600 mm Linear Translation Stage, Direct-Drive Brushless Servo Motor

- 600 mm Travel at Speeds up to 400 mm/s

- Brushless DC Servo Motor

- Bidirectional Repeatability of ±0.25 µm

DDSA04

Platform

Height Adapter

BBD301

1-Channel Controller

(Sold Separately)

MJC2

2-Axis Joystick

DDS600

600 mm (23.6") Servo Motor Translation Stage

Please Wait

| Key Specificationsa | |

|---|---|

| Travel Range | 600 mm (23.6") |

| Speed (Max) | 400 mm/s |

| Acceleration (Max)b | 10 000 mm/s2 |

| Bidirectional Repeatability | ±0.25 µm |

| Backlashc | N/A |

| Horizontal Load Capacity (Max)d | 10.0 kg (22.0 lbs) |

| Min Achievable Incremental Movement | 100 nm |

| Absolute On-Axis Accuracy | ±12.0 µm |

| Cable Length | 2.2 m (7.2') |

| Required Controllere | Benchtop: BBD30x; Rackmount: RBD201, MBD602 |

| Stage Dimensions (L x W x H) | 800 mm x 130 mm x 50 mm (31.5" x 5.12" x 1.97") |

| Motorized Linear Translation Stages | |

|---|---|

| 100 mm | Stepper |

| DC Servo | |

| 150 mm | Stepper |

| Stepper with Integrated Controller | |

| 220 mm | DC Servo |

| 300 mm | Stepper with Integrated Controller |

| DC Servo | |

| 600 mm | DC Servo |

| Optical Delay Line Kits | |

| Other Translation Stages | |

Features

- 600 mm (23.6") Travel

- High Speeds up to 400 mm/s

- Low Profile: 50 mm (1.97")

- Integrated, Brushless DC Linear Servo Motor Actuators

- High-Quality, Precision-Engineered Linear Bearings

- Controller Sold Separately (See Table to the Right)

- Accessories Available:

- Height Adapter for 62.5 mm Platform Height

- 2-Axis or 3-Axis Joysticks for Precise Manual Control

Thorlabs' DDS600(/M) low-profile, direct-drive translation stage provides 600 mm (23.6") of travel with 100 nm resolution and a maximum speed of 400 mm/s. This stage is ideal for applications that require high speeds and high positioning accuracy, including automated alignment, surface inspection, mapping, and probing.

An innovative, low-profile design with integrated, brushless linear motors eliminates the external housings that create mechanical clash points and impede access to the moving platform. The direct-drive technology removes the need for a leadscrew, eliminating backlash, and internal flexible ducting ensures cables cannot become trapped as the mechanism moves. Twin, precision-grooved linear bearings provide superior rigidity and linearity with excellent on-axis accuracy (±12 µm). This backlash-free operation coupled with high-resolution, closed-loop optical feedback ensures a minimal bidirectional repeatability of ±0.25 μm.

Notes:

This stage is not suitable for operation in a vertical (Z-axis) orientation. Additionally, when no power is applied, the mounting platform has very little inertia and is virtually free running. This may make the stage unsuitable for applications where the stage's platform needs to remain in a set position when power is off.

Controller Options

We recommend the BBD30x One-, Two-, or Three-Channel Benchtop Brushless DC Motor Controllers (sold separately below) for this stage. These controllers provide a user-configurable, trapezoidal or S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock. They are ideal for motion control applications demanding operation at high speeds (hundreds of mm/s) and high encoder resolution (100 nm). The design incorporates the latest digital and analog techniques as well as high-bandwidth, high-power servo control circuitry. The controllers ship with our Kinesis or APT software for easy integration into an existing system. See below for a brief overview or click here to view the full presentation for these Brushless DC Motor Controllers.

We also offer the RBD201 Rackmount Controller for implementation into a 19" rack and the MBD602 Rackmount Controller Module designed for use with the MMR60x Motion Control 19" Modular Rack System. These controllers are compatible with the DDS600 direct-drive, linear translation stage and allow for customizing more complex systems with multiple motor controls.

Joystick Options

Two optional joysticks are also available for remote positioning applications, the MJC2 Two-Axis Joystick and the MJC3 Three-Axis Joystick. See the presentation below for more details. Please note that in order to control two stages simultaneously, a multi-channel controller is required.

Optical Height Adapter Plate

The DDSA04 riser plate raises the deck height of the stage to 62.5 mm to match that of our NanoMax, MicroBlock, and RollerBlock stages.

| Item # | DDS600(/M)a,b | |

|---|---|---|

| Travel Range | 600 mm (23.6") | |

| Speed (Max) | 400 mm/s | |

| Acceleration (Max)c | 10 000 mm/s2 | |

| Bidirectional Repeatability | ±0.25 µm | |

| Backlashd | N/A | |

| Encoder Resolution | 50 nm | |

| Minimum Achievable Incremental Movement |

100 nm | |

| Horizontal Load Capacity (Max)e | 10.0 kg (22.0 lbs) | |

| Absolute On-Axis Accuracy | ±12.0 µm | |

| Straightness/Flatness | ±10.0 µm | |

| Pitch | ±100 µrad | |

| Yaw | ±75 µrad | |

| Continuous Motor Force | 10.0 N | |

| Peak Motor Force (2 s) | 20.0 N | |

| Bearing Type | High Rigidity, Recirculating, Precision Linear Bearings |

|

| Limit Switches | Magnetic Sensor at Each End of Stage | |

| Operating Temperature Rangef | 5 to 40 °C (41 to 104 °F) | |

| Motor Type | Brushless DC Linear Motor | |

| Cable Length | 2.2 m (7.2') | |

| Dimensions | 800 mm x 130 mm x 50 mm (31.5" x 5.12" x 1.97") |

|

| Mass (Weight) |

Excluding Cables | 8.8 kg (19.4 lbs) |

| Including Cables | 9.1 kg (20.0 lbs) | |

| Item # | BBD301 | BBD302 |

|---|---|---|

| Number of Channels | 1 | 2 |

| Drive Connector | 8 Pin DIN, Round, Female | |

| Feedback Connector | 15-Pin D-Type, Female | |

| Brushless Continuous Output | 2.5 A per Channel, 5 A Max All-Channel Total Output | |

| Brushless Peak Output | 4.0 A per Channel, 5 A Max All-Channel Total Output | |

| PWM Frequency | 40 kHz | |

| Operating Modes | Position and Velocity | |

| Control Algorithm | 16-Bit Digital PID Servo Loop with Velocity and Acceleration Feedforward |

|

| Velocity Profile | Trapezoidal/S-Curve | |

| Position Count | 32 Bit | |

| Position Feedback | Incremental Encoder | |

| Encoder Bandwidth | 2.5 MHz (10 M Counts/sec) | |

| Encoder Supply | 5 V | |

| AUX Control Connector | 37-Pin D-Type Female (User Digital IO, 5 V O/P) | |

| Front Panel Display | 4.3" Full-Color LCD, 480 x 272 Pixels | |

| Input Power Requirements |

250 VA Voltage: 100 to 240 VAC Frequency: 47 to 63 Hz Fuse: 3.15 A |

|

| Dimensions (W x D x H) | 199.8 mm x 229.1 mm x 108.8 mm (7.87" x 9.02" x 4.28") |

250.0 mm x 279.1 mm x 108.8 mm (9.84" x 10.99" x 4.28") |

| Mass (Weight) | 1.20 kg (2.65 lbs) | 1.70 kg (3.75 lbs) |

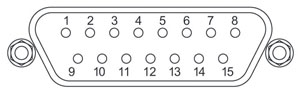

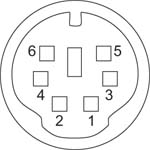

DDS600(/M) Stage Pin Out Descriptions

The flying leads are terminated in a male 15-pin D-Type and male 8-pin round DIN connector. Pin details are given below.

Feedback Connector

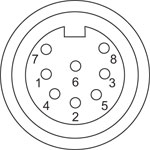

Motor Drive Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Used | 9 | Ground |

| 2 | Ground | 10 | Limit Switch + |

| 3 | Not Used | 11 | Limit Switch - |

| 4 | Enc Index - | 12 | Enc Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7* | 5 V | 15 | Not Used |

| 8* | 5 V |

*Pins 7 and 8 are shorted together internally

| Pin | Description |

|---|---|

| 1 | Motor Phase V |

| 2 | Ground |

| 3 | Thermistor (Not Used) |

| 4 | Motor Phase U |

| 5 | Stage ID |

| 6 | Ground |

| 7 | Motor Phase W |

| 8 | Enable |

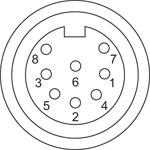

BBD302 Controller Pin Out Descriptions

MOTOR DRIVE

Female DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Motor Phase V | 5 | Stage ID |

| 2 | GND | 6 | GND |

| 3 | Temp. Sensor (Not Used) | 7 | Motor Phase W |

| 4 | Motor Phase U | 8 | Enable |

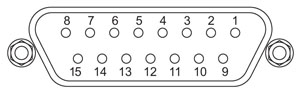

FEEDBACK

Female D-Type Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | Not Connected | 9 | GND |

| 2 | GND | 10 | Limit Switch + |

| 3 | Not Connected | 11 | Limit Switch - |

| 4 | Index - | 12 | Index + |

| 5 | QB - | 13 | QB + |

| 6 | QA - | 14 | QA + |

| 7a | 5 V | 15 | Not Connected |

| 8a | 5 V |

HANDSET

Female Mini DIN Connector

| Pin | Description | Pin | Description |

|---|---|---|---|

| 1 | RX (Controller Input) |

4 | Supply Voltage for Handset 5 V |

| 2 | Ground | 5 | TX (Controller Output) |

| 3 | Ground | 6 | Ground |

AUX I/O

Female D-Type Connector

| Pin | Description | Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|---|---|

| 1 | RS232 TX | 11 | User Digital O/P 11+ | 21 | +5 V | 31 | User Digital O/P 4+ |

| 2 | RS232 RX | 12 | User Digital O/P 10- | 22 | User Digital I/P 3 | 32 | User Digital O/P 4- |

| 3 | Ground | 13 | User Digital O/P 10+ | 23 | User Digital I/P 2 | 33 | User Digital O/P 5+ |

| 4 | Differential I/P 2+ | 14 | User Digital O/P 9- | 24 | User Digital I/P 1 | 34 | User Digital O/P 5- |

| 5 | Differential I/P 2- | 15 | User Digital O/P 9+ | 25 | User Digital I/P 0 | 35 | User Digital O/P 6+ |

| 6 | Differential I/P 1- | 16 | User Digital O/P 8- | 26 | User Digital O/P 0 | 36 | User Digital O/P 6- |

| 7 | Differential I/P 1+ | 17 | User Digital O/P 8+ | 27 | User Digital O/P 1 | 37 | Ground |

| 8 | User Digital O/P 12- | 18 | User Digital O/P 7- | 28 | User Digital O/P 2 | - | - |

| 9 | User Digital O/P 12+ | 19 | User Digital O/P 7+ | 29 | User Digital O/P 3 | ||

| 10 | User Digital O/P 11- | 20 | +5 V | 30 | Ground |

USB

Type B USB Female

I/O

Female BNC Connector

5 V TTL

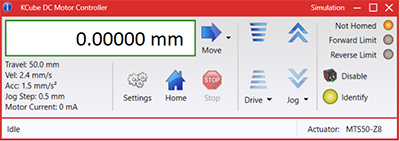

Thorlabs offers two platforms to drive our wide range of motion controllers: our Kinesis® software package or the legacy APT™ (Advanced Positioning Technology) software package. Either package can be used to control devices in the Kinesis family, which covers a wide range of motion controllers ranging from small, low-powered, single-channel drivers (such as the K-Cubes™ and T-Cubes™) to high-power, multi-channel, modular 19" rack nanopositioning systems (the APT Rack System).

The Kinesis Software features .NET controls which can be used by 3rd party developers working in the latest C#, Visual Basic, LabVIEW™, or any .NET compatible languages to create custom applications. Low-level DLL libraries are included for applications not expected to use the .NET framework. A Central Sequence Manager supports integration and synchronization of all Thorlabs motion control hardware.

Kinesis GUI Screen

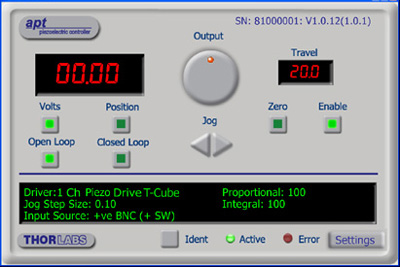

APT GUI Screen

Our legacy APT System Software platform offers ActiveX-based controls which can be used by 3rd party developers working on C#, Visual Basic, LabVIEW™, or any Active-X compatible languages to create custom applications and includes a simulator mode to assist in developing custom applications without requiring hardware.

By providing these common software platforms, Thorlabs has ensured that users can easily mix and match any of the Kinesis and APT controllers in a single application, while only having to learn a single set of software tools. In this way, it is perfectly feasible to combine any of the controllers from single-axis to multi-axis systems and control all from a single, PC-based unified software interface.

The software packages allow two methods of usage: graphical user interface (GUI) utilities for direct interaction with and control of the controllers 'out of the box', and a set of programming interfaces that allow custom-integrated positioning and alignment solutions to be easily programmed in the development language of choice.

A range of video tutorials is available to help explain our APT system software. These tutorials provide an overview of the software and the APT Config utility. Additionally, a tutorial video is available to explain how to select simulator mode within the software, which allows the user to experiment with the software without a controller connected. Please select the APT Tutorials tab above to view these videos.

Software

Kinesis Version 1.14.47

The Kinesis Software Package, which includes a GUI for control of Thorlabs' Kinesis and APT™ system controllers.

Also Available:

- Communications Protocol

The APT video tutorials available here fall into two main groups - one group covers using the supplied APT utilities and the second group covers programming the APT System using a selection of different programming environments.

Disclaimer: The videos below were originally produced in Adobe Flash. Following the discontinuation of Flash after 2020, these tutorials were re-recorded for future use. The Flash Player controls still appear in the bottom of each video, but they are not functional.

Every APT controller is supplied with the utilities APTUser and APTConfig. APTUser provides a quick and easy way of interacting with the APT control hardware using intuitive graphical control panels. APTConfig is an 'off-line' utility that allows various system wide settings to be made such as pre-selecting mechanical stage types and associating them with specific motion controllers.

APT User Utility

The first video below gives an overview of using the APTUser Utility. The OptoDriver single channel controller products can be operated via their front panel controls in the absence of a control PC. The stored settings relating to the operation of these front panel controls can be changed using the APTUser utility. The second video illustrates this process.

APT Config Utility

There are various APT system-wide settings that can be made using the APT Config utility, including setting up a simulated hardware configuration and associating mechanical stages with specific motor drive channels. The first video presents a brief overview of the APT Config application. More details on creating a simulated hardware configuration and making stage associations are present in the next two videos.

APT Programming

The APT Software System is implemented as a collection of ActiveX Controls. ActiveX Controls are language-independant software modules that provide both a graphical user interface and a programming interface. There is an ActiveX Control type for each type of hardware unit, e.g. a Motor ActiveX Control covers operation with any type of APT motor controller (DC or stepper). Many Windows software development environments and languages directly support ActiveX Controls, and, once such a Control is embedded into a custom application, all of the functionality it contains is immediately available to the application for automated operation. The videos below illustrate the basics of using the APT ActiveX Controls with LabVIEW, Visual Basic, and Visual C++. Note that many other languages support ActiveX including LabWindows CVI, C++ Builder, VB.NET, C#.NET, Office VBA, Matlab, HPVEE etc. Although these environments are not covered specifically by the tutorial videos, many of the ideas shown will still be relevant to using these other languages.

Visual Basic

Part 1 illustrates how to get an APT ActiveX Control running within Visual Basic, and Part 2 goes on to show how to program a custom positioning sequence.

LabVIEW

Full Active support is provided by LabVIEW and the series of tutorial videos below illustrate the basic building blocks in creating a custom APT motion control sequence. We start by showing how to call up the Thorlabs-supplied online help during software development. Part 2 illustrates how to create an APT ActiveX Control. ActiveX Controls provide both Methods (i.e. Functions) and Properties (i.e. Value Settings). Parts 3 and 4 show how to create and wire up both the methods and properties exposed by an ActiveX Control. Finally, in Part 5, we pull everything together and show a completed LabVIEW example program that demonstrates a custom move sequence.

Part 1: Accessing Online Help

Part 2: Creating an ActiveX Control

Part 3: Create an ActiveX Method

Part 4: Create an ActiveX Property

Part 5: How to Start an ActiveX Control

The following tutorial videos illustrate alternative ways of creating Method and Property nodes:

Create an ActiveX Method (Alternative)

Create an ActiveX Property (Alternative)

Visual C++

Part 1 illustrates how to get an APT ActiveX Control running within Visual C++, and Part 2 goes on to show how to program a custom positioning sequence.

MATLAB

For assistance when using MATLAB and ActiveX controls with the Thorlabs APT positioners, click here.

To further assist programmers, a guide to programming the APT software in LabVIEW is also available here.

| Posted Comments: | |

Dr. Kiran Kabotu

(posted 2024-02-29 16:52:06.72) Dear Sandra,

Greetings of the day!

We are interested in procuring the following components,

1. DDS600/M

2. DDSA04/M

3. BBD303

4. MJC3

please send us the quotation.

We need an additional 50 mm travel in Y and Z directions, please add a compatible YZ stage in the quotation.

Is controller can be programmed with LabVIEW software?

Also, we need a 5-meter length USB cable for connecting the controller to the Laptop, please add a compatible USB cable in the quote.

What is the minimum step size for the Joystick? Is it compatible with a controller?

Thank you in advance for your support.

With regards, cstroud

(posted 2024-03-12 12:47:36.0) Thanks for reaching out. The joystick is controllable via Labview and is compatible with our benchtop brushless and benchtop stepper motor controllers. I will reach out to you directly to discuss the YZ stage and quote. xiong qin

(posted 2023-07-07 12:53:59.39) I bought a DDS600/M. Now, I want to know the fastest refresh rate of this product.In other word,how much time for the fastest reciprocating motion in a certain distance. do'neill

(posted 2023-07-20 06:43:00.0) Response from Daniel at Thorlabs. The max speed for the DDS600 is 400mm/s with regards to the speed at which you can send movement commands this will depend more on the controller than the stage and how you are sending the commands. I will reach out to you directly to discuss your application. David Goldovsky

(posted 2021-08-10 15:12:30.623) Hi Thorlabs,

I have a homing problem. After pressing the homing buttom from my BBD301, the stage enters 'homing' mode, goes to the middle position, comes back to the start, and stays there forever without changing status to 'homed' and the stage is stuck. The only way I can end the homing process is by manually playing with the controller knob after the stage stops from moving (by first moving the knob to the left, and then to the right. after that the status of the stage turns into 'homed' and I can use the stage).

in addition, while trying to operate the stage from my computer using the apt.dll (I am using a python wrapper library called 'thorlabs_apt'), I encounter similar problem: when I send the stage to a position, it changes status to 'moving', and even after the movement ended the 'moving' status never stops, hence i cannot give further commands to the stage, until I manually disable and then enable the device.

Any help would be appreciated,

Thanks! cwright

(posted 2021-08-10 06:27:29.0) Response from Charles at Thorlabs: Thank you for your query. We will reach out to you directly to diagnose this issue and support you with a solution. YLohia

(posted 2021-08-27 02:53:16.0) Thank you for your query. We will reach out to you directly to diagnose this issue and support you with a solution. Sergej Safonov

(posted 2021-06-18 07:48:13.76) Hello Thorlabs. An error occurs when using the delay line "DDS600/M". Kinesis detects the serial number and connection to the device, but the "Home" command does not work.

How to solve this problem? jcater

(posted 2021-06-18 09:15:34.0) Response from Jack at Thorlabs: Thank you for your feedback. To resolve this problem we advise updating to the most recent version of Kinesis, this can be downloaded from the website after this please ensure you have the most recent firmware flashed to your controller, this can be checked by opening the 'FirmwareUpdateUtility' found in C:\Program Files\Thorlabs\Kinesis\Firmware Update Utility. If, after pressing 'Discover Hardware' a '!' appears next to your controller you can update to the newest firmware by pressing 'Flash Firmware'.

We also advise that you change the 'Integral Limit' to 12,000 within the 'Current Loop' and 'Current Loop (Settled)' sections in the Advanced tab of the settings in Kinesis. To do this you will need to create custom settings. I will reach out to you directly to help further. Ori Golani

(posted 2021-06-07 19:25:58.767) Hi Thorlabs,

When using the control unit BBD301is it possible to get a position vs. time data after a movement was performed? This is needed in order to compensate for position and velocity errors in the measurement.

I looked into the controller’s manual and programming manual, but couldn’t find a command that records and outputs the position data throughout the movement (there is a command for getting the current position, but this is not good enough for characterizing the full position vs. time profile).

Thanks, Ori cwright

(posted 2021-06-08 08:10:15.0) Response from Charles at Thorlabs: Thank you for your query. Unfortunately there is not currently a way to create a data dump like that described from this controller. I would suggest the closest option is to use the 0x0491 status update command and set it in a loop to catch positional data. Craig Brideau

(posted 2020-11-04 23:00:34.66) I have added ~5kg to my stage and would like to adjust the motor control constants in Kinesis to give better performance. How do I do this? The constants in the "settings" pane in Kinesis are locked, and creating a custom configuration still doesn't unlock them. DJayasuriya

(posted 2020-11-06 04:11:31.0) Hi Craig, Thank you for your inquiry. After creating a custom configuration you would have to switch to 'start up' tab (note that this wont work in the 'current tab'). Then tick “Enable Restricted Settings” at the bottom of the window.

You should be allowed to edit the parameters in the “Position Loop”, “Current Loop”, “Track / Settle”, “Current Loop (Settled)” and “Motor Output” sections. After making the changers you should be able to save and apply the changers to the current device settings. DJayasuriya

(posted 2020-11-06 04:11:31.0) Hi Craig, Thank you for your inquiry. After creating a custom configuration you would have to switch to 'start up' tab (note that this wont work in the 'current tab'). Then tick “Enable Restricted Settings” at the bottom of the window.

You should be allowed to edit the parameters in the “Position Loop”, “Current Loop”, “Track / Settle”, “Current Loop (Settled)” and “Motor Output” sections. After making the changers you should be able to save and apply the changers to the current device settings. Konstantin Polyakov

(posted 2020-02-06 04:57:27.78) Hi, we have some questions about the DDS600/M. When the unit is turned on using the BBD201 and Kinesis, the platform cannot get to the Home position, which means that the hardware cannot be used. During use, when you press the Home command, the platform goes some way and stops, nothing else happens and the Not Homed indicator keeps flashing. The semicolon values in the Position window continue to fluctuate. No errors occur. The platform stops only at the value of 300 and never reaches 0. AManickavasagam

(posted 2020-02-07 07:26:09.0) Response from Arunthathi at Thorlabs: Thanks for your query. I have contacted you directly for some additional details to troubleshoot the issue. Mats Ärlelid

(posted 2019-05-15 11:21:11.86) Hi, I have a question regarding the accuracy of the speed translation, I can't find any spec on the accuracy and is it dependent on the speed? Are there other factors that could impact on accuracy such as load, controller etc.?

Thanks,

Mats rmiron

(posted 2019-05-16 10:24:56.0) Response from Radu at Thorlabs: Hello, Mats. I assume that you are looking for the velocity stability specification. Both load and the demanded velocity would have an impact on this specification. Unfortunately, we do not have sufficient test data to guarantee a certain performance level when it comes to velocity stability. With that being said, based on the internal data that I was able to find, assuming max velocity and no load, I expect the stability to be around +/- 1.5 mm/s.This stability specification improves significantly at lower velocities. If you contact your local tech support team and let them know what load you plan on placing on the stage and how fast you plan on moving it, they might be able to source some test data that is more relevant to your operating conditions. ygreddy

(posted 2017-06-30 01:20:32.29) Hello Thorlabs

We have purchased 600 mm Linear Motor stage & Controller (DDS600-E) which is extremely useful for research purpose. We can record our data minimum 4 nanosecond(delay), which is only possible with 600mm stage. Thanks and appreciations for providing such wonderful stages.

PS: LabVIEW example which is provided by you to work with real applications is not sufficient. The one which is provided by you only sufficient to connect to the stage and get the current position of the stage. But in real application we need to move the stage to different positions as well as record that position simultaneously while stage is moving. I request you to provide such labview example which really helpful for research purpose.

Thanks&Regards,

Y.G. Reddy

IISER-Pune

India bwood

(posted 2017-07-03 03:16:31.0) Response from Ben at Thorlabs: Thank you for your feedback. We are glad to hear the DDS600 stage is working well here, in the kind of high precision application it was built for. As regards the LabView examples, it is difficult to provide examples relevant to all applications, however we are constantly evolving our support documentation and I will relay this need to our software engineers. If you have any issues programing for our stages, please feel free to contact Thorlabs tech support with any questions you may have. |

Motorized Linear Translation Stages

Thorlabs' motorized linear translation stages are offered in a range of maximum travel distances, from a stage with 20 µm of piezo translation to our 600 mm direct drive stage. Many of these stages can be assembled in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our multi-axis stages, which offer finer adjustment than our standard motorized translation stages. In addition to motorized linear translation stages, we offer motorized rotation stages and goniometers. We also offer manual translation stages.

Piezo Stages

These stages incorporate piezoelectric elements in a variety of drive mechanisms. ORIC® stages incorporate piezo inertia drives that use "stick-slip" friction properties to obtain extended travel ranges. Our Nanoflex™ translation stages use standard piezo chips along with manual actuators. Elliptec® stages use resonant piezo motors to push and pull the moving platform through resonant elliptical motion. Our LPS710E z-axis stage features a mechanically amplified piezo design and includes a matched controller.

| Piezoelectric Stages | ||||

|---|---|---|---|---|

| Product Family | ORIC® PDXZ1 Closed-Loop 4.5 mm Vertical Stage |

ORIC® PD2 Open-Loop 5 mm Stage |

ORIC® PDX2 Closed-Loop 5 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

| Travel | 4.5 mm | 5 mm | ||

| Speed | 1 mm/s (Typ.)a | 10 mm/s (Typ. Max)b | 8 mm/s (Typ.)c | |

| Drive Type | Piezoelectric Inertia Drive | |||

| Possible Axis Configurations | Z | X, XY, XYZ | ||

| Mounting Surface Size |

45.0 mm x 42.0 mm | 13 mm x 13 mm | ||

| Additional Details | ||||

| Piezoelectric Stages | |||||

|---|---|---|---|---|---|

| Product Family | ORIC® PD1 Open-Loop 20 mm Stage |

ORIC® PD1D Open-Loop 20 mm Monolithic XY Stage |

ORIC® PDX1 Closed-Loop 20 mm Stage |

ORIC® PD3 Open-Loop 50 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

| Travel | 20 mm | 50 mm | |||

| Speed | 3 mm/s (Typ. Max)a | 20 mm/s (Typ. Max)b | 10 mm/sc | ||

| Drive Type | Piezoelectric Inertia Drive | ||||

| Possible Axis Configurations | X, XY, XYZ | XY, XYZ | X, XY, XYZ | X, XY, XYZ | |

| Mounting Surface Size |

30 mm x 30 mm | 80 mm x 30 mm | |||

| Additional Details | |||||

| Piezoelectric Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | Nanoflex™ 20 µm Stage with 5 mm Actuator |

Nanoflex™ 25 µm Stage with 1.5 mm Actuator |

Elliptec® 28 mm Stage | Elliptec® 60 mm Stage | LPS710E 1.1 mm Vertical Stage | |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 20 µm + 5 mm Manual | 25 µm + 1.5 mm Manual | 28 mm | 60.0 mm | 1.1 mm | |

| Maximum Velocity | - | 180 mm/s | 90 mm/s | - | ||

| Drive Type | Piezo with Manual Actuator | Resonant Piezoelectric Motor | Amplified Piezo | |||

| Possible Axis Configurations | X, XY, XYZ | X | Z | |||

| Mounting Surface Size | 75 mm x 75 mm | 30 mm x 30 mm | 15 mm x 15 mm | 21 mm x 21 mm | ||

| Additional Details | ||||||

Stepper Motor Stages

These translation stages feature removable or integrated stepper motors and long travel ranges up to 300 mm. Many of these stages either have integrated multi-axis capability (PLSXY) or can be assembled into multi-axis configurations (PLSX, LNR Series, NRT Series, and LTS Series stages). The MLJ150 stage also offers high load capacity vertical translation.

| Stepper Motor Stages | |||||

|---|---|---|---|---|---|

| Product Family | PLSX with and without PLST(/M) Top Plate 1" Stage |

PLSXY with and without PLST(/M) Top Plate 1" Stage |

LNR Series 25 mm Stage |

LNR Series 50 mm Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

| Travel | 1" | 25 mm | 50 mm | ||

| Maximum Velocity | 7.0 mm/s | 2.0 mm/s | 50 mm/s | ||

| Possible Axis Configurations |

X, XY | X, XY, XYZ | X, XY, XYZ | ||

| Mounting Surface Size |

3" x 3" | 60 mm x 60 mm | 100 mm x 100 mm | ||

| Additional Details | |||||

| Stepper Motor Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | NRT Series 100 mm Stage |

NRT Series 150 mm Stage |

LTS Series 150 mm Stage |

LTS Series 300 mm Stage |

MLJ250 50 mm Vertical Stage |

|

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 100 mm | 150 mm | 150 mm | 300 mm | 50 mm | |

| Maximum Velocity | 30 mm/s | 50 mm/s | 3.0 mm/s | |||

| Possible Axis Configurations |

X, XY, XYZ | X, XY, XYZ | Z | |||

| Mounting Surface Size |

84 mm x 84 mm | 100 mm x 90 mm | 148 mm x 131 mm | |||

| Additional Details | ||||||

DC Servo Motor Stages

Thorlabs offers linear translation stages with removable or integrated DC servo motors. These stages feature low profiles and many can be assembled in multi-axis configurations.

| DC Servo Motor Stages | ||||

|---|---|---|---|---|

| Product Family | MT Series 12 mm Stages |

PT Series 25 mm Stages |

MTS Series 25 mm Stage |

MTS Series 50 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

| Travel | 12 mm | 25 mm | 25 mm | 50 mm |

| Maximum Velocity | 2.6 mm/s | 2.4 mm/s | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | ||

| Mounting Surface Size |

61 mm x 61 mm | 101.6 mm x 76.2 mm | 43 mm x 43 mm | |

| Additional Details | ||||

| DC Servo Motor Stages | ||||

|---|---|---|---|---|

| Product Family | M30 Series 30 mm Stage |

M30 Series 30 mm Monolithic XY Stage |

M150 Series 150 mm XY Stage |

KVS30 30 mm Vertical Stage |

| Click Photo to Enlarge |

|

|

|

|

| Travel | 30 mm | 150 mm | 30 mm | |

| Maximum Velocity | 2.4 mm/s | X-Axis: 170 mm/s Y-Axis: 230 mm/s |

8.0 mm/s | |

| Possible Axis Configurations | X, Z | XY, XZ | XY | Z |

| Mounting Surface Size |

115 mm x 115 mm | 272.4 mm x 272.4 mm | 116.2 mm x 116.2 mm | |

| Additional Details | ||||

Direct Drive Stages

These low-profile stages feature integrated brushless DC servo motors for high speed translation with zero backlash. When no power is applied, the platforms of these stages have very little inertia and are virtually free running. Hence these stages may not be suitable for applications where the stage's platform needs to remain in a set position when the power is off. We do not recommend mounting these stages vertically.

| Direct Drive Stages | |||||

|---|---|---|---|---|---|

| Product Family | DDS Series 50 mm Stage |

DDS Series 100 mm Stage |

DDS Series 220 mm Stage |

DDS Series 300 mm Stage |

DDS Series 600 mm Stage |

| Click Photo to Enlarge |

|

|

|

|

|

| Travel | 50 mm | 100 mm | 220 mm | 300 mm | 600 mm |

| Maximum Velocity | 500 mm/s | 300 mm/s | 400 mm/s | 400 mm/s | |

| Possible Axis Configurations | X, XY | X, XY | X | X | |

| Mounting Surface Size | 60 mm x 52 mm | 88 mm x 88 mm | 120 mm x 120 mm | ||

| Additional Details | |||||

Characterized by high-speed translation and high positional accuracy, the DDS600(/M) stage is well-suited for surface mapping and characterization applications where there is a need to move a camera or probe at constant velocity while simultaneously capturing data. Very precise, fine positioning and control can be achieved with the associated MJC2 or MJC3 joystick option (available below)

Notes:

This stage is not suitable for operation in a vertical (Z-axis) orientation. Additionally, when no power is applied, the mounting platform has very little inertia and is virtually free running. This may make the stage unsuitable for applications where the stage's platform needs to remain in a set position when power is off.

We recommend using our BBD Series Brushless DC Servo Motor Controllers with the stages above, selecting the controller with the required number of channels. If using a standalone stage, the BBD301 can be used; if also using a MJC2 joystick, the BBD302 is recommended. The BBD303 3-Channel Controller can be used for applications requiring additional accessories; all three channels can be controlled via the MJC3 joystick.

With a user-configurable, S-curve acceleration/deceleration profile that enables fast, smooth positioning without vibration or shock, these controllers are ideal for motion control applications demanding operation at high speeds (hundreds of mm/s) and high encoder resolution. Incorporating the latest digital and analog techniques as well as high-bandwidth, high-power servo control circuitry, each BBD series controller is designed to drive brushless DC servo motor products with continuous output currents of up to 2.5 A (Item # BBD301) or 5 A (Item #s BBD302 and BBD303).

These DC servo controllers are supported by Thorlabs' Kinesis® and APT control and programming interfaces, enabling easy integration into automated motion control applications. For greater flexibility, both a USB and RS232 computer interface is provided, and automated PC control of the stage is supported with the supplied software development kit (SDK). The fully documented SDK supports all major development languages running on Windows and comes in the form of ActiveX libraries or a conventional dynamic link library (DLL).

USB connectivity provides easy plug-and-play PC operation. Multiple units can be connected to a single PC via standard USB hub technology for multi-axis motion control applications. Combining this feature with our user-friendly software allows the user to program and carry out complex move sequences in a short space of time. For more information, please see the full Brushless DC Servo Motor Controller presentation.

- High-Reliability Joysticks Utilizing USB HID Protocol

- 2-Axis or 3-Axis Control Via a Joystick Knob

- Two Different Modes for Fast or High Precision Moves

- Speed Dial for Sensitivity Adjustment

- Allows Remote Manual Control

- Can be Reprogrammed using a PC

- Ergonomic Design

The MJC2 and MJC3 Joysticks have been designed for microscope users and provide intuitive, tactile, manual positioning of a stage. The joysticks feature a two-axis joystick knob for XY control or a three-axis joystick knob for XYZ control, respectively. Both joystick knobs can be moved left or right and up or down, with the MJC3 joystick knob also twisting clockwise or counterclockwise for third axis control. A push button to switch between fast or high-precision movement and a speed dial to fine tune speed control are also integrated into the joysticks. In most applications, the default parameter settings saved within the controller allow the joystick to be used out-of-the-box with no need for further setup. This operation mode eliminates the need for connection to a host PC and allows for true remote operation. Parameter settings can also be reprogrammed and saved to a paired controller using a PC, allowing the controller to be disconnected from the computer and remote operation continued.

The MJC2 and MJC3 Joysticks are compatible with our Benchtop Brushless DC Servo Controllers, Rack-Mounted Brushless DC Servo Controller, Rack-Mounted Brushless DC Servo Controller Module, and Stepper Motor Controllers. The joysticks have both a Mini-DIN and a USB Type-C port and are each shipped complete with two cables, a 6-pin Mini-DIN plug to plug cable and a USB 3.1 Type-A to Type-C cable, for use with these controllers as well as setups utilizing the USB HID class. For more information about configuring and setting up the joystick over USB HID, please see the manual by clicking on the red Docs icon (![]() ) below.

) below.

Click to Enlarge

DDS600 stage with DDSA04 riser plate fitted, shown aligning to a MAX311D 3-axis stage.

- Height Adapter to Match 62.5 mm Deck Height, the same as our NanoMax 300, MicroBlock, and RollerBlock Stages

- Resulting Overall Optical Height: 75.0 mm

- Array of 48 Tapped Holes with 16 of Each of the Following: 1/4"-20 (M6), 8-32 (M4), and 4-40 (M3)

The DDSA04 Optical Height Adapter is designed to raise the deck height of the DDS600(/M) stage to 62.5 mm, which is the same as our NanoMax 300, MicroBlock, and RollerBlock stages. This gives an optical axis height of 75.0 mm and allows our range of tongue and grooved optical accessories to be used with the DDS600(/M) stage. The plate is fixed to the moving platform of the stage using four 1/4"-20 x 3/8" (M6 x 10 mm) bolts.

Products Home

Products Home

Zoom

Zoom

600 mm Travel DC Servo Stage

600 mm Travel DC Servo Stage