Ø1" (Ø25.0 mm) Pillar Posts

- Stainless Steel or Fiberglass Construction

- Mounting Taps at Both Ends

RS12

RS6

RS4

RS3

RS2

RS1.5

RS1

RS075

RS05

RS10M

RS8M

RS024

RS016

Post Spacers

Smooth or Threaded Bore

Turn Ø1" Posts into

Pedestal-Style Posts

CF125

BE1

Application Idea

Optical Construction Posts for Building Complex Optomechanical Assemblies

RS1G

RS2G

Insulating

Fiberglass

Posts

RS4T

RS4C

RS01M

Please Wait

Click to Enlarge

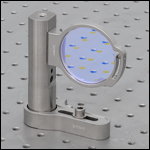

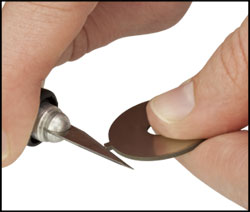

The RB2 Ø1" Pillar Post Mount is shown with an RS4P8 Ø1" Pillar Post. Our Ø1" pillar posts include a hole for 3/16" (5 mm) balldrivers for extra leverage during tightening.

Features

- Pillar Posts with Non-Magnetic Stainless Steel Construction

- Standard Pillar Posts can be Used to Extend the Height of Our Pedestal Posts

- Posts Designed for use with Polaris Mounts

- Construction Posts for Side or Angle Mounting

- Options with 8-32 (M4) or 1/4"-20 (M6) Taps

- Insulating Fiber Glass Posts with 1/4"-20 (M6) Taps on Both Ends

- Large-Diameter Relief Cut on Top and Bottom for Mounting Stability

- Torque Hole Provides Extra Leverage During Tightening

Thorlabs' Ø1" (Ø25.0 mm) Pillar Posts are a basic component in any optical setup. Posts with heights between 0.5" (12.5 mm) and 12" (300 mm) are available below, as well as a variety of post construction accessories. Ø1" (Ø25 mm) posts designed to mount our Polaris mirror mounts are also available.

Standard Ø1" (Ø25.0 mm) Posts

Our standard Ø1" (Ø25.0 mm) posts have a tap on both the top and bottom, allowing them to be threaded to another post or optical table in any orientation. We offer posts with 8-32, M4, 1/4"-20, or M6 taps on both ends. A Ø0.24" (Ø6.0 mm) hole in the center of each post is provided so that a 3/16" (5 mm) balldriver can be used to provide extra leverage when securing a mounted component. These posts can also be mounted with arbitrary height adjustments using Ø1" post mounts or Ø1" post holders. Alternatively, our BE1 pedestal adapter, sold below, can be threaded into the end of the post for functionality similar to that of our Ø1" pedestal posts.

Pillar posts are available in a variety of heights from 0.5" (12.5 mm) to 12" (300 mm). Additional heights can be achieved by stacking posts with heights of 0.39" (10 mm) or shorter on top of a standard pillar post. These posts can be stacked easily and securely by using the SPW501 or a balldriver on the torque hole, which provides extra leverage while tightening the components onto each other.

Click to Enlarge

Mirror Center of a Ø1/2" Polaris Mirror Mount Raised to a Standard 2.00" Height Using the PLS-P150 Post

Click to Enlarge

RS4 Pillar Post Shown Mounted in a Flexure Clamping Base, Allowing for Small Height Adjustments

Ø1" (Ø25.0 mm) Posts Designed for Polaris Mirror Mounts

These posts are designed for use with Polaris mirror mounts. They contain one or three top-located 8-32 (M4) taps, for directly attaching a mirror mount without using a thread adapter, and a bottom-located 1/4"-20 (M6) tap. A precision 0.24" (6 mm) hole, located 20 mm from the base of the post, allows for alignment of multiple mounts along a common optical axis or for fine angle tuning. Popular post lengths are available from stock; custom lengths can be requested using the configurator below (single-mounting-hole versions only) or by contacting Tech Support. Although these posts can be mounted utilizing the options described above for our standard posts, we recommend using our Polaris clamping arms, sold below. These clamping arms, which are constructed from heat-treated stainless steel, remove the bridging effect commonly seen with standard clamping forks (described in further detail below), while also providing a higher holding force.

Construction Posts

These construction posts are designed for mounting optomechanical components in custom configurations. They are available with three tapped holes and two mounting flats or three clearance holes and one mounting flat. Versions are available with an 8-32 (M4 x 0.7) or 1/4"-20 (M6 x 1.0) tapped hole on each end.

Ø1" (Ø25.0 mm) Fiberglass Posts for Thermal and Electrical Isolation

These G10/FR4 fiberglass posts are designed to provide a high level of thermal and electrical isolation. They feature 1/4"-20 (M6) threaded steel inserts and torque holes for tightening leverage.

| Posted Comments: | |

Jan Lowinski

(posted 2022-06-08 15:42:15.5) Dear Thorlabs,

Would you consider selling the spacers in 5 packs without the screws that are normally added? I use extensively spacers, in particular 5 mm high and I find a bit ridiculous that each of them arrives in a separate bag and two screws that I don't use anyway.

Best,

Jan jdelia

(posted 2022-06-08 01:36:22.0) Thank you for contacting Thorlabs, and for providing this valuable feedback. While we do not have any current plans to offer this, I could certainly pass this request to our engineers through our internal suggestion forum. Amir Hen

(posted 2021-10-10 21:10:50.923) Can you pleas make 0.5mm thick spacer? YLohia

(posted 2021-10-11 02:19:15.0) Thank you for your feedback. We will consider offering a 0.5 mm spacer in the future. karsten.sperlich

(posted 2018-07-13 10:53:57.733) Hello,

I like the pedestal post with pillar post concept as it is very stable.

Usually, I use 1" pedestal posts with M4 taps to directly mount the optomechanical mounts. If the height does not fit, I use spacer, which is fine. But if the difference is more than 10 mm, I always wonder, why there are no pillar post with M4 taps. I have to use expensive adapters (M4-M6) to extend my pedestal posts to end up with M6 taps and to use another expensive adapter to go back to M4 again.

Do you think, you could extend your portfolio with M4 tap pillar posts?

As one can see from the other comments, this is highly desired.

Thanks and best regards,

Karsten llamb

(posted 2018-07-27 04:09:11.0) Hello Karsten, thank you for your feedback. All of our standard pillar posts will ship with either a #8-32 or M4 screw thread adapter to satisfy this thread conversion in most cases. Otherwise, connecting a short pillar post with M6 taps (RS10/M for example) to your main post with an M6 setscrew may be more convenient than using a spacer, so you can save the included thread adapter for the topmost, shorter post. I will also reach out to you directly in case a custom post solution may be more beneficial. lzcarid

(posted 2017-09-14 00:32:11.917) Dear Thorlabs,

Is it possible that you sell 1/8'' spacers? I think they are in general very useful in the lab, but I can't find them in your website. Then I need to go to Newport to buy it...

Best,

Zeren tfrisch

(posted 2017-09-21 11:49:59.0) Hello, thank you for contacting Thorlabs. I will reach out to you about a custom quote. popei

(posted 2016-02-22 06:41:22.243) 25mm diameter metric pillar post with M4 tapped holes for use with M4 tapped Pedistal posts.

These would be useful for making up non standard post hights which require larger spacers. EG a 50mm pedistal post plus a 19 mm pillar post to give a total height of 69mm. besembeson

(posted 2016-03-04 11:56:20.0) Response from Bweh at Thorlabs USA: This can be achieved currently using the AP6M4M single external thread adapter: http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_ID=1745 jjurado

(posted 2011-08-15 14:21:00.0) Response from Javier at Thorlabs to last poster: Thank you very much for your feedback. We understand that the prices of some of our components are slightly higher than those offered by a few competitors. However, we constantly strive to offer fair prices for all of our products, without sacrificing functionality nor quality. Please contact us at techsupport@thorlabs.com if you would like to discuss your concerns a bit further. user

(posted 2011-08-07 22:46:09.0) Ok, I remember when you guys had the best prices but not so any more. . When you made these new spacers you were supposed to make them less expensive than the other guys, not more. Dont be greedy....And don be evil. Thorlabs

(posted 2010-10-20 17:33:23.0) Response from Javier at Thorlabs to fabian.luecking: The metric post extensions are M6 threaded, but they ship with an M6 to M4 adapter, which has external M6 threads and internal M4 threads (p/n AE4M6M). fabian.luecking

(posted 2010-10-20 16:13:35.0) Please provide spacers and extensions for M4, too. Actually, on the post page it says "extendable with M4 and M6 taps (see RS-extensions)" - but there seem to be no M4-tapped extensions... jens

(posted 2009-06-29 13:07:56.0) A reply from Jens at Thorlabs: thanks for the suggestion. I will contact our engineers and add the idea to our internal database. Besides that most customers at the moment would use a RB2 or depending on the setup the spacer plates, e.g. BA2S2 to create small height offsets. patricia.lee3

(posted 2009-06-29 11:39:44.0) It would be great if you would offer fractional-inch length spacers, i.e. RS025 for 1/4" and RS0125 for 1/8". RS01 through RS04 are really hard to use for imperial standards. jens

(posted 2009-06-10 11:17:41.0) A reply from Jens at Thorlabs: Thomas, I just recognized in addition that the description which show on the main page is misleading since the adapter is not the best choice for connecting two RS posts, the adapter is really meant to give you the option to use 8-32 threaded parts with the RS posts. In order to connect two RS posts a solid 1/40-20 set screw as included in our HW-KIT4 will be the best choice. The page is being change at the moment. jens

(posted 2009-06-04 08:22:08.0) A reply from Jens at Thorlabs: Thomas, thanks for the feedback. I looked at a couple of studs/set-screws yesterday and tightened them using a lot of mechanical force. Since that worked fine I am wondering if you might have gotten a set which should not have passed our quality checks. Let me contact you directly via your email and get you a few new ones to check if this was the case or if we are using different ways of fixing these and a change of the design might be required. thomasce2

(posted 2009-06-01 19:04:12.0) Hi.

I really like the 1" post extensions with 1/4-20 threaded holes, however, the 1/4-20 studs/set-screws that come with them are complete junk! They tear apart if you look at them. I tried to use a couple and then just started ordering studs/set-screws from Amazon and Grainger. Thin hollow studs that tear apart when looked at just dont cut it. After I tore up a couple I just gave up and ordered a real stud/set-screw. Lets make a good product even better and include studs/set-screws that dont tear up like tissue paper--make em solid stainless, not hollow!!

best regards, tommy thomas Laurie

(posted 2009-01-26 08:57:14.0) Response from Laurie at Thorlabs to flickingerd: Thank you for taking the time to provide us with some feedback concerning our website. Thorlabs business model is focused around customer centricity. That is why youll find a "You Speak, We Listen" link on the homepage. In this case, you as well as many other customers contacted us asking that we bring back our product pages and we have listened. Youll note that we have made slight changes to the product pages like removing the drop down menu to find the support documents. Instead, they now appear on the page itself. However, the pages, for the most part, will look exactly like they did in the past. We hope that you find these slight changes to be even more user friendly. Please feel free to speak up in the future if you have additional suggestions for improving your web experience. flickingerd

(posted 2009-01-21 11:18:07.0) I *REALLY DISLIKE* the recent change to the Thorlabs website--where now clicking on a product takes you directly to the catalog page and the individual product web pages dont seem to exist any more. Please change back! I really liked the individual product web pages because they made it easy to access all of the support documentation/drawings for that specific product. Now you have to search through the (often long) lists of support documents that are on the full product line pages for the proper item number. And when youre transferring order information from the website to something else, you cant isolate one product on the page any more so you keep having to scan the full product line page to re-find your specific product each time you look away. This makes a difference if you do a lot of shopping, and product recommendation, which I do.

I hardly ever want to see the catalog pages either, so dont think they deserve such a prominent position.

Dan |

- Directly Mount Optomechanical Components

- Extend the Height of Our Ø1" Pedestal Posts

- 8-32 Tapped Hole on Both Ends

- Torque Hole for 3/16" Balldriver or SPW501 Spanner Wrench Provides Extra Leverage During Tightening

These pillar posts are machined from nonmagnetic 303 stainless steel and provide strong support in an optical setup. By combining the rigidity of these solid Ø1" posts with Ø1" post mounts or Ø1" post holders, any arbitrary height support structure can be constructed. Each post is machined with a 8-32 tapped hole in both ends for direct mounting to an optical mount and breadboard. These posts can be adapted to bases with 1/4" (M6) counterbores by using SD1 counterbore adapters.

8-32 setscrews, available in our HW-KIT3 hardware kit, can be used to secure posts on top of each other, or to our Fixed Lens Mounts with Internal Threads.

- Directly Mount Optomechanical Components

- Extend the Height of Our Ø25.0 mm Pedestal Posts

- M4 Tapped Hole on Both Ends

- Torque Hole for 5 mm Balldriver or SPW501 Spanner Wrench Provides Extra Leverage During Tightening

These pillar posts are machined from nonmagnetic 303 stainless steel and provide strong support in an optical setup.By combining the rigidity of these solid Ø25.0 mm posts with Ø25.0 mm post mounts or Ø25.0 mm post holders, any arbitrary height support structure can be constructed. Each post is machined with a M4 tapped hole in both ends for direct mounting to an optical mount and breadboard. These posts can be adapted to bases with M6 (1/4") counterbores by using SD1 counterbore adapters.

M4 setscrews, available in our HW-KIT3/M hardware kit, can be used to secure posts on top of each other, or to our Fixed Lens Mounts with Internal Threads.

- Extend the Height of Our Ø1" Pedestal Posts

- 1/4"-20 Tapped Hole on Both Ends

- Torque Hole for 3/16" Balldriver or SPW501 Spanner Wrench Provides Extra Leverage During Tightening

These pillar posts provide strong support in an optical setup. By combining the rigidity of these solid Ø1" posts with our high stability RB2 base, any arbitrary height support structure can be constructed. Each post is machined with a 1/4"-20 tapped hole in both ends for direct mounting to an optical table or standard base and an optical mount. These posts are machined from nonmagnetic 303 stainless steel.

To convert the 1/4"-20 taps to 8-32 taps, we separately offer the AE8E25E thread adapter, which has external 1/4"-20 threading and internal 8-32 threading. The adapter can be used with an 8-32 setscrew to attach many of Thorlabs' imperial optomechanical parts to a Ø1" imperial pillar post. In principle, the adapter can also be used to connect two pillar posts, but a solid 1/4"-20 setscrew, which is included in our HW-KIT4 hardware kit, is a more stable choice for this.

- Extend the Height of Our Ø25.0 mm Pedestal Posts

- M6 Tapped Hole on Both Ends

- Torque Hole for 5 mm Balldriver or SPW501 Spanner Wrench Provides Extra Leverage During Tightening

These pillar posts provide strong support in an optical setup. By combining the rigidity of these solid Ø25.0 mm posts with our high stability RB2 base, any arbitrary height support structure can be constructed. Each post is machined with an M6 tapped hole in both ends for direct mounting to an optical table or standard base and an optical mount. These posts are machined from nonmagnetic 303 stainless steel.

To convert the M6 taps to M4 taps, we separately offer the AE4M6M adapter, which has external M6 threading and internal M4 threading. The adapter can be used with an M4 setscrew to attach many of Thorlabs' metric optomechanical parts to a Ø25.0 mm metric pillar post. In principle that adapter can also be used to connect two pillar posts but a solid M6 setscrew as included in the hardware kit HW-KIT4/M will provide a more stable solution.

Click for Details

Directly attach a Polaris mount via a top-located 8-32 (M4) mounting hole without the need for a thread adapter. Dowel pins (not included) provide precision mounting.

- One or Three Top-Located 8-32 (M4 x 0.7) Mounting Holes

- One Bottom-Located 1/4"-20 (M6 x 1.0) Mounting Holes

- Two Ø2 mm Alignment Pin Holes Around Each Tap for Precision Mounting (Dowel Pins Not Included)

- Vacuum Compatible to 10-9 Torr at 25 °C with Proper Bake Out

- 303 Stainless Steel Heat-Treated to Remove Internal Stresses for Increased System Stability

- Large-Diameter Relief Cut on Top and Bottom for Additional Mounting Stability

- Configurator Available Below for Custom Lengths and Usage Features

Our Polaris® Posts are machined from heat-treated stainless steel to provide stable support for our Polaris Mirror Mounts. Heat treating the materials removes the internal stresses that can cause temperature-dependent hysteresis. All of our Polaris mirror mounts, clamping arms, and 45° adapters are constructed from this same material, which has a relatively low coefficient of thermal expansion (CTE). Matching the CTE of materials within an optical setup is essential to achieve optimal thermal repeatability.

Each post contains one or three top-located 8-32 (M4 x 0.7) mounting holes and a bottom-located 1/4"-20 (M6 x 1.0) mounting hole. The 8-32 (M4 x 0.7) threads allow a mirror mount to be attached directly to the post, eliminating the need for thread adapters and thereby reducing the instability created when stacking multiple optomechanical components.

Versions of these posts with a single 8-32 (M4 x 0.7) mounting hole can be used with our smaller Polaris mounts, while the posts with three 8-32 (M4 x 0.7) mounting holes are ideal for securing larger Ø2" and Ø3" Polaris mounts with more than one screw. Popular post lengths are available from stock; custom lengths can be requested using the configurator below (single-mounting-hole versions only) or by contacting Tech Support.

Created with OEM and custom systems in mind, each post features holes for DIN-7m6 ground dowel pins (not included) on either side of the central threaded hole at each end to aid with alignment. Securing posts and accessories within a system using dowel pins prevents them coming loose due to vibrations, shipping, or incidental contact.

Our Polaris Clamping Arms, available below, are the ideal mounting solution for these posts. These clamping arms feature a non-bridging design that reduces the gap, or “bridge,” that traditionally results between the back of a standard clamping fork and a Ø1" pedestal post base.

Click here for more information on these posts including OEM mounting options, mounting stability details, and test data.

OEM Solutions and Volume Orders

Thorlabs manufactures custom and high-volume Polaris products for use in custom and OEM systems. See our custom configurator below for our custom post options. High-volume discounts are built into the configurator, with a minimum order size of 26 posts required to recieve the discount.

For pricing information on high-volume orders of our standard posts, please contact OEM Sales.

Alignment Bore

A Ø6 mm bore is located 20 mm above the base of the post to allow for fine alignment. The alignment bore will not be covered when these posts are secured with a Polaris clamping arm, sold below. Please note that this bore does not go completely through the posts with lengths of 1.0" or shorter; these posts contain two bores on opposite sides, within ±0.3°, that are 0.20" (5.1 mm) deep. Given their shorter length, a through bore would interfere with the mounting threads, preventing anything from being securely attached to the post. Any post with a length of 1.49" (37.6 mm for metric posts) or less will have a similar alignment bore configuration.

Cleanroom and Vacuum Compatibility

These posts are designed to be compatible with cleanroom and vacuum applications. They are chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, they are double vacuum bagged so that they can be transported into a cleanroom environment without introducing contamination. Please contact Tech Support for details.

| Polaris® Mount and Post Interoperabilitya | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item # | Post Length (L) |

Resulting Optical Axis Heights with Polaris Mounts (Mirror Center) | Post Mounting Holes | |||||||

| Ø1/2" Fixed & Kinematicb |

POLARIS-K05P2 Ø1/2" Kinematic |

Ø19 mm Kinematic & Ø1" Fixed |

Ø1" & Ø25 mm Kinematic |

Ø1.5" Kinematic & Ø2" Fixed |

Ø2" Kinematic |

Ø3" Kinematic |

Top | Bottom | ||

| PLS-P1 | 1.00" | 1.50" | 1.62" | 1.75" | 2.00" | 2.25" | 2.40" | 3.00" | One 8-32 | One 1/4"-20 |

| PLS-T1 | Three 8-32 | |||||||||

| PLS-P150 | 1.50" | 2.00" | 2.12" | 2.25" | 2.50" | 2.75" | 2.90" | 3.50" | One 8-32 | |

| PLS-P2 | 2.00" | 2.50" | 2.62" | 2.75" | 3.00" | 3.25" | 3.40" | 4.00" | One 8-32 | |

| PLS-T2 | Three 8-32 | |||||||||

| PLS-P238 | 2.38" | 2.88" | 3.00" | 3.13" | 3.38" | 3.63" | 3.78" | 4.38" | One 8-32 | |

| PLS-T238 | Three 8-32 | |||||||||

| PLS-P3 | 3.00" | 3.50" | 3.62" | 3.75" | 4.00" | 4.25" | 4.40" | 5.00" | One 8-32 | |

| PLS-T3 | Three 8-32 | |||||||||

| PLS-P4 | 4.00" | 4.50" | 4.62" | 4.75" | 5.00" | 5.25" | 5.40" | 6.00" | One 8-32 | |

| PLS-T4 | Three 8-32 | |||||||||

| 24.2 mm | 36.9 mm | 39.9 mm | 43.3 mm | 49.6 mm | 56.0 mm | 59.8 mm | 75.0 mm | Three M4 x 0.7 | One M6 x 1.0 |

|

| 24.6 mm | 37.3 mm | 40.3 mm | 43.7 mm | 50.0 mm | 56.4 mm | 60.2 mm | 75.4 mm | One M4 x 0.7 | ||

| 37.3 mm | 50.0 mm | 53.0 mm | 56.4 mm | 62.7 mm | 69.1 mm | 72.9 mm | 88.1 mm | One M4 x 0.7 | ||

| 49.2 mm | 61.9 mm | 64.9 mm | 58.3 mm | 74.6 mm | 81.0 mm | 84.8 mm | 100.0 mm | Three M4 x 0.7 | ||

| PLS-P496/M | 49.6 mm | 62.3 mm | 65.3 mm | 68.7 mm | 75.0 mm | 81.4 mm | 85.2 mm | 100.4 mm | One M4 x 0.7 | |

| PLS-P605/M | 60.5 mm | 73.2 mm | 76.2 mm (3.00") |

73.2 mm | 85.9 mm | 92.3 mm | 96.1 mm | 111.3 mm | One M4 x 0.7 | |

| PLS-T605/M | Three M4 x 0.7 | |||||||||

| PLS-P746/M | 74.6 mm | 87.3 mm | 90.3 mm | 93.7 mm | 100.0 mm | 106.4 mm | 110.2 mm | 125.4 mm | One M4 x 0.7 | |

| PLS-T746/M | Three M4 x 0.7 | |||||||||

| PLS-P996/M | 99.6 mm | 112.3 mm | 115.3 mm | 118.7 mm | 125.0 mm | 131.4 mm | 135.2 mm | 150.4 mm | One M4 x 0.7 | |

| PLS-T996/M | Three M4 x 0.7 | |||||||||

Click to Enlarge

POLARIS-B2S Mount with DMLP490L Beasmplitter on RS4P8T Post in

POLARIS-CA1 Clamping Arm

Click to Enlarge

Back View of RS4P8C Post

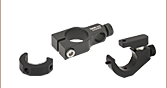

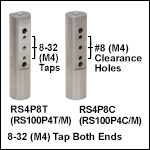

- Posts with Taps or Clearance Holes Through the Side for Constructing Custom Mounting Configurations

- RS4P8T (RS100P4T/M): Three 8-32 (M4 x 0.7) Tapped Holes

- RS4P8C (RS100P4C/M): Three #8 (M4) Clearances Holes in a Counterbored Slot

- Two Torque Holes for 3/16" (5 mm) Balldriver Provide Extra Leverage During Tightening

- 8-32 (M4 x 0.7) Tapped Hole on Each End

These construction posts are designed for mounting optomechanical components in custom configurations. The RS4P8T (RS100P4T/M) post offers three 8-32 (M4) tapped holes and two mounting flats, while the RS4P8C (RS100P4C/M) post offers three #8 (M4) clearance holes in a counterbored slot and one mounting flat. A single construction post may be used to mount an optomechanical component on its side, as shown in the photo to the right. Additionally, the two construction post variants can be combined using a cap screw, as shown below, to enable mounting components at an arbitrary angle. Each end of these posts has an 8-32 (M4 x 0.7) tapped hole.

Click to Enlarge

RS4T and RS4C Posts with RSH1.5 Post Holder and PF125B Clamp Combined for Mounting at Arbitrary Angles

Click to Enlarge

Back View of RS4C Post

- Posts with Taps or Clearance Holes Through the Side for Constructing Custom Mounting Configurations

- RS4T (RS100T/M): Three 1/4"-20 (M6 x 1.0) Tapped Holes

- RS4C (RS100C/M): Three 1/4" (M6) Clearances Holes in a Counterbored Slot

- Two Torque Holes for 3/16" (5 mm) Balldriver Provide Extra Leverage During Tightening

- 1/4"-20 (M6 x 1.0) Tapped Hole on Each End

These construction posts are designed for mounting optomechanical components in custom configurations. The RS4T (RS100T/M) post offers three 1/4"-20 (M6 x 1.0) tapped holes and two mounting flats, while the RS4C (RS100C/M) post offers three 1/4" (M6) clearance holes in a counterbored slot and one mounting flat. A single construction post may be used to mount an optomechanical component on its side. Additionally, the two construction post variants can be combined using a cap screw, as shown in the photo to the right, to enable mounting components at an arbitrary angle. Each end of these posts has a 1/4"-20 (M6 x 1.0) tapped hole.

Click to Enlarge

Comparison of thermal conduction in stainless steel and fiberglass pillar posts.

- Ø1" (Ø25.0 mm) Pillar Posts Made from G10/FR4 Fiberglass

- Low Thermal Conductivity: 0.29 W/m•K

- High Electrical Resistivity: 1.00 x 1011 Ω•cm

- Max Operating Temperature: 70 °C

- 1/4"-20 (M6 x 1.0) Threaded Inserts in Both Ends

- Torque Hole for 1/8" (3 mm) Balldriver Provides Extra Leverage During Tightening

- Max Torque: 75 lb-in (8.4 N•m)

Thorlabs' Ø1" (Ø25.0 mm) fiberglass posts provide thermal and electrical isolation between the mounted device(s) and the breadboard surface. Each post end features threaded steel inserts and a machined dot on top of each metric post denotes a metric threaded insert. The G10/FR4 fiberglass construction features excellent insulation compared to stainless steel (see the isolated posts page for details). These posts have the same profile as our Ø1" (Ø25.0 mm) stainless steel pillar posts (Item #s RS1, RS2, RS25/M, and RS50/M).

The plot to the right depicts the measured temperatures of a heated breadboard and the tops of four attached Ø1" posts, including stainless steel and fiberglass variants. The data illustrates the increased thermal insulation of our G10/FR4 fiberglass pillar posts compared to stainless steel posts.

Click to Enlarge

Deep Base Allows Height Adjustment

- RB2 Base Allows Post Extensions to be Used as a Variable Height Mounting Structure

- Hollow Base Allows Post Extension to Pass Through for 0.5" of Height Adjustability

- Convenient Vertically Accessed Locking Screw

The RB2(/M) pillar post base mounts Ø1" (25 mm) optical posts at a variable height (shown to the right). The hollow base allows the post to pass through, allowing 0.5" of post height adjustment. Translation is locked via a top-located clamping screw.

Click to Enlarge

SPW501 Spanner Wrench Being Used to Tighten a Small Ø1" Post Spacer onto a Ø1" Pillar Post

- Solid Stainless Steel Construction

- 1/4"-20 (M6) Tapped Hole

- Large Diameter Relief Cut on Top and Bottom for Additional Mounting Stability

- Spanner Wrench Slots

These small post spacers are designed for achieving "in between" heights of our Ø1" (Ø25.0 mm) Posts without compromising structural rigidity. The center 1/4"-20 (M6) tapped through hole allows threaded studs to pass through to the mating tap of the components on the top and bottom. Each spacer ≤0.31" (8 mm) long features two slots on the side that allow it to be securely tightened onto a post using the SPW501 spanner wrench (sold below), as shown in the image to the right. Spacers with lengths 0.35" (9 mm) or larger feature a through hole instead of the two slots; this through hole accepts a 1/8" (3 mm) balldriver as well as the SPW501 for providing leverage while tightening or loosening.

Click to Enlarge

Click to EnlargePost Spacer Being Used to Increase the Post Height

by 5 mm (0.2")

- Solid Stainless Steel Construction

- Clearance Holes Accept Ø1/4" (M6) Screws

- ≥1 mm Thick Spacers have Large Diameter Relief Cuts on Top and Bottom for Additional Mounting Stability

These spacers are designed for achieving heights in between those of our catalog Ø1" (Ø25 mm) Posts offering without compromising structural rigidity. The center clearance hole allows Ø1/4" (M6) threaded studs to pass through to the mating tap of the components on either side of the spacer. Achieving, for example, a total post height of 8.2" is as simple as inserting one RS5M spacer (0.2" thickness) in between two RS4 posts (4" length).

Note that spacers 0.9 mm and thinner have an indent on the side due to the manufacturing process. This feature is cosmetic and does not interfere with the spacer's functionality.

- Peel Away Individual Layers as Needed

- Stainless Steel

- Tabbed for Easy Peeling

- Sold in Packs of 5

This Ø25 mm, peelable, laminated shim provides fine height adjustment when using our Ø1" posts. These 1.0 mm ± 10% thick shims come in packs of 5 and have 14 layers, which are each 0.075 mm thick. They have a through hole to accommodate a 1/4"-20 (M6) screw.

Be aware the finish on some shims may appear tarnished due to the manufacturing process. This does not affect form, fit, or function. Only the appearance is altered.

To peel, take a sharp edge like a box cutter and hold it at a 45° angle to the tab on the shim as shown in the photo to the right. Gently flick the knife upward until the layer begins to lift. In general, you should be able to lift an edge within 5 attempts. If you cannot get an edge to lift, gently tap the corner of the tab on a table until the material begins to flare.

Once an edge is lifted, insert the blade under the layer, squeeze the layer between your thumb and the blade, and roll your wrist down and then up to start peeling (see photo in the upper left). Once the layer has been peeled up enough, you can use your thumb and forefinger to remove it the rest of the way. Repeat this process until you have removed as many layers as desired. Discard all peeled-off layers.

| RS-KIT Post Spacer and Setscrew Kit | |||

|---|---|---|---|

| Item | Qty. | Item | Qty. |

| Ø25 mm Post Spacer, 1 mm Thick (RS1M) | 5 | Ø25 mm Post Spacer, 7 mm Thick (RS7M) | 1 |

| Ø25 mm Post Spacer, 2 mm Thick (RS2M) | 5 | Ø25 mm Post Spacer, 8 mm Thick (RS8M) | 1 |

| Ø25 mm Post Spacer, 3 mm Thick (RS3M) | 5 | Ø25 mm Post Spacer, 9 mm Thick (RS9M) | 1 |

| Ø25 mm Post Spacer, 4 mm Thick (RS4M) | 5 | Ø25 mm Post Spacer, 10 mm Thick (RS10M) | 5 |

| Ø25 mm Post Spacer, 5 mm Thick (RS5M) | 5 | 1/4"-20 Setscrew, 7/8" Long | 25 |

| Ø25 mm Post Spacer, 6 mm Thick (RS6M) | 1 | 1/4"-20 Setscrew, 1" Long (SS25S10) | 25 |

| RS-KIT/M Post Spacer and Setscrew Kit | |||

|---|---|---|---|

| Item | Qty. | Item | Qty. |

| Ø25 mm Post Spacer, 1 mm Thick (RS1M) | 5 | Ø25 mm Post Spacer, 7 mm Thick (RS7M) | 1 |

| Ø25 mm Post Spacer, 2 mm Thick (RS2M) | 5 | Ø25 mm Post Spacer, 8 mm Thick (RS8M) | 1 |

| Ø25 mm Post Spacer, 3 mm Thick (RS3M) | 5 | Ø25 mm Post Spacer, 9 mm Thick (RS9M) | 1 |

| Ø25 mm Post Spacer, 4 mm Thick (RS4M) | 5 | Ø25 mm Post Spacer, 10 mm Thick (RS10M) | 5 |

| Ø25 mm Post Spacer, 5 mm Thick (RS5M) | 5 | M6 x 1.0 mm Setscrew, 20 mm Long (SS6MS20) | 25 |

| Ø25 mm Post Spacer, 6 mm Thick (RS6M) | 1 | M6 x 1.0 mm Setscrew, 25 mm Long (SS6MS25) | 25 |

Click to Enlarge

The BE1R has a magnet in the base for stability in temporary setups.

Click to Enlarge

Click to EnlargeThese base adapters feature a 1/8" (3 mm) hex socket on the bottom for tightening.

Click to Enlarge

Several Slot Lengths Available

- BE1(/M) and BE1R(/M) Adapters Convert Standard Ø1/2" Post Holders and Ø1" Posts into Pedestal-Style Mounts

- Clamping Fork or CL8 Table Clamp Secures Pedestal-Style Mount to a Breadboard or Optical Table

- Three Sizes Provide Clamping with 1/4"-20 (M6) Cap Screws

- 0.40" (10.2 mm) Long Counterbored Slot [CF038-P5 and CF038C(/M)-P5]

- 1.24" (31.5 mm) Long Counterbored Slot [CF125 and CF125C(/M)]

- 1.75" (44.4 mm) Long Counterbored Slot [CF175 and CF175C(/M)]

- Swivel Clamping Fork 360° to Select Most Convenient Mounting Hole

- CF038C(/M)-P5, CF125C(/M) and CF175C(/M) Each Include a 1/4"-20 (M6)-Threaded Captive Screw

- BE1(/M) and All Clamping Forks Available in Packs of Five [CF038-P5 and CF038C(/M)-P5 Not Sold Individually]

Pedestal Base Adapters

The BE1(/M) and BE1R(/M) pedestal base adapters feature a 1/4"-20 (M6)-threaded stud that fit into the bottom of our standard Ø1/2" post holders or Ø1" posts to convert them into pedestal-style mounts for added stability. The BE1R(/M) adapter features a magnet in the base that is sufficiently strong to securely hold the base in place without clamping to an optical table (see photo at the top right). Made from solid 303 stainless steel with a 1.25" (31.8 mm) outer diameter, these adapters allow standard Ø1" posts to be used with the clamping forks sold below.

The BE1(/M) base adapter is available in a pack of five for ease of ordering.

Clamping Forks

These clamping forks are designed to provide exceptional clamping force when used with our Ø1/2" post holders and Ø1" posts that have been adapted using the BE1(/M) or BE1R(/M) to pedestal-style mounts. They can also be used with our pedestal-style Ø1/2" post holders or Ø1" pedestal posts without any need for the BE1(/M) or BE1R(/M).

Fabricated from solid 303 stainless steel, all of these clamping forks create three points of contact with the table for high stability. For flexibility in the positioning of post assemblies, the CF038-P5 and CF038C(/M)-P5 forks offer 0.40" (10.2 mm) long counterbored slots, the CF125 and CF125C(/M) forks offer 1.24" (31.5 mm) long counterbored slots, and the CF175 and CF175C(/M) forks have 1.75" (44.4 mm) long counterbored slots. The counterbored slots on the CF038-P5, CF125, and CF175 forks are designed for user-supplied 1/4"-20 (M6)-threaded cap screws. For further convenience, the CF038C(/M)-P5, CF125C(/M), and CF175C(/M) forks each include a 1/4"-20 (M6)-threaded captive screw. Please note that significant over tightening of clamping forks can deform the surface of an optical table, which can cause misalignment of components and decrease stability.

Our clamping forks are also available in packages of five for ease of ordering (note: the CF038-P5 and CF038C(/M)-P5 clamping forks are only available in packs of five).

Click to Enlarge

Click for POLARIS-CA1/M Holding Torque Results*

The Polaris clamping fork design has undergone extensive testing to ensure high-quality performance. See the full presentation for more details.

*It is important to note that the 1/4"-20 and M6 x 1.0 clamping torque values have been adjusted to provide the same clamping post and table forces. Also note that the maximum recommended tightening torque for an 18-8 stainless steel screw is 75.2 in-lbs for a 1/4"-20 screw and 8.8 N-m for an M6 x 1.0 screw. Higher mounting torques can cause the screw to fail.

Click to Enlarge

The arm can be mounted with either flat surface in contact with the table, allowing for compact setups.

Click to Enlarge

Side-Located 1/4"-20 (M6) Screw Actuates Clamping Bore

- 3-Point Contact Bore with Flexure Clamping Mechanism

- Versions for Ø1" or Ø25 mm Posts for Polaris Mounts and Ø1" Monolithic Polaris Mount (See Table Below)

- 0.60" Bore Depth Supports Height Adjustments Up to 0.25"

- Allows Posts to be Rotated 360°

- 0.75" (19.1 mm) or 1.30" (33.0 mm) Slot for 1/4"-20 (M6) Cap Screw

- Heat-Treated, Stress-Relieved Stainless Steel Provides Large Clamping Force

- Design Supports Left- and Right-Handed Orientations (See Lower Left Image)

- High Stability Ideal for Use with Our Kinematic Polaris Mirror Mounts

- Vacuum Compatible to 10-9 Torr at 25 °C with Proper Bake Out

- ±0.001" (±0.02 mm) Surface Flatness

The Polaris® Clamping Arms are the ideal solution for stably mounting our Ø1" or Ø25 mm Posts for Polaris Mounts or Ø1" Monolithic Polaris Mount. Each clamping arm, which is machined from heat-treated, stress-relieved stainless steel bar stock, provides extremely high holding forces with minimal torquing of the mounting screws (see the graph to the right).

The flat, non-bridging top and bottom surfaces of each clamping arm allow it to be used with either side in contact with an optical table or other mounting surface. This feature allows the clamp to be positioned in left- or right-handed orientations and optical components to be placed in near contact to one another while minimizing the footprint (see the image to the left). On each side of the arm, a relief cut around the slot protects the ±0.001" (±0.02 mm) flat surface from any marring due to the screw and washer, allowing for more stable mounting.

The clamping arms are offered with slot lengths of 0.75" (19.1 mm) or 1.30" (33.0 mm), providing flexibility when used in applications such as tight laser cavity setups. Four of our clamping arms are designed to hold Ø1" posts, while the remaining two are designed to hold Ø25 mm posts; see the table below for details. Note the arms with a Ø1" (25.4 mm) bore are not compatible with Ø25 mm posts; the bore diameter is too large and will not contact the post when clamping.

Non-Bridging Design: Industry Standard Clamping Fork

vs. Polaris Clamping Arm

Industry standard clamping forks are designed with a bridge, as shown in Figure 1, for clamping to pedestal-style posts or post holders. This design will slightly damage the laser platform during each use by pulling up the part of the platform located under the bridge. The Polaris clamping arm, as shown in Figure 2, is designed with a flat top and bottom to eliminate this problem.

Click to Enlarge

Click to EnlargeFigure 1: A Bridge is Created When an Industry Standard Clamping Fork is Used with a Pedestal Post

Click to Enlarge

Click to EnlargeFigure 2: The Polaris Clamping Arm Eliminates the Bridge Created by an Industry Standard Clamping Fork

The flexure clamp, shown in the photo to the left, is actuated using a side-located 1/4"-20 (M6 x 1.0) cap screw and allows a post to be rotated 360° about its center. As the flexure clamp and mounting slot are secured with separate screws, the position of the fork and the rotational alignment of the post can be adjusted independently. While best performance is achieved with full post engagement, the 0.60" (15.2 mm) thick mounting bore supports up to 0.25" of post height adjustment.

The Polaris clamping fork design has undergone extensive testing to ensure high-quality performance; see the graph to the upper right. For optimal performance, we recommend tightening the flexure clamping screw of an imperial clamping arm with 15 to 25 in-lb of torque and the flexure clamping screw of a metric clamping arm with 1.75 to 3 N•m of torque. When mounting to a table or platform, we recommend using 40 to 65 in-lb of torque for an imperial clamping arm and 4.75 to 7 N•m of torque for a metric clamping arm. Please note that the values for imperial and metric clamps are not a direct conversion due to an efficiency difference between 1/4"-20 and M6 x 1.0 screws. The efficiency of M6 x 1.0 screws is about 5% less than that of 1/4"-20 screws due to differences in diameter and pitch. For best results, use the maximum recommended torques from each range. These torque values can be dialed in using a torque driver.

| Item # | Compatible Post Size |

Clamping Screw |

Slot Length | Footprint |

|---|---|---|---|---|

| POLARIS-SCA1 | Ø1" (25.4 mm) |

1/4"-20 (3/16" Hex) |

0.75" (19.1 mm) |

2.78" x 1.60" (70.5 mm x 40.6 mm) |

| POLARIS-CA1 | 1.30" (33.0 mm) |

3.33" x 1.60" (84.5 mm x 40.6 mm) |

||

| POLARIS-SCA1/M | M6 x 1.0 (5 mm Hex) |

0.75" (19.1 mm) |

2.78" x 1.60" (70.5 mm x 40.6 mm) |

|

| POLARIS-CA1/M | 1.30" (33.0 mm) |

3.33" x 1.60" (84.5 mm x 40.6 mm) |

||

| POLARIS-SCA25/M | Ø25.0 mm (Ø0.98") |

0.75" (19.1 mm) |

2.78" x 1.60" (70.5 mm x 40.6 mm) |

|

| POLARIS-CA25/M | 1.30" (33.0 mm) |

3.33" x 1.60" (84.5 mm x 40.6 mm) |

Click to Enlarge

The SPW501 wrench tightens Ø1" posts that have torque slots or holes.

The SPW501 Spanner Wrench is designed to tighten or loosen Ø1" posts that have torque slots, as illustrated in the photo to the right. The SPW501 can also be used with Ø1/2" posts and Ø1" posts that have through holes. The wrench is designed to fit into the slot or through hole and provide leverage for tightening or loosening the post when mounting the post directly to a tapped hole. Please use minimal force when tightening to prevent binding due to overtightening.

Products Home

Products Home

Zoom

Zoom

Click to Enlarge

Click to Enlarge

Ø1" Posts

Ø1" Posts