the flexure stage mount.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Plates |

Extension Platforms |

Fiber Chucks |

Slide Holders |

Kinematic Platforms |

Adapter Plates |

Deck Height is the distance from the base of the mounting surface of an optical table or breadboard to the top mounting surface of the stage. There are two standard deck heights: 62.5mm for the MBT, RollerBlock, and Max300 Series Stages or 112.5mm deck height for the Max600 and NBM series stages. A wide range of riser blocks and plates are available to accommodate for variations when stacking stages on top of each other.

Optical Axis is the nominal height at which the beam should pass over the stage and through a given optical component or device. Most standard flexure system mounts use a 12.5mm optical axis.

The combination of the deck and optical axis height results in two standard beam heights above the optical table or breadboard: 75mm for the MBT, RollerBlock, and Max300 series stages or 125mm for the Max600 and NBM series stages.

| Posted Comments: | |

huw.major

(posted 2016-07-19 16:47:04.883) I appreciate that the clear aperture on the reverse of the mount is less than 12.7mm. However, both the 2D drawing and the Solidworks model show a 10mm diameter hole on the front of the mount where the mirror should be inserted. I think there is a drawing error. huw.major

(posted 2016-07-11 12:11:04.51) How does one fit a 1/2inch optic into this mount when the clear aperture only has a radius of 0.2inch? msoulby

(posted 2016-07-12 09:54:10.0) Response from Mike at Thorlabs: The mount does indeed hold a 12.7mm (half inch) optic, despite the clear aperture being smaller. The optic is simply placed into the mount on the side where the hole is large enough for the 12.7mm optic, the optic is then held in place using the grub screw. |

- Holds Ø1/2" Optics

- Holds RMS Threaded Microscope Objective or Accessories with the HMA001 Adapter Plate

- ±3° Angular Range

- Flexure Stage Mount with 12.5 mm Optical Axis Height

- Fabricated from Black Anodized Aluminum

This kinematic flexure mount allows for fine angular control of 1/2" diameter optics mounted on multi-axis flexure stages. A possible application for the HMM001 flexure stage mount would be to use it in the construction of a fiber based interferometer. The fine angular control of a mirror mounted in the HMM001 would allow the laser beam emerging from the fiber to be retro-reflected back into the fiber.

Externally RMS-threaded (0.800"-36) components can be mounted on the HMM001 by attaching the HMA001 adapter plate. With the HMA001 adapter plate, the kinematic flexure mount is ideal for use as a fiber coupling objective mount when fine angular control of the coupling objective is needed to maximize coupling efficiency.

RMS adapter rings make it possible to mount components with alternative thread types (see below).

The SM05RMS adapter allows any SM05- (0.535"-40) compatible products to be integrated into applications fitted with RMS threads. The adapter has an SM05 internal thread and an RMS external thread.

The RMSRR retaining ring is used to lock RMS-threaded components into place using the internal threads of the component. The retaining ring can be tightened or loosened by using an SPW801 spanner wrench.

To use the SM05RMS with the Kinematic Flexure Stage Mount and RMS Adapter, the RMSRR should first be inserted into the HMA001 to set the depth. Then, the SM05RMS can be tightened against it.

Click to view additional RMS adapters.

Click for Details

Accessories mounted in close proximity using the AMA110 Mounting Block.

- Secures Components to NanoMax, MicroBlock, or RollerBlock Stages

- Cleats for Mounting Single Components

- Mounting Blocks and Clamps for Close Proximity Mounting of Multiple Components

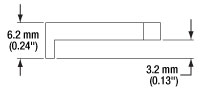

The AMA010(/M) Cleats have a flat milled along one side. To lock an accessory along the center alignment groove, rotate the cleat so that the flat is facing the groove. Place the accessory into the groove between the cleats, rotate the cleat so that the rounded edge covers the edge of the mount, and lock down the 6-32 (M3) locking screw and washer. The cleats can be rotated without needing to remove the locking screws. See the animation to the right for details. The included screws are 5/16" (8 mm) long and are used with a 3/32" (2.5 mm) hex key.

For mounting multiple components in close proximity, we offer the AMA110 mounting blocks. These mounting blocks feature a line of nylon-tipped setscrews to secure components, and allow for easy repositioning and very close mounting. The blocks are secured via two holes and are supplied with either 6-32 or M3 cap screws.

The AMA111 Narrow Device Mounting Clamps offer an alternative solution when devices need to be mounted close together. They are secured using an M3.5 or M3 washer and a 6-32 or M3 cap screw, compatible with a 7/64" or 2.5 mm hex key, respectively.

Products Home

Products Home

Zoom

Zoom

Kinematic Mounts and Accessories

Kinematic Mounts and Accessories