Pigtailed Laser Diodes, Single Mode Fiber

- Wavelengths from 405 to 1625 nm

- FC/PC or FC/APC Connector

- Custom Pigtail Options Available

TO-Packaged Pigtail,

Single Mode Fiber

FC/PC Connector

FC/APC Connector

Please Wait

| Webpage Features | |

|---|---|

| Clicking this icon opens a window that contains specifications and mechanical drawings. | |

| Clicking this icon allows you to download our standard support documentation. | |

|

Choose Item |

Clicking the words "Choose Item" opens a drop-down list containing all of the in-stock lasers around the desired center wavelength. The red icon next to the serial |

| Pin Code | Monitor Photodiode |

|---|---|

| A | Yes |

| B | Yes |

| C | Yes |

| D | Yes |

| E | No |

| F | Yes |

| G | No |

| H | No |

Features

- Single Mode Pigtailed Laser Diodes from 405

nm to 1625nm - Internal 8°-Angle-Cleaved Fiber (See the Design Tab)

- Connector: FC/PC or FC/APC (2.0 mm Narrow Key)

- 1 m of Single Mode Fiber

- Custom Pigtails Available Upon Request by Contacting Tech Support

Our precise pigtail alignment process for laser diodes includes multiple test and inspection points that ensure that the coupling efficiency of the laser emission into the single mode pigtail is maximized. In addition, the input end of the fiber is cleaved at an 8° angle in order to minimize back reflections that can cause the output intensity to fluctuate (see the Design tab for details). We offer versions based on TO-packaged diodes (Ø5

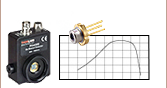

While the center wavelength is listed for each laser diode, this is only a typical number. The center wavelength of a particular unit varies from production run to production run, so the diode you receive may not operate at the typical center wavelength. After clicking "Choose Item" below, a list will appear that contains the dominant wavelength, output power, and operating current of each in-stock unit. Clicking on the red Docs Icon next to the serial number provides access to a PDF with serial-number-specific L-I-V and spectral characteristics.

The reliability of the laser diode rapidly declines at higher temperatures. Therefore, for stable output power and wavelength, it is highly recommended that you use a temperature controller with these products. Diodes can also be temperature tuned, which will alter the lasing wavelength.

Laser diodes are sensitive to electrostatic shock. Please take the proper precautions when handling the device, such as using an ESD wrist strap. These lasers are also sensitive to optical feedback, which can cause significant fluctuations in the output power of the laser diode depending on the application.

We recommend cleaning the fiber connector before each use, if there is any chance that dust or other contaminants may have deposited on the surface. To view our fiber cleaning products, click here. The laser intensity at the center of the fiber tip can be very high and may burn the tip of the fiber if contaminants are present. While the connectors on these pigtailed laser diodes are cleaned and capped before shipping, we cannot guarantee that they will remain free of contamination after they are removed from the package. For all of these pigtailed laser diodes, the laser should be off when connecting or disconnecting the device from other fibers, particularly for lasers with power levels above 10

Please contact Tech Support if you would like a quote on custom pigtailed laser diodes or for a volume order.

The drawing to the right shows a laser diode's emitted light focused into an angle-polished fiber. By angling the optical fiber at 8°, light that is not coupled into the optical fiber is reflected away from the laser diode. If this reflected light were reflected back toward the diode, light would be coupled into the diode and cause fluctuations in power and wavelength.

Further Reducing Back Reflection

Although we use a fiber coupling design that minimizes back reflections, other factors may couple light back into the fiber. Many of our standard pigtailed laser diodes feature optical fiber with an FC/PC connector. When the FC/PC connector is not connected directly to another FC/PC connector, about 4% of light in the fiber is reflected back toward the laser diode due to the silica/air interface. Customers who require a silica/air interface or minimal back reflections in their application can contact Tech Support to request FC/APC connectors. As FC/APC connectors have an angled polish, light reflected back toward the diode will be further minimized.

When operated within their specifications, laser diodes have extremely long lifetimes. Most failures occur from mishandling or operating the lasers beyond their maximum ratings. Laser diodes are among the most static-sensitive devices currently made and proper ESD protection should be worn whenever handling a laser diode. Due to their extreme electrostatic sensitivity, laser diodes cannot be returned after their sealed package has been opened. Laser diodes in their original sealed package can be returned for a full refund or credit.

Handling and Storage Precautions

Because of their extreme susceptibility to damage from electrostatic discharge (ESD), care should be taken whenever handling and operating laser diodes.

Wrist Straps

Use grounded anti-static wrist straps whenever handling diodes.

Anti-Static Mats

Always work on grounded anti-static mats.

Laser Diode Storage

When not in use, short the leads of the laser together to protect against ESD damage.

Operating and Safety Precautions

Use an Appropriate Driver

Laser diodes require precise control of operating current and voltage to avoid overdriving the laser. In addition, the laser driver should provide protection against power supply transients. Select a laser driver appropriate for your application. Do not use a voltage supply with a current-limiting resistor since it does not provide sufficient regulation to protect the laser diode.

Power Meters

When setting up and calibrating a laser diode with its driver, use a NIST-traceable power meter to precisely measure the laser output. It is usually safest to measure the laser diode output directly before placing the laser in an optical system. If this is not possible, be sure to take all optical losses (transmissive, aperture stopping, etc.) into consideration when determining the total output of the laser.

Reflections

Flat surfaces in the optical system in front of a laser diode can cause some of the laser energy to reflect back onto the laser’s monitor photodiode, giving an erroneously high photodiode current. If optical components are moved within the system and energy is no longer reflected onto the monitor photodiode, a constant-power feedback loop will sense the drop in photodiode current and try to compensate by increasing the laser drive current and possibly overdriving the laser. Back reflections can also cause other malfunctions or damage to laser diodes. To avoid this, be sure that all surfaces are angled 5-10°, and when necessary, use optical isolators to attenuate direct feedback into the laser.

Heat Sinks

Laser diode lifetime is inversely proportional to operating temperature. Always mount the laser diode in a suitable heat sink to remove excess heat from the laser package.

Voltage and Current Overdrive

Be careful not to exceed the maximum voltage and drive current listed on the specification sheet with each laser diode, even momentarily. Also, reverse voltages as little as 3 V can damage a laser diode.

ESD-Sensitive Device

Laser diodes are susceptible to ESD damage even during operation. This is particularly aggravated by using long interface cables between the laser diode and its driver due to the inductance that the cable presents. Avoid exposing the laser diode or its mounting apparatus to ESD at all times.

ON/OFF and Power-Supply-Coupled Transients

Due to their fast response times, laser diodes can be easily damaged by transients less than 1 µs. High-current devices such as soldering irons, vacuum pumps, and fluorescent lamps can cause large momentary transients, and thus surge-protected outlets should always be used when working with laser diodes.

If you have any questions regarding laser diodes, please contact Thorlabs Technical Support for assistance.

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

| Posted Comments: | |

Peter Fischer

(posted 2023-12-12 09:21:50.5) Hallo,

I do not find the laser safety class information for your products. Could you please help?

In particular, what class is LP642-SF20 ? ksosnowski

(posted 2023-12-12 12:25:13.0) Hello Peter, thanks for reaching out to Thorlabs. Because these laser pigtails are not sold as part of a system, we are unable to provide a classification as the exact rating will depend on the user's operating conditions upon installation. While we do provide a serialized LIV with this pigtail, and we do not recommend overdriving, it is not impossible for a user to temporarily overdrive past the max diode ratings for example. Our benchtop lasers like S1FC635 on the other hand are full systems with programmed limits and we are able to rate those systems as a whole. An engineer from your local tech support team has reached out to discuss this application further. Basile K

(posted 2023-11-23 14:45:59.4) Greeting,

I would like to make some changes inside the lens body of the LP660-SP20. Can you tell me if the laser diode is fixed or glued, or is it plugged in?

I already know that there will be a power loss due to the diode change but that's not a problem for me.

Thank you for your answer. jpolaris

(posted 2023-11-29 06:51:09.0) Thank you for contacting Thorlabs. I am afraid that I cannot recommend that you attempt to remove the diode from the body of LP660-SF20. This would destroy the laser as the chip is epoxied in place. user

(posted 2022-09-12 21:37:32.727) Greetings, I would like to know what is the typical lifetime of a Thorlab laser diode? I couldn't find this information on the Thorlab's website. cdolbashian

(posted 2022-09-26 04:38:49.0) Thank you for reaching out to us with this inquiry! The lifetime of a diode depends on many factors including, but not limited to, diode style, driving current, maximum power, cooling method, and mounting method. As such we cannot make a reasonable estimate for any given diode in our catalogue. I have reached out to you directly with recommendations for lengthening your diode lifetime. kh w

(posted 2021-12-14 23:02:54.2) 此激光二极管线宽是多少?带宽是多少? YLohia

(posted 2021-12-14 01:26:39.0) Hello, thank you for contacting Thorlabs. An applications engineer from our team in China (techsupport-cn@thorlabs.com) will discuss this directly with you. Thomas Panier

(posted 2021-01-22 11:21:23.64) Greetings, I would like to know why the Compact Laser Diode Drivers CLD1010LP and CLD1010LP are not recommended for these pigtailed laser diodes. Many thanks for your answer. soswald

(posted 2021-01-25 02:36:03.0) This is a reply from Soenke at Thorlabs: Dear Thomas,

thank you for your feedback. Depending on the diodes pin code, either the CLD1010LP or the CLD1011LP are the recommended mounts/drivers for all of these diodes.

You can either use a combination of LDM9LP (mount) and ITC4001 (driver) or just the CLD1010LP or CLD1011LP alone, as these are combined drivers and mounts. Iskander Usenov

(posted 2020-11-19 16:02:34.973) Hello, can you please specify the wavelength/temperature coefficient (nm/C)? How broad can these lasers be tuned? I'm also interested in LP852-SF30. Thank you YLohia

(posted 2020-11-19 01:59:22.0) Thank you for contacting Thorlabs. The temperature tuning coefficient for both the LP785-SF100 and LP852-SF30 is around 0.25 nm/C. The tunability is entirely limited by the center wavelength spec (at 25 C) and minimum/maximum operating temperature specs. Nishimiya Fuyuki

(posted 2020-07-22 16:37:19.347) Greetings, I would like to know how fast can I modulate the light source? Thank you! YLohia

(posted 2020-07-22 09:37:19.0) Hello, thank you for contacting Thorlabs. Unfortunately, we do not characterize the rise/fall time or bandwidth for these laser diodes. That being said, we expect speeds > 100 MHz to be achievable with the proper drivers/mounts. carolina.franciscangelis

(posted 2018-05-03 10:38:19.25) Greetings,

I would like to know the linewidth of this laser.

Thanks, YLohia

(posted 2018-05-03 08:32:11.0) Hello, thank you for contacting Thorlabs. All of our pigtailed laser diodes are individually tested and come with their unique spec sheets. These are available online and contain the measured spectrum to help our customers pick the particular diode that works better for their application. These individual spec sheets can be accessed by clicking on the "Choose Item" link on the left side of the product number. This will open up a drop-down of different serial numbers we currently have in stock of that part number. Clicking on the red "document" icon next to the serial number will bring up the spec sheet. scottie730318

(posted 2017-10-17 18:33:28.8) Dear sir

We are interest in Pigtailed Laser Diode (LP940-SF30).

How can I buy the Pigtailed Laser Diode and specify the emission wavelength at 940nm? nbayconich

(posted 2017-11-14 03:08:52.0) Thank you for contacting Thorlabs. A particular serial number can be selected from our inventory closer to your desired center wavelength. Additionally these lasers can be slightly tuned by changing the operating temperature. I will contact you directly with a quote for our closest matching centerwavelength diode. yjb4174

(posted 2017-06-20 16:04:58.793) Can I change diode only? I already bought that some months ago but it doesn't work now so I need to have a new one but I want to save my money as much as possible.

I used this laser for alignment a few months but the power of the laser decreased gradually even I can not find the beam with light.

Please, let me know can I buy and change diode only instead of buying the whole product.

Best regards

Jungbae Yoon

Korea University tfrisch

(posted 2017-06-27 10:45:34.0) Hello, thank you for contacting Thorlabs. Unfortunately, the diode is not replaceable in a pigtailed laser diode. The coupling optics and fiber are permanently fixed in the housing and would not be aligned to a different diode. user

(posted 2017-04-13 02:16:24.717) Dear,

Could you let me know the bandwidth of LPS-635-FC?

Thank you. tfrisch

(posted 2017-04-20 01:46:19.0) Hello, thank you for contacting Thorlabs. The bandwidth will vary slightly from unit to unit. We give individualized spec sheets for available units on the webpage. They can be viewed by clicking the "Choose Item" link below and then selecting the spec sheet from the documents list. The bandwidth is typically around 1.5nm FWHM. Please contact us at TechSupport@Thorlabs.com to discuss further. sales

(posted 2016-11-16 01:05:24.24) Dear Sir,

We are planning to UTILIZE the pigtailed laser diodes in our products, Will we able to sell our products to our Customers?, Please advise, Thanks for fast reply, Best Regards, Michael Winik tfrisch

(posted 2016-11-16 02:02:13.0) Hello Michael, thank you for contacting Thorlabs. I have reached out to you directly. kinsung.chan

(posted 2015-08-26 12:34:22.643) Regarding the LPS-635-FC, all the choices of the diodes are 637 nm. May I ask is it possible to replace the laser diode of one's own choice. In other words, can Thorlab customize for me? I'm interested in using the laser diode HL6312G. jlow

(posted 2015-09-21 10:34:17.0) Response from Jeremy at Thorlabs: We can customize our laser pigtail with other LD. For this case, the HL6312G has a central wavelength tolerance range of 625-640nm so there's no guarantee that a laser pigtail made with this LD will have 635nm central wavelength. muttahid07

(posted 2015-06-04 22:25:14.187) Hello,

Please inform me refractive index of core & cladding "LP405-SF10" of this optical fiber.

Thanks. jlow

(posted 2015-08-25 11:53:52.0) Response from Jeremy at Thorlabs: We are not permitted to publish this information on the website. I will contact you directly to provide this. You can also contact us directly at techsupport@thorlabs.com for similar requests in the future. tcohen

(posted 2012-06-20 10:19:00.0) Response from Tim at Thorlabs: Thank you for your feedback. I would like to review your profile and share some pictures of ones we have tested to compare. Please ensure that both the collimator and the fiber are clean. Dirt can accumulate on the fiber tip which will impose dark spots on your image. These can be seen clearly through a fiber scope and can be remedied with our fiber cleaning products, http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=3317. To see imperfections on the scale of darkening that a multimodal pattern would produce is highly irregular. I will contact you to get more information so we can determine the cause of the problem. nizamov.shawkat

(posted 2012-06-18 07:41:14.0) Hello,

I have a question regarding LP642-SF20. I have installed it and coupled its FC/PC output connector via FCB1 to P1-630-FC-2. Now I image the beam onto the CCD camera at ca. 30 cm distance (7x7mm, 1 MPixels). I observe practically homogenous illumination of CCD. Then I install the F280FC-B collimator, which should give us a Gaussian beam with ca. 3-4 mm diameter. I tried with CFC-11X-B too.

The problem is that while beam profile looks like a Gaussian beam in general, it contains also a lot of distortions in it - it is not homogenous and contains some structure in it - brighter / darker spots (not speckles!), like in multimode fibers. I do not have an experience with fibers - is it something to be expected or something is really wrong with my setup? Idea was to use such fiber spatial filter instead of a generic pinhole spatial filter and get a more or less homogenous illumination of area of about 1 mm2. tcohen

(posted 2012-05-08 09:22:00.0) Response from Tim at Thorlabs: Thank you for your feedback! We do have plans to spectrum test every laser pigtail in the future. I have opened a discussion with our engineers regarding your suggestions so that we may provide more useful documentation in the future. Thank you for your suggestions! alexandru.serb05

(posted 2012-05-04 14:17:18.0) Dear ThorLabs,

I always liked the straight-forward organisation of the ThorLabs website. Finding anything is quick and easy. If I can't find it I know it most likely isn't there.

For that reason I'd like to recommend that when uploading documentation for light sources (I'm looking at pigtailed lasers) this documentation is complete and thorough. For example, for the LP-1550-FC the manual is merely 2 pages. A number of crucial things are missing, such as plots of output power vs wavelength at a reference electrical power input and steady state, plots of the power spectral density of noise as detected by a well-characterised photodetector (mathematically discounting for the noise of the photodetector would also be very useful in this case) and, equally crucially, in the online version of the manual there is no indication of the IEEE laser classification. Admittedly this is often easy to guess, but not always... This can delay H&S preparations (as it did in my case when I found out that my 1,5mW IR laser diode is a class 3R and not 3B as I guessed).

As such, I wish to reiterate my recommendation that all components that make it to the market should be extensively characterised and proper, extensive manuals should also be provided along with the 'executive summaries' currently displayed for many such products. Incidentally, I've had a similar problem with SLDs. Unless I can get my hands on noise data for them I can not make a convincing case to my supervisor for buying one.

This is my only criticism to an otherwise unusually user-friendly and well-organised website.

Thank you. bdada

(posted 2011-10-04 19:49:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. Our list of stock PM pigtailed diodes is smaller than our selection of SM pigtails but we will take your request into consideration as we continue expanding our selection of PM pigtails.

In the meantime, we have contacted you regarding a custom version of the LPS-675-FC. johannes.kaschke

(posted 2011-10-04 11:23:14.0) Why is it not possible to get the model LPS-675-FC with a polarization maintaining fiber? Is this setup simply not listed or not possible for other reasons? apalmentieri

(posted 2010-01-27 09:11:12.0) A response from Adam at Thorlabs to Juergen: The diodes that are used in our pigtails can be found under the specifications tab, and they contain links direct to the manufacturers specification sheet. For the LPS-1550-FC, they use the ML925B45F. This diode has a maximum voltage requirement of 1.5V and a maximum rise time of .7ns. I will email you a copy of the specification sheet for this diode. juergen.bosse

(posted 2010-01-27 05:50:32.0) And the product would be REALLY useful if I knew exactly which diode you are using here. I need to modulate it with 2.5 GHz, so the forward voltage and rise/fall time would be the most important parameters to know. Why dont you include the link to the manufacturers data sheet as you do on so many other products?

Thank you in advance, Juergen Bosse acable

(posted 2007-07-26 15:17:56.0) I would go one further and say the drive current and other main specifications need to be listed on the Specs tab for each of the pigtailed lasers. I would probably not recommend that we list this information in the catalog becasue it is nice to be able to switch diodes as they periodically change due to obsolescence or short supply.

Also please make it clear that the angle cleave is internally to the package, i also beleive this design is used for all the pigtails. cjohns

(posted 2007-07-26 13:56:45.0) We should definately show the which diode is used in these so the customers can easily tell the drive current needed |

| The rows shaded green below denote single-frequency lasers. |

| Item # | Wavelength | Output Power | Operating Current | Operating Voltage | Beam Divergence | Laser Mode | Package | |

|---|---|---|---|---|---|---|---|---|

| Parallel | Perpendicular | |||||||

| L375P70MLD | 375 nm | 70 mW | 110 mA | 5.4 V | 9° | 22.5° | Single Transverse Mode | Ø5.6 mm |

| L404P400M | 404 nm | 400 mW | 370 mA | 4.9 V | 13° (1/e2) | 42° (1/e2) | Multimode | Ø5.6 mm |

| LP405-SF10 | 405 nm | 10 mW | 50 mA | 5.0 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L405P20 | 405 nm | 20 mW | 38 mA | 4.8 V | 8.5° | 19° | Single Transverse Mode | Ø5.6 mm |

| LP405C1 | 405 nm | 30 mW | 75 mA | 4.3 V | 1.4 mrad | 1.4 mrad | Single Transverse Mode | Ø3.8 mm, SM Pigtail with Collimator |

| L405G2 | 405 nm | 35 mW | 50 mA | 4.9 V | 10° | 21° | Single Transverse Mode | Ø3.8 mm |

| DL5146-101S | 405 nm | 40 mW | 70 mA | 5.2 V | 8° | 19° | Single Transverse Mode | Ø5.6 mm |

| L405A1 | 405 nm | 175 mW (Min) | 150 mA | 5.0 V | 9° | 20° | Single Transverse Mode | Ø5.6 mm |

| LP405-MF300 | 405 nm | 300 mW | 350 mA | 4.5 V | - | - | Multimode | Ø5.6 mm, MM Pigtail |

| L405G1 | 405 nm | 1000 mW | 900 mA | 5.0 V | 13° | 45° | Multimode | Ø9 mm |

| LP450-SF25 | 450 nm | 25 mW | 75 mA | 5.0 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L450G3 | 450 nm | 100 mW (Min) | 80 mA | 5.2 V | 8.4° | 21.5° | Single Transverse Mode | Ø3.8 mm |

| L450G2 | 450 nm | 100 mW (Min) | 80 mA | 5.0 V | 8.4° | 21.5° | Single Transverse Mode | Ø5.6 mm |

| L450P1600MM | 450 nm | 1600 mW | 1200 mA | 4.8 V | 7° | 19 - 27° | Multimode | Ø5.6 mm |

| L473P100 | 473 nm | 100 mW | 120 mA | 5.7 V | 10 | 24 | Single Transverse Mode | Ø5.6 mm |

| LP488-SF20 | 488 nm | 20 mW | 70 mA | 6.0 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP488-SF20G | 488 nm | 20 mW | 80 mA | 5.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L488P60 | 488 nm | 60 mW | 75 mA | 6.8 V | 7° | 23° | Single Transverse Mode | Ø5.6 mm |

| LP515-SF3 | 515 nm | 3 mW | 50 mA | 5.3 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L515A1 | 515 nm | 10 mW | 50 mA | 5.4 V | 6.5° | 21° | Single Transverse Mode | Ø5.6 mm |

| LP520-SF15A | 520 nm | 15 mW | 100 mA | 7.0 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP520-SF15 | 520 nm | 15 mW | 140 mA | 6.5 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| L520A1 | 520 nm | 30 mW (Min) | 80 mA | 5.5 V | 8° | 22° | Single Transverse Mode | Ø5.6 mm |

| PL520 | 520 nm | 50 mW | 250 mA | 7.0 V | 7° | 22° | Single Transverse Mode | Ø3.8 mm |

| L520P50 | 520 nm | 45 mW | 150 mA | 7.0 V | 7° | 22° | Single Transverse Mode | Ø5.6 mm |

| L520A2 | 520 nm | 110 mW (Min) | 225 mA | 5.9 V | 8° | 22° | Single Transverse Mode | Ø5.6 mm |

| DJ532-10 | 532 nm | 10 mW | 220 mA | 1.9 V | 0.69° | 0.69° | Single Transverse Mode | Ø9.5 mm (non-standard) |

| DJ532-40 | 532 nm | 40 mW | 330 mA | 1.9 V | 0.69° | 0.69° | Single Transverse Mode | Ø9.5 mm (non-standard) |

| LP633-SF50 | 633 nm | 50 mW | 170 mA | 2.6 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL63163DG | 633 nm | 100 mW | 170 mA | 2.6 V | 8.5° | 18° | Single Transverse Mode | Ø5.6 mm |

| LPS-635-FC | 635 nm | 2.5 mW | 70 mA | 2.2 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| LPS-PM635-FC | 635 nm | 2.5 mW | 60 mA | 2.2 V | - | - | Single Transverse Mode | Ø9.0 mm, PM Pigtail |

| L635P5 | 635 nm | 5 mW | 30 mA | <2.7 V | 8° | 32° | Single Transverse Mode | Ø5.6 mm |

| HL6312G | 635 nm | 5 mW | 50 mA | <2.7 V | 8° | 31° | Single Transverse Mode | Ø9 mm |

| LPM-635-SMA | 635 nm | 8 mW | 50 mA | 2.2 V | - | - | Multimode | Ø9 mm, MM Pigtail |

| LP635-SF8 | 635 nm | 8 mW | 60 mA | 2.3 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL6320G | 635 nm | 10 mW | 60 mA | 2.2 V | 8° | 31° | Single Transverse Mode | Ø9 mm |

| HL6322G | 635 nm | 15 mW | 75 mA | 2.4 V | 8° | 30° | Single Transverse Mode | Ø9 mm |

| L637P5 | 637 nm | 5 mW | 20 mA | <2.4 V | 8° | 34° | Single Transverse Mode | Ø5.6 mm |

| LP637-SF50 | 637 nm | 50 mW | 140 mA | 2.6 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP637-SF70 | 637 nm | 70 mW | 220 mA | 2.7 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL63142DG | 637 nm | 100 mW | 140 mA | 2.7 V | 8° | 18° | Single Transverse Mode | Ø5.6 mm |

| HL63133DG | 637 nm | 170 mW | 250 mA | 2.8 V | 9° | 17° | Single Transverse Mode | Ø5.6 mm |

| HL6388MG | 637 nm | 250 mW | 340 mA | 2.3 V | 10° | 40° | Multimode | Ø5.6 mm |

| L637G1 | 637 nm | 1200 mW | 1100 mA | 2.5 V | 10° | 32° | Multimode | Ø9 mm (non-standard) |

| L638P040 | 638 nm | 40 mW | 92 mA | 2.4 V | 10° | 21° | Single Transverse Mode | Ø5.6 mm |

| L638P150 | 638 nm | 150 mW | 230 mA | 2.7 V | 9 | 18 | Single Transverse Mode | Ø3.8 mm |

| L638P200 | 638 nm | 200 mW | 280 mA | 2.9 V | 8 | 14 | Single Transverse Mode | Ø5.6 mm |

| L638P700M | 638 nm | 700 mW | 820 mA | 2.2 V | 9° | 35° | Multimode | Ø5.6 mm |

| HL6358MG | 639 nm | 10 mW | 40 mA | 2.4 V | 8° | 21° | Single Transverse Mode | Ø5.6 mm |

| HL6323MG | 639 nm | 30 mW | 100 mA | 2.5 V | 8.5° | 30° | Single Transverse Mode | Ø5.6 mm |

| HL6362MG | 640 nm | 40 mW | 90 mA | 2.5 V | 10° | 21° | Single Transverse Mode | Ø5.6 mm |

| LP642-SF20 | 642 nm | 20 mW | 90 mA | 2.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP642-PF20 | 642 nm | 20 mW | 90 mA | 2.5 V | - | - | Single Transverse Mode | Ø5.6 mm, PM Pigtail |

| HL6364DG | 642 nm | 60 mW | 120 mA | 2.5 V | 10° | 21° | Single Transverse Mode | Ø5.6 mm |

| HL6366DG | 642 nm | 80 mW | 150 mA | 2.5 V | 10° | 21° | Single Transverse Mode | Ø5.6 mm |

| HL6385DG | 642 nm | 150 mW | 250 mA | 2.6 V | 9° | 17° | Single Transverse Mode | Ø5.6 mm |

| L650P007 | 650 nm | 7 mW | 28 mA | 2.2 V | 9° | 28° | Single Transverse Mode | Ø5.6 mm |

| LPS-660-FC | 658 nm | 7.5 mW | 65 mA | 2.6 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP660-SF20 | 658 nm | 20 mW | 80 mA | 2.6 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LPM-660-SMA | 658 nm | 22.5 mW | 65 mA | 2.6 V | - | - | Multimode | Ø5.6 mm, MM Pigtail |

| HL6501MG | 658 nm | 30 mW | 75 mA | 2.6 V | 8.5° | 22° | Single Transverse Mode | Ø5.6 mm |

| L658P040 | 658 nm | 40 mW | 75 mA | 2.2 V | 10° | 20° | Single Transverse Mode | Ø5.6 mm |

| LP660-SF40 | 658 nm | 40 mW | 135 mA | 2.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP660-SF60 | 658 nm | 60 mW | 210 mA | 2.4 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL6544FM | 660 nm | 50 mW | 115 mA | 2.3 V | 10° | 17° | Single Transverse Mode | Ø5.6 mm |

| LP660-SF50 | 660 nm | 50 mW | 140 mA | 2.3 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL6545MG | 660 nm | 120 mW | 170 mA | 2.45 V | 10° | 17° | Single Transverse Mode | Ø5.6 mm |

| L660P120 | 660 nm | 120 mW | 175 mA | 2.5 V | 10° | 17° | Single Transverse Mode | Ø5.6 mm |

| L670VH1 | 670 nm | 1 mW | 2.5 mA | 2.6 V | 10° | 10° | Single Transverse Mode | TO-46 |

| LPS-675-FC | 670 nm | 2.5 mW | 55 mA | 2.2 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| HL6748MG | 670 nm | 10 mW | 30 mA | 2.2 V | 8° | 25° | Single Transverse Mode | Ø5.6 mm |

| HL6714G | 670 nm | 10 mW | 55 mA | <2.7 V | 8° | 22° | Single Transverse Mode | Ø9 mm |

| HL6756MG | 670 nm | 15 mW | 35 mA | 2.3 V | 8° | 24° | Single Transverse Mode | Ø5.6 mm |

| LP685-SF15 | 685 nm | 15 mW | 55 mA | 2.1 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL6750MG | 685 nm | 50 mW | 70 mA | 2.3 V | 9° | 21° | Single Transverse Mode | Ø5.6 mm |

| HL6738MG | 690 nm | 30 mW | 85 mA | 2.5 V | 8.5° | 19° | Single Transverse Mode | Ø5.6 mm |

| LP705-SF15 | 705 nm | 15 mW | 55 mA | 2.3 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL7001MG | 705 nm | 40 mW | 75 mA | 2.5 V | 9° | 18° | Single Transverse Mode | Ø5.6 mm |

| LP730-SF15 | 730 nm | 15 mW | 70 mA | 2.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| HL7302MG | 730 nm | 40 mW | 75 mA | 2.5 V | 9° | 18° | Single Transverse Mode | Ø5.6 mm |

| L760VH1 | 760 nm | 0.5 mW | 3 mA (Max) | 2.2 V | 12° | 12° | Single Frequency | TO-46 |

| DBR760PN | 761 nm | 9 mW | 125 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L763VH1 | 763 nm | 0.5 mW | 3 mA (Max) | 2.0 V | 10° | 10° | Single Frequency | TO-46 |

| DBR767PN | 767 nm | 23 mW | 220 mA | 1.87 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR770PN | 770 nm | 35 mW | 220 mA | 1.92 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L780P010 | 780 nm | 10 mW | 24 mA | 1.8 V | 8° | 30° | Single Transverse Mode | Ø5.6 mm |

| LP780-SAD15 | 780 nm | 15 mW | 180 mA | 2.2 V | - | - | Single Frequency | Ø9 mm, SM Pigtail |

| DBR780PN | 780 nm | 45 mW | 250 mA | 1.9 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L785P5 | 785 nm | 5 mW | 28 mA | 1.9 V | 10° | 29° | Single Transverse Mode | Ø5.6 mm |

| LPS-PM785-FC | 785 nm | 6.5 mW | 60 mA | - | - | - | Single Transverse Mode | Ø5.6 mm, PM Pigtail |

| LPS-785-FC | 785 nm | 10 mW | 65 mA | 1.85 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP785-SF20 | 785 nm | 20 mW | 85 mA | 1.9 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| DBR785S | 785 nm | 25 mW | 230 mA | 2.0 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| DBR785P | 785 nm | 25 mW | 230 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L785P25 | 785 nm | 25 mW | 45 mA | 1.9 V | 8° | 30° | Single Transverse Mode | Ø5.6 mm |

| FPV785S | 785 nm | 50 mW | 410 mA | 2.2 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| FPV785P | 785 nm | 50 mW | 410 mA | 2.1 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP785-SAV50 | 785 nm | 50 mW | 500 mA | 2.2 V | - | - | Single Frequency | Ø9 mm, SM Pigtail |

| L785P090 | 785 nm | 90 mW | 125 mA | 2.0 V | 10° | 17° | Single Transverse Mode | Ø5.6 mm |

| LP785-SF100 | 785 nm | 100 mW | 300 mA | 2.0 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| FPL785P | 785 nm | 200 mW | 500 mA | 2.1 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL785S-250 | 785 nm | 250 mW (Min) | 500 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| LD785-SEV300 | 785 nm | 300 mW | 500 mA (Max) | 2.0 V | 8° | 16° | Single Frequency | Ø9 mm |

| LD785-SH300 | 785 nm | 300 mW | 400 mA | 2.0 V | 7° | 18° | Single Transverse Mode | Ø9 mm |

| FPL785C | 785 nm | 300 mW | 400 mA | 2.0 V | 7° | 18° | Single Transverse Mode | 3 mm x 5 mm Submount |

| LD785-SE400 | 785 nm | 400 mW | 550 mA | 2.0 V | 7° | 16° | Single Transverse Mode | Ø9 mm |

| FPV785M | 785 nm | 600 mW | 1100 mA | 1.9 V | - | - | Multimode | Butterfly, MM Pigtail |

| L795VH1 | 795 nm | 0.25 mW | 1.2 mA | 1.8 V | 20° | 12° | Single Frequency | TO-46 |

| DBR795PN | 795 nm | 40 mW | 230 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR808PN | 808 nm | 42 mW | 250 mA | 2 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP808-SA60 | 808 nm | 60 mW | 150 mA | 1.9 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| M9-808-0150 | 808 nm | 150 mW | 180 mA | 1.9 V | 8° | 17° | Single Transverse Mode | Ø9 mm |

| L808P200 | 808 nm | 200 mW | 260 mA | 2 V | 10° | 30° | Multimode | Ø5.6 mm |

| FPL808P | 808 nm | 200 mW | 600 mA | 2.1 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL808S | 808 nm | 200 mW | 750 mA | 2.3 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| L808H1 | 808 nm | 300 mW | 400 mA | 2.1 V | 14° | 6° | Single Transverse Mode | Ø9 mm |

| LD808-SE500 | 808 nm | 500 mW | 750 mA | 2.2 V | 7° | 14° | Single Transverse Mode | Ø9 mm |

| LD808-SEV500 | 808 nm | 500 mW | 800 mA (Max) | 2.2 V | 8° | 14° | Single Frequency | Ø9 mm |

| L808P500MM | 808 nm | 500 mW | 650 mA | 1.8 V | 12° | 30° | Multimode | Ø5.6 mm |

| L808P1000MM | 808 nm | 1000 mW | 1100 mA | 2 V | 9° | 30° | Multimode | Ø9 mm |

| DBR816PN | 816 nm | 45 mW | 250 mA | 1.95 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP820-SF80 | 820 nm | 80 mW | 230 mA | 2.3 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L820P100 | 820 nm | 100 mW | 145 mA | 2.1 V | 9° | 17° | Single Transverse Mode | Ø5.6 mm |

| L820P200 | 820 nm | 200 mW | 250 mA | 2.4 V | 9° | 17° | Single Transverse Mode | Ø5.6 mm |

| DBR828PN | 828 nm | 24 mW | 250 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LPS-830-FC | 830 nm | 10 mW | 120 mA | - | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LPS-PM830-FC | 830 nm | 10 mW | 120 mA | - | - | - | Single Transverse Mode | Ø5.6 mm, PM Pigtail |

| LP830-SF30 | 830 nm | 30 mW | 115 mA | 1.9 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| HL8338MG | 830 nm | 50 mW | 75 mA | 1.9 V | 9° | 22° | Single Transverse Mode | Ø5.6 mm |

| L830H1 | 830 nm | 250 mW | 3 A (Max) | 2 V | 8° | 10° | Single Transverse Mode | Ø9 mm |

| FPL830P | 830 nm | 300 mW | 900 mA | 2.22 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL830S | 830 nm | 350 mW | 900 mA | 2.5 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| LD830-SE650 | 830 nm | 650 mW | 900 mA | 2.3 V | 7° | 13° | Single Transverse Mode | Ø9 mm |

| LD830-MA1W | 830 nm | 1 W | 2 A | 2.1 V | 7° | 24° | Multimode | Ø9 mm |

| LD830-ME2W | 830 nm | 2 W | 3 A (Max) | 2.0 V | 8° | 21° | Multimode | Ø9 mm |

| L840P200 | 840 nm | 200 mW | 255 mA | 2.4 V | 9 | 17 | Single Transverse Mode | Ø5.6 mm |

| L850VH1 | 850 nm | 1 mW | 6 mA (Max) | 2 V | 12° | 12° | Single Frequency | TO-46 |

| L850P010 | 850 nm | 10 mW | 50 mA | 2 V | 10° | 30° | Single Transverse Mode | Ø5.6 mm |

| L850P030 | 850 nm | 30 mW | 65 mA | 2 V | 8.5° | 30° | Single Transverse Mode | Ø5.6 mm |

| FPV852S | 852 nm | 20 mW | 400 mA | 2.2 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| FPV852P | 852 nm | 20 mW | 400 mA | 2.2 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR852PN | 852 nm | 24 mW | 300 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP852-SF30 | 852 nm | 30 mW | 115 mA | 1.9 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| L852P50 | 852 nm | 50 mW | 75 mA | 1.9 V | 9° | 22° | Single Transverse Mode | Ø5.6 mm |

| LP852-SF60 | 852 nm | 60 mW | 150 mA | 2.0 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| L852P100 | 852 nm | 100 mW | 120 mA | 1.9 V | 8° | 28° | Single Transverse Mode | Ø9 mm |

| L852P150 | 852 nm | 150 mW | 170 mA | 1.9 V | 8° | 18° | Single Transverse Mode | Ø9 mm |

| L852SEV1 | 852 nm | 270 mW | 400 mA (Max) | 2.0 V | 9° | 12° | Single Frequency | Ø9 mm |

| L852H1 | 852 nm | 300 mW | 415 mA (Max) | 2 V | 7° | 15° | Single Transverse Mode | Ø9 mm |

| FPL852P | 852 nm | 300 mW | 900 mA | 2.35 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL852S | 852 nm | 350 mW | 900 mA | 2.5 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| LD852-SE600 | 852 nm | 600 mW | 950 mA | 2.3 V | 7° (1/e2) | 13° (1/e2) | Single Transverse Mode | Ø9 mm |

| LD852-SEV600 | 852 nm | 600 mW | 1050 mA (Max) | 2.2 V | 8° | 13° (1/e2) | Single Frequency | Ø9 mm |

| LP880-SF3 | 880 nm | 3 mW | 25 mA | 2.2 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L880P010 | 880 nm | 10 mW | 30 mA | 2.0 V | 12° | 37° | Single Transverse Mode | Ø5.6 mm |

| L895VH1 | 895 nm | 0.2 mW | 1.4 mA | 1.6 V | 20° | 13° | Single Frequency | TO-46 |

| DBR895PN | 895 nm | 12 mW | 300 mA | 2 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP904-SF3 | 904 nm | 3 mW | 30 mA | 1.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L904P010 | 904 nm | 10 mW | 50 mA | 2.0 V | 10° | 30° | Single Transverse Mode | Ø5.6 mm |

| LP915-SF40 | 915 nm | 40 mW | 130 mA | 1.5 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| DBR935PN | 935 nm | 13 mW | 300 mA | 1.75 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LP940-SF30 | 940 nm | 30 mW | 90 mA | 1.5 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| M9-940-0200 | 940 nm | 200 mW | 270 mA | 1.9 V | 8° | 28° | Single Transverse Mode | Ø9 mm |

| L960H1 | 960 nm | 250 mW | 400 mA | 2.1 V | 11° | 12° | Single Transverse Mode | Ø9 mm |

| FPV976S | 976 nm | 30 mW | 400 mA (Max) | 2.2 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| FPV976P | 976 nm | 30 mW | 400 mA (Max) | 2.2 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR976PN | 976 nm | 33 mW | 450 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L976SEV1 | 976 nm | 270 mW | 400 mA (Max) | 2.0 V | 9° | 12° | Single Frequency | Ø9 mm |

| BL976-SAG3 | 976 nm | 300 mW | 470 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| BL976-PAG500 | 976 nm | 500 mW | 830 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| BL976-PAG700 | 976 nm | 700 mW | 1090 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| BL976-PAG900 | 976 nm | 900 mW | 1480 mA | 2.5 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| L980P010 | 980 nm | 10 mW | 25 mA | 2 V | 10° | 30° | Single Transverse Mode | Ø5.6 mm |

| LP980-SF15 | 980 nm | 15 mW | 70 mA | 1.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L980P030 | 980 nm | 30 mW | 50 mA | 1.5 V | 10° | 35° | Single Transverse Mode | Ø5.6 mm |

| L980P100A | 980 nm | 100 mW | 150 mA | 1.6 V | 6° | 32° | Multimode | Ø5.6 mm |

| LP980-SA60 | 980 nm | 60 mW | 230 mA | 2.0 V | - | - | Single Transverse Mode | Ø9.0 mm, SM Pigtail |

| LP980-SA100 | 980 nm | 100 mW | 180 mA | 1.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| L980H1 | 980 nm | 200 mW | 300 mA (Max) | 2.0 V | 8° | 13° | Single Transverse Mode | Ø9 mm |

| L980P200 | 980 nm | 200 mW | 300 mA | 1.5 V | 6° | 30° | Multimode | Ø5.6 mm |

| DBR1060SN | 1060 nm | 130 mW | 650 mA | 2.0 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| DBR1060PN | 1060 nm | 130 mW | 650 mA | 1.8 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR1064S | 1064 nm | 40 mW | 150 mA | 2.0 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| DBR1064P | 1064 nm | 40 mW | 150 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| DBR1064PN | 1064 nm | 110 mW | 550 mA | 2.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LPS-1060-FC | 1064 nm | 50 mW | 220 mA | 1.4 V | - | - | Single Transverse Mode | Ø9 mm, SM Pigtail |

| M9-A64-0200 | 1064 nm | 200 mW | 280 mA | 1.7 V | 8° | 28° | Single Transverse Mode | Ø9 mm |

| L1064H1 | 1064 nm | 300 mW | 700 mA | 1.92 V | 7.6° | 13.5° | Single Transverse Mode | Ø9 mm |

| L1064H2 | 1064 nm | 450 mW | 1100 mA | 1.92 V | 7.6° | 13.5° | Single Transverse Mode | Ø9 mm |

| DBR1083PN | 1083 nm | 100 mW | 500 mA | 1.75 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L1270P5DFB | 1270 nm | 5 mW | 15 mA | 1.1 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1290P5DFB | 1290 nm | 5 mW | 16 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| LP1310-SAD2 | 1310 nm | 2.0 mW | 40 mA | 1.1 V | - | - | Single Frequency | Ø5.6 mm, SM Pigtail |

| LP1310-PAD2 | 1310 nm | 2.0 mW | 40 mA | 1.0 V | - | - | Single Frequency | Ø5.6 mm, PM Pigtail |

| LPS-1310-FC | 1310 nm | 2.5 mW | 20 mA | 1.1 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LPS-PM1310-FC | 1310 nm | 2.5 mW | 20 mA | 1.1 V | - | - | Single Transverse Mode | Ø5.6 mm, PM Pigtail |

| L1310P5DFB | 1310 nm | 5 mW | 16 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| ML725B8F | 1310 nm | 5 mW | 20 mA | 1.1 V | 25° | 30° | Single Transverse Mode | Ø5.6 mm |

| LPSC-1310-FC | 1310 nm | 50 mW | 350 mA | 2 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| FPL1053S | 1310 nm | 130 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL1053P | 1310 nm | 130 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL1053T | 1310 nm | 300 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Ø5.6 mm |

| FPL1053C | 1310 nm | 300 mW (Pulsed) | 750 mA | 2 V | 15° | 27° | Single Transverse Mode | Chip on Submount |

| L1310G1 | 1310 nm | 2000 mW | 5 A | 1.5 V | 7° | 24° | Multimode | Ø9 mm |

| L1330P5DFB | 1330 nm | 5 mW | 14 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1370G1 | 1370 nm | 2000 mW | 5 A | 1.4 V | 6° | 22° | Multimode | Ø9 mm |

| BL1425-PAG500 | 1425 nm | 500 mW | 1600 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| BL1436-PAG500 | 1436 nm | 500 mW | 1600 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| L1450G1 | 1450 nm | 2000 mW | 5 A | 1.4 V | 7° | 22° | Multimode | Ø9 mm |

| BL1456-PAG500 | 1456 nm | 500 mW | 1600 mA | 2.0 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| L1470P5DFB | 1470 nm | 5 mW | 19 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1480G1 | 1480 nm | 2000 mW | 5 A | 1.6 V | 6° | 20° | Multimode | Ø9 mm |

| L1490P5DFB | 1490 nm | 5 mW | 24 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1510P5DFB | 1510 nm | 5 mW | 20 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1530P5DFB | 1530 nm | 5 mW | 21 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| LPS-1550-FC | 1550 nm | 1.5 mW | 30 mA | 1.0 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LPS-PM1550-FC | 1550 nm | 1.5 mW | 30 mA | 1.1 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| LP1550-SAD2 | 1550 nm | 2.0 mW | 40 mA | 1.0 V | - | - | Single Frequency | Ø5.6 mm, SM Pigtail |

| LP1550-PAD2 | 1550 nm | 2.0 mW | 40 mA | 1.0 V | - | - | Single Frequency | Ø5.6 mm, PM Pigtail |

| L1550P5DFB | 1550 nm | 5 mW | 20 mA | 1.0 V | 8° | 10° | Single Frequency | Ø5.6 mm |

| ML925B45F | 1550 nm | 5 mW | 30 mA | 1.1 V | 25° | 30° | Single Transverse Mode | Ø5.6 mm |

| SFL1550S | 1550 nm | 40 mW | 300 mA | 1.5 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| SFL1550P | 1550 nm | 40 mW | 300 mA | 1.5 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| LPSC-1550-FC | 1550 nm | 50 mW | 250 mA | 2 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| FPL1009S | 1550 nm | 100 mW | 400 mA | 1.4 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL1009P | 1550 nm | 100 mW | 400 mA | 1.4 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| ULN15PC | 1550 nm | 140 mW | 650 mA | 3.0 V | - | - | Single Frequency | Extended Butterfly, PM Pigtail |

| ULN15PT | 1550 nm | 140 mW | 650 mA | 3.0 V | - | - | Single Frequency | Extended Butterfly, PM Pigtail |

| FPL1001C | 1550 nm | 150 mW | 400 mA | 1.4 V | 18° | 31° | Single Transverse Mode | Chip on Submount |

| FPL1055T | 1550 nm | 300 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Ø5.6 mm |

| FPL1055C | 1550 nm | 300 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Chip on Submount |

| L1550G1 | 1550 nm | 1700 mW | 5 A | 1.5 V | 7° | 28° | Multimode | Ø9 mm |

| DFB1550 | 1555 nm | 100 mW (Min) | 1000 mA (Max) | 3.0 V | - | - | Single Frequency | Butterfly, SM Pigtail |

| DFB1550P | 1555 nm | 100 mW (Min) | 1000 mA (Max) | 3.0 V | - | - | Single Frequency | Butterfly, PM Pigtail |

| L1570P5DFB | 1570 nm | 5 mW | 25 mA | 1.0 V | 7° | 9° | Single Frequency | Ø5.6 mm |

| L1575G1 | 1575 nm | 1700 mW | 5 A | 1.5 V | 6° | 28° | Multimode | Ø9 mm |

| LPSC-1625-FC | 1625 nm | 50 mW | 350 mA | 1.5 V | - | - | Single Transverse Mode | Ø5.6 mm, SM Pigtail |

| FPL1054S | 1625 nm | 80 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL1054P | 1625 nm | 80 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL1054C | 1625 nm | 250 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Chip on Submount |

| FPL1054T | 1625 nm | 200 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Ø5.6 mm |

| FPL1059S | 1650 nm | 80 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL1059P | 1650 nm | 80 mW | 400 mA | 1.7 V | - | - | Single Transverse Mode | Butterfly, PM Pigtail |

| FPL1059C | 1650 nm | 225 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Chip on Submount |

| FPL1059T | 1650 nm | 225 mW (Pulsed) | 750 mA | 2 V | 15° | 28° | Single Transverse Mode | Ø5.6 mm |

| FPL1940S | 1940 nm | 15 mW | 400 mA | 2 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL2000S | 2 µm | 15 mW | 400 mA | 2 V | - | - | Single Transverse Mode | Butterfly, SM Pigtail |

| FPL2000C | 2 µm | 30 mW | 400 mA | 5.2 V | 8° | 19° | Single Transverse Mode | Chip on Submount |

| ID3250HHLH | 3.00 - 3.50 µm (DFB) | 5 mW | 400 mA (Max) | 5 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Two-Tab C-Mount |

| QF3850T1 | 3.85 µm (FP) | 200 mW | 600 mA (Max) | 13.5 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF3850HHLH | 3.85 µm (FP) | 320 mW (Min) | 1100 mA (Max) | 13 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QF4040HHLH | 4.05 µm (FP) | 320 mW (Min) | 1100 mA (Max) | 13 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QD4500CM1 | 4.00 - 5.00 µm (DFB) | 40 mW | 500 mA (Max) | 10.5 V | 30° | 40° | Single Frequency | Two-Tab C-Mount |

| QF4050T2 | 4.05 µm (FP) | 70 mW | 250 mA | 12 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF4050C2 | 4.05 µm (FP) | 300 mW | 400 mA | 12 V | 30 | 42 | Single Transverse Mode | Two-Tab C-Mount |

| QF4050T1 | 4.05 µm (FP) | 300 mW | 600 mA (Max) | 12.0 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF4050D2 | 4.05 µm (FP) | 800 mW | 750 mA | 13 V | 30° | 40° | Single Transverse Mode | D-Mount |

| QF4050D3 | 4.05 µm (FP) | 1200 mW | 1000 mA | 13 V | 30° | 40° | Single Transverse Mode | D-Mount |

| QD4472HH | 4.472 µm (DFB) | 85 mW | 500 mA (Max) | 11 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QF4600T2 | 4.60 µm (FP) | 200 mW | 500 mA (Max) | 13.0 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF4600T1 | 4.60 µm (FP) | 400 mW | 800 mA (Max) | 12.0 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF4600C2 | 4.60 µm (FP) | 600 mW | 600 mA | 12 V | 30° | 42° | Single Transverse Mode | Two-Tab C-Mount |

| QF4600T3 | 4.60 µm (FP) | 1000 mW | 800 mA (Max) | 13 V | 30° | 40° | Single Transverse Mode | Ø9 mm |

| QF4600D4 | 4.60 µm (FP) | 2500 mW | 1800 mA | 12.5 V | 40° | 30° | Single Transverse Mode | D-Mount |

| QF4600D3 | 4.60 µm (FP) | 3000 mW | 1700 mA | 12.5 V | 30° | 40° | Single Transverse Mode | D-Mount |

| QD4602HH | 4.602 µm (DFB) | 150 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QF4650HHLH | 4.65 µm (FP) | 1500 mW (Min) | 1100 mA | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QD5500CM1 | 5.00 - 6.00 µm (DFB) | 40 mW | 700 mA (Max) | 9.5 V | 30° | 45° | Single Frequency | Two-Tab C-Mount |

| QD5250C2 | 5.20 - 5.30 µm (DFB) | 60 mW | 700 mA (Max) | 9.5 V | 30° | 45° | Single Frequency | Two-Tab C-Mount |

| QD5263HH | 5.263 µm (DFB) | 130 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD6500CM1 | 6.00 - 7.00 µm (DFB) | 40 mW | 650 mA (Max) | 10 V | 35° | 50° | Single Frequency | Two-Tab C-Mount |

| QD6134HH | 6.134 µm (DFB) | 50 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD7500CM1 | 7.00 - 8.00 µm (DFB) | 40 mW | 600 mA (Max) | 10 V | 40° | 50° | Single Frequency | Two-Tab C-Mount |

| QD7500HHLH | 7.00 - 8.00 µm (DFB) | 50 mW | 700 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD7500DM1 | 7.00 - 8.00 µm (DFB) | 100 mW | 600 mA (Max) | 11.5 V | 40° | 55° | Single Frequency | D-Mount |

| QD7416HH | 7.416 µm (DFB) | 100 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD7716HH | 7.716 µm (DFB) | 30 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QF7900HB | 7.9 µm (FP) | 700 mW | 1600 mA (Max) | 9 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QD7901HH | 7.901 µm (DFB) | 50 mW | 700 mA (Max) | 10 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD8050CM1 | 8.00 - 8.10 µm (DFB) | 100 mW | 1000 mA (Max) | 9.5 V | 55° | 70° | Single Frequency | Two-Tab C-Mount |

| QD8500CM1 | 8.00 - 9.00 µm (DFB) | 100 mW | 900 mA (Max) | 9.5 V | 40° | 55° | Single Frequency | Two-Tab C-Mount |

| QD8500HHLH | 8.00 - 9.00 µm (DFB) | 100 mW | 600 mA (Max) | 10.2 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QF8450C2 | 8.45 µm (FP) | 300 mW | 750 mA | 9 V | 40° | 60° | Single Transverse Mode | Two-Tab C-Mount |

| QF8500HB | 8.5 µm (FP) | 500 mW | 2000 mA (Max) | 9 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QD8650CM1 | 8.60 - 8.70 µm (DFB) | 50 mW | 900 mA (Max) | 9.5 V | 55° | 70° | Single Frequency | Two-Tab C-Mount |

| QD8912HH | 8.912 µm (DFB) | 150 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD9500CM1 | 9.00 - 10.00 µm (DFB) | 60 mW | 800 mA (Max) | 9.5 V | 40° | 55° | Single Frequency | Two-Tab C-Mount |

| QD9500HHLH | 9.00 - 10.00 µm (DFB) | 100 mW | 600 mA (Max) | 10.2 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD9062HH | 9.062 µm (DFB) | 130 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QF9150C2 | 9.15 µm (FP) | 200 mW | 850 mA | 11 V | 40° | 60° | Single Transverse Mode | Two-Tab C-Mount |

| QF9200HB | 9.2 µm (FP) | 250 mW | 2000 mA (Max) | 9 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Transverse Mode | Horizontal HHL |

| QF9500T1 | 9.5 µm (FP) | 300 mW | 550 mA | 12 V | 40° | 55° | Single Transverse Mode | Ø9 mm |

| QD9550C2 | 9.50 - 9.60 µm (DFB) | 60 mW | 800 mA (Max) | 9.5 V | 40° | 55° | Single Frequency | Two-Tab C-Mount |

| QF9550CM1 | 9.55 µm (FP) | 80 mW | 1500 mA | 7.8 V | 35° | 60° | Single Transverse Mode | Two-Tab C-Mount |

| QD9697HH | 9.697 µm (DFB) | 80 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD10500CM1 | 10.00 - 11.00 µm (DFB) | 40 mW | 600 mA (Max) | 10 V | 40° | 55° | Single Frequency | Two-Tab C-Mount |

| QD10500HHLH | 10.00 - 11.00 µm (DFB) | 50 mW | 700 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD10530HH | 10.530 µm (DFB) | 50 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD10549HH | 10.549 µm (DFB) | 60 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| QD10622HH | 10.622 µm (DFB) | 60 mW | 1000 mA (Max) | 12 V | 6 mrad (0.34°) | 6 mrad (0.34°) | Single Frequency | Horizontal HHL |

| The rows shaded green above denote single-frequency lasers. |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LP405-SF10 | 405 nm | 10 mW | 50 mA / 60 mA | Bb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP450-SF25 | 450 nm | 25 mW | 75 mA / 140 mA | G | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP488-SF20 | 488 nm | 20 mW | 70 mA / 110 mA | Bb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP488-SF20G | 488 nm | 20 mW | 80 mA / 120 mA | G | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LP515-SF3 | 515 nm | 3 mW | 50 mA / 100 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP520-SF15A | 520 nm | 15 mW | 100 mA / 160 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LP633-SF50 | 633 nm | 50 mW | 170 mA / 210 mA | G | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LPS-635-FC | 635 nm | 2.5 mW | 70 mA / 95 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP635-SF8 | 635 nm | 8 mW | 85 mA / 100 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP637-SF50 | 637 nm | 50 mW | 140 mA / 180 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP637-SF70 | 637 nm | 70 mW | 220 mA / 300 mA | G | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP642-SF20 | 642 nm | 20 mW | 90 mA / 140 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LPS-660-FC | 658 nm | 7.5 mW | 80 mA / 95 mA | Cb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP660-SF20 | 658 nm | 20 mW | 80 mA / 110 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP660-SF40 | 658 nm | 40 mW | 135 mA / 170 mA | H | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP660-SF60 | 658 nm | 60 mW | 210 mA / 250 mA | H | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP660-SF50 | 660 nm | 50 mW | 140 mA / 200 mA | Cb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LPS-675-FC | 670 nm | 2.5 mW | 55 mA / 90 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP685-SF15 | 685 nm | 15 mW | 55 mA / 80 mA | Cb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LP705-SF15 | 705 nm | 15 mW | 55 mA / 80 mA | Cb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP730-SF15 | 730 nm | 15 mW | 70 mA / 100 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LPS-785-FC | 785 nm | 10 mW | 65 mA / 90 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP785-SF20 | 785 nm | 20 mW | 85 mA / 120 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d | |

| LP785-SF100 | 785 nm | 100 mW | 300 mA / 450 mA | H | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP808-SA60 | 808 nm | 60 mW | 150 mA / 220 mA |

Bb | Ø9 mm SM Pigtail, FC/APC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP820-SF80 | 820 nm | 80 mW | 230 mA / 400 mA |

Cb | Ø5.6 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LPS-830-FC | 830 nm | 10 mW | 50 mA / 80 mA | Cb | Ø5.6 mm SM Pigtail, FC/PC | S7060Rc | Yes | Single Transverse Mode | LDM9LP or CLD1011LP |

ITC4001d | |

| LP830-SF30 | 830 nm | 30 mW | 115 mA / 160 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001d |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LP852-SF30 | 852 nm | 30 mW | 115 mA / 160 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP852-SF60 | 852 nm | 60 mW | 150 mA / 220 mA |

Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP880-SF3 | 880 nm | 3 mW | 25 mA / 40 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rd | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP904-SF3 | 904 nm | 3 mw | 30 mA / 60 mA | Ab | Ø5.6 mm SM Pigtail, FC/PC | S7060Rd | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP915-SF40 | 915 nm | 40 mW | 130 mA / 200 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP940-SF30 | 940 nm | 30 mW | 90 mA / 120 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP980-SF15 | 980 nm | 15 mW | 70 mA / 90 mA | E | Ø5.6 mm SM Pigtail, FC/PC | S7060Rd | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP980-SA60 | 980 nm | 60 mW | 230 mA / 400 mA |

H | Ø9.0 mm SM Pigtail, FC/APC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LP980-SA100 | 980 nm | 100 mW | 180 mA / 240 mA |

Ge | Ø5.6 mm SM Pigtail, FC/APC | S7060Rd | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LPS-1060-FC | 1064 nm | 50 mW | 220 mA / 300 mA | Ab | Ø9 mm SM Pigtail, FC/PC | S8060 or S8060-4 |

Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LPS-1310-FC | 1310 nm | 2.5 mW | 20 mA / 35 mA | Db | Ø5.6 mm SM Pigtail, FC/PC | - | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LPSC-1310-FC | 1310 nm | 50 mW | 350 mA / 500 mA | E | Ø5.6 mm SM Pigtail, FC/PC | S7060R | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c |

| Item # | Info | Wavelength | Power (Typ.)a |

Typical/Max Drive Currenta |

Pin Code |

Package | Compatible Socket |

Wavelength Tested |

Laser Mode | Recommended Mounts |

Recommended Driver |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LPS-1550-FC | 1550 nm | 1.5 mW | 30 mA / 50 mA | Db | Ø5.6 mm SM Pigtail, FC/PC | - | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c | |

| LPSC-1550-FC | 1550 nm | 50 mW | 250 mA / 500 mA | E | Ø5.6 mm SM Pigtail, FC/PC | S7060R | Yes | Single Transverse Mode | LDM9LP or CLD1010LP |

ITC4001c |

Products Home

Products Home

SM Pigtailed Laser Diodes, TO Can

SM Pigtailed Laser Diodes, TO Can