45° AOI Beamsplitter Compensation Plates, UV Fused Silica for UV to NIR

- Antireflective Coating on Both Surfaces

- Optimized for 45° Angle of Incidence

- Broadband Wavelength Ranges in the UV, Visible, and NIR

- Round and Rectangular Options

BCP44R

AR Coating Range: 600 nm to 1700 nm

25 mm x 36 mm x 1 mm

BCP4510

AR Coating Range: 700 mm to 1100 nm

Ø1" and 5 mm Thick

Please Wait

Features

- AR Coatings Customized for 45° AOI, with Broadband Wavelength Ranges:

- 250 nm - 450 nm with <1.0% at 45° AOI

- 350 nm - 1100 nm with <2.0% at 45° AOI

- 400 nm - 700 nm with <1.0% at 45° AOI

- 600 nm - 1700 nm with <1.5% at 45° AOI

- 700 nm - 1100 nm with <1.0% at 45° AOI

- 1200 nm - 1600 nm with <1.0% at 45° AOI

- Ø1" Round and 25 mm x 36 mm Rectangular Options

- Round Compensation Plates have 30 arcmin Back Surface Wedge to Minimize Ghosting

- UV Fused Silica Substrate (Transmission Curve)

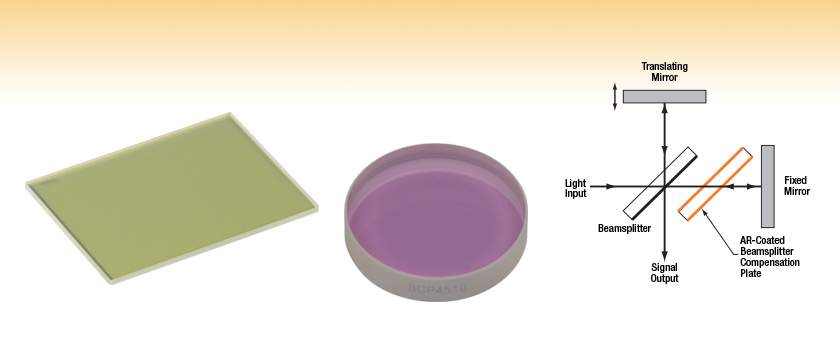

These Beamsplitter Compensation Plates are designed for use in Michelson and other interferometers, and they are additionally ideal as 45° windows in optical enclosures. The substrate material of both the rectangular and wedged round versions of these beamsplitter compensation plates is UV fused silica. For best results when pairing a plate with beamsplitter, choose the two so that their substrate materials and thicknesses are the same. When these plates are used as 45° windows in optical enclosures, the 1.0 mm thick rectangular plates are preferred where space is limited and the wedged round plates when it is of interest to suppress ghosting.

As both surfaces of these beamsplitter compensation plates are antireflection (AR) coated for a 45° angle of incidence (AOI), they are optimally oriented at a 45° angle to the incident light. This is in contrast to our other UV Fused Silica AR coated wedged and flat windows that are designed to be used with their coated surfaces oriented normally to the incident light (0° AOI). The coated surfaces of the 25 mm x 36 mm x 1 mm rectangular versions are parallel with one another and perpendicular to the ground edge. The Ø1" round versions are 5 mm thick and feature a front surface that is perpendicular to the ground edge and a back surface that makes a 30 arcmin angle with the ground edge. The slight wedge on the back surface of the round plates causes any reflected light to diverge from the incident light path, which acts to suppress ghosting and fringe patterns that may arise from reflections.

UV-grade fused silica is well suited for applications that benefit from increased transmission deeper into the UV than N-BK7. UV fused silica also offers a lower index of refraction for a given wavelength, better homogeneity, and a lower coefficient of thermal expansion than N-BK7. Approximately 4% of the incident light is reflected from uncoated UV silica surfaces. The broadband AR coatings on these 45° AOI beamsplitter compensation plates reduce the average reflection to less than 1.0% to 2.0%, depending on the wavelength range of the coating.

When used in a Michelson or similar interferometer, the plate is paired with a beamsplitter as shown in the image above to compensate for the non-zero thickness of the beamsplitter. Placing the compensation plate between the beamsplitter and the fixed mirror essentially sandwiches the reflective surface of the beamsplitter between two equal thicknesses of glass, so that this composite beamsplitter contributes the same optical path length, dispersion, and other optical effects for both arms of the interferometer. Without the plate, light travelling the fixed mirror arm travels through a total of one third the thickness of glass as light travelling through the translating mirror arm.

In addition to the UV fused silica flat and wedged windows offered here, Thorlabs also offers flat and wedged windows with other substrate materials (see the selection guides below). Additionally, flat and wedged windows with custom sizes and thicknesses are available; please contact Tech Support for more information.

| Flat Window Selection Guide | |

|---|---|

| Wavelength Range | Substrate Material |

| 180 nm - 8.0 μm | Calcium Fluoride (CaF2) |

| 185 nm - 2.1 μm | UV Fused Silica |

| 200 nm - 5.0 μm | Sapphire |

| 200 nm - 6.0 μm | Magnesium Fluoride (MgF2) |

| 250 nm - 1.6 µm | UV Fused Silica, for 45° AOI |

| 250 nm - 26 µm | Potassium Bromide (KBr) |

| 300 nm - 3 µm | Infrasil® |

| 350 nm - 2.0 μm | N-BK7 |

| 400 nm - 1.1 µm | UV Fused Silica, Textured Antireflective Surface |

| 600 nm - 16 µm | Zinc Selenide (ZnSe) |

| 1 - 1.7 µm | Infrasil®, Textured Antireflective Surface |

| 1.2 - 8.0 μm | Silicon (Si) |

| 1.9 - 16 μm | Germanium (Ge) |

| 2 - 5 μm | Barium Fluoride (BaF2) |

| V-Coated Laser Windows | |

| Wedged Window Selection Guide | |

|---|---|

| Wavelength Range | Substrate Material |

| 180 nm - 8.0 µm | Calcium Fluoride (CaF2) |

| 185 nm - 2.1 μm | UV Fused Silica |

| 200 nm - 5.0 μm | Sapphire |

| 200 nm - 6.0 µm | Magnesium Fluoride (MgF2) |

| 200 nm - 11 µm | Barium Fluoride (BaF2) |

| 250 nm - 1.6 µm | UV Fused Silica for 45° AOI |

| 350 nm - 2.0 μm | N-BK7 |

| 600 nm - 16 µm | Zinc Selenide (ZnSe) |

| 1.2 - 8.0 µm | Silicon (Si) |

| 2.0 - 16 µm | Germanium (Ge) |

| V-Coated Wedged Windows | |

| Posted Comments: | |

Tony Hainsworth

(posted 2023-07-10 15:48:22.277) Hi, This looks like a good optic to use to introduce a visible pointing laser - 532nm - into a 1064nm beam. Will there be a useful reflectivity (>50%?) at this wavelength? cdolbashian

(posted 2023-07-13 02:22:27.0) Thank you for reaching out to us Tony. All of the transmission and reflection data can be found on the overview tab above each listed product. I have reached out directly to assist you in locating said data. user

(posted 2018-08-28 13:15:54.01) Is the LIDT for these plates similar to that of

these windows?

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=3983

Are the 700-1100nm and the 650-1050nm coatings similar with regards to LIDT?

Thanks YLohia

(posted 2018-08-30 02:33:45.0) Hello, thank you for contacting Thorlabs. You are correct -- the LIDT of this would be similar to that of our standard B coatings. That being said, we have not performed conclusive damage threshold testing for these windows. user

(posted 2017-12-17 22:40:44.863) A 3mm half inch version to match the BSW25 beamsplitter would be nice :-) nbayconich

(posted 2017-12-20 05:12:40.0) Thank you for your feedback. I have forwarded your request to our R&D team for future consideration. We can provide custom versions of these compensation plates. If you need custom sized optics please contact us at techsupport@thorlabs.com. |

| Window Selection Guide (Table Sorted by Wavelength) | |||||

|---|---|---|---|---|---|

| Substrate and Window Type | Wavelength Range | Available AR Coatings | Reflectance over AR Coating Rangea | Transmission Data | Reflectance Data |

| Calcium Fluoride (CaF2): Flat or Wedged |

180 nm - 8.0 μm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| UV Fused Silica: Flat, Wedged, V-Coated Flat, or V-Coated Wedged |

185 nm - 2.1 μm | Uncoated (Flat or Wedged) |

- | Raw Data |

- |

| -UV Coating, 245 - 400 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C3 Coating, 261 - 266 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C6 Coating, 350 - 450 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -A Coating, 350 - 700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -B Coating, 650 - 1050 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| Sapphire: Flat or Wedged |

200 nm - 5.0 μm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E1 Coating, 2.0 - 5.0 µm | Ravg < 1.50%, Rabs < 3.0% (per Surface, 2.0 - 5.0 µm); Ravg < 1.75% (per Surface, 2.0 - 4.0 µm) at 0° AOI |

Raw Data |

Raw Data |

||

| Magnesium Fluoride (MgF2): Flat or Wedged |

200 nm - 6.0 μm | Uncoated | - | Raw Data |

- |

| Barium Fluoride (BaF2): Flat or Wedged |

200 nm - 11 µm | Uncoated (Wedged Only) |

- | Raw Data |

- |

| -E1 Coating, 2 - 5 µm | Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data |

Raw Data |

||

| UV Fused Silica, for 45° AOI: Flat or Wedged |

250 nm - 1.6 µm | Coating for 250 nm - 450 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|

| Coating for 350 nm - 1100 nm |

Ravg < 2.0% at 45° AOI | Raw Data |

|||

| Coating for 400 nm - 700 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Coating for 600 nm - 1700 nm |

Ravg < 1.5% at 45° AOI | Raw Data |

|||

| Coating for 700 nm - 1100 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Coating for 1200 nm - 1600 nm |

Ravg < 1.0% at 45° AOI | Raw Data |

|||

| Potassium Bromide (KBr): Flat |

250 nm - 26 µm | Uncoated | - | - | |

| Infrasil®: Flat |

300 nm - 3 µm | Uncoated | - | Raw Data |

- |

| N-BK7: Flat, Wedged, V-Coated Flat, or V-Coated Wedged |

350 nm - 2.0 μm | Uncoated (Flat or Wedged) |

- | Raw Data |

- |

| -A Coating, 350 - 700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C7 Coating, 400 - 700 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C10 Coating, 523 - 532 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C11 Coating, 610 - 860 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -B Coating, 650 - 1050 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C13 Coating, 700 - 1100 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| C14 Coating, 1047 - 1064 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C15 Coating, 523 - 532 nm & 1047 - 1064 nm (V-Coated) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) |

Ravg < 0.5% at 0° AOI | - | Raw Data |

||

| Zinc Selenide (ZnSe): Flat or Wedged |

600 nm - 16 µm | Uncoated | - | Raw Data |

- |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E4 Coating, 2 - 13 µm (Only Flat) |

Ravg < 3.5%; Rabs < 6% at 0° AOI | Raw Data |

Raw Data |

||

| -E2 Coating, 4.5 - 7.5 µm (Only Flat) |

Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -E3 Coating, 7 - 12 µm (Only Wedged) |

Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

| -G Coating, 7 - 12 µm (Only Flat) |

Ravg < 1% at 0° AOI | Raw Data |

Raw Data |

||

| Silicon (Si): Flat or Wedged |

1.2 - 8.0 μm | Uncoated | - | Raw Data |

- |

| -E1 Coating, 2 - 5 µm (Only Wedged) |

Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data |

Raw Data |

||

| -E Coating, 3 - 5 µm (Only Flat) |

Ravg < 2% at 0° AOI | Raw Data |

Raw Data |

||

| Germanium (Ge): Flat or Wedged |

1.9 - 16 μm | Uncoated, 2.0 - 16 μm | - | Raw Data |

- |

| -C9 Coating, 1.9 - 6 µm (Only Flat) |

Ravg < 2% at 0° AOI | Raw Data |

Raw Data |

||

| -E3 Coating, 7 - 12 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data |

Raw Data |

||

Click to Enlarge

Note: Not Drawn to Scale

Coated surfaces are parallel with one another and perpendicular to the ground edge.

| Common Specifications | |

|---|---|

| Substrate Material | UV Fused Silicaa |

| Dimensions | 25 mm x 36 mm x 1 mm |

| Dimensional Tolerance | ±0.1 mm |

| Clear Aperture | >22.5 mm x 32.4 mm |

| Surface Quality | 40-20 Scratch-Dig |

| Transmitted Wavefront Error | <λ/4 at 633 nm |

| Parallelism | <3 arcmin |

| Item # | BCP41R | BCP42R | BCP43R | BCP44R | BCP45R | BCP46R |

|---|---|---|---|---|---|---|

| Wavelength Range of AR Coating | 250 nm - 450 nm | 350 nm - 1100 nm | 400 nm - 700 nm | 600 nm - 1700 nm | 700 nm - 1100 nm | 1200 nm - 1600 nm |

| Average Reflectance Over Coating Range | <1.0% at 45° AOI |

<2.0% at 45° AOI |

<1.0% at 45° AOI |

<1.5% at 45° AOI |

<1.0% at 45° AOI |

<1.0% at 45° AOI |

| 45° AOI Transmittance and Reflectance Data | ||||||

| Raw Data for All Plots | BCP41R | BCP42R | BCP43R | BCP44R | BCP45R | BCP46R |

| Compatible Beamsplitters | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate |

Click to Enlarge

Note: Not Drawn to Scale

The 30 arcmin wedge, in addition to the AR coating, reduces unwanted interference effects (e.g. ghost images) caused by the interaction of light from the front and back surfaces; light reflected from the wedged surface diverges.

| Common Specifications | |

|---|---|

| Substrate Material | UV Fused Silicaa |

| Diameter | Ø1" |

| Diameter Tolerance | +0.0 mm/ -0.2 mm |

| Thickness | 5 mm |

| Thickness Tolerance | ±0.1 mm |

| Wedge Angle of Back Surface | 30 arcmin |

| Wedge Tolerance | ±10 arcmin |

| Clear Aperture | >Ø22.86 mm |

| Surface Quality | 20-10 Scratch-Dig |

| Surface Flatness | <λ/10 at 633 Over Clear Aperture |

| Item # | BCP4110 | BCP4210 | BCP4310 | BCP4410 | BCP4510 | BCP4610 |

|---|---|---|---|---|---|---|

| Wavelength Range of AR Coating | 250 nm - 450 nm | 350 nm - 1100 nm | 400 nm - 700 nm | 600 nm - 1700 nm | 700 nm - 1100 nm | 1200 nm - 1600 nm |

| Average Reflectance Over Coating Range | <1.0% at 45° AOI |

<2.0% at 45° AOI |

<1.0% at 45° AOI |

<1.5% at 45° AOI |

<1.0% at 45° AOI |

<1.0% at 45° AOI |

| 45° AOI Transmittance and Reflectance Data | ||||||

| Raw Data for All Plots | BCP4110 | BCP4210 | BCP4310 | BCP4410 | BCP4510 | BCP4610 |

| Compatible Beamsplitters | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate | UVFS Plate |

Products Home

Products Home

Zoom

Zoom

45° AOI UVFS Windows

45° AOI UVFS Windows