Miniature Temperature-Controlled Mount for TO-Can Laser Diodes

- Ø5.6 mm and Ø9.0 mm Laser Diode Mount with TEC

- Compact Housing Compatible with SM1 and 30 mm Cage System Products

- Compatible Pin Configurations: Style A, B, C, D, E, and H

LDM21

Front

Back

Application Idea

LDM21 Mount, SM1A6T and

S05TM08 Adapters, and Aspheric Lens

Please Wait

| Item # | LDM21(/M) |

|---|---|

| Laser Diode Package | 5.6 mm and 9 mm |

| Supported Pin Configurations | A, B, C, D, E, and H |

| Maximum Laser Current | 500 mA |

| Maximum Laser Input Powera | 600 mW |

| Laser Interface | DB9 Female |

| Polarity of Laser Diode | Selectable |

| Polarity of Monitor Diode | Selectable |

| Maximum TEC Current | 2.5 A |

| Maximum TEC Voltage | 1.8 V |

| TEC Heating / Cooling Capacity | 2 W |

| TEC Interface | DB9 Male |

| Temperature Sensor | 10 kΩ NTC Thermistor |

| Temperature Range (@ 25 °C) | 20 - 30 °C |

| Dimensions (W x H x D) | 1.75" x 1.75" x 1.66" (44.5 mm x 44.5 mm x 42.1 mm) |

Features

- Compact Mount for Ø5.6 mm and Ø9 mm Laser Diodes

- Pin Code Compatibility: A, B, C, D, E, and H

- SM1 Thread and 30 mm Cage System Compatible

The LDM21(/M) Miniature TE-Cooled Laser Diode Mount is capable of accepting both Ø5.6 mm and Ø9 mm laser diode packages. With an integrated thermal electric cooler element and a 10 kΩ thermistor, this mount keeps laser wavelengths stabilized by precisely holding the case temperature to within 0.2 °C. For more details on the operation and limitations of the temperature control, please see the TEC Operation tab above. The small size of the LDM21(/M) makes this mount ideal for optical setups where space is limited.

This mount is compatible with our extensive line of Laser Diode and TEC Controllers and can operate laser diodes with A, B, C, D, E, and H pin configurations. Please see the Pin Configurations tab for more info. The front side of the mount has a standard SM1 (1.035"-40) thread, making it compatible with our Ø1" lens tubes and allowing for the addition of collimating or focusing optics. The back side of the mount accepts DB9 inputs from a laser current source and TEC controller. The housing has four 8-32 (M4 x 0.7) taps to attach the mount to a Ø1/2" post. An AS4M8E adapter with internal M4 threads is included to mount the LDM21 to metric posts.

Mounting collimating and other optics is easy using standard Thorlabs optomech parts. Step by step procedures for mounting optics and controlling the laser diode are found in the manual and the Controllers and LD Collimation tabs above. Contact Tech Support for more information.

Pin Codes

The LDM21(/M) Mount is only compatible with A, B, C, D, E, and H pin code styles. These drawings do not represent exact wiring diagrams.

Figure 1. Supported and Unsupported Pin Configurations

Laser Diode Pin Configurations

Thorlabs offers several different laser diodes in the UV, visible, and NIR. Many laser diode packages also include a built-in monitor photodiode, and the electrical connections for the diodes vary based on the internal circuitry of the package. Thorlabs labels these different configurations, shown in Figure 1, as styles A through H. Thorlabs notes the pin configuration styles of the diodes we offer both in the specifications provided on our website and on the specification sheets included with the diodes. To determine the style of any laser diode package, compare its pin diagram supplied with the styles shown in Figure 1. Use the style type, pin configuration, and the following information to properly power the laser diode.

The laser diode orientation is engraved on the front of the LDM21 mount and also shown in Figure 2.

LDM21 Mount Compatibility

The LDM21 Laser Diode Mount is compatible with all three-pin Ø5.6 mm and Ø9 mm laser diode packages that have an A, B, or C pin configuration style. These configurations include both a laser diode and a monitor photodiode, and the packages feature a common ground pin and independent control of the Laser Diode (LD) and Photodiode (PD) voltages.

Figure 2. The LDM21 has a standard 4-pin mounting configuration.

Figure 2. The LDM21 has a standard 4-pin mounting configuration.This mount is also compatible with style E and H laser diodes, which do not possess a monitor photodiode. These are three-pin packages that include a laser diode pin and a ground pin, as shown in Figure 1.

Lastly, the LDM21 mount is also compatible with all of our currently available four-pin laser diodes possessing a style D configuration (see Figure 1). As with style A, B, and C laser diodes, style D laser diodes feature a laser diode and monitoring photodiode; however, the photodiode floats with respect to the case in style D packages.

The LDM21 mount is NOT compatible with style F or G configurations. These pin configurations have pin layouts that prohibit their use in this mount. Please see our high-power laser diode mounts for compatibility with these pin configurations.

Full details of the assembly and operation of the LDM21 Mount can be found in the operating manual.

| Label | Descriptiona |

|---|---|

| GND | Ground |

| LD | Laser Diode Cathode or Anode |

| PD | Photodiode Cathode or Anode |

LD Driver

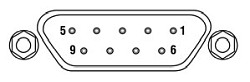

9-Pin D-Type Female

| Pin | Signal | Description |

|---|---|---|

| 1 | Interlock (LDC Specific) | This pin is the input to the Interlock Circuits. When using Thorlabs LDCs no external circuitry is required. |

| 2 | Photodiode Cathode | This pin is connected to the 9 o'clock pin on the laser socket when the PD Polarity Switch is set to anode ground (AG). It is attached to ground and the 12 o'clock and 6 o'clock pins on the laser socket when the PD Polarity Switch is set to cathode ground (CG). |

| 3 | Laser Ground (Case) | This pin is connected to the 12 o'clock and 6 o'clock pins on the laser socket and corresponds to the settings of the LD and PD polarity switches. i.e. If the LD and PD switches are set to AG then this pin grounds the Anodes of the laser and photo diodes. |

| 4 | Photodiode Anode | This pin is connected to the 9 o'clock pin on the laser socket when the PD Polarity Switch is set to CG. It is attached to ground and the 12 o'clock and 6 o'clock pins on the laser socket when the PD Polarity Switch is set to AG. |

| 5 | Interlock Return | This pin is the return side of the Interlock circuitry. Pin 1 and 5 are shorted internally in the LDM21. |

| 6 | N.C. | Not Used. |

| 7 | Laser Diode Cathode | This pin is connected to the 3 o'clock pin on the laser socket when the LD Polarity Switch is set to AG. Otherwise it is floating. |

| 8 | Laser Diode Anode | This pin is connected to the 3 o'clock pin on the laser socket when the LD Polarity Switch is set to CG. Otherwise it is floating. |

| 9 | N.C. | Not Used. |

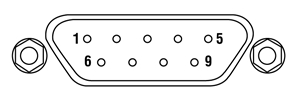

TEC Controller

9-Pin D-Type Male

| Pin | Signal | Description |

|---|---|---|

| 1 | N.C. | Not Used |

| 2 | +Thermistor | The 10 kΩ at 25 °C NTC thermistor (provided for temperature feedback). |

| 3 | -Thermistor | The thermistor return pin. |

| 4 | +TEC | This pin is connected to the positive terminal of the TEC element. |

| 5 | -TEC | This pin is connected to the negative terminal of the TEC element. |

| 6 | N.C. | Not Used. |

| 7 | AD592(-) | The negative terminal of the AD592 temperature transducer. When using Thorlabs TEDs no external circuitry is required. To use this device with third party controllers it must be properly biased. Refer to Analog Devices AD592 Data for application information. |

| 8 | N.C. | Not Used. |

| 9 | AD592(+) | The positive terminal of the AD592 |

Laser Diode Current Controllers

The laser diode current controller should be chosen to be compatible with the particular laser diode and application. Thorlabs offers a wide variety of laser diode controllers ranging from low power (low current and low voltage) to high power (high current and/or voltage) versions. Thorlabs also offers several dual laser diode current/temperature controllers. See the TEC Controllers section that follows for discussion of the temperature controllers.

Thorlabs' LDC2xxC series of controllers are suitable for use with a large majority of popular laser diodes. Thorlabs' LDC200CV is specifically designed to handle and safely operate Vertical Cavity Surface Emitting Lasers (VCSELs), while the LDC201CU provides users with an ultra-low noise current (<0.2 μA RMS) for stable operation of low power laser diodes. If your application requires the higher voltages typically necessary for driving blue and other short laser diodes, consider our LDC202C, LDC205C, or LDC210C controller. For driving higher power laser diodes, the LDC220C and LDC240C offer drive currents of 2 A and 4 A, respectively. Higher current (5 and 20 A), T-Cube-compatible, and rack mount controllers are also available. All of these controllers operate in a similar manor. Only the LDC2xxC series controllers will be discussed in more detail.

TEC Controllers

Thorlabs also offers a wide variety of TEC controllers as stand-alone units and dual laser diode/ temperature controllers. The TED200C benchtop temperature controller is ideally suited to regulate the temperature of a laser diode mounted in our LDM21(/M) Laser Diode Mount. This unit features a wide operating temperature range, 12 W of cooling, and high temperature stability. For more cooling power and even higher temperature stability, the TED4015 225 W temperature controller can be used.

The TEC elements in these mounts can be connected to a temperature controller via the DB9 female connection on the side of the unit. Adapter cables are available for temperature controllers with other connector types. For third-party controllers, please refer to the operating manual for pin layouts and descriptions. Follow the instructions for the TEC controller, paying careful attention not to overdrive the TEC elements in the mount.

TEC Operation Limits

The LDM21(/M) mount is intended to be operated at a fixed temperature setpoint of 25 °C but can be operated as low as 20 °C as long as the input power to the laser diode (LD current x LD voltage) does not exceed the values specified in the Safe Operating Area curve, as shown to the right, as a function of ambient temperature. It is not recommended that the LDM21(/M) be driven with more than 600 mW of input power, set to a temperature below 20 °C, or operated in an ambient temperature above 35 °C. Operating the LDM21(/M) outside of the safe operating area (the area under the curve in the figure to the right) will result in damage to the laser diode.

Choosing Collimation and Ellipticity Correction Optics for Your Laser Diode

Since the output of a laser diode is highly divergent, collimating optics are often necessary. Due to their excellent ability to correct spherical aberration, aspheric lenses are the most commonly used optics when the desired collimated beam waist is between one and five millimeters. Choosing an appropriate aspheric lens for collimating a laser diode is essential, as the resulting beam size and transmission range are dependent on the lens used. To calculate the beam size of a collimated laser diode, we first need to know its divergences.

The beam divergences of an edge-emitting laser diode will be different in the parallel and perpendicular directions, leading to an elliptical beam. This can be compensated for by inserting anamorphic prism pairs or cylindrical lenses into the collimated beam. The divergences are typically specified as "Beam Divergence (FWHM) - Parallel" and "Beam Divergence (FWHM) - Perpendicular" for the two axes of the chip. There are variations from lot to lot of laser diodes, but using the typical divergence values should be adequate for most applications.

The simple example below will illustrate the key specifications to consider when choosing the correct optics for a given application.

Example: 785 nm, 25 mW Laser Diode, L785P25, Ø3 mm Desired Collimated

Step 1: Collimating Emission

The specifications for the L785P25 laser diode indicate that the typical perpendicular and parallel beam divergences are 30o and 8o, respectively. The major (perpendicular) beam divergence is shown in Figure 1. The minor (parallel) beam divergence is shown in Figure 2. Because of this asymmetry in the two axes, an elliptical beam will form as the light diverges. To collect as much light as possible during the collimation process, consider the larger of these two divergence angles in any calculations (i.e., in this case use 30o).

Note: Parallel and perpendicular notation are specified relative to the junction plane of the laser diode.

Figure 1. Perpendicular beam divergence from L785P25 style B laser diode

Figure 2. Parallel beam divergence from L785P25 style B laser diode

In the above schematics, LD denotes the laser diode,

To calculate the focal length needed to achieve a Ø3 mm collimated beam diameter, we can use:

where

This equation yields the focal length to achieve our desired major (perpendicular) axis diameter. Use this to then select an aspheric lens with a focal length that most closely matches the focal length given by the equation. Please note that the diameter of the lens must be larger than your desired major axis beam diameter.

Thorlabs offers a large selection of aspheric lenses. For this application, the ideal lens is an -B AR-coated molded glass aspheric lens with focal length near 5.6 mm. The C171TMD-B (mounted) or 354171-B (unmounted) aspheric lenses have a focal length of 6.20 mm. Next, check to see if the numerical aperture (NA) of the diode is smaller than the NA of the lenses so that the light emitted from the laser diode is not clipped by the lens:

0.30 = NALens > NADiode ~ sin(15) = 0.26

Figure 3. Anamorphic Prism Pair and optic trace for an ellipse to round beam.

Solving the first equation again with your actual focal length and major axis divergence angle yields the actual major axis beam diameter,

Step 2: Correcting Ellipticity

Emission from an edge emitting laser diode is elliptical (asymmetric with respect to two different axes), as shown in Figures 1 and 2. To correct for this and produce a circular beam, the minor axis diameter,

To determine what magnification of the minor axis is needed to produce a round beam, solve Eq. 1 using the focal length from the aspheric lens, = 6.20 mm,

Lens Tube Mounting

For mounted aspheric lenses, our SM05Txx or S1TMxx adapters can be used. Take care to ensure that the lens does not contact the laser diode. The SM05Txx adapters will require the use of an SM1A6T SM1-to-SM05 adapter.

Unmounted aspheres can be epoxied to an LMRAxx adapter, which can then be mounted in an SM1A6T SM1-to-SM05 adapter. The SM1 threading of the adapter can then be used to attach the lens/mount/adapter to the laser diode mount's front plate. The SM1A6T adapter has a mounting range of 10 mm, covering almost the entire focal length range of our aspheric lenses.

In the above example, the C171TMD-B mounted lens features M8 x 0.5 threading, thus requiring the S05TM08-threaded adapter. The S05TM08 M8-to-SM05 adapter can be mounted in the laser diode mount using the SM1A6T SM- to-SM05 adapter. The correct distance between the laser diode and lens can be achieved by adjusting both the S05TM08 and the SM1A6T adapters.

If the 354171-B, unmounted ashperic lens is used, it must first be epoxied to the LMRA5 adapter. It can then be mounted in the SM1A6T SM1-to-SM05 adapter. Again, adjustment of the aspheric lens can be made at the LMRA5 and SM1A6T adapters.

Cage Assembly Mounting

Mounted and unmounted aspheric lenses with focal lengths greater than 8 mm can be cage mounted using our 30 mm cage system. Cage rods can be attached directly to the front plate of the laser diode mount. The CP33(/M) cage plate may be used to hold the S1TMxx adapter with mounted aspheric lens or the SM1A6T adapter with unmounted aspheric lens epoxied to an LMRAxx adapter.

For larger translational adjustments, the CT1A(/M) 1/2" Travel Translator can be used. The CT1A(/M) translator has a graduated micrometer which provides 1/2" (13 mm) of linear translation and has 0.001" (10 µm) graduations. The smallest incremental movement of the carriage is approximately 1 µm.

Anamorphic Prism Pair Mounting

The asymmetric output of the laser diode can be corrected using either anamorphic prisms or cylindrical lenses. As determined in the example above, a 3.5X mounted anamorphic prism pair (i.e., PS881-B) was needed to produce a round beam profile. Unmounted prisms may be used as well.

The PS881-B Mounted Anamorphic Prism Pair features SM05 threading on the output end or may be mounted inside an SM1 Lens tube. Since the input and output beams from the Anamorphic Prism Pair are offset from each other, prisms should be mounted on another cage or lens tube axis.

Video Insight: Setting Up a TO Can Laser Diode

Installing a TO can laser diode in a mount and setting it up to run under temperature and current control presents many opportunities to make a mistake that could damage or destroy the laser. This step-by-step guide includes tips for keeping humans and laser diodes safe from harm.

If you would like more information about tips, tricks, and other methods we often use in the lab, we recommend our other Video Insights. In addition, our webinars provide practical and theoretical introductions to our different products.

| Laser Diode Mount Selection Guide | |||||||

|---|---|---|---|---|---|---|---|

| Item # | LDM38(/M) | LDM56(/M) | LDM56F(/M) | LDM90(/M) | LDM21 | LDM9T(/M) | |

| Click Photo to Enlarge |  |

|

|

|

|

|

|

| Laser Diode | |||||||

| Supported Laser Diode Package(s) | Ø3.8 mm | Ø5.6 mm | Ø5.6 mm | Ø9 mm | Ø5.6 mm and Ø9 mm | Ø5.6 mm and Ø9 mm | |

| Supported Pin Configuration(s) | G | A, B, C, D, E, Ga, H (Switch Selectable) |

F and G (Switch Selectable) |

A, B, C, D, E, Ga, H (Switch Selectable) |

A, B, C, D, E, and H | A, B, C, D, E, G, and H (Some Modification Necessary for G Style)b |

|

| Maximum Laser Current (Tambient = 25 °C) |

1 A | 2 A | 500 mA | 200 mA | |||

| RF Modulation Frequency Rangec | 100 kHz to 500 MHz | 100 kHz to 600 MHz | N/A | 200 kHz to 1 GHz | |||

| Temperature Controller | |||||||

| TEC Heating/Cooling Capacity (Tambient = 25 °C) |

8 W | 8 W | 2 W | 0.5 W | |||

| Temperature Adjustment Range | - | 0 to 70 °C | 20 to 30 °C | ||||

| General Specifications | |||||||

| Laser Interface | DB9 Female | ||||||

| TEC Interface | DB9 Male | N/Ad | |||||

| Compatible Current and Temperature Controllers | LDC Series and T-Cube LD Controllerse, ITC Series Combined LD/TEC Controllersf, and Temperature Controllersf | LDC Series and T-Cube LD Series Controllerse |

|||||

| Mounting Features | Imperial Mounts | 1/4"-20 Tapped Hole (9 Places) | 8-32 Tapped Holeg (4 Places) |

8-32 Tapped Hole (3 Places) |

|||

| Metric Mounts | M6 x 1.0 Tapped Hole (9 Places) | N/A | M4 x 0.7 Tapped Hole (3 Places) |

||||

| Accommodations for Collimating Optics | SM1 (1.035"-40) Series Internal Thread; LDMXY Flexure Adapter (Sold Separately) |

SM1 (1.035"-40) Series Internal Thread | |||||

| Cage System Compatibility | 4-40 Tap (8 Places) for 30 mm and 60 mm Cage Systems |

4-40 Tap (4 Places) for 30 mm Cage System | |||||

| Dimensions | 4.00" x 4.00" x 2.07" (101.6 x 101.6 x 52.6 mm) |

1.75" x 1.75" x 1.66" (44.5 x 44.5 x 42.1 mm) |

3.09" x 2.89" x 1.79" (78.5 x 73.3 x 45.5 mm) |

||||

| Posted Comments: | |

Andrea Sardella

(posted 2023-10-05 06:27:42.633) Which is the swithc configuration to support a style D laser diode? Do you have an electrical schematic ? cdolbashian

(posted 2023-10-18 04:59:59.0) Thank you for reaching out to us with this inquiry. Information regarding the configuration of the device with respect to the pin configuration of the diode, can be found within the manual and diode spec sheet. I have reached out to you directly to assist in locating such documents on our website. In general, they will be located by clicking the red "Docs" icon on the respective product page. Hugo Pereira

(posted 2022-10-27 09:14:32.4) I have a TO-46 package VCSEL and I am looking for a TEC mount. Does Thorlabs provide a solution for these packages, such as an adapter, or is able to produce a custom mount compatible with my laser diode? ksosnowski

(posted 2022-10-27 04:47:12.0) Hello Hugo, thanks for reaching out to Thorlabs. Currently we have not designed any TEC actively-cooled mounts for the TO-46 package, we only have passive mounts like S1LM46. We do carry sockets like STO46S designed for TO-46 diodes however we do not offer custom mounts for other pin types not currently covered by our products. Liam Bradshaw

(posted 2022-03-29 16:21:46.113) It would be nice if Thor Labs could provide stickers that could be affixed to their diode mounts to bring them into compliance with 21 CFR section 1040, even if the diode mounts are not required to meet these standards. Stickers such as an aperture label and a laser radiation warning are often required by laser safety programs but are difficult to make as a one-off by the end-user. ksosnowski

(posted 2022-03-31 11:38:06.0) Thanks for reaching out to us, Liam. Currently our only signage like this is our LSS10x series which are 10" x 14" placards for our LSS10 sign. Though we currently have not started developing a new sticker sign series, I have added this to our internal forum to consider in the future. I've reached out directly to discuss your application further. Jeonghun Lee

(posted 2020-08-07 09:04:55.79) If I am using a third party controller with LDM21, could you tell me what I should do with pin 1 (interlock) and pin 5 (interlock return) on the LD connector side? Can I just short-circuit them? This information is missing on the manual. asundararaj

(posted 2020-08-10 10:22:55.0) Thank you for contacting Thorlabs. The interlock circuit is designed to directly integrate with Thorlabs Laser Diode Drivers as a safety such that without the interlock circuit being complete, the laser diode drivers will not supply current. When using with 3rd party controllers, the pins 1 and 5 on the mount does not have to be connected unless required by your driver. I have reached out to you to discuss this further. s.hinckley

(posted 2017-09-25 15:01:07.993) I have a number of TO-18 5.6mm laser diodes of different wavelengths (mainly 850nm at this stage with output powers of 1 mW to 300 mW). I am looking for a TEC mount (such as the LDM21) but also need to couple the laser diodes to optical fibres. What is the best solution?

I have a laser diode controller and TEC controller.

Thanks

A/Prof Steven Hinckley nbayconich

(posted 2017-10-13 09:36:52.0) Thank you for contacting Thorlabs. Depending on the type of fiber you are using in your setup you can incorporate a fiberport collimator in a cage system and attach it to your LDM21 mount. For example after collimating your laser a fiberport collimator/coupler can be mounted to the LDM21 using the CP08FP cage plate. I will contact you directly to discuss your application requirements. p.k.molony

(posted 2017-02-21 11:21:28.467) The polarity switch settings in the manual (figure 2) are not clear. There are drawings of the switches, but I can't tell which side the switch throw is on. Does the black square represent the position of the switch, or the white rectangle? This should probably be clarified. Also, shouldn't the diagram show the same layout as the switches in the device? tfrisch

(posted 2017-02-23 09:55:51.0) Hello, thank you for pointing out this unclear diagram. Please reference the drawing on the Electronic Control tab which pictures a textured knurl on the switch. I will reach out to you directly about your layout concerns. daniel.brunner

(posted 2016-06-03 18:22:25.22) Hello, I want to mount a fiber pigtaled sm fiber with a TO56 package (LP660-SF20) into the LDM21. Do I need an adapter for that, as this laser mount has not a round shape. besembeson

(posted 2016-06-08 08:54:56.0) Response from Bweh at Thorlabs USA: The LDM21 is designed for 5.6mm and 9.6mm diameter bare laser diode packages. The LP660-SF20 has this diode in a pigtail flange so it can't be used with the LDM21. The recommended mount for your pigtail source will be the LDM9LP or the CLD1010LP if you need a mount with integrated driver and TEC control. alan.davies

(posted 2016-04-26 11:04:24.81) Is the LDM21 operable without connecting anything to the TEC input? The TCLDM9 has a jumper to bypass the TEC, is there something similar on this mount? besembeson

(posted 2016-04-28 12:04:31.0) Response from Bweh at Thorlabs USA: Yes this is possible. We don't recommend this though as the risk of damaging your laser diode will be higher. anthony.ardizzi

(posted 2014-07-11 15:35:32.567) It would be nice if the datasheet provided the equation for the thermistor resistance vs. temperature instead of a select few points in a table (is there any way for me to get my hands on it?). Also, since the diode itself is seated using only its pins, there is no guarantee that any lens you mount to the front face will align with the laser. I wasted quite some time trying to seat the diode so that it was aligned with the front face. Perhaps some way of finely adjusting the front face position would be nice. Other than that the mount has worked nicely so far. jlow

(posted 2014-07-14 11:53:30.0) Response from Jeremy at Thorlabs: We will look into updating the web presentation and the datasheet to provide this equation. With manufacturing tolerance (of the laser diode chip, lens, and mount), there can be a slight lateral misalignment. The front plate has 4 #4-40 holes for 30mm cage system. You could possibly put a XY positioner using those holes and some cage rods. Depending on the lens you want to use, you will probably need some adapter as well. myanakas

(posted 2014-07-30 03:14:30.0) Response from Mike at Thorlabs: The manual has now been updated to include the equation for the thermistor resistance vs. temperature plot. It can be found on page 10, section 4.6. gdavis

(posted 2011-04-11 12:04:00.0) A response from Greg at Thorlabs to yjlee76: The output for the HL6335G is slightly elliptical as the typical beam divergence parallel to the junction is 17 degrees, whereas the typical beam divergence perpendicular to the junction is 20 degrees. To circularize a beam, we recommend using anamorphic prism pairs to magnify one axis of the beam. More on anamorphic prism pairs can be found on this web page by viewing the LD Collimation tab (Correcting Astigmatism section) and on our anamorphic prism pair web page (http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=149). yjlee76

(posted 2011-04-10 20:14:21.0) I have a HL6335G laser diode (Thorlabs part number HL6335G) mounted on a LDM21. I thought the laser beam from the LD is nearly circular, but when I try to collimate according to the directions shown from Thorlabs website, I get a line of light with a bright spot in the middle. Is this typical of the edge emitting LD or am I doing something wrong? The collimating aspheric lens I used is C660TME-B. apalmentieri

(posted 2010-03-26 21:00:37.0) A response from Adam at Thorlabs to pavel: Thanks for bringing this to our attention. I have looked over the design and agree with your assessment. I believe this would require a 4-5mm thicker adapter. I have asked our mechanical engineering to consider making this modification to the stock product. In the meantime, if you are interested, we can offer this item as a custom item. I will email you directly to get further information. pavel.trojek

(posted 2010-03-26 18:21:02.0) The big drawback of the LD head LDM21 is that the lens adapter S1TM09 cannot be always locked with the retaining ring SM1NT as shown at the website, so the angular positioning of the laser beam is not stable over the time. This happens always when aspheric lens with a short focal length (I guess below 6 mm) is used. In such a case the adapter S1TM09 has to be threaded far inside the head to collimate the beam, so that it is flush with the front plate of the head (or does not stick out enough above the front surface of the head) and the retaining ring SM1NT cannot be mounted.

My personal experience is with collimating the blue laser diode using the lens C671TME (f=4 mm).

To resolve this problem, the laser head or possibly the lens adapter should be redesigned. It would be probably sufficient to make the adapter S1TM09 thicker. Tyler

(posted 2009-03-12 10:22:39.0) A response from Tyler at Thorlabs to Kent: The diodes in the circuit provide some ESD protection for the laser diode and will not affect the normal operation of the laser diode mount. I will have a member of our technical support department contact you directly to discuss the circuit and answer your questions. kent

(posted 2009-03-06 19:10:47.0) Im confident that there is something wrong with the circuit board in my LDM21. To debug it would be great to have the schematic. Monday Ill bring the tools from home to disassemble the circuit board from the housing so I can see more.

My ohm meter says that the diodes are connected in series across the laser supply terminals, pins 7 & 8 and the laser ground (laser common) connects to the point where the diodes connect to each other. If that is the design, it is not going to work. Im hoping that there is a solder opps or something. It is possible that the switch is suppose to short out one of the diodes, depending upon its position, but isnt. That would make sense.

If youll get me the schematic and tell me what you are trying to do with the diodes, Ill give you some guidance.

Have a good weekend.

Kent kent

(posted 2009-03-06 18:05:47.0) The circuit board and switches are not behaving as I expected. Also there are diodes that I did not expect. Can you get me a schematic of the circuit board? That will probably answer all my questions. |

- Compact Mount for Ø5.6 mm and Ø9 mm Laser Diodes

- Supports A, B, C, D, E, and H Pin Configuration

The LDM21(/M) Miniature TE-Cooled Laser Diode Mount accepts both Ø5.6 mm and Ø9 mm laser diode packages with A, B, C, D, E, or H pin codes. SM1 (1.035"-40) threads provide compatibility with our Ø1" lens tubes, and 4-40 holes provide compatibility with Thorlabs' 30 mm cage system. For more information on the mount, including laser diode and controller compatability, see the tabs above.

The S1TM09 Lens Cell Adapter adapts an internally SM1-threaded component to a component with external M9 x 0.5 threads. The adapter has two Ø0.05" (Ø1.2 mm) holes for use with a SPW909 and SPW801 spanner wrench.

The SM1NT Locking Ring has internal SM1 threads to secure the position of externally SM1-threaded components. The locking ring can be tightened by hand to secure the components.

Products Home

Products Home

Zoom

Zoom

Miniature Mount with TEC

Miniature Mount with TEC