Adjustable SM1 Lens Tubes

- Translate Ø1/2" Optics, Ø1" Optics, or Ø1" Lens Tubes Along the Optical Axis

- Rotating or Non-Rotating Adjustment

- Compatible with SM-Threaded Components

- Create Variable-Length Lens Tube Assemblies

SM1V15

Ø1" Adjustable Lens Tube, 1.31" Travel Range

SM1U

Adjustable Collimation Adapter

SM1ZM

High-Precision Zoom Housing

SM1NR1

Non-Rotating Zoom Housing

SM1V10V

Ø1" Vacuum-Compatible Adjustable Lens Tube,

0.31" Travel Range

OVERVIEW

Additional Vacuum-Compatible Components

Many of our other optomechanical components can be special ordered for vacuum use. Contact techsupport@thorlabs.com for details.

Features

- Allow Precise Positioning of an Optic within SM1 Lens Tube Systems

- Compatible with SM-Threaded Components

- Mount SM1-Threaded Lens Tubes, Ø1" (25.4 mm) Optics, Ø25 mm Optics, or Ø1/2" (12.7 mm) Optics

- Vacuum-Compatible Rotating Optic Adjustment Versions Available

Adjustable lens tubes allow for the adjustment of an optic's position within an SM lens tube system. The SM1V05, SM1V10, SM1V10V, and SM1V15 provide rotating adjustment, while the SM1ZM, SM1NR1, and SM1NR05 zoom housings use helical drive mechanisms to provide linear travel of the internal cell without rotation.

Unlike the other items on this page, the SM1V05, SM1V10, and SM1V15 must be combined with another SM1-threaded lens tube in order to provide adjustment. The SM1V10V adjustable lens tube is a vacuum-compatible version of the SM1V10 that features vented channels along its threading and at the ends the tube.

The SM1ZM and SM1NR1 can be combined with a standard SM1 lens tube to construct a non-rotating telescoping lens tube system. Finally, the SM1U adjustable collimation adapter provides 11 mm of non-telescoping, rotating adjustment of a Ø1" (Ø25 mm) collimation optic.

APPLICATION

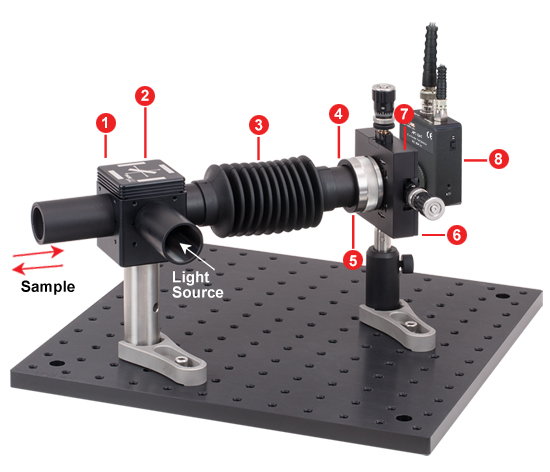

| # | Product Description | Qty. | Photo (Click to Enlarge) |

|---|---|---|---|

| 1 | DFM1 - Kinematic Dichroic Filter Cube |

1 |  |

| 2 | Microscopy Filters | 1 Set |  |

| 3 | SM1B3 - Lens Tube Bellows | 1 |  |

| 4 | SM1ZM - Non-Rotating SM1 Zoom Housing |

1 |  |

| 5 | Focusing Lens Inside Zoom Housing |

1 |  |

| 6 | ST1XY-D - XY Translator with Differential Drives |

1 |  |

| 7 | Precision Pinhole Between XY Translator and Photodetector |

1 |  |

| 8 | Photodetector SM1-Compatible Photodetector |

1 |  |

SM1ZM Zoom Housing - Optic Alignment in a Confocal Microscope

Thorlabs' SM1ZM High-Precision Zoom Housing (denoted by 4 in the image below) is useful when precise Z-positioning of optics is necessary. In the following example of a partial confocal microscope, a light-tight connection can be created between a DFM1 Dichroic Filter Cube (1) containing a Microscopy Filter Set (2), and an APD130A(/M) Photodetector (8). A lens (5) located inside the SM1ZM Zoom Housing (4) focuses the beam onto a precision pinhole (7) located just before the avalanche photodetector's sensor. The SM1ZM zoom housing is mounted directly onto the ST1XY-D XY Translation Mount with Differential Adjusters (6), creating a compact XYZ mount. SM1 Lens Tubes and the SM1B3 Lens Tube Bellows (3) allow for a light-tight connection without inhibiting the free movement of the XYZ mount.

Components used in the configuration pictured below are listed in the table to the right. These parts, along with SM1 Lens Tubes and 1" Post Assemblies, are sold separately.

THREADING SPECS

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

Ø1" Lens Tubes with Rotating Optic Adjustment

Adjustable Lens Tube Usage

Click for Details

Amin and Amax are the minimum and maximum distances another lens tube can be positioned from the back of the lens cell when using the locking ring.

- Long Externally Threaded Section for Adjustable Positioning of Mounted Optics

- Adjustment Range up to 1.31" (33.3 mm)

- Maximum Optic Thickness 0.42" (10.7 mm)

These SM1-threaded (1.035"-40) adjustable lens tubes have an extra-long externally threaded section, allowing Ø1" optics to be precisely positioned along the optical axis of a lens tube system.

To operate, mount the optic in the internally threaded section using the included SM1RR retaining ring. Then thread the adjustable lens tube into a compatible SM1-threaded lens tube until the optic is at the desired position. Use the included SM1NT locking ring to fix the position of the lens tube. See the video to the right for a demonstration.

For applications where it is difficult to reach the locking ring by hand, we offer the SM1NT1 Slotted Locking Ring and SPW502 Spanner Wrench. This locking ring contains slots for the 1¼" end of the spanner wrench.

These adjustable lens tubes are an ideal solution for fine tuning of the first and last lenses in a lens tube system. Although a lens tube can be attached to the front of the adjustable lens tube, it should only be done after the position has been fixed, since this lens tube will need to be free to rotate and translate if the position is changed. Like our standard lens tubes, these adjustable lens tubes are made of black anodized aluminum.

| Item # | External Thread Length (L) | Adjustment Range (Amin to Amax)a |

|---|---|---|

| SM1V05 | 0.5" (12.7 mm) | 0.11" - 0.42" (2.8 mm - 10.7 mm) |

| SM1V10 | 1.0" (25.4 mm) | 0.11" - 0.92" (2.8 mm - 23.4 mm) |

| SM1V15 | 1.5" (38.1 mm) | 0.11" - 1.42" (2.8 mm - 36.1 mm) |

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1V05 | Ø1" Adjustable Lens Tube, 0.31" Travel Range | $32.72 | Today |

SM1V10 | Ø1" Adjustable Lens Tube, 0.81" Travel Range | $36.24 | Today |

SM1V15 | Ø1" Adjustable Lens Tube, 1.31" Travel Range | $38.66 | Today |

Ø1" Vacuum-Compatible Lens Tube with Rotating Optic Adjustment

Click to Enlarge

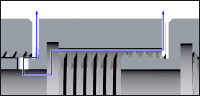

Vents along the threading and at the ends of our vacuum-compatible lens tubes provide a free path for air to escape when under vacuum.

- Vacuum-Compatible: >10-6 Torr

- Long Externally Threaded Section for Adjustable Positioning of Mounted Optics

- 0.81" (20.6 mm) Adjustment Range

- Maximum Optic Thickness 0.42" (10.7 mm)

This Ø1" vacuum-compatible adjustable lens tube allows optics to be precisely positioned along the optical axis of a vacuum-compatible lens tube system. Made from 6061-T6 aluminum, this vented lens tube is vacuum compatible down to 10-6 Torr.

To operate, mount the optic in the internally threaded section using the included SM1RRV retaining ring. Then thread the adjustable lens tube into a compatible SM1-threaded lens tube until the optic is at the desired position. At this point, the included SM1NT1V Slotted Locking Ring can be used to fix the position of the lens tube. See the video above for a demonstration. This locking ring contains slots for the 1¼" end of the SPW502 Spanner Wrench.

This rotating adjustable lens tube is an ideal solution for fine tuning of the first and last lenses in a lens tube system. Although a lens tube can be attached to the front of the adjustable lens tube, it should only be done after the position of the optic has been fixed, since this lens tube will need to be free to rotate and translate if the position of the optic is changed.

| Item # | External Thread Length (L) | Adjustment Range (Amin to Amax)a |

|---|---|---|

| SM1V10V | 1.0" (25.4 mm) | 0.11" - 0.92" (2.8 mm - 23.4 mm) |

| Vacuum Specifications | |

|---|---|

| Vacuum Compatibility as Packageda | >10-6 Torr |

| Materials | 6061-T6 Aluminum |

| Preparation and Packaging | Chemically Cleaned and Double Vacuum-Bagged |

| Aluminum Outgassing Rate at 20 °C | 7.6 x 10-9 Torr-Liters/s/cm2 |

Click for Details

Amin and Amax are the minimum and maximum distances another lens tube can be positioned from the back of the lens cell when using the locking ring.

| Alternatives | Ø1/2" Vacuum-Compatible Adjustable Lens Tubes | |

|---|---|---|

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1V10V | Customer Inspired! Vacuum-Compatible Ø1" Adjustable Lens Tube, 0.81" Travel Range | $58.17 | Today |

Zoom Housing for Ø1" Optics and SM1 Lens Tubes, 2" (50.8 mm) Travel

Click to Enlarge

Each Tick on the Engraved Scale Indicates 0.25 mm of Internal Translation

Click to Enlarge

SM1NR1 Zoom Housing Usage

Click to Enlarge

A Standard SM1 Lens Tube can be Threaded to the Internal Translating Cell to Create a Telescoping Lens Tube Assembly

- Non-Rotating Translation of SM1 Lens Tubes and Ø1" Optics up to 0.3" (7.6 mm) Thick

- Fixed External and Translating Internal SM1 (1.035"-40) Mounting Threads

- Create a Light-Tight Telescoping Lens Tube Assembly

- 2" (50.8 mm) of Travel at 0.63" (16 mm) per Revolution

The SM1NR1 is an SM1-threaded, non-rotating zoom housing. It features an internal SM1-threaded (1.035"-40) translating cell for mounting Ø1" optics using the included SM1RR retaining ring, or for connecting SM1 lens tubes. A double-helical mechanism allows this cell to be translated along the optical axis without rotation (see video to the lower left). Each engraved tick mark on the rotating adjustment collar indicates 0.25 mm of linear travel of the inner cell (see photo to the far right). An 0.050" hex setscrew located by the Thorlabs engraving locks the movement, and tungsten disulfide dry film lubricant on the exposed internal surfaces ensures smooth translation.

The back of the housing includes an external SM1 thread for integration into lens tube systems. Additionally, the front of the housing includes a Ø1.38" (Ø35 mm) boss for 30 mm cage system integration using our CP37 cage plate (see photo above, to the immediate right).

Telescoping Lens Tube

A smooth Ø1.2" bore on one end of the housing allows standard SM1 lens tubes to be connected to the internal translating cell. This creates a light-tight adjustable-length lens tube assembly (see photo to the right).

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1NR1 | SM1 Zoom Housing for Ø1" Optics, Non-Rotating, 2" (50.8 mm) Travel | $236.40 | Today |

High-Precision Zoom Housing for Ø1" Optics, 0.14" (3.5 mm) Travel

- Non-Rotating Translation of Ø1" Optics up to 0.42" (10.7 mm) Thick

- 0.14" (3.5 mm) of Travel at 0.5 mm Per Revolution

- Fixed External SM1 and Translating Internal SM1 Mounting Threads

The SM1ZM non-rotating zoom housing provides 0.14" (3.5 mm) of linear travel without rotating the optical element mounted in it. A fine helical mechanism moves the front barrel back and forth while restricting any rotational movement, preventing any rotation of the attached lens tubes or optics. This high-precision (0.5 mm per revolution) zoom housing provides the ability to accurately control the exact working distance of an optical element within a system. Once the desired position is achieved, it can be locked by tightening the setscrew on the outside of the tube with a 0.035" hex key.

To operate, mount a Ø1" optic in the zoom housing and secure it using the included SM1RR retaining ring. Then attach the SM1ZM to an internally threaded SM1 lens tube or mount. Once secure, the outer ring of the SM1ZM can be used to precisely position the optic. This simple setup is shown to the right. For a more involved application within a confocal microscope setup, please see the Application tab.

Note that mounting a lens tube to the zoom housing may result in misalignments due to excessive torque being applied to the translation mechanism. If a lens tube or similar item must be mounted to the zoom housing, verify that downstream optical elements do not require realignment.

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1ZM | SM1 Zoom Housing for Ø1" Optics, Non-Rotating, 3.5 mm Travel | $193.64 | Today |

Zoom Housing for Ø1/2" Optics, 0.7" (18 mm) Travel

SM1NR05 Zoom Housing Usage

- Non-Rotating Translation of Ø1/2" Optics up to 0.25" (6.4 mm) Thick

- 18 mm of Travel at 17 mm Per Revolution

- Internal and External SM1 Threading for Attachment Between Two Fixed SM1 Lens Tubes

The SM1NR05 non-rotating zoom housing provides 18 mm of linear travel without rotating the optical element mounted in it. A double helical mechanism moves the interior SM05 barrel back and forth while restricting any rotational movement. This 17 mm per revolution zoom housing provides the ability to accurately control the exact working distance of an optical element within a system. To operate, mount a Ø1/2" optic in the zoom housing and secure it using the included SM05RR retaining ring. Then the SM1NR05 can be mounted on any SM1 threaded lens tube or mount. Once secure, the outer ring of the SM1NR05 can be used to precisely position the optic.

Unlike the other lens tubes and housing on this page, the SM1NR05 offers fixed SM1 threading on both ends, allowing it to be attached between two fixed Ø1" lens tubes while still retaining the ability to adjust the position of the optic (see the video to the right).

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1NR05 | SM1 Zoom Housing for Ø1/2" Optics | $218.58 | Today |

Adjustable Collimation Adapter for Ø1" or Ø25 mm Optics

- Translation of Ø1" or Ø25 mm Collimation Optic with 11 mm of Travel

- External SM1 Threading (1.035"-40) at Input and Internal SM2 Threading (2.035"-40) at Output

- Remove Threading Adapter at Output to Reveal Internal M34 x 0.5 Threading

- 6.0 mm (0.24") Thick Retaining Ring Ideal for Aspheric Lenses

- Recommended for Collimating Mounted LEDs Using Condenser Lenses

This Adjustable Collimation Adapter provides 11 mm of non-telescoping, rotating translation for a Ø1" (Ø25 mm) optic with a clear aperture of Ø24.0 mm. Versions with pre-mounted aspheric condenser lenses are also available here. As seen in the drawing to the right, the output aperture of the collimation adapter is equipped with a removable, external M34 x 0.5 to internal SM2 thread adapter. For SM1 thread compatibility, the SM1A38 external M34 x 0.5 to internal SM1 thread adapter is available separately. The SM1U collimation adapter should be used at temperatures from 15 to 60 °C (non-condensing).

The inner carriage can be translated along the Z-axis by turning the adjustment ring (engraved with the Item # in the photo above) and locked into position by turning the locking screw on the side of the adjustment ring with a 2 mm (5/64") hex key. While the lens cell will rotate within the adapter housing when translated, the mounting threads on the housing remain fixed, allowing the SM1U to be mounted between fixed lens tubes. Lines with a 2 mm spacing are engraved on the housing as a rough guide for how far the carriage has been translated. The collimation adapter also includes a 6 mm thick, SM1-threaded retaining ring that allows an aspheric condenser lens to be mounted with our SPW602 Spanner Wrench.

Inserting or Removing Optics

To insert or remove an optic, use the adjustment ring on the collimation adapter to translate the inner carriage to the output end of the housing. Remove the included retaining ring using the SPW602 spanner wrench. If there is a lens installed already, remove it from the carriage. Insert another Ø1" or Ø25 mm optic into the carriage, and use the retaining ring to secure it.

Part Number | Description | Price | Availability |

|---|---|---|---|

SM1U | Adjustable Collimation Adapter for Ø1" or Ø25 mm Optic | $297.50 | 7-10 Days |