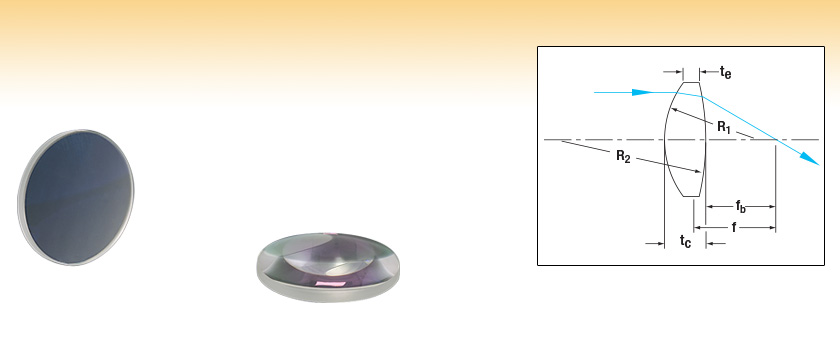

Ø1" N-BK7 Best Form Spherical Lenses, Uncoated

- Best Possible Performance from a Spherical Singlet

- Optimized for Infinite Conjugates

- Diffraction-Limited Performance at Small Input Diameters

- Uncoated for High-Power Applications

LBF254-200

Ø1"

LBF254-040

Please Wait

| Uncoated N-BK7 Best Form Lenses | |

|---|---|

| Lens Shape | Convex/Convex |

| Substrate Material | N-BK7a |

| Design Wavelength | 587.6 nm |

| Diameter Tolerance | +0.0 mm / -0.1 mm |

| Index of Refraction | 1.5167 at Design Wavelength |

| Surface Quality | 10-5 Scratch-Dig |

| Spherical Surface Powerb | 3λ/2 |

| Spherical Surface Irregularity | λ/4 |

| Centration | <3 arcmin |

| Clear Aperture | ≥90% of Diameter |

| Focal Length Tolerance | ±1% @ Design Wavelength |

| Click on the red Document icon next to the item numbers below to access the Zemax file download. Our entire Zemax Catalog is also available. |

Features

- Best Possible Performance from a Spherical Singlet

- Uncoated Design for High Power Applications

- Ideal for High-Power Applications

- Diffraction-Limited Performance at Small Input Diameters

Thorlabs' N-BK7 Best Form lenses are designed to minimize spherical aberration while still using spherical surfaces to form the lens. They are typically employed at infinite conjugates in high-power applications where doublets are not an option. The lenses presented here are uncoated. Versions of our best form lenses are also available with one of three antireflection coatings deposited on both surfaces to reduce the light reflected from each surface of the lens (see table to the right).

For spherical lenses, a given focal length can be produced by more than one combination of the front and back radii of curvature. Each combination of surface curvatures will result in a different amount of aberration caused by the lens (see the Graphs tab). The radius of curvature for each surface of these "best form" lenses has been chosen to minimize the spherical aberration and coma produced by the lens, optimizing it for use at infinite conjugates. This process makes these lenses more expensive than plano-convex or bi-convex lenses, but still significantly less expensive than our premium line of CNC-polished aspheric lenses. Since the lenses are optimized for minimum spot size, they can theoretically reach diffraction-limited performance for small input beam diameters (see the table below for details).

For best performance in focusing applications, place the surface with the shorter radius of curvature (i.e., the more steeply curved surface) towards the collimated source. Lens kits are also available. Please click here for more information.

| N-BK7 Best Form Lenses Selection Guide |

|---|

| Uncoated |

| -A Coating (350 - 700 nm) |

| -B Coating (650 - 1050 nm) |

| -C Coating (1050 - 1700 nm) |

| Item # | Input Diameter for Diffraction-Limited Performance @ 632.8 nm |

Input Diameter for Diffraction-Limited Performance @ 1064 nm |

|---|---|---|

| LBF254-040 | 5.0 mm | 6.0 mm |

| LBF254-050 | 6.0 mm | 7.0 mm |

| LBF254-075 | 8.0 mm | 9.5 mm |

| LBF254-100 | 10.0 mm | 11.5 mm |

| LBF254-150 | 13.5 mm | 16.0 mm |

| LBF254-200 | 17.0 mm | 20.0 mm |

| Quick Links to Other Spherical Singlets | ||||||

|---|---|---|---|---|---|---|

| Plano-Convex | Bi-Convex | Best Form | Plano-Concave | Bi-Concave | Positive Meniscus | Negative Meniscus |

Click to Enlarge

Click Here for Raw Data

The transmission curve for N-BK7, a RoHS-compliant form of BK7, is shown above. Total transmission is given for a 10 mm thick, uncoated sample and includes surface reflections.

Lens Shape vs.

Spherical Aberration

The plot to the right shows coma and spherical aberration plotted as a function of the curvature (c) of the front face of the lens for an N-BK7 lens with focal length of 100 mm, the stop set at the front surface of the lens, and a ±20 field. The curvature (c) is related to the more familiar radius of curvature (r) by c = 1/r. The minimum of the spherical abberation almost coincides with the zero coma location. The lens shape where the spherical aberration is at a minimum provides the basis for a "best form" design.

| Recommended Mounting Options for Thorlabs Lenses | ||

|---|---|---|

| Item # | Mounts for Ø2 mm to Ø10 mm Optics | |

| Imperial | Metric | |

| (Various) | Fixed Lens Mounts and Mini-Series Fixed Lens Mounts for Small Optics, Ø5 mm to Ø10 mm | |

| (Various) | Small Optic Adapters for Use with Standard Fixed Lens Mounts, Ø2 mm to Ø10 mm | |

| Item # | Mounts for Ø1/2" (Ø12.7 mm) Optics | |

| Imperial | Metric | |

| LMR05 | LMR05/M | Fixed Lens Mount for Ø1/2" Optics |

| MLH05 | MLH05/M | Mini-Series Fixed Lens Mount for Ø1/2" Optics |

| LM05XY | LM05XY/M | Translating Lens Mount for Ø1/2" Optics |

| SCP05 | 16 mm Cage System, XY Translation Mount for Ø1/2" Optics | |

| (Various) | Ø1/2" Lens Tubes, Optional SM05RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mounts for Ø1" (Ø25.4 mm) Optics | |

| Imperial | Metric | |

| LMR1 | LMR1/M | Fixed Lens Mount for Ø1" Optics |

| LM1XY | LM1XY/M | Translating Lens Mount for Ø1" Optics |

| ST1XY-S | ST1XY-S/M | Translating Lens Mount with Micrometer Drives (Other Drives Available) |

| CXY1A | 30 mm Cage System, XY Translation Mount for Ø1" Optics | |

| (Various) | Ø1" Lens Tubes, Optional SM1RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Mount for Ø1.5" Optics | |

| Imperial | Metric | |

| LMR1.5 | LMR1.5/M | Fixed Lens Mount for Ø1.5" Optics |

| (Various) | Ø1.5" Lens Tubes, Optional SM1.5RR Retaining Ring for Ø1.5" Lens Tubes and Mounts |

|

| Item # | Mounts for Ø2" (Ø50.8 mm) Optics | |

| Imperial | Metric | |

| LMR2 | LMR2/M | Fixed Lens Mount for Ø2" Optics |

| LM2XY | LM2XY/M | Translating Lens Mount for Ø2" Optics |

| CXY2 | 60 mm Cage System, XY Translation Mount for Ø2" Optics |

|

| (Various) | Ø2" Lens Tubes, Optional SM2RRC Retaining Ring for High-Curvature Lenses (See Below) |

|

| Item # | Adjustable Optic Mounts | |

| Imperial | Metric | |

| LH1 | LH1/M | Adjustable Mount for Ø0.28" (Ø7.1 mm) to Ø1.80" (Ø45.7 mm) Optics |

| LH2 | LH2/M | Adjustable Mount for Ø0.77" (Ø19.6 mm) to Ø2.28" (Ø57.9 mm) Optics |

| VG100 | VG100/M | Adjustable Clamp for Ø0.5" (Ø13 mm) to Ø3.5" (Ø89 mm) Optics |

| SCL03 | SCL03/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

| SCL04 | SCL04/M | Self-Centering Mount for Ø0.15" (Ø3.8 mm) to Ø3.00" (Ø76.2 mm) Optics |

| LH160C | LH160C/M | Adjustable Mount for 60 mm Cage Systems, Ø0.50" (Ø13 mm) to Ø2.00" (Ø50.8 mm) Optics |

| SCL60C | SCL60C/M | Self-Centering Mount for 60 mm Cage Systems, Ø0.15" (Ø3.8 mm) to Ø1.77" (Ø45.0 mm) Optics |

Mounting High-Curvature Optics

Thorlabs' retaining rings are used to secure unmounted optics within lens tubes or optic mounts. These rings are secured in position using a compatible spanner wrench. For flat or low-curvature optics, standard retaining rings manufactured from anodized aluminum are available from Ø5 mm to Ø4". For high-curvature optics, extra-thick retaining rings are available in Ø1/2", Ø1", and Ø2" sizes.

Extra-thick retaining rings offer several features that aid in mounting high-curvature optics such as aspheric lenses, short-focal-length plano-convex lenses, and condenser lenses. As shown in the animation to the right, the guide flange of the spanner wrench will collide with the surface of high-curvature lenses when using a standard retaining ring, potentially scratching the optic. This contact also creates a gap between the spanner wrench and retaining ring, preventing the ring from tightening correctly. Extra-thick retaining rings provide the necessary clearance for the spanner wrench to secure the lens without coming into contact with the optic surface.

| Posted Comments: | |

Alfonso Suances

(posted 2021-05-10 03:05:16.82) Hello.

I'm an engineering student from the University of Vigo (Spain) and I was interested in recieving information about the Damage Threshold of your N-BK7 Best Form Spherical Lenses as we are developing a laser head for a project.

Please, contact us as soon as posible.

Sincerely, Alfonso, YLohia

(posted 2021-05-12 11:03:40.0) Thank you for contacting Thorlabs. Unfortunately, we have not yet obtained conclusive damage threshold test data on these uncoated optics. tcohen

(posted 2012-04-05 18:28:00.0) Response from Tim at Thorlabs: Thank you for helping us improve our presentation! For these lenses, Zemax files are available by clicking the red icon next to the part number. Using these, theoretical focal length shifts and OPD graphs can be generated. We also provide data on diameters needed for diffraction-limited performance for our Best Form Lenses under the “Specs” tab and we are able to provide focal shift graphs for our Achromatic Doublets. I will talk to our web team to see how we can better integrate this data together within the presentation to make the performance between the two more obvious. For any immediate needs you can always contact us at techsupport@thorlabs.com where an Applications Engineer will be able to help you. user

(posted 2012-04-02 10:55:49.0) Trying to compare the best form lenses to an achromat for focusing a laser beam to the smallest possibe spot. It would be great to have some data that allows us to see when one is better than the other. technicalmarketing

(posted 2008-06-05 17:20:44.0) Response from Inge at Thorlabs: Thank you for your feedback. We removed the page break from the product table on this page. We liked the solution and reviewed several other product pages and did the same. Please let us know what you think of the solution. acable

(posted 2008-03-30 09:09:37.0) Since there are only 4 lenses on the second page can you just have them all appear on one page. |

Products Home

Products Home

Best Form Lenses

Best Form Lenses