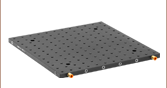

Solid Aluminum Optical Breadboards

- Matte Black Anodized Finish Reduces Unwanted Reflections

- Grid of Through-Tapped 1/4"-20 (M6) Mounting Holes

- 1/2" (12.7 mm) or 3/4" (19.05 mm) Thick

- Custom Sizes Available

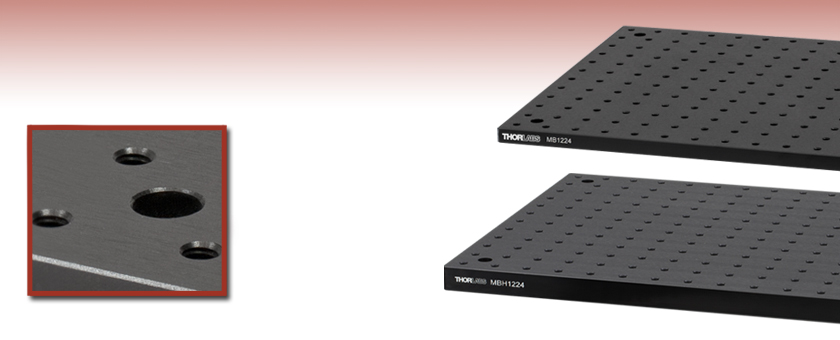

Counterbored

Ø1/4" (M6)

Mounting Holes

MBH1224

3/4" Thick

MB1224

1/2" Thick

Please Wait

| Specification | Imperial Boards | Metric Boards | ||

|---|---|---|---|---|

| Breadboard Thickness | 0.5" | 0.75" | 12.7 mm | 19.05 mm |

| Material | Aluminum Plate | |||

| Finish | Matte Black Anodized | |||

| Flatness | ±0.006" over 1 ft2 | ±0.15 mm over 0.09 m2 | ||

| Hole Size and Spacing | 1/4"-20 Tapped Holes on 1" Centers | M6 Tapped Holes on 25 mm Centers | ||

| Distance from Edge to First Hole |

0.5" on All Sides | 12.5 mm on All Sides | ||

| Number of Counterbored Holesa | Four 1/4"-20 Located at Corners - Inset 1" | Four M6 Located at Corners - Inset 25 mm | ||

Features

- Large Range of Sizes Available from Stock

- 1/2" (12.7 mm) or 3/4" (19.05 mm) Thick

- Standard Imperial and Metric Breadboard Hole Patterns

- Offset Mounting Counterbores Allow a Full, Uninterrupted, Threaded Hole Matrix

- Larger Breadboards Have a Fifth Center-Located Counterbore

- Imperial: At Least 18" Wide

- Metric: At Least 450 mm Wide

- Black Anodized Surface with Low Reflectance

- Double-Density, High-Density Versions, and Custom Sizes Available

These solid aluminum, nonmagnetic baseplates provide a convenient and cost-effective platform for assembling prototype optical assemblies, conducting experiments, and mounting small subsystems. They are finished with a black, minimally reflective anodized coating and are through-drilled with a standard 1" (imperial) or 25 mm (metric) hole pattern offset 1/2" or 12.5 mm, respectively, from the edges of the board. The holes are threaded completely through these breadboards, allowing components to be mounted on both sides at once. Breadboards are offered in either 1/2" or 3/4" thicknesses.

Each breadboard features four or five mounting holes that are offset from the array of 1/4"-20 (M6) threaded holes to create an uninterrupted surface for any intended application. The four standard mounting holes are located at each corner of the breadboard, inset 1" from each edge (25 mm on metric). The larger imperial and metric breadboards have a fifth counterbored mounting hole at the center of each board (imperial boards 18" or wider, metric boards 450 mm or wider). Utilizing the center mounting hole increases the mounting options available, reduces stress at the corner mounting holes, and increases rigidity when heavy loads are placed on the boards (see photo to the right). The mounting holes may be used to attach the breadboards to variety of surfaces and mounts, including optical tables, other breadboards, mounting posts, and brackets. Please see the Mounting Options tab for more details.

Click to Enlarge

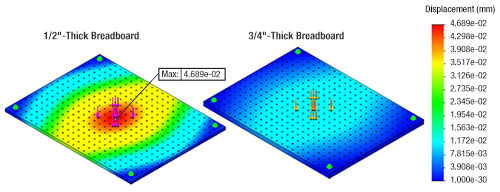

This finite element analysis simulation shows the vertical displacement of two breadboards with 120 N force applied at center. The 1/2"-thick breadboard on the left shows a maximum displacement of 0.047 mm, while the 3/4"-thick breadboard on the right shows only 0.014 mm. The 3/4"-thick breadboard's increased stiffness leads to lower board displacement.

Click to Enlarge

A fifth mounting hole in the middle of larger breadboards increases rigidity and reduces stress when mounting heavy loads.

Other Breadboard Options

For vacuum applications, we recommend using our selection of Unanodized Breadboards. Optical Breadboard Enclosures are available to protect sensitive equipment from dust, stray light, acoustic noise, and thermal variations. Enclosures are offered completely sealed or with sliding door access.

Thorlabs also offers Double Hole Density Aluminum Breadboards with 1/2" offset hole spacing, doubling the density of mounting holes. These are offered in sizes ranging from 4" x 24" to 8" x 36"

(100 mm x 600 mm to 200 mm x 900 mm) with thicknesses of 0.5" (12.7 mm), making their slim profile ideal for compact work areas. The same double-hole-density pattern is also available on our Circular Breadboards.

For applications with limited space, Thorlabs offers Mini-Series Breadboards with 4-40 (M3) or both 8-32 (M4) and 1/4"-20 (M6) tapped holes. These breadboards feature an increased tapped hole density and thinner breadboard thickness.

Custom Breadboards

We offer a service for custom breadboard orders, with options that include hole pattern and spacing, size, thickness, and anodizing. For a quote, please fill out our custom breadboards form.

Vertical Arrangement

Thorlabs' aluminum breadboards can be mounted vertically (or perpendicular to a mounting surface) using a wide variety of 90 degree mounting plates. For tall arrangements, we recommend the setup shown to the left. Here, the MB12 breadboard is vertically oriented using two VB01 Vertical Brackets. For smaller arrangements, the AB90, AP90, or AP90L Right-Angle Brackets may be used.

Vibration Isolating Feet

Thorlabs' aluminum breadboards may be mounted on a set of vibration isolation feet. These Sorbothane Mounting Feet may be used to isolate a small breadboard from its mounting surface.

Not shown: Standard RDF1 Rubber Damping Feet may also be used where high vibrational damping is not necessary.

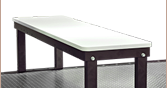

Elevated Arrangement with Adjustable Mounting Feet

A set of Ø1.5" Mounting Posts can be used to elevate an aluminum breadboard off of the work surface. At left, an MB1824 breadboard is shown with four P6 Mounting Posts. An adjustable, self-leveling BMF4 Mounting Foot is attached to each mounting post. The self-leveling mounting feet feature rubberized feet and screw thread height adjustment.

Not shown: DP14A Damped Posts are available in 14" lengths for vibration sensitive elevated mounting applications.

Elevated Breadboard Arrangement

A more permanent Aluminum Breadboard mounting option, shown to the left, features pedestal-style Ø1.5" Mounting Posts clamped to an optic bench. The MB1824 Aluminum Breadboard to the left is elevated off the optic bench surface using a set of four P6 Mounting Posts, each with a PB4 Pedestal Base Adapter and PF175B Clamping Fork.

Not shown: Ø1.5" Translating Posts or Ø1.5" Damped Posts may also be used in lieu of the P6 Mounting Posts for applications requiring further height adjustment or reduced sensitivity to vibrations, respectively.

Breadboard Enclosure Systems

Enclosures may be added to Thorlabs' aluminum breadboards to house light and dust-sensitive equipment. Thorlabs offers a variety of plexiglass and standard darkening enclosures. The enclosure shown to the left has the front panel removed for access. Enclosures with sliding doors fabricated from plexiglass or black hardboard are also available.

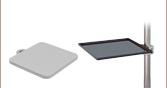

Breadboard Mounting Brackets

The PSY321(/S) Post Mounted Breadboard Brackets are designed to securely mount breadboards onto Ø1.5" posts. Each bracket will support any aluminum breadboard up to 12" x 12" (300 mm x 300 mm) in size, and has a maximum load capacity of 20 kg (44 lbs).

Not shown: PSY360 and PSY361 Breadboard Mounting Brackets can be used to mount breadboards to the lean bars of a ScienceDesk™ workstation.

| Item # | Dimensions (L x W x H) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) |

Weight (lbs) |

Mass (kg)a |

Weight (lbs)a |

||

| Imperial | |||||

| MB4 | 4" x 6" x 0.5" | 0.50 | 1.10 | 0.52 | 1.15 |

| MB412 | 4" x 12" x 0.5" | 1.0 | 2.2 | 1.3 | 2.86 |

| MB6 | 6" x 6" x 0.5" | 0.75 | 1.65 | 0.81 | 1.78 |

| MB612F | 6" x 12" x 0.5" | 1.5 | 3.3 | 1.8 | 3.96 |

| MB618 | 6" x 18" x 0.5" | 2.3 | 5.06 | 2.72 | 5.98 |

| MB624 | 6" x 24" x 0.5" | 3.00 | 6.61 | 4.60 | 10.13 |

| MB636 | 6" x 36" x 0.5" | 4.50 | 9.92 | 6.14 | 13.50 |

| MB648 | 6" x 48" x 0.5" | 6.00 | 13.23 | 6.14 | 13.50 |

| MB8 | 8" x 8" x 0.5" | 1.33 | 2.93 | 1.40 | 3.09 |

| MB810 | 8" x 10" x 0.5" | 1.66 | 3.66 | 1.76 | 3.87 |

| MB1012 | 10" x 12" x 0.5" | 2.50 | 5.51 | 2.64 | 5.80 |

| MB12 | 12" x 12" x 0.5" | 3.00 | 6.61 | 3.36 | 7.40 |

| MB1218 | 12" x 18" x 0.5" | 4.50 | 9.92 | 5.84 | 12.85 |

| MB1224 | 12" x 24" x 0.5" | 6.00 | 13.23 | 7.36 | 16.20 |

| MBH1224 | 12" x 24" x 3/4" | 9.00 | 20.00 | 10.00 | 22.05 |

| MB1236 | 12" x 36" x 0.5" | 9.00 | 19.84 | 10.52 | 23.15 |

| MB1248 | 12" x 48" x 0.5" | 12.00 | 26.45 | 14.32 | 31.50 |

| MB1445 | 14" x 45" x 0.5" | 13.0 | 28.7 | 23.0 | 50.7 |

| MB1456 | 14" x 56" x 0.5" | 16.2 | 35.7 | 32.0 | 70.5 |

| MB18 | 18" x 18" x 0.5" | 6.70 | 14.7 | 7.50 | 16.5 |

| MBH18 | 18" x 18" x 3/4" | 11.00 | 24.25 | 13.00 | 28.66 |

| MB1824 | 18" x 24" x 0.5" | 9.00 | 19.84 | 11.02 | 24.25 |

| MBH1824 | 18" x 24" x 3/4" | 13.00 | 28.66 | 15.00 | 33.07 |

| MB1830 | 18" x 30" x 0.5" | 11.50 | 25.3 | 13.0 | 28.6 |

| MB1836 | 18" x 36" x 0.5" | 13.5 | 29.7 | 15.0 | 33.0 |

| MB2424 | 24" x 24" x 0.5" | 12.00 | 26.45 | 14.61 | 32.15 |

| MBH24 | 24" x 24" x 3/4" | 18.00 | 39.68 | 20.00 | 44.09 |

| MB2436 | 24" x 36" x 0.5" | 18.00 | 39.68 | 18.04 | 39.68 |

| MB2448 | 24" x 48" x 0.5" | 24.00 | 52.91 | 27.05 | 59.52 |

| MB30 | 30" x 30" x 0.5" | 19.20 | 42.24 | 21.0 | 46.2 |

| Item # | Dimensions (L x W x H) |

Unpackaged | Packaged Shipping | ||

|---|---|---|---|---|---|

| Mass (kg) |

Weight (lbs) |

Mass (kg)a |

Weight (lbs)a |

||

| Metric | |||||

| MB1015/M | 100 mm x 150 mm x 12.7 mm | 0.50 | 1.10 | 0.67 | 1.47 |

| MB1030/M | 100 mm x 300 mm x 12.7 mm | 1.0 | 2.2 | 1.3 | 2.86 |

| MB1515/M | 150 mm x 150 mm x 12.7 mm | 0.75 | 1.65 | 0.92 | 2.03 |

| MB1530F/M | 150 mm x 300 mm x 12.7 mm | 1.5 | 3.3 | 1.8 | 3.96 |

| MB1545/M | 150 mm x 450 mm x 12.7 mm | 2.3 | 5.06 | 2.72 | 5.98 |

| MB1560/M | 150 mm x 600 mm x 12.7 mm | 3.00 | 6.61 | 4.60 | 10.13 |

| MB1590/M | 150 mm x 900 mm x 12.7 mm | 4.50 | 9.92 | 6.14 | 13.50 |

| MB15120/M | 150 mm x 1200 mm x 12.7 mm | 6.00 | 13.23 | 6.14 | 13.50 |

| MB2020/M | 200 mm x 200 mm x 12.7 mm | 1.33 | 2.93 | 1.42 | 3.12 |

| MB2025/M | 200 mm x 250 mm x 12.7 mm | 1.66 | 3.66 | 1.82 | 4.00 |

| MB2530/M | 250 mm x 300 mm x 12.7 mm | 2.50 | 5.51 | 2.73 | 6.00 |

| MB3030/M | 300 mm x 300 mm x 12.7 mm | 3.00 | 6.61 | 3.64 | 8.00 |

| MB3045/M | 300 mm x 450 mm x 12.7 mm | 4.50 | 9.92 | 5.61 | 12.35 |

| MB3060/M | 300 mm x 600 mm x 12.7 mm | 6.00 | 13.23 | 7.27 | 16.00 |

| MBH3060/M | 300 mm x 600 mm x 19.05 mm | 9.00 | 19.84 | 10.00 | 22.05 |

| MB3090/M | 300 mm x 900 mm x 12.7 mm | 9.00 | 19.84 | 10.74 | 23.63 |

| MB30120/M | 300 mm x 1200 mm x 12.7 mm | 12.00 | 26.45 | 14.32 | 31.50 |

| MB35115/M | 350 mm x 1150 mm x 12.7 mm | 13.0 | 28.7 | 23.0 | 50.7 |

| MB35142/M | 350 mm x 1425 mm x 12.7 mm | 16.2 | 35.7 | 32.0 | 70.5 |

| MB4545/M | 450 mm x 450 mm x 12.7 mm | 6.70 | 14.7 | 7.50 | 16.5 |

| MBH4545/M | 450 mm x 450 mm x 19.05 mm | 11.00 | 24.25 | 13.00 | 28.66 |

| MB4560/M | 450 mm x 600 mm x 12.7 mm | 9.00 | 19.84 | 10.73 | 23.60 |

| MBH4560/M | 450 mm x 600 mm x 19.05 mm | 13.00 | 28.66 | 15.00 | 33.07 |

| MB4575/M | 450 mm x 750 mm x 12.7 mm | 11.20 | 24.64 | 13.0 | 28.6 |

| MB4590/M | 450 mm x 900 mm x 12.7 mm | 13.5 | 29.7 | 15.0 | 33.0 |

| MB6060/M | 600 mm x 600 mm x 12.7 mm | 12.00 | 26.45 | 13.86 | 30.50 |

| MBH6060/M | 600 mm x 600 mm x 19.05 mm | 17.00 | 37.48 | 19.00 | 41.89 |

| MB6090/M | 600 mm x 900 mm x 12.7 mm | 18.00 | 39.68 | 24.50 | 53.90 |

| MB60120/M | 600 mm x 1200 mm x 12.7 mm | 23.00 | 50.71 | 27.05 | 59.52 |

| MB7575/M | 750 mm x 750 mm x 12.7 mm | 18.60 | 40.92 | 21.0 | 46.2 |

| Posted Comments: | |

Sion Richards

(posted 2024-03-12 09:59:19.067) We have 2 of your black anodized breadboards in one of our X-ray test lab in STFC. We have recently been testing the lab for lead contamination and found that lead sheeting that has been used on the breadboards have left significant contamination. Our attempts at decontaminating these breadboards and other black anodized surfaces of Thorlabs equipment has had limited success.

It has been suggested that the porous nature of the anodized surfaces and the soft nature of lead means that lead has worked its way into the surfaces. Are you able to tell us anything about the anodizing process you use, specifically if you know anything about the porosity of the surface, the composition of the dye you use and how you seal them?

Best regards,

Sion spolineni

(posted 2024-03-15 07:59:26.0) Thank you for reaching out to us and sharing your concerns about anodized breadboards. I will personally investigate this matter and contact you to discuss the issue in detail and provide you with all the relevant information about our anodization process as far as it is possible. We appreciate your patience and understanding in this matter. Héctor Álvarez Martínez

(posted 2022-01-20 08:21:55.72) Good afternoon,

I would like to know;

1/ Lead time of the MB1545/M Aluminium Breadboard.

2/ Price and lead time of a customized Aluminium Breadboard: 150 mm x 400 mm x 12.7 mm, M6 Taps.

Thanks in advance,

Héctor cwright

(posted 2022-01-20 11:05:26.0) Response from Charles at Thorlabs: Thank you for your query. Requests for lead times and custom items are most readily answered by contacting your local sales office: https://www.thorlabs.com/locations.cfm. We will look into this and reach out to you about this by email. Zohair Mahmoud Osama Hassan Usfoor

(posted 2021-12-14 11:57:52.603) Hello,

I would like to request a quote for this product, please.

Shipping address is:

Maria-Goeppert-Mayer-Straße 2

44227 Dortmund

Best regards,

Zohair Usfoor cwright

(posted 2021-12-15 04:57:00.0) Response from Charles at Thorlabs: Thank you for contacting us. Orders can be placed through the website by adding the item to your cart or by contacting your local sales team. These details can be found here, https://www.thorlabs.com/locations.cfm. I will ask your local sales team to reach out to you with a quote. 健一 梶山

(posted 2021-11-24 16:39:32.737) パッケージ重量(目安):4.65 kg / Eachは、MB3030/Mの3.00 kg / Eachより重いのは明らかに間違っている気がします。 cwright

(posted 2021-11-25 07:54:53.0) Response from Charles at Thorlabs: Thank you for your feedback. The packaged weight should be much closer to the item weight. In this case 1.74 kg is a good estimate. Mika C

(posted 2020-07-15 10:02:20.213) What temperature do these breadboards go up to? I would like to use one to support a vacuum chamber during a high temperature bake. cwright

(posted 2020-07-16 10:24:04.0) Response from Charles at Thorlabs: Thank you for your query. We do not have a specified upper limit for these boards. Since aluminium oxide and aluminium have different thermal expansion coefficients it is possible, depending on the number of heating cycles, the temperature you are using and how quickly it is heated, that you could experience cracking of the coating. I would recommend using our unanodised breadboards for such an application. CC Kwong

(posted 2020-05-17 23:45:49.9) May I know what is the type of anodization that is applied to the breadboards? Thank you. DJayasuriya

(posted 2020-05-18 09:35:32.0) Thank you for your inquiry. It's sulphuric acid anodising that we use with our breadboards. DJayasuriya

(posted 2020-05-18 09:35:32.0) Thank you for your inquiry. It's sulphuric acid anodising that we use with our breadboards. James Jelen

(posted 2020-05-06 12:57:06.133) What grade of aluminum is the board made from? For example 70/75 T6? 60/65, etc. I did not find it in the specs cited. Thanks very much. DJayasuriya

(posted 2020-05-07 07:20:14.0) Thank you for your inquiry. For solid aluminium breadboard we use 5083 Aluminium Alloy. Fedor Talantov

(posted 2020-04-27 22:19:02.29) Hello,

It appears that the solidmodels for the 0.75" thick breadboard (as well as some of the metric breadboards) have an issue with downloading, and do not import correctly. Specifically, the downloaded file is is ~24kB, as compared to 1953kB for the MB1830 solidmodel.

Thanks,

Fedor. DJayasuriya

(posted 2020-04-28 07:15:49.0) Hello Fedor, Thank you for your question. We will gt in touch with you directly to resolve this issue. DJayasuriya

(posted 2020-04-28 07:15:49.0) Hello Fedor, Thank you for your question. We will gt in touch with you directly to resolve this issue. user

(posted 2019-12-12 13:37:37.84) Could you please tell me what is the pitch of the threading in the M6 holes of the aluminium breadboards? Is it e.g. fine 0.75 mm or coarse 1 mm? YLohia

(posted 2019-12-12 04:24:46.0) Hello, the pitch on the threaded M6 holes is M6 X 1.0. jwlock

(posted 2018-02-27 10:01:19.703) What is the flatness tolerance on the face of your solid breadboards? E.g. MB4560/M

Thank you bwood

(posted 2018-03-02 05:57:28.0) Response from Ben at Thorlabs: Thank you for your question. The flatness tolerance of the top face of our aluminium breadboards is ±0.15 mm over 0.09 m². Ryan.springer

(posted 2016-05-04 17:45:14.523) Please tell me specifically what type/grade of aluminum this breadboard is made from. Thank you msoulby

(posted 2016-05-05 10:24:30.0) Response from Mike at Thorlabs: The breadboards are made using aluminium tooling plate C250 eddie.ross

(posted 2016-03-03 11:01:40.48) When using the breadboard in the vertical arrangement, what is the maximum weight that can be mounted? bhallewell

(posted 2016-03-03 11:39:00.0) Response from Ben at Thorlabs: Thank you for your feedback. We will contact you directly to discuss the load characteristics of the vertically orientated breadboard as the recommended load would be dependent upon a number of factors e.g. stability based on the size of the board used & whether the length or height is aligned parallel to the mounting surface, vertical position of the load, the height/moment of the load etc. I will contact you directly to obtain some details and work this through with you. jay.a.cote

(posted 2016-01-19 08:03:59.677) What is the hole location tolerance for the 1/4-20s and the counterbored holes??? from the edge and between holes. besembeson

(posted 2016-01-19 01:23:17.0) Response from Bweh at Thorlabs USA: The tolerance is +/-0.25mm. bhallewell

(posted 2016-01-21 04:08:28.0) Response from Ben at Thorlabs: The following are referenced from hole centres.

Counterbore-Edge Distance - 25.4mm ± 0.25mm

Mounting Hole-Edge Distance - 12.7mm ± 0.25mm

Hole-hole Distance - 25.4mm ± 0.25mm

I hope this is of use to you. cddarne

(posted 2015-09-03 17:26:03.24) I wanted to know the maximum weight bearing capacity for the breadboards. I need to make up my mind based on this criterion. Is this information included in the product information? msoulby

(posted 2015-09-07 09:19:23.0) Response from Mike at Thorlabs: The MB breadboards are made from a solid piece of aluminium tooling plate which is 12.7mm thick. We do not have and load capacity data for this as it is simply a solid piece of metal. However if you are using a larger sized breadboard then the amount of deflection due to load on the breadboard will be higher. If you intended to us a large breadboard with a large amount of weight then we would recommend using our thicker Nexus honeycomb breadboards instead http://www.thorlabs.de/navigation.cfm?guide_id=44 or even an optical table http://www.thorlabs.de/navigation.cfm?guide_id=41 elkeneu

(posted 2015-04-27 16:21:55.847) for stray light sensitive applications it would be useful to have breadboars where the M6 threaded holes do not go all the way through the breadboard. msoulby

(posted 2015-04-28 07:03:29.0) Response from Mike at Thorlabs: We have custom breadboard capabilities and have contacted you directly to get more information about the breadboard that you require. tcohen

(posted 2012-06-25 08:59:00.0) Response from Tim at Thorlabs: Thank you for your feedback! The current design has the mounting holes for the breadboard counterbored and offset which allows the full surface of the table to be used for mounting components. We would like to discuss the details and benefits of your proposed design with you, but we do not have your email. Please email us at techsupport@thorlabs.com to further discuss your design. user

(posted 2012-06-18 10:25:09.0) Opposite mount hole spacing to the hole pattern would be useful. As would having the mount holes counterbored so that the corner three holes in the breadboard can be used. bdada

(posted 2011-09-20 17:34:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. The MB series breadboards are made from solid aluminum so they are non-magnetic. We will clarify this on our website. mabdelrahman

(posted 2011-09-14 08:58:35.0) Are these breadboards magnetized?

It may be useful to add this to the item description.

Mohamed Ramy tor

(posted 2010-12-08 08:31:01.0) Response from Tor at Thorlabs to bezdecny: Thank you for your suggestion. We are using it to help determine whether this should be added as a stock item. In the meantime, I will contact you for more details to see whether we can provide this to you as a custom item. bezdecny

(posted 2010-12-07 11:08:17.0) It would be very useful if you had an option to purchase breadboards with opposite mounting hole spacing to hole pattern. For example a 300mm x 300mm board with M6 thread, but with mounting holes 10" apart. apalmentieri

(posted 2010-03-05 10:48:42.0) A response from Adam at Thorlabs: Thanks for your suggestion, we will work to make it easier to submit any required drawings with an RFQ. Please note that all drawings can be emailed to techsupport@thorlabs.com for an immediate quote. user

(posted 2010-03-04 14:42:52.0) It would be benifical to be able to attach a drawing to the custom breadboard RFQ page kbuffington

(posted 2007-09-20 13:53:19.0) There was no place for feedback on the custom breadboard page. Customers should be able to enter more than one custom breadboard request at a time, before submitting. |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

|---|---|---|---|---|---|

| Construction | |||||

| Breadboard Thickness | 60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

| Working Surface | 4003 Grade Stainless Steel or 304L Grade Nonmagnetic Steel Top Plate |

4003 Grade Stainless Steel Top Plate | Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb | N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) | Black Laminated Aluminum Sides |

N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options | Non-Sealed | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6), 4-40 (M3), or 8-32 (M3) and 1/4"-20 (M6) Tapped Holes |

|

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers or 0.5" (12.7 mm) Centers |

|

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) on all Sides | |

| Performancea | |||||

| Damping |  |

|

|

N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick |

|||

Optical Breadboard Selection Guides

The selection guides below list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer anodized aluminum water cooled breadboards in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale operations. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Imperial Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MS12B/M MSB30/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

Products Home

Products Home

Standard Series Optical Breadboards

Standard Series Optical Breadboards