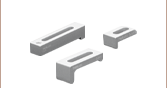

Vacuum-Compatible Fixed Lens Mounts

- Fixed Mounts for Ø1/2", Ø1", and Ø2" Optics

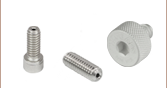

- 8-32 (M4) Vented Tap for Post Mounting

- Vacuum-Compatible to >10-6 Torr

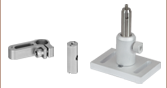

LMR1V

For Ø1" Optics

LMR2V

For Ø2" Optics

LMR05V

For Ø1/2" Optics,

Back View

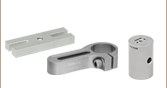

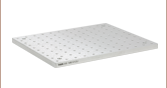

Application Idea

Build a vacuum-compatible optical assembly by mounting these fixed lens mounts to our vacuum-compatible Ø1/2" post system.

Please Wait

Click for Details

This cross-sectional view of a post-mounted LMRV1 shows how the vent hole at the rear of the mount prevents air from being trapped behind the mounting screw.

Additional Vacuum-Compatible Components

Many of our other optomechanical components can be special ordered for vacuum use. Contact techsupport@thorlabs.com for details.

Features

- Internal SM Threading with Retention Lip, One Retaining Ring Included

- Ø1/2", Ø1", and Ø2" Versions Available

- Unanodized 6061-T6 Aluminum

- Vented Mounting Hole to Avoid Virtual Leaks

- All Components Compatible with >10-6 Torr Environments Directly Out of the Packaging

- All Components are Shipped Double Vacuum-Bagged for Cleanroom Use

Thorlabs offers vacuum-compatible versions of our standard fixed lens mounts for Ø1/2", Ø1", and Ø2" optics. Optics are secured against a retention lip at the back of the mount with the included retaining ring, threaded to our SM standard; see the Threading Specs tab to learn more about SM threading. These mounts are fabricated from unanodized 6061-T6 aluminum and double vacuum-bagged making them suitable for cleanroom and vacuum chamber applications. An 8-32 (M4) tapped mounting hole at the bottom of each mount is vented through the back of the body. Venting this tapped hole prevents air from becoming trapped behind the screw and causing virtual leaks in a vacuum system.

These vacuum-compatible fixed lens mounts can have their lens cells extended with vacuum-compatible lens tubes. Lens mounts can be used with our vacuum-compatible Ø1/2" post systems to build free-space optical assemblies within a vacuum chamber. Such assemblies can be fastened to unanodized aluminum breadboards, which are also vacuum compatible to 10-6 Torr when properly cleaned by the user. When building assemblies for vacuum systems, remember to use vented screws to prevent trapping air in blind threaded holes.

Vacuum Compatibility Information

Our vacuum-compatible optomechanics are chemically cleaned and prepared for vacuum applications before packaging. They are compatible directly out of the packaging with vacuum environments down to 10-6 Torr. With additional cleaning and processing, they can be used at even lower pressures, only limited by the outgassing rate of the aluminum (see the table below). The material properties of the aluminum and the cleaning methods completed by the end user should be used to determine the appropriateness of these products and materials in a specific vacuum system.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

Nick M

(posted 2020-08-27 10:55:22.167) The LMR1V lens mount is easily the worst Thorlabs product I've used during my career. The retaining ring grinds against the internal threading to such a degree that it's liable to get stuck. Indeed, one of them was shipped to us with a stuck retaining ring.

Even if the retaining ring doesn't get stuck, the act of tightening or loosening it will probably cover your optic in a fine dust of aluminium. How this passed QA is beyond me. llamb

(posted 2020-09-18 03:45:26.0) Thank you for contacting Thorlabs, and I'm very sorry to hear about your experience with the LMR1V. These parts are acid-etched and wiped down with alcohol and lint-free wipes during the manufacturing/assembly process. If you are seeing more dust or sticking, additional wiping with alochol/isopropanol could help alleviate that. In case you received faulty items, I have also reached out to you directly by email to troubleshoot further and help rectify the situation. |

| Vacuum Specifications | |

|---|---|

| Vacuum Compatibility as Packageda |

>10-6 Torr |

| Materials | 6061-T6 Aluminum |

| Preparation and Packaging |

Chemically Cleaned and Double Vacuum-Bagged |

| Aluminum Outgassing Rate at 20 °C |

7.6 x 10-9 Torr-Liters/s/cm2 |

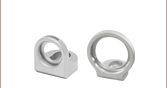

Click to Enlarge

The back of each mount features a vent for the tapped mounting holes.

- Mount Ø1/2", Ø1", or Ø2" Optics

- Internally SM Treaded with Retention Lip

- Low Outgassing

- Included Retaining Ring

These fixed optic mounts feature internal threading and a retention lip. The optic diameter and maximum thickness for each mount is given below. This thickness takes into account the depth required for the retaining ring to fully engage its threads to secure the optic against the retention lip. The retaining ring can be adjusted with any of the suggested spanner wrenches listed below.

The body of the mount features a vent hole, allowing for air trapped under the set screw to easily escape. Do not plug this vent hole or attempt to use it as a mounting point.

| Item # | Optic Diameter |

Max Optic Thicknessa |

Clear Apertureb | Optical Height | Replacement Retaining Ring | Suggested Spanner Wrench |

|---|---|---|---|---|---|---|

| LMR05V(/M) | Ø1/2" | 0.21" (5.0 mm) | Ø0.44" (Ø11.0 mm) | 0.63" (16.0 mm) | SM05RRV | SPW603, SPW603L, or SPW801 |

| LMR1V(/M) | Ø1" | 0.28" (7.1 mm) | Ø0.90" (Ø23.0 mm) | 0.87" (22.1 mm) | SM1RRV | SPW602, SPW606 or SPW801 |

| LMR2V(/M) | Ø2" | 0.36" (9.2 mm) | Ø1.90" (Ø48.5 mm) | 1.36" (34.4 mm) | SM2RRV | SPW604 or SPW801 |

Products Home

Products Home

Zoom

Zoom Vacuum-Compatible Fixed Lens Mounts

Vacuum-Compatible Fixed Lens Mounts