Coreless Termination Fiber

- Minimizes Back Reflections and Reduces Power Density at Fiber End

- Ø125 µm, Ø250 µm, and Ø400 µm Versions Available

- Splice Onto End of Standard Optical Fiber

FG125LA

Ø125 µm Glass Rod

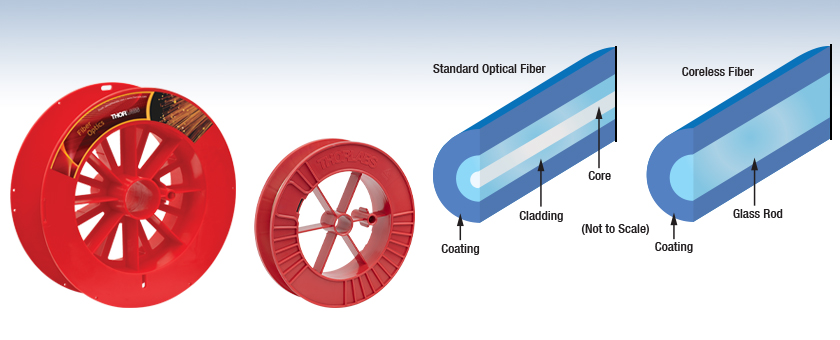

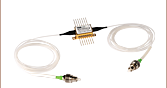

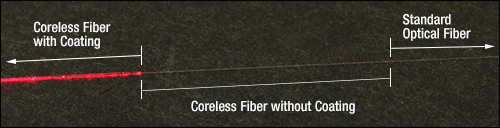

Shown is a comparison between a standard fiber with a core (left) and our coreless termination fiber (right).

FG400LA

Ø400 µm Glass Rod

Please Wait

Click to Enlarge

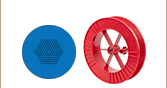

Adding a coreless fiber as an end cap to terminate a fiber reduces the power density, which protects the fiber.

Features

- Solid Silica Glass Rod with an Acrylate Coating

- Ø125 µm, Ø250 µm, and Ø400 µm Termination Fibers Available

- Return Loss of More than 65 dB with 0.25 m of Termination Fiber

- Splice to Unused Fiber Branches to Eliminate Back Reflections

- Useful as Protective End Caps for Fiber Amplifiers and High-Power Lasers

Thorlabs' Coreless Termination Fiber consists of a pure silica glass rod and an acrylate coating. Where a standard optical fiber would have an inner core, our coreless termination fiber simply has a glass rod without a distinct core or cladding (as seen in the figure above). The absence of a waveguide makes this termination fiber useful for reducing back reflections or to prevent damage to the fiber end face in high-power applications. Coreless fiber can be attached to the end of an optical fiber using a fusion splicer.

Prevent Laser-Induced Fiber Damage

Coreless termination fiber can be spliced to fiber end faces to protect them from high-power, laser-induced damage. Without a termination fiber end cap, the beam diameter of light coupled into standard optical fiber must match the core size, creating a high power density at the air-to-glass interface and cause damage to the fiber. However, the termination fiber end cap contains no waveguide. Thus, the light path is not confined and can enter the termination fiber with a larger beam diameter before converging on the core of the standard optical fiber, as shown in the image to the right. This reduces the optical power density at the air-to-glass interface and helps to prevent damage.

A coreless fiber end cap can have a short length of approximately a millimeter, though the appropriate length will vary based on the wavelength and power of the source and the standard fiber that is being capped. Ideally, the end cap should have an end face cleaved at about 8° on the non-spliced side to reduce back reflections. Additionally, the coating of the termination fiber should be stripped to minimize light leakage. Similar to the return loss application described above, the fiber end cap should not be connectorized. Please note that end caps are not necessary if the fiber laser source is spliced directly to the standard fiber, as no air-to-glass interface would be present.

This end-cap method is also useful for sealing off the air holes in photonic crystal fiber to prevent water from entering.

Click to Enlarge

Light is coupled from free space into a standard optical fiber with coreless end caps spliced to either side. On the right, back reflections are prevented from re-entering the core of the standard optical fiber.

Reduce Back Reflections

Coreless fiber is ideal for minimizing back reflections from unused branches of fiber components, such as our fused fiber optic couplers. With 0.25 m of the termination fiber spliced to the end of a standard fiber, the return loss is improved to more than 65 dB. By adding index matching gel to the end of the coreless fiber, similar return loss results can also be achieved with shorter lengths of about 0.1 to 0.25 m.

Since the coating on the coreless fiber has a higher index of refraction than the glass rod, much of the loss occurs where the coating is left intact, as shown by the image below. Thus, for minimizing back reflections, as much of the coating as possible should be retained during splicing. Please note that the end of the termination fiber should be scissor cut for best results and that the termination fiber is not intended to be connectorized. With this application, our splice protector sleeves or fiber recoaters are useful for protecting the fiber joint.

Intact Coating Reduces Back Reflections

The photo to the left shows a segment of coreless fiber spliced to standard optical fiber to improve return loss. The section of coreless fiber with the coating stripped shows minimal light leakage, whereas the section with the coating intact allows much more light to escape.

| Posted Comments: | |

Chao Xu

(posted 2023-10-13 09:53:00.38) Could you provide the refractive index profile of this coreless fiber? Thank you. jdelia

(posted 2023-10-24 02:17:52.0) Thank you for contacting Thorlabs. For the coreless termination fibers, we specify the following refractive indices:

1.467287 @ 436 nm

1.458965 @ 589.3 nm

1.450703 @1020 nm

1.444 @1550 nm

I have also reached out to you directly to discuss your application further. Kevin Williamson

(posted 2022-04-05 17:53:36.367) The FG250LA fiber is not compatible with the T12S16. The insert is to small and the fiber with the coating cannot make it through to be stripped. The T12S18 looks like it would be the correct stripper for this fiber. jgreschler

(posted 2022-04-06 10:49:45.0) Thank you for reaching out to Thorlabs. The coating diameter of FG250LA is 400+/-20um, so it is possible for the fiber on the larger end of that tolerance range to be out of spec for the T12S16. In that case, you are correct that the T12S18 is the better choice for stripping tool within the fiber parameters. Luo Xing

(posted 2019-11-15 09:45:43.107) Dear Sir/Madam,

May I ask you a technical question? If my want to splice a short piece of FG125LA core-less fiber to a piece of SMF-28 as the endcap of the laser source, how can I control the length of the core-less fiber? For example, if I need a piece of core-less fiber with length of 500um, How can I get it ? Do you have any solutions ?Thanks a lot.

Best Regards

Luo Xing YLohia

(posted 2019-11-16 11:24:04.0) Hello Luo, thank you for contacting Thorlabs. We fusion splice a long piece of coreless fiber in a connector, just inside the ferrule. Then, we cleave and polish the connector to yield a small piece. I will reach out to you directly to discuss this further. Jonas Hedman

(posted 2019-10-02 09:52:51.24) Hi!

the following is written in the product description:

"Since the coating on the coreless fiber has a higher index of refraction than the glass rod, much of the loss occurs where the coating is left intact, as shown by the image below. Thus, for minimizing back reflections, as much of the coating as possible should be retained during splicing."

I was hoping for a clarification regarding this, will the loss of light in the fiber be higher with the polymer coating intact but the back reflection reduced? YLohia

(posted 2019-10-07 10:51:28.0) Hello, thank you for contacting Thorlabs. Yes, that's correct. The back reflections are reduced when the coating is left on, but there is more light leakage along the length of the fiber due to the higher index of refraction of the coating. sabine.tiedeken

(posted 2015-11-27 10:43:35.11) Hello,

for a special application we need to know the refractive index of the coreless fiber at 1550nm. besembeson

(posted 2015-12-02 01:06:20.0) Response from Bweh at Thorlabs USA: The refractive index is 1.444 at 1550nm. lee.cairns

(posted 2014-10-29 10:18:00.85) Hi,

Could you also do 250um termination fiber? jlow

(posted 2014-10-30 01:42:17.0) Response from Jeremy at Thorlabs: We could do custom draw of the fiber. I will contact you directly for more details. |

| Item # | Wavelength Range |

Glass Diameter |

Coating Diameter |

Coating Material |

Glass Refractive Index |

Return Loss | Operating Temperature |

Proof Test Level |

Stripping Tool |

|---|---|---|---|---|---|---|---|---|---|

| FG125LA | 400 - 2400 nm | 125 +1/-2 µm | 250 ± 12.5 µm | Acrylate | 1.467287 @ 436 nm 1.458965 @ 589.3 nm 1.450703 @1020 nm 1.444 @1550 nm |

>65 dB with 0.25 m End Cap |

-40 to 85 °C | >100 kpsi | T06S13 FTS4 |

| FG250LA | 250 ± 10 µm | 400 ± 20 µm | T12S16 | ||||||

| FG400LA | 400 ± 15 µm | 550 ± 20 µm | T18S25 |

Products Home

Products Home

Coreless Termination Fiber

Coreless Termination Fiber